Hydroelectric end connecting device for rotating target

A terminal connection and rotating target technology, which is applied in the field of hydropower terminal connection devices, can solve problems such as inability to rotate and adjust, unstable connection, complex structure of hydropower terminals, etc., and achieve the effect of reducing disassembly steps and facilitating smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

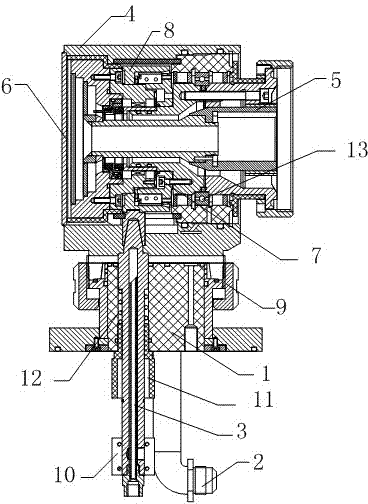

[0014] Such as figure 1 The shown hydroelectric terminal connection device for a rotating target includes a seat core 1, which is different: a water pipe 2 and a conductive rod 3 are respectively installed on the seat core 1 used in the present invention. At the same time, a housing assembly 4 is connected to the seat core 1 , a shaft retaining ring 5 is provided at one end of the housing assembly 4 , and a cover 6 is provided at the other end of the housing assembly 4 . Moreover, a skeleton type oil seal assembly 7 is arranged at the tail end of the shaft retaining ring 5 , and a conductive rod head 8 is sheathed on the periphery of the skeleton type oil seal assembly 7 .

[0015] In view of a preferred embodiment of the present invention, in order to improve the firmness of the whole, a base fitting 9 is provided on the periphery of the seat core 1 . Moreover, in order to facilitate the effective combing of the wire harness and the normal operation of the conductive rod 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com