One-dimensional nitrogen-doped double-layer carbon shell/sulfur composite positive electrode material for lithium-sulfur battery and preparation method thereof

A lithium-sulfur battery and cathode material technology, which is applied in battery electrodes, lithium storage batteries, and positive electrodes to achieve high rate performance, novel structure, and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step: the FeCl 3 and NH 4 h 2 PO 4 After mixing according to the molar ratio of 28:1, put it into the hydrothermal reaction kettle, heat it at 240 degrees for 20 hours, filter and wash it after cooling to room temperature, and obtain the hollow Fe 2 o 3 Rod precursor; the resulting Fe 2 o 3 The precursor was dispersed into a 0.5g concentration of dopamine aqueous solution and stirred for 2 hours, filtered and cleaned, and vacuum dried to obtain a PDA@Fe2O3 composite material;

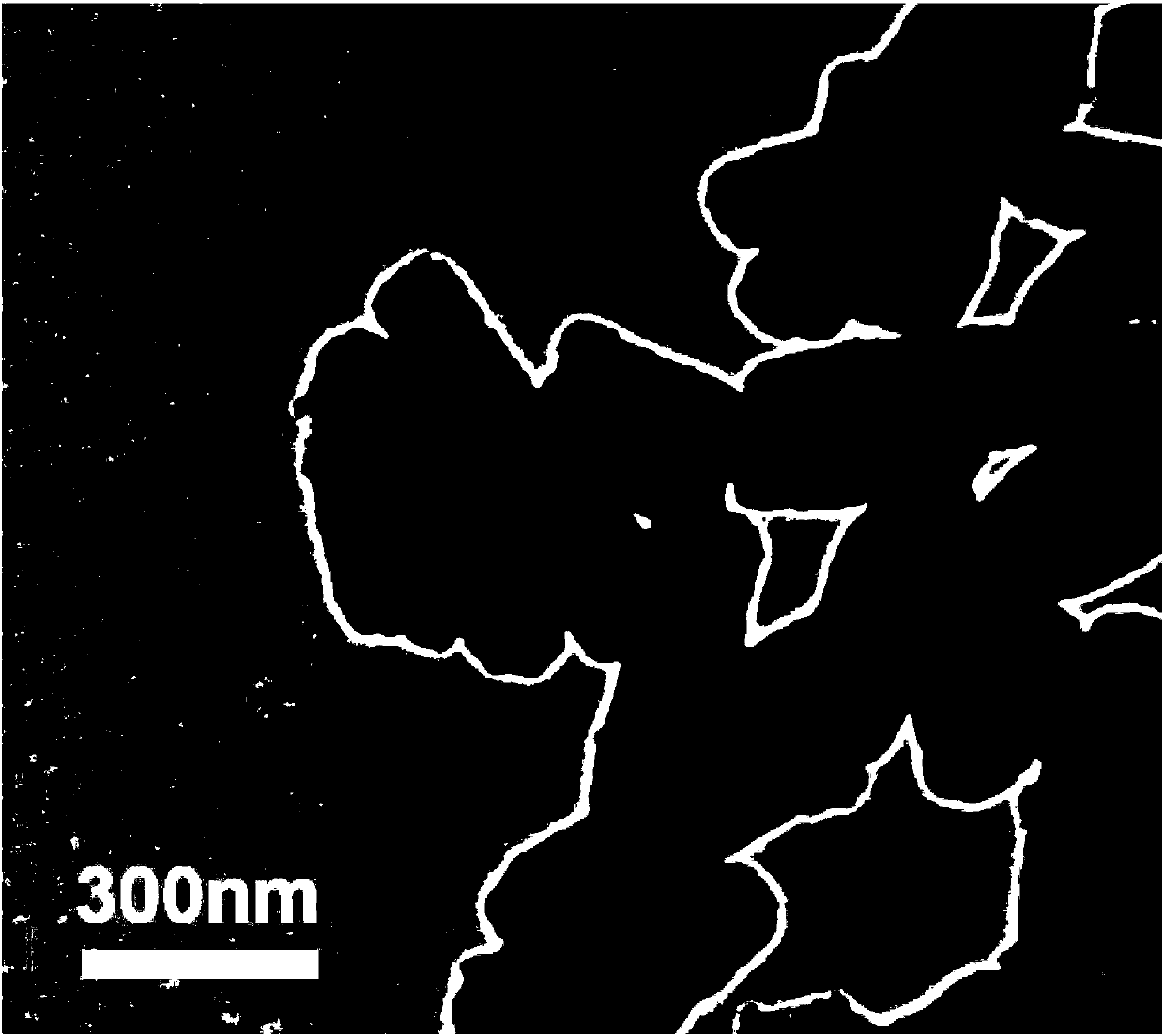

[0030] The second step: put the obtained composite material into a mixed gas of argon and ammonia (Ar:NH 3 =1:1) in a tube furnace with a gas flow rate of 50 ml / min, high temperature carbonization for 1 hour at a temperature of 1000°C, and then the product obtained was etched in an aqueous hydrochloric acid solution with a concentration of 0.1 moles per liter for 4 hours, cleaned After filtration and vacuum drying, a one-dimensional nitrogen-doped double-layer carbon shell was ob...

Embodiment 2

[0034] The first step: except that it is heated for 30 hours under the condition of 220 degrees, other is the same as embodiment one;

[0035] The second step: put the obtained composite material into a tube furnace with nitrogen gas, the gas flow rate is 300 ml / min, carbonize at high temperature for 2 hours, the temperature is 1000 ° C, and then the obtained product is put into a concentration of 0.1 moles per It was etched in 1 liter of hydrochloric acid aqueous solution for 4 hours, cleaned and filtered, and then vacuum-dried to obtain a one-dimensional nitrogen-doped double-layer carbon shell.

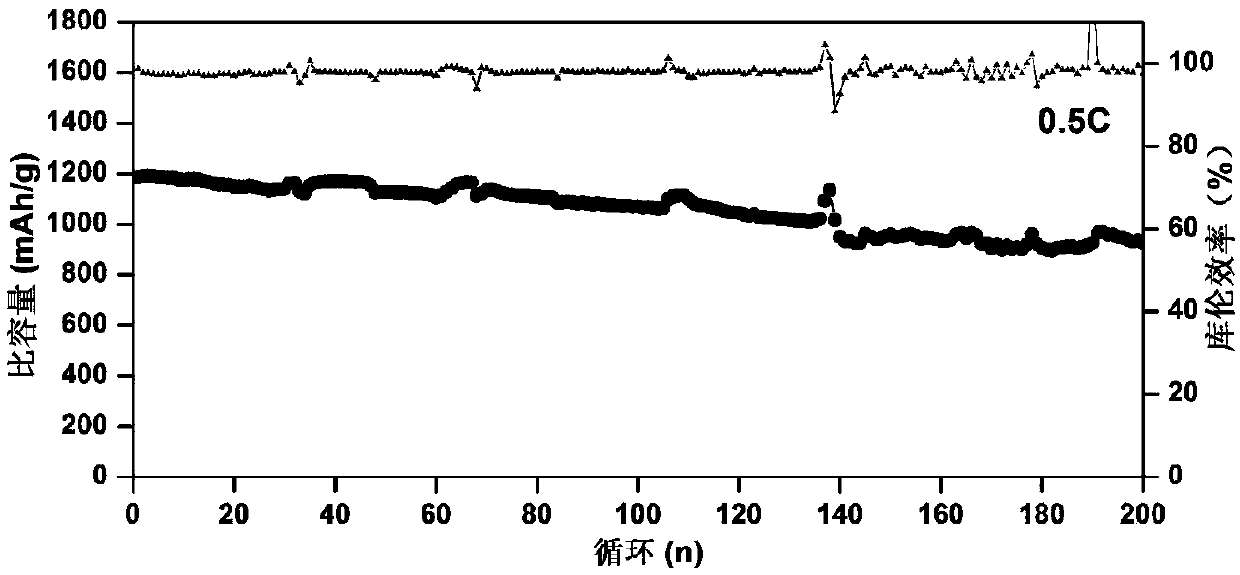

[0036] Step 3: Mix commercial sulfur powder and one-dimensional nitrogen-doped double-layer carbon shell according to the weight ratio of 2:1, then put it into a closed container, vacuumize to 300Pa, and then use 2 degrees / min The heating rate was increased to 200 degrees, kept for 12 hours, then cooled to 160 degrees, kept for 12 hours, and rapidly cooled to room temperature to ob...

Embodiment 3

[0039] The first step: except that it is heated for 10 hours under the condition of 250 degrees, it is the same as embodiment one;

[0040] Step 2: Put the obtained composite material into a tube furnace with protective gas, carbonize at high temperature for 2 hours at a temperature of 1200°C, then put the obtained product into an appropriate concentration of hydrochloric acid solution for etching for 4 hours, wash and filter After vacuum drying, a one-dimensional nitrogen-doped double-layer carbon shell was obtained.

[0041] Step 3: Mix commercial sulfur powder and one-dimensional nitrogen-doped double-layer carbon shell at a ratio of 3:1, and then put it in a closed container. After vacuuming, the vacuum degree is 100 Pa, and the temperature is 2 degrees / min. Slowly increase the rate to 250°C, hold for 20 hours, then cool down to 155°C, hold for 10 hours, and rapidly cool to room temperature to obtain a one-dimensional nitrogen-doped double-layer carbon shell / sulfur composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity decay rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com