Metal material casting system and method

A metal material, melting and casting technology, applied in the field of electromechanical equipment systems for melting and casting of high melting point active non-ferrous metal materials, can solve problems other than the final forming and processing of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

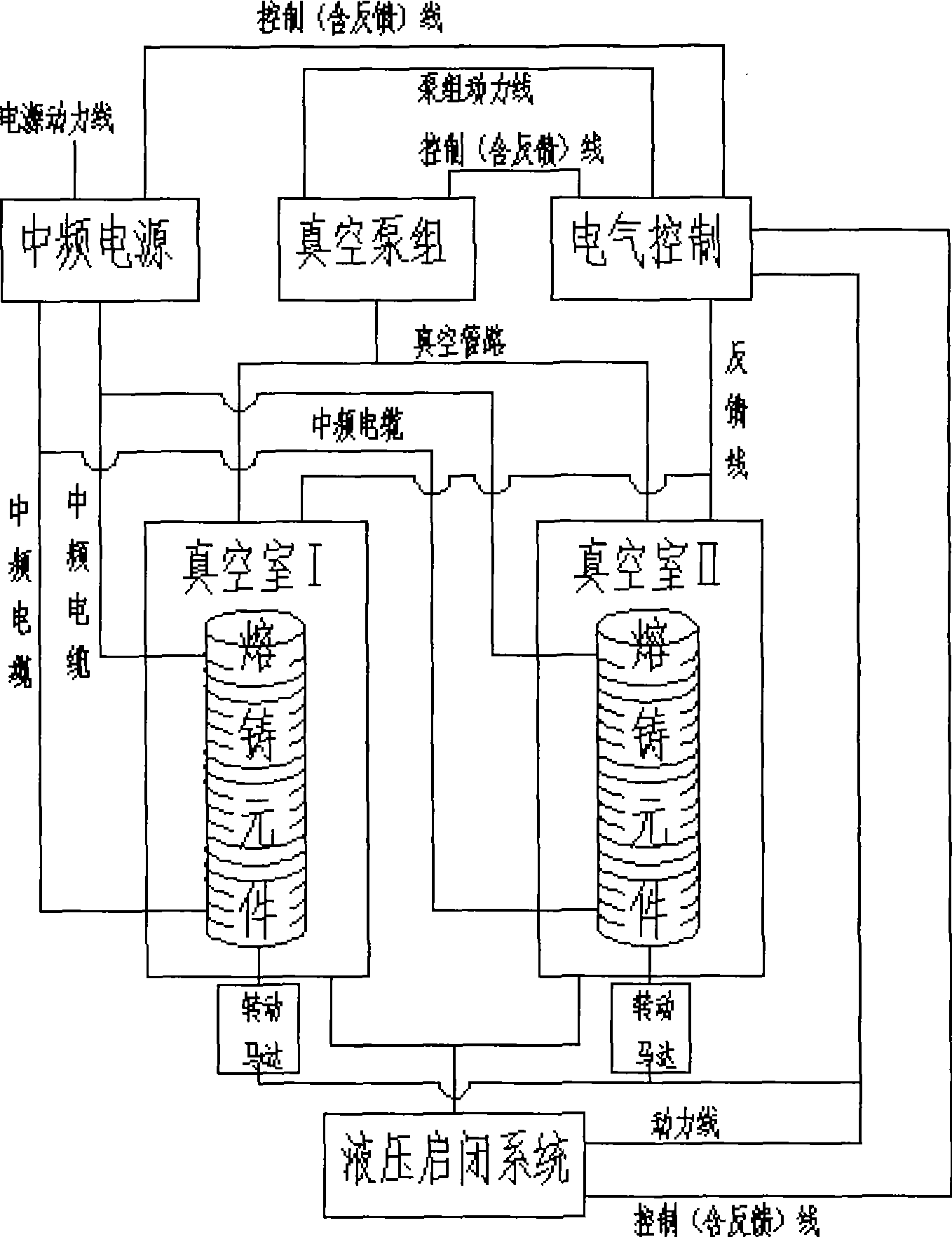

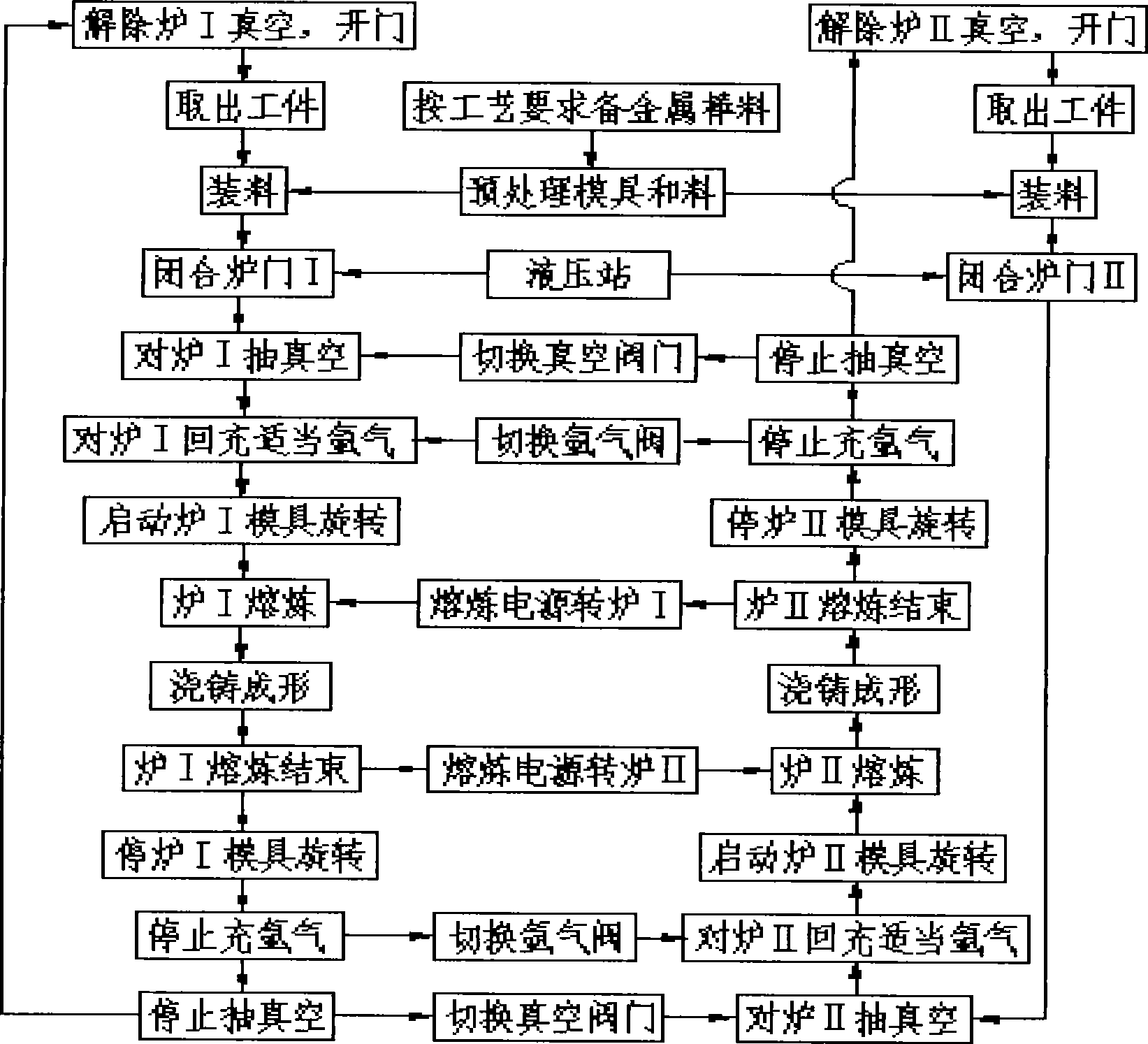

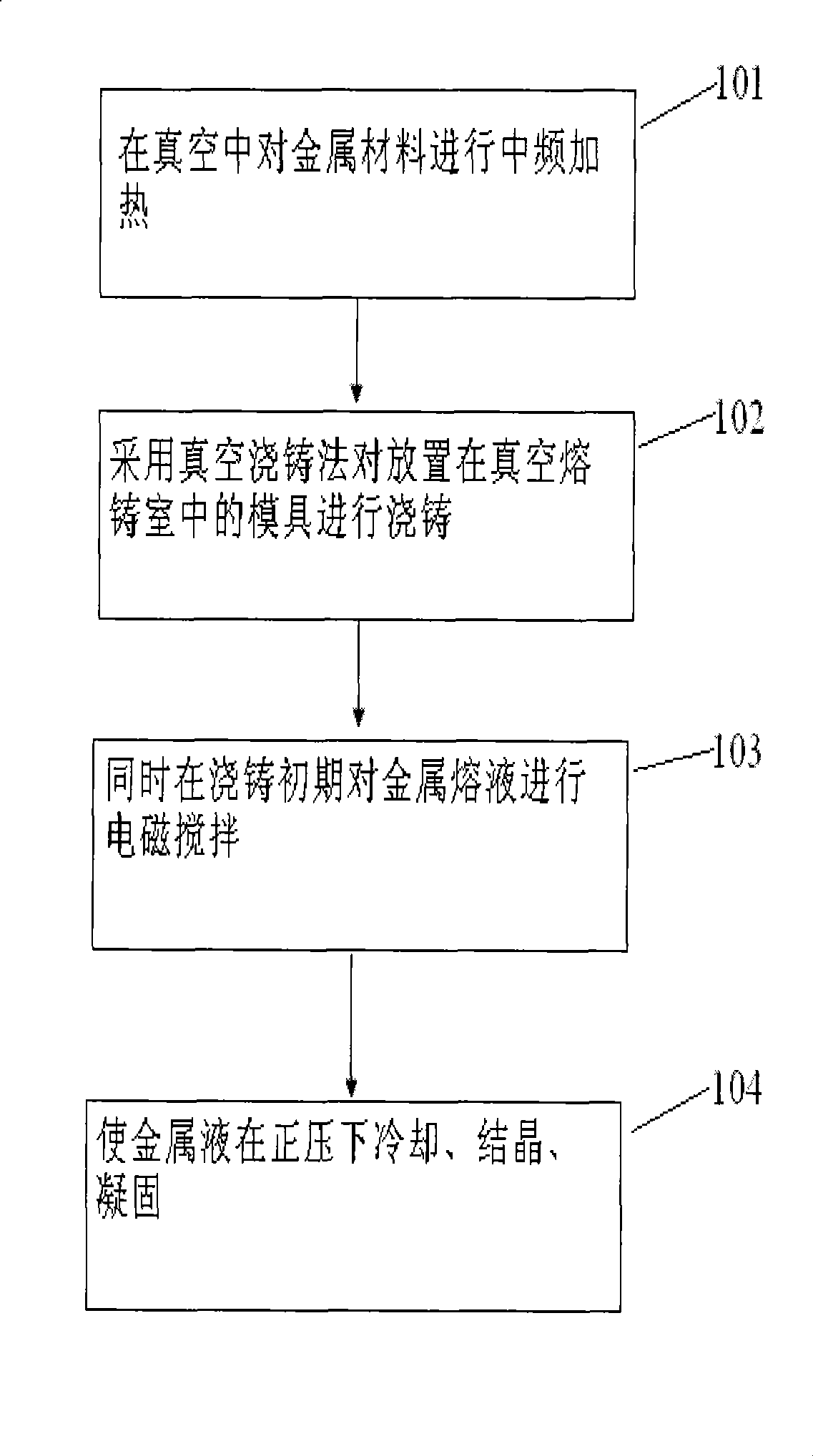

[0034] Realize that the overall system structure of the present invention has four parts (as figure 1 Shown): intermediate frequency power supply, electrical control device, hydraulic opening and closing device and vacuum device (including vacuum pump unit, vacuum casting chamber and rotating motor). The system adopts an intermediate frequency power supply with a dual power supply structure, and there are two sets of vacuum casting chambers and rotating motors, so that when one of the vacuum melting casting chambers is loading and unloading workpieces and cooling and crystallizing, the power supply is used for melting and casting in the other vacuum casting chamber. The vacuum casting chamber in the vacuum device adopts a crucible-less structure (not shown) and includes an induction heating element for generating electromagnetic heating or stirring (such as figure 1 The arc shown in the casting element) allows for higher mold filling capabilities, while also avoiding contamina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com