Production process of solar energy grade polysilicon

A technology of solar energy level and production method, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low input-output rate, difficult transportation, long construction period, etc., and achieve a large degree of free combination and process flow Simple, highly automated results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

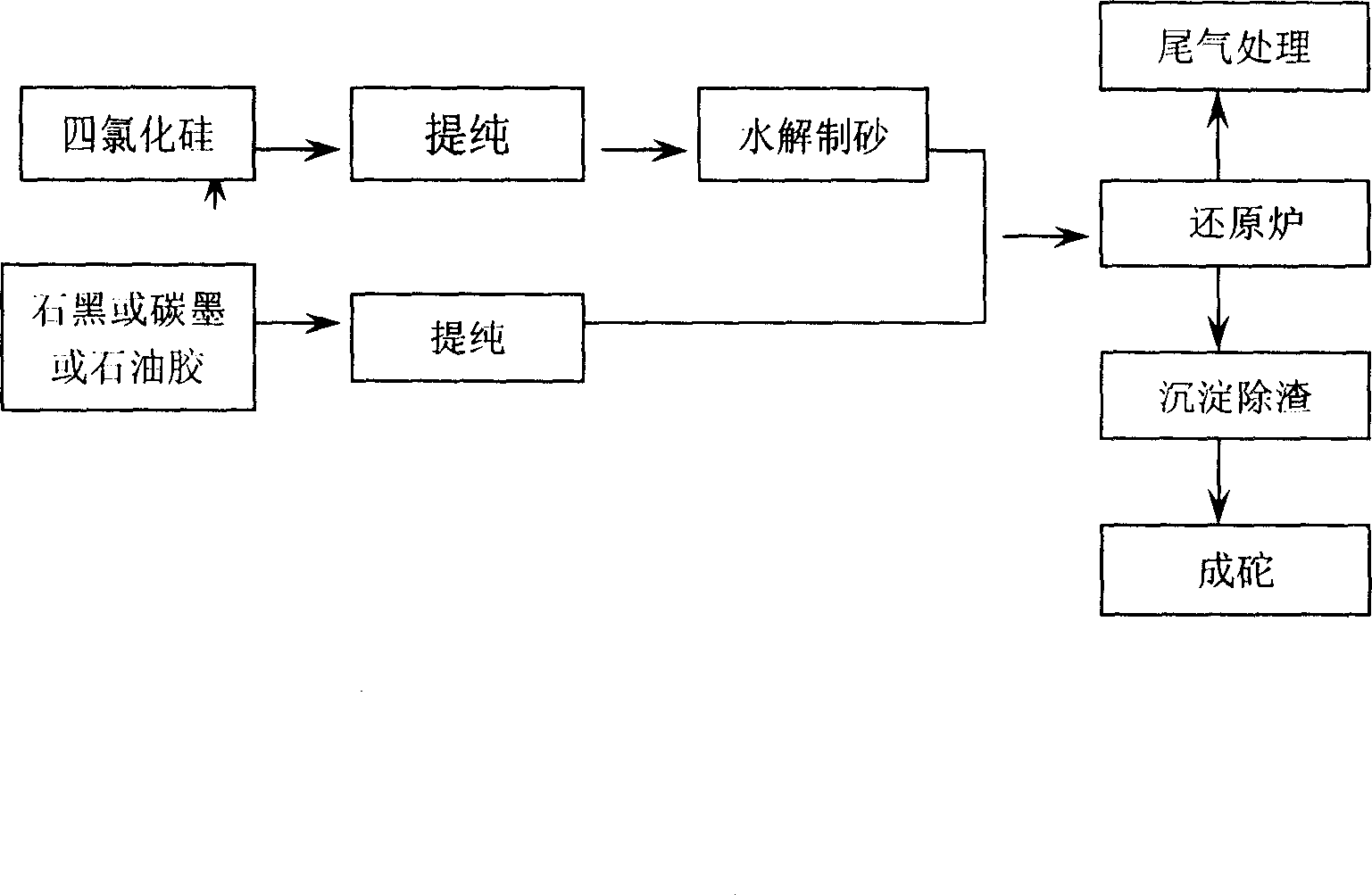

[0023] As shown in the figure, take high-purity quartz sand with a purity of 99.9999% to 99.99999% for use. Burn graphite or carbon black or petroleum jelly in a high temperature environment of 1500-2000°C in a vacuum to purify to obtain high-purity graphite or carbon black or petroleum jelly; combine high-purity quartz sand with high-purity graphite or carbon black or petroleum Glue is added to the reduction furnace for reduction according to the ratio of the substance to 1:2 to produce a silicon product with low impurity content; then the silicon is vacuum melted in the vacuum melting furnace, the temperature is controlled according to the melting point of the silicon, and the slag is filtered to remove carbon and carbonization. Silicon and silicon dioxide powder impurities, and then pour the molten silicon into the mold, and directional solidify, you can get 6N grade solar grade polysilicon.

Embodiment 2

[0025] As shown in the figure, take high-purity quartz sand with a purity of 99.9999% for use. Burn graphite or carbon black or petroleum jelly in a high temperature environment of 1500-1700°C or 1800-2000°C in a vacuum to purify to obtain high-purity graphite or carbon black or petroleum jelly; high-purity quartz sand and high-purity graphite Or carbon black or petroleum jelly is added into the reduction furnace for reduction according to the ratio of the substance to 1:2 to produce a silicon product with low impurity content; then the silicon is vacuum melted in the vacuum melting furnace, the temperature is controlled according to the melting point of silicon, and the slag is removed by filtration , remove carbon, silicon carbide and silicon dioxide powder impurities, and then pour the molten silicon into the mold, directional solidification, you can get 6N grade solar grade polysilicon.

Embodiment 3

[0027] As shown in the figure, take high-purity quartz sand with a purity of 99.99999% for use. Burn graphite or carbon black or petroleum jelly in a high temperature environment of 1800-2000°C or 1500-1700°C in a vacuum for purification to obtain high-purity graphite or carbon black or petroleum jelly; high-purity quartz sand and high-purity graphite Or carbon black or petroleum jelly is added into the reduction furnace for reduction according to the ratio of the substance to 1:2 to produce a silicon product with low impurity content; then the silicon is vacuum melted in the vacuum melting furnace, the temperature is controlled according to the melting point of silicon, and the slag is removed by filtration , remove carbon, silicon carbide and silicon dioxide powder impurities, and then pour the molten silicon into the mold, directional solidification, you can get 6N grade solar grade polysilicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com