Electronickelling alloy solution for improving corrosion resistance of coating

A corrosion-resistant and nickel-plating technology, applied in the field of high-performance nickel-plating solution, can solve the problems of leakage plating and poor dispersion ability of nickel-phosphorus alloy coating, and achieve the effect of prolonging the test time, good coating brightness and less components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of electroplating nickel solution that the present invention improves coating corrosion resistance, consists of

[0035] Nickel sulfate 250g / L

[0036] Phosphorous acid 35g / L

[0037] Boric acid 30g / L

[0038] Tartaric acid 100g / L

[0039] Hydroxymethacrylic acid 5g / L

[0040] PH: 2.0-2.5

[0041] Temperature: 60-65℃

[0042] Current: 2A

[0043] Time: 10 minutes

[0044] Preparation method: Take by weighing 250g of nickel sulfate, 35g of phosphorous acid, 30g of boric acid, 100g of tartaric acid, 5g of hydroxymethylacrylic acid, dissolve in water, adjust the pH to 2.5, and settle to 1000ml to obtain the electroplating nickel solution of the present invention.

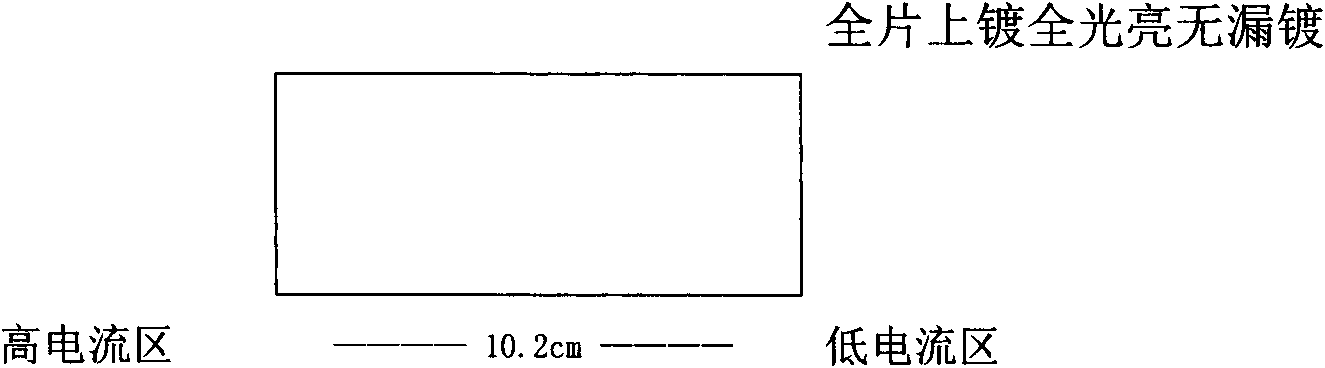

[0045] The 10.2cm×6cm×0.05cm iron sheet is degreased and cleaned in hot lye, washed with water, corroded in dilute sulfuric acid, washed with water, and then subjected to the following 250ml Hull cell test, the results are as follows figure 1 Shown: In the low current area, the entire chip is full...

Embodiment 2

[0047] Comparative Test

[0048] Nickel sulfate: 250g / L

[0049] Phosphorous acid: 35g / L

[0050] Boric acid: 30g / L

[0051] PH: 2.0-2.5

[0052] Temperature: 60-65°C

[0053] Current: 2A

[0054] Time: 10 minutes

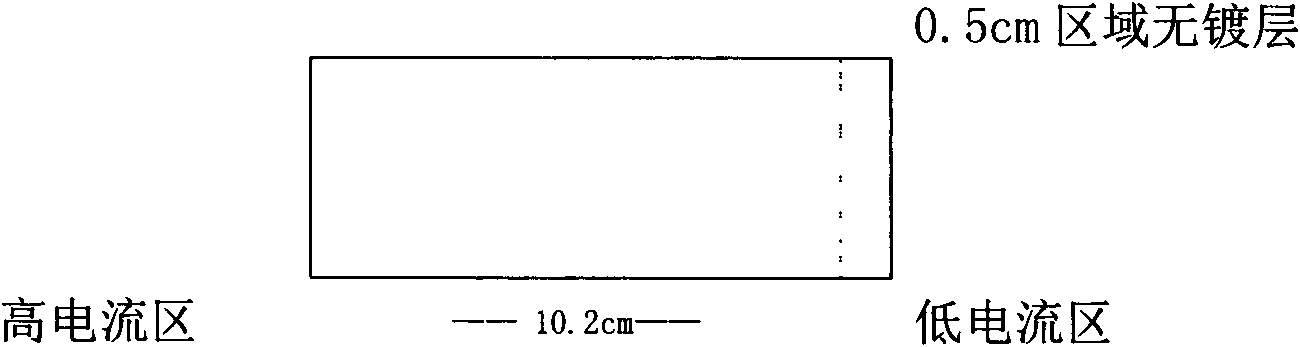

[0055] The results of the Hull cell test strips are as follows: figure 2 Shown: In the low current area, there is no coating in the 0.5cm area, that is, there is missing plating in the low current density area.

Embodiment 3

[0057] Nickel amino acid 250g / L

[0058] Phosphorous acid 35g / L

[0059] Boric acid 30g / L

[0060] Tartaric acid 100g / L

[0061] Hydroxymethacrylic acid 5g / L

[0062] PH: 2.0-2.5

[0063] Current: 2A

[0064] Time: 10 minutes

[0065] Preparation method: take by weighing 250g of nickel aminoglobulinate, 35g of phosphorous acid, 30g of boric acid, 100g of tartaric acid, 5g / L of hydroxymethacrylic acid, dissolve in water, adjust the pH to 2.5, and set the volume to 1000ml to obtain the present invention. Electroplating nickel solution.

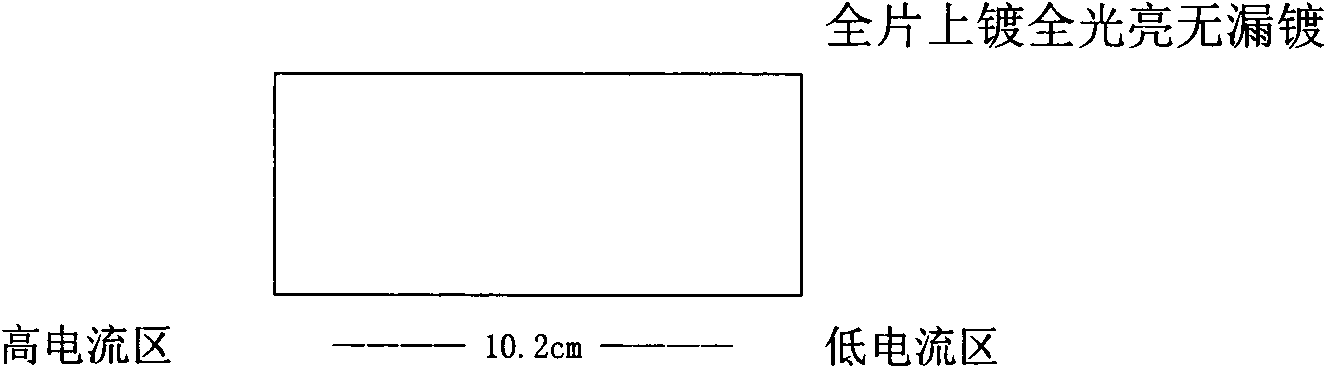

[0066] The 10.2cm×6cm×0.05cm iron sheet is degreased and cleaned in hot lye, washed with water, corroded in dilute sulfuric acid, washed with water, and then subjected to the following 250ml Hull cell test, the results are as follows image 3 Shown: In the low current area, the entire chip is fully brightly plated without missing plating.

[0067] Thus it can be concluded that the plating solution of the present invention has solved the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com