Thermocouple vacuum fusion welding system

A thermocouple and thermocouple wire technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the performance of thermocouples, the oxidation reaction of thermocouple wires, etc., to facilitate the technological transformation process, improve work efficiency, Achieving the effect of operating and observing synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

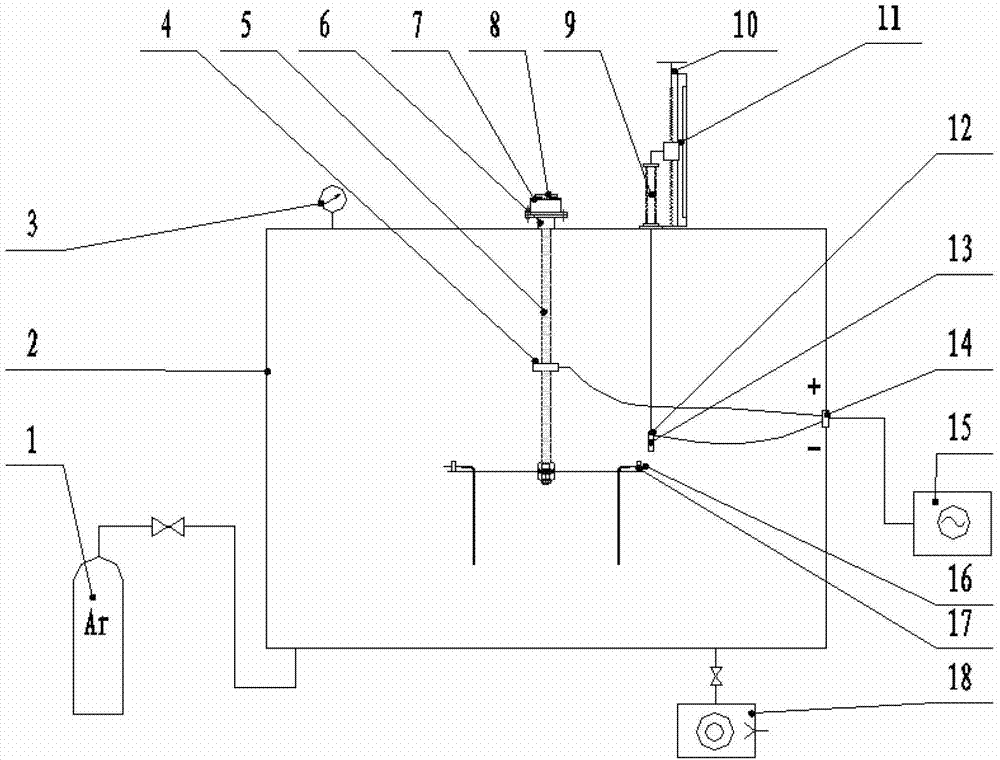

[0019] Below with the accompanying drawings ( figure 1 ) to illustrate the present invention.

[0020] figure 1 It is a structural schematic diagram of a thermocouple vacuum fusion welding system implementing the present invention. Such as figure 1 As shown, the thermocouple vacuum fusion welding system includes a vacuum chamber 2, and a thermocouple wire clamp 17 is arranged in the vacuum chamber 2, and a melting point is set at a corresponding position of the thermocouple wire clamp 17 clamping the thermocouple wire butt end 16. Welding carbon rod 13, the welding carbon rod 13 is connected to the feed movement device, the thermocouple wire clamp 17 is connected to one pole of the welding power supply, and the welding carbon rod 13 is connected to the other pole of the welding power supply . The thermocouple wire clamp 17 and the welding carbon rod 13 constitute a welding assembly, and the welding carbon rod 13 is connected to the negative terminal of the welding power su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com