A welding wire suitable for submerged arc welding of low-grade pipeline steel below l360/x52

A technology of submerged arc welding and pipeline steel, applied in welding equipment, welding medium, welding equipment, etc., can solve the problems of deterioration of steel pipe performance, weld strength, high hardness, increase in steel pipe welding cost, etc., to improve weldability, The effect of reducing welding production cost and reducing welding wire cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1: Using a vacuum induction furnace, it is necessary to use raw materials with low P, S, and C impurities, and strictly control the S, P content of molten iron. After deoxidation and alloying, the molten steel that meets the composition requirements is smelted and cast into continuous casting. billet, rolled by high-speed twist-free rolling mill Wire rod, The wire rod is made by shelling and derusting-electrolytic pickling-boration treatment-drawing-degreasing-electrolytic alkaline cleaning-electrolytic pickling-electroless copper plating and Finished welding wire. The mass percent content of the welding wire is: C 0.06, Mn 1.05, Si 0.23, P 0.007, S 0.008, Cr 0.26, Cu 0.15; Ti 0.025; the rest is Fe.

[0024] The welding wire of the present invention is matched with SJ301G flux to carry out deposited metal welding. According to the standard requirements of "GB / T12470-2003 Low-alloy Steel Welding Wire and Flux for Submerged Arc Welding", the test plate adop...

example 2

[0028] Example 2: The welding wire produced by the above process, the mass percentage of the welding wire is: C 0.06, Mn 1.05, Si0.23, P 0.007, S 0.008, Cr 0.26, Cu 0.15; Ti 0.025; the rest is Fe.

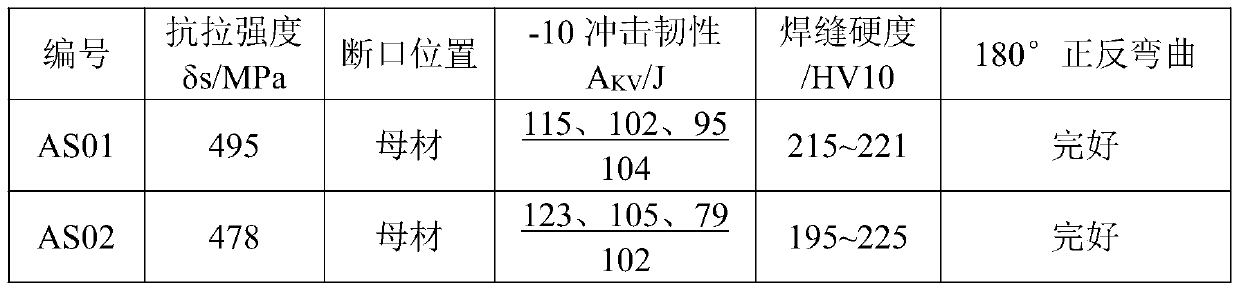

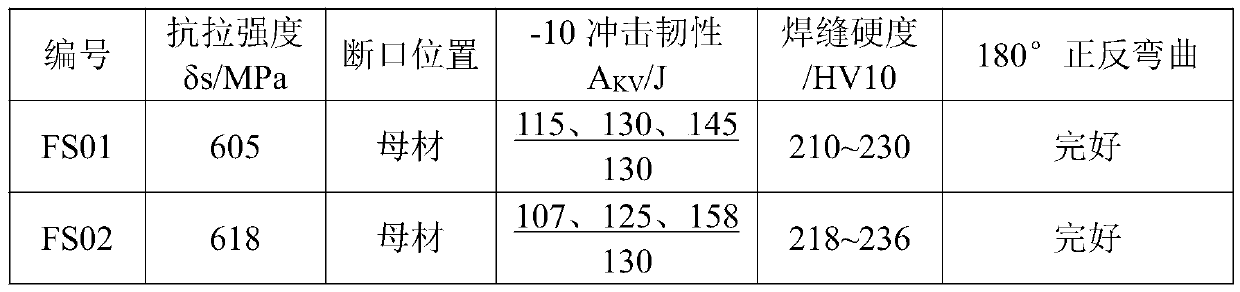

[0029] The welding wire of the present invention is matched with BG-SJ301G flux to weld Q235B pipeline steel with a thickness of 12.5mm. The composition of Q235B pipeline steel is C 0.15, Si 0.22, Mn 0.22, P 0.014, S 0.01, Cu 0.06, Ni 0.04, Cr0 .02, Al 0.01, B 0.0004, and the rest are iron. The process method is X-type joint form, the inner groove angle is 30°, the outer groove angle is 45°, and the size of the blunt edge is 5-6mm. The welding specification is: internal welding welding current 550-780A, welding voltage 29.5-32V; external welding welding current 1100-1250A, welding voltage 31-33V, welding speed 1.62-1.98m / min, internal and external double-wire submerged arc welding, after welding The weld shape is good, and the transition at the weld toe is good. The mechanical pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com