Method for pretreating pickled lotus root slices based on high-voltage pulsed electric field treatment device

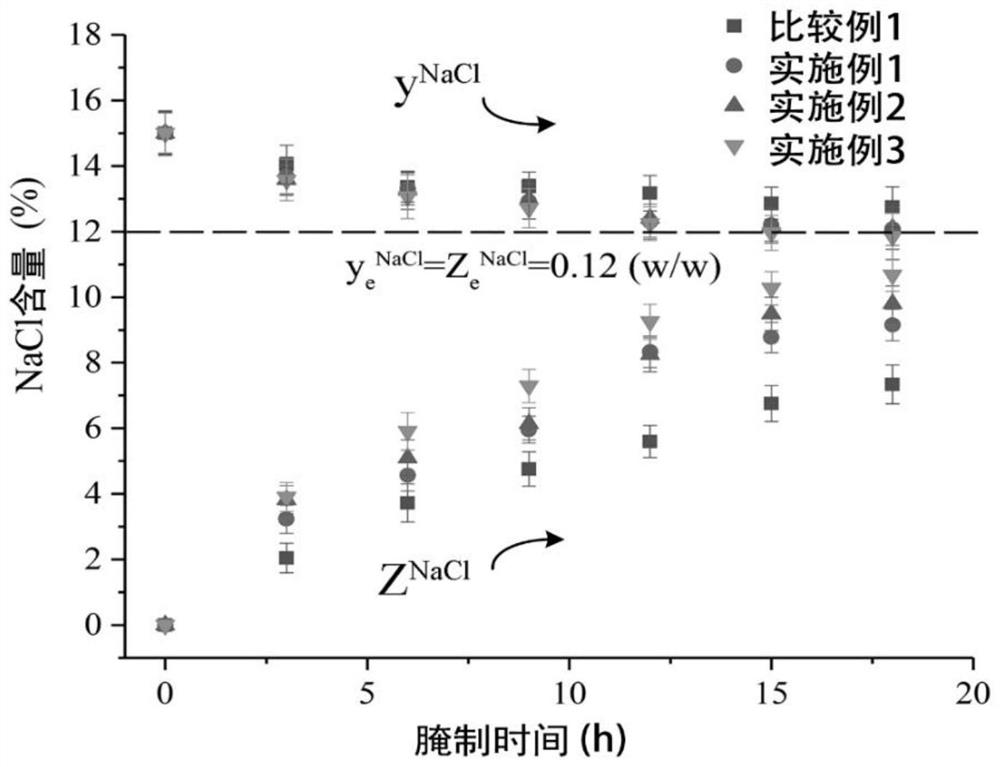

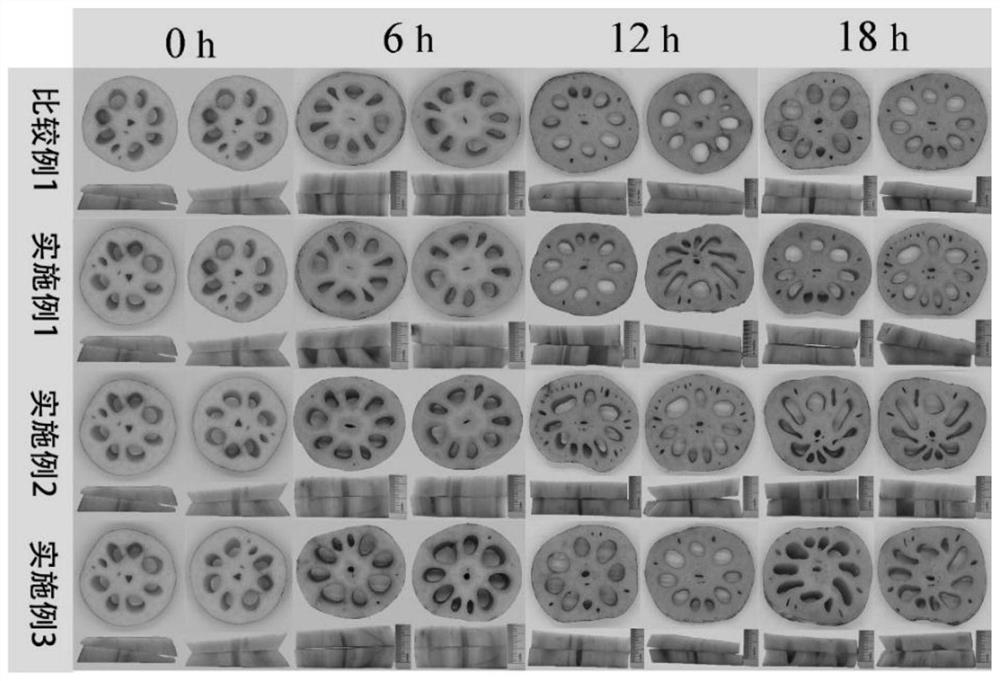

A technology of high-voltage pulse electric field and high-voltage pulse power supply, which is applied in the field of pretreatment processing of pickled lotus root slices, can solve the problems of low production efficiency, long processing cycle of pickled lotus root slices, and high salt content of products, so as to reduce salt content and shorten production Cycle, good color and fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

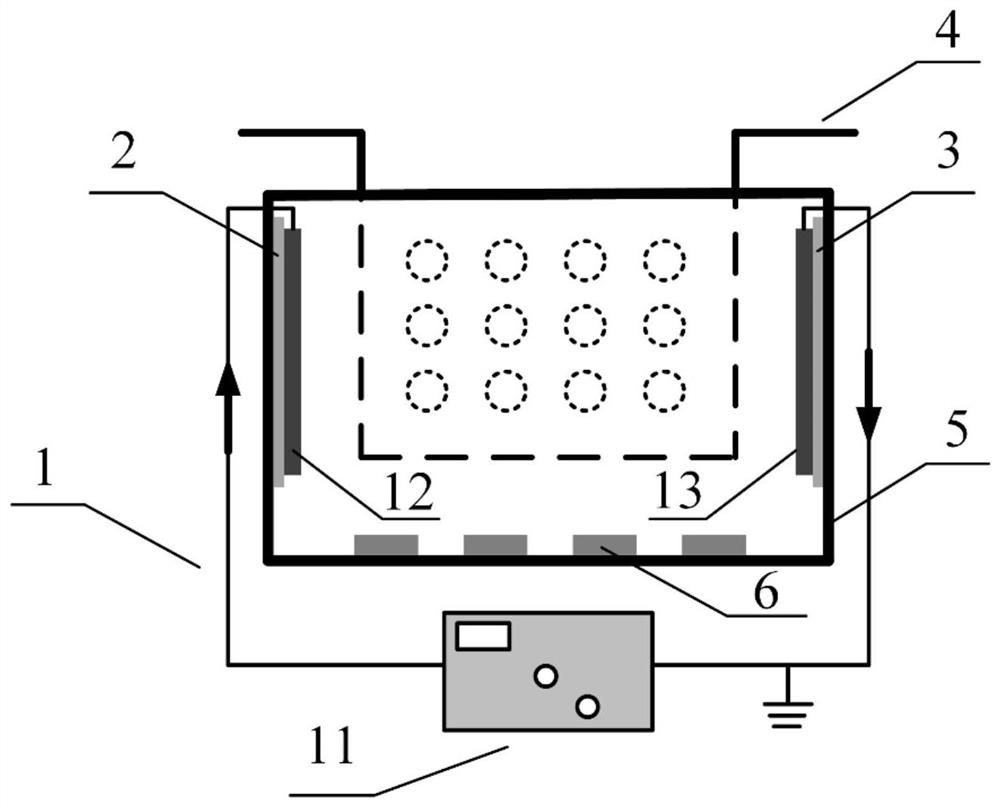

[0039] A high-voltage pulsed electric field treatment device, such as figure 1 As shown, the high-voltage pulsed electric field processing device includes: a high-voltage pulsed electric field device 1 , a separator 2 , a separator 2 3 , an inner box 4 , an outer box 5 and a heating wire 6 .

[0040] The high-voltage pulsed electric field device 1 is composed of a high-voltage pulsed power supply 11, a positive plate 12 and a negative plate 13; the high-voltage pulsed power supply 11 is independently arranged on the outside of the outer box 5, and is used to control the switch of the high-voltage pulsed electric field; the positive plate 12 and the negative plate 13 are installed on the opposite partitions of the inner walls on both sides of the outer box body 5 respectively; the material used for the positive plate 12 and the negative plate 13 is food-grade stainless steel.

[0041] The partition is close to the inner wall on both sides of the outer box body 5; the material u...

Embodiment 2

[0052] (1) Wash the fresh lotus root, remove the front and rear ends, keep the middle lotus root, remove the skin, cut into thin slices with a thickness of about 1 cm, and soak in clean water for 10 minutes for later use.

[0053] (2) Take 300g of soaked fresh-cut lotus root slices and put them in such as figure 1 In the shown high-voltage pulsed electric field processing device, it is specifically placed in the inner box 4, and the inner box 4 is suspended in the outer box 5, and clear water is added to cover the lotus root slices; the electric field parameter is set to 1kV / cm, and the pulse The frequency is 500Hz, the pulse width is 200μs, and the processing time is 15s; after the processing parameters are set by the high-voltage pulse power supply 11, a stable high-voltage pulse electric field is formed between the positive plate 12 and the negative plate 13 to process the lotus root slices; after the treatment, turn off the power supply and wait for the lotus root slices A...

Embodiment 3

[0058] (1) Wash the fresh lotus root, remove the front and rear ends, keep the middle lotus root, remove the skin, cut into thin slices with a thickness of about 1 cm, and soak in clean water for 10 minutes for later use.

[0059] (2) Take 300g of soaked fresh-cut lotus root slices and put them in such as figure 1 In the shown high-voltage pulsed electric field processing device, it is specifically placed in the inner box 4, and the inner box 4 is suspended in the outer box 5, and clear water is added to cover the lotus root slices; the electric field parameter is set to 1.5kV / cm, The pulse frequency is 500Hz, the pulse width is 200μs, and the processing time is 15s; after the processing parameters are set by the high-voltage pulse power supply 11, a stable high-voltage pulse electric field is formed between the positive plate 12 and the negative plate 13 to process the lotus root slices; Soak the slices for 20 minutes, remove and drain;

[0060] (3) Open the heating system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com