Installation method of vertical guide rail of ship elevator

A technology of vertical guide rail and installation method, which is applied in the directions of elevators, transportation and packaging, etc., which can solve the problems that welding gaskets cannot be inclined to the outside, increase the adjustment workload, and slow the progress of steel wire drawing, etc., and achieve fast measurement speed and convenient adjustment , Reduce the effect of adjustment workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

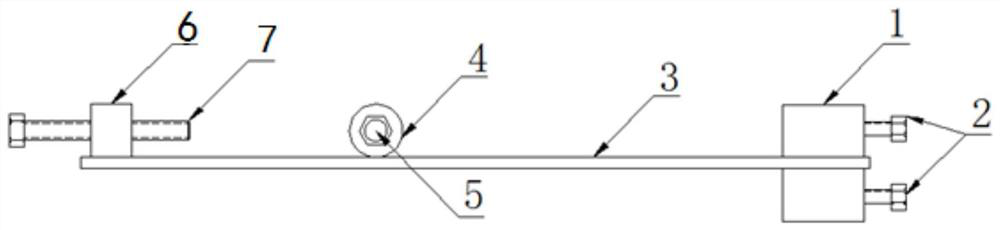

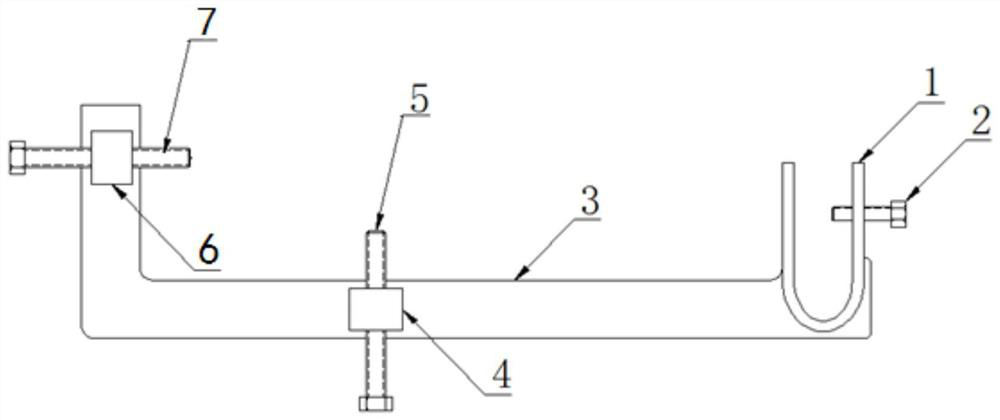

[0046] This embodiment provides an installation and adjustment device for a vertical guide rail of an elevator, which includes two installation and adjustment mechanisms used in conjunction with each other, and the installation and adjustment mechanisms are symmetrically arranged on both sides of the vertical guide rail. The installation adjustment mechanism includes a U-shaped bottom plate 1, a fixing bolt 2, a support plate 3, a first adjustment mechanism, and a second adjustment mechanism.

[0047] The width of the slot of the U-shaped bottom plate 1 is greater than the thickness of the base panel of the installation base, and a bolt mounting hole is provided through the side wall of the U-shaped bottom plate 1, and the fixing bolt 2 is installed in the bolt mounting hole. The U-shaped bottom plate 1 and the fixing bolts 2 form the bottom fixing mechanism. The U-shaped bottom plate 1 is clamped on the base panel of the vertical guide rail, and the U-shaped bottom plate 1 can...

Embodiment 2

[0059] This embodiment provides a method for installing a vertical guide rail of a ship lift, which includes the following steps:

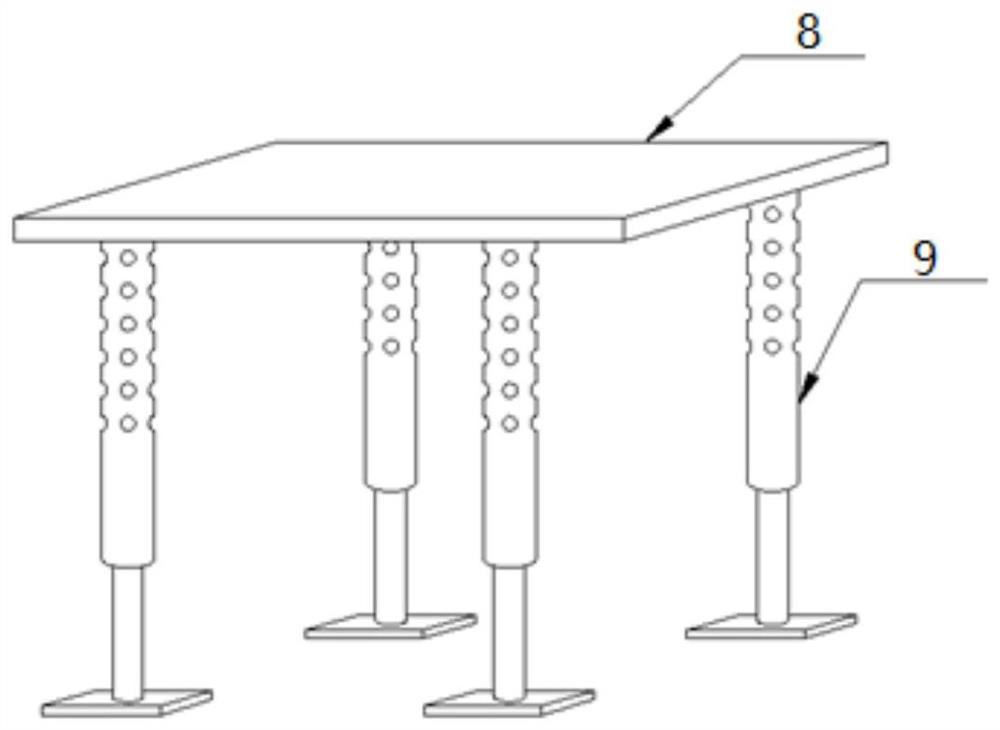

[0060] Step 1. Make the bottom support. The bottom support includes an upper plate 8 and an adjustable column 9. The upper plate 8 is a steel plate with a thickness of 50mm planed on the upper surface by a planer. There are 4 adjustable columns, and the adjustable column 9 is used for Support the upper plate 8, adjust the levelness of the upper plate 8 and the distance between the upper plate 8 and the deck to the theoretical value required by the drawing, and then adjust the bottom adjustable column 9 with the help of a spirit level to adjust the upper plate 8 supported by the bottom to level. Fix by spot welding after adjustment.

[0061] Step 2. According to the Yang Chong mark point on the center line of the lift platform body, draw the platform cross center line on the lift platform body. The platform cross center line includes the platform h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com