Electromagnetic-stirring pressurized centrifugal large-opening vacuum fusion casting furnace

A technology of electromagnetic stirring and electromagnetic stirrer, applied in the field of precision casting, can solve the problems of high inflation pressure and limitation, and achieve the effects of accurate composition, refinement of grain structure, and reduction of physical and chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

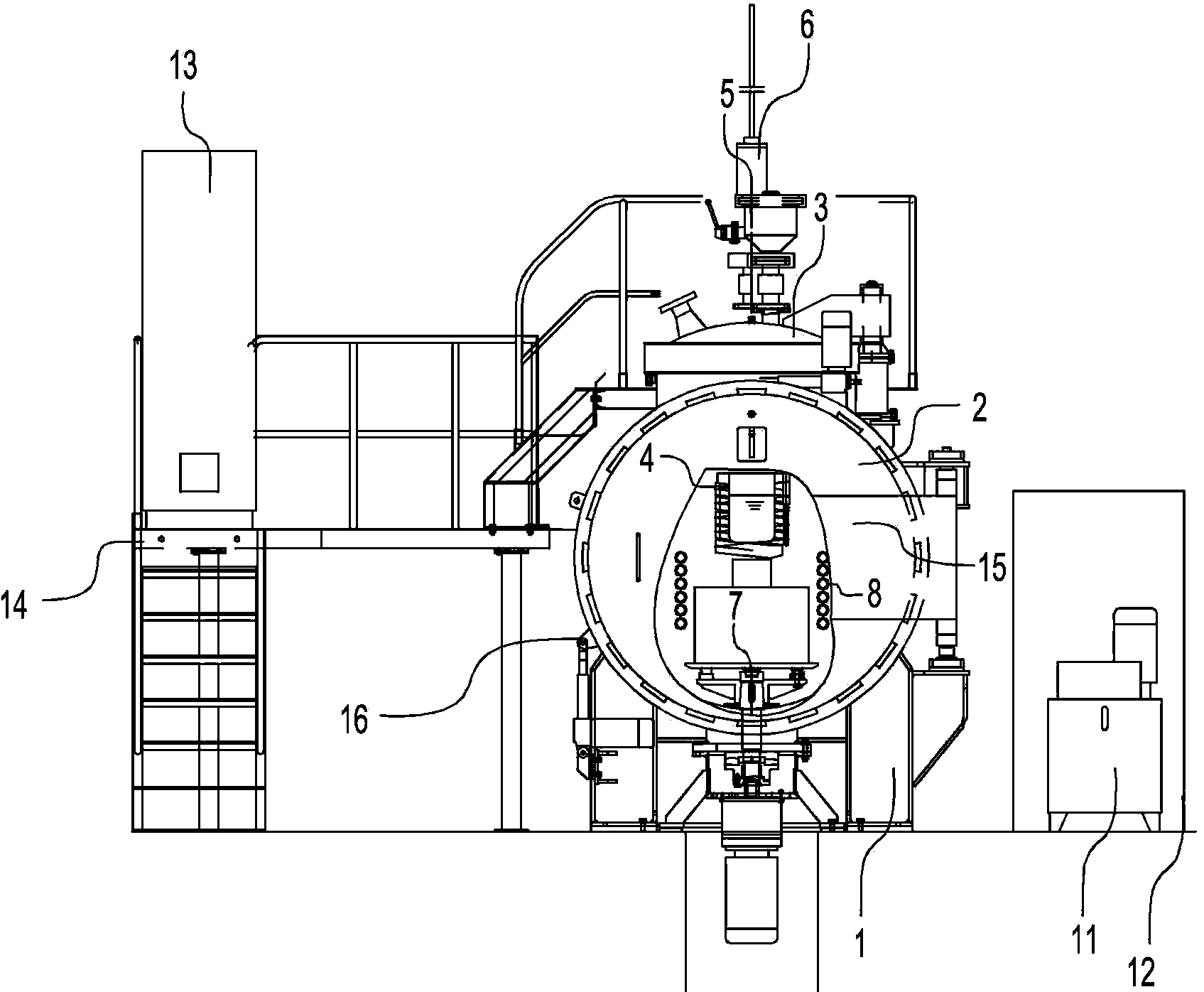

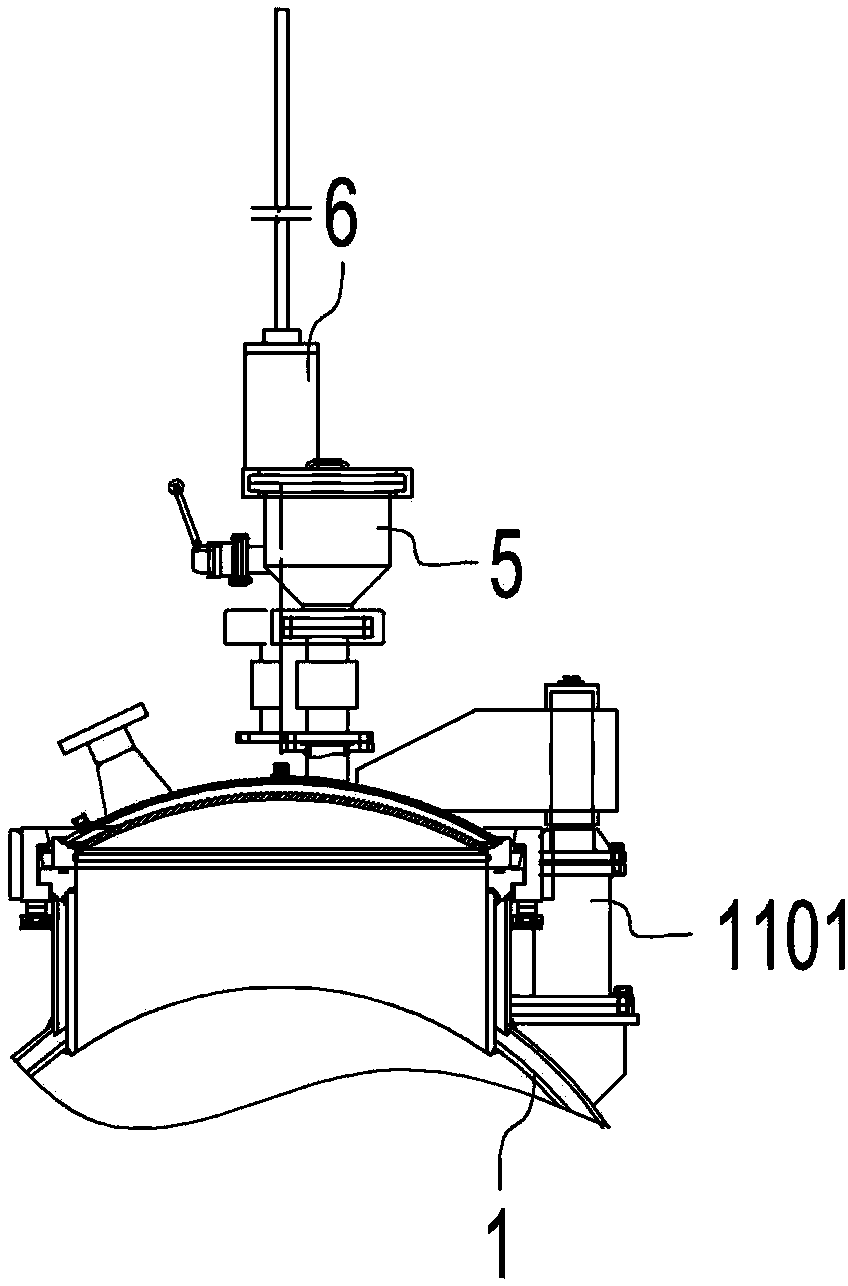

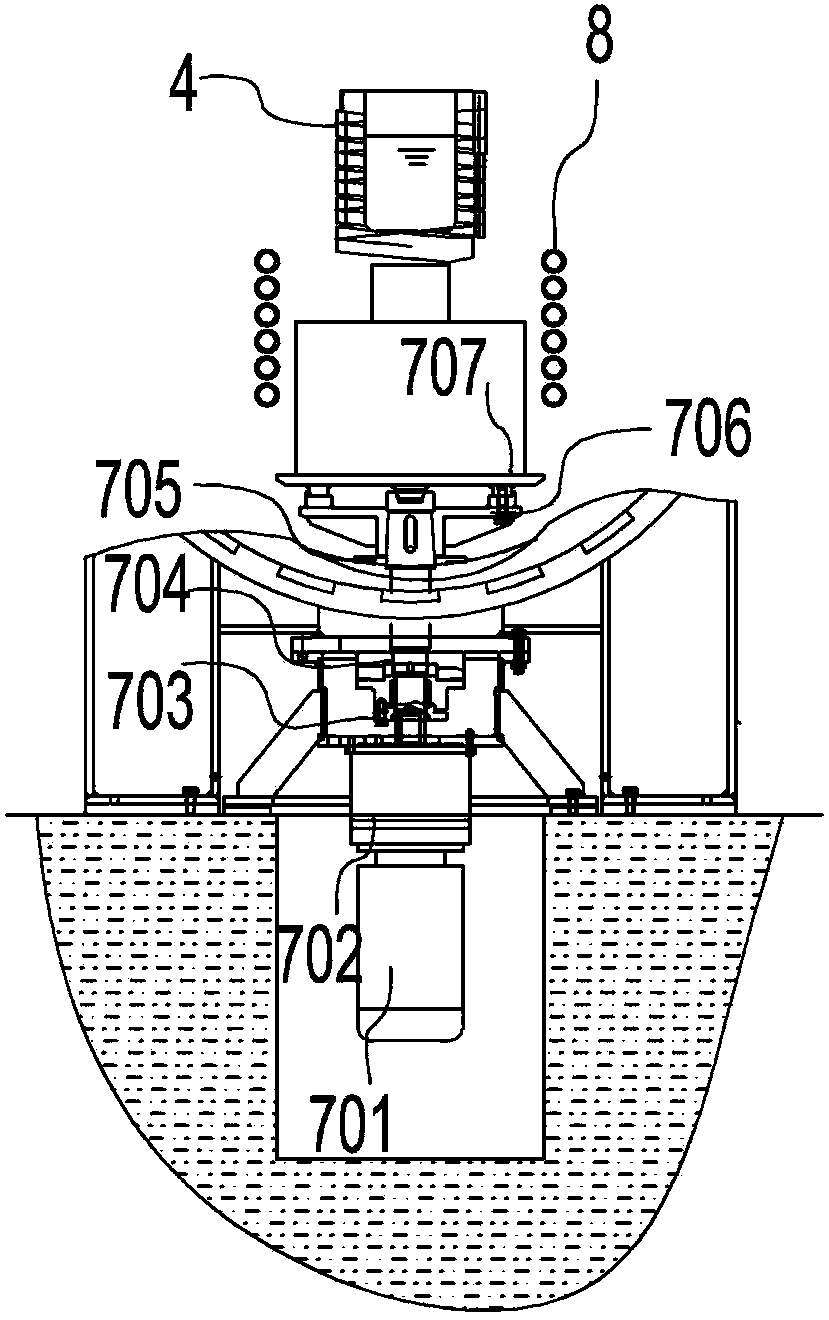

[0025] As shown in the figure, the electromagnetic stirring pressurized centrifugal large-opening vacuum casting furnace includes a furnace body 1, a furnace door 2, a furnace cover 3, an inductor 4, a feeding mechanism 5, a centrifugal rotating mechanism 7, an electromagnetic stirrer 8, a vacuum System 9, inflatable pressurization system 10 and intermediate frequency power supply 12; the furnace cover 3 is docked with the flange of the large opening on the top of the furnace body 1; the furnace door 2 is arranged on the front of the furnace body 1; the evacuation of the vacuum system 9 The connecting port communicates with the cavity of the furnace body 1; the charging mechanism 5 is arranged on the furnace cover 3; Connected; a locking mechanism 16 is provided on the butt joint surface of the furnace body 1, the furnace door 2 and the furnace cover 3; the inflation and pressure port of the inflation and pressure system 10 communicates with the working cavity of the vacuum sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com