Multi-impact composite structure for cooling walls

A technology of composite structure and cooling fluid, which is applied in the direction of supporting elements of blades, combustion methods, manufacturing converters, etc., can solve problems such as incapable of precision manufacturing, and achieve the effect of optimizing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

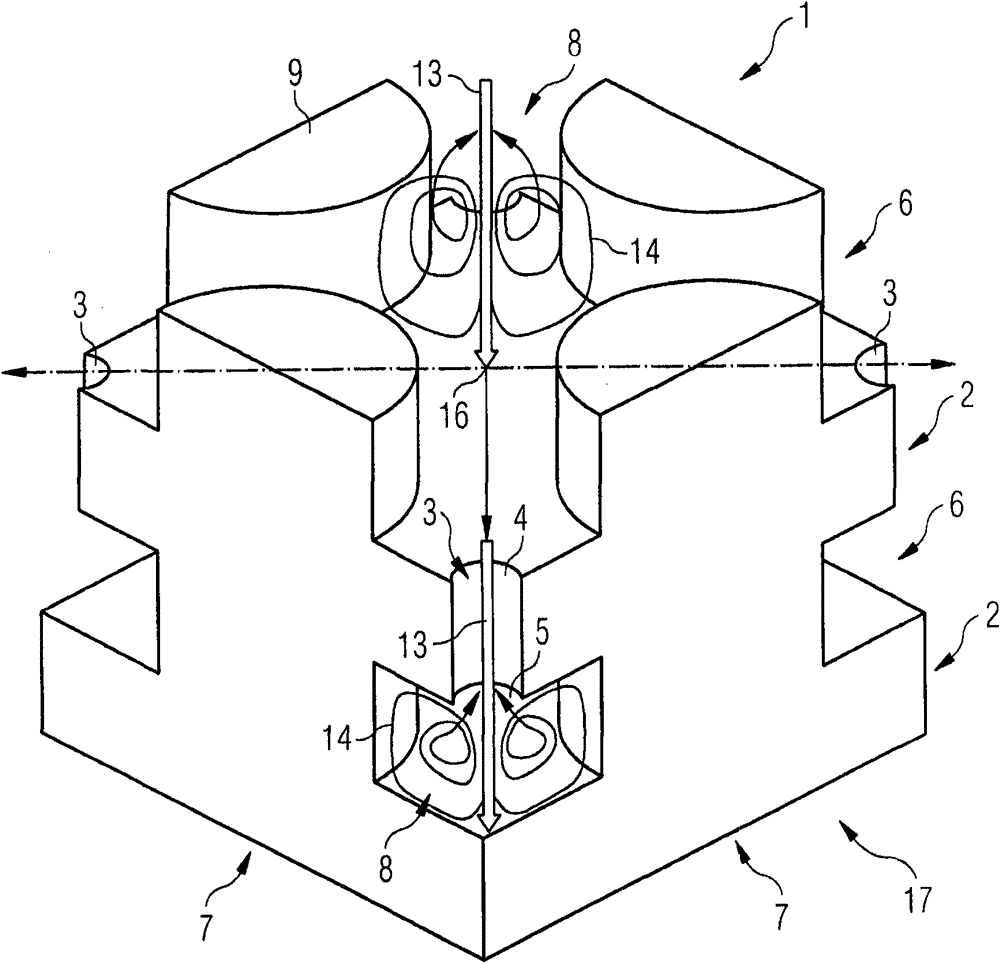

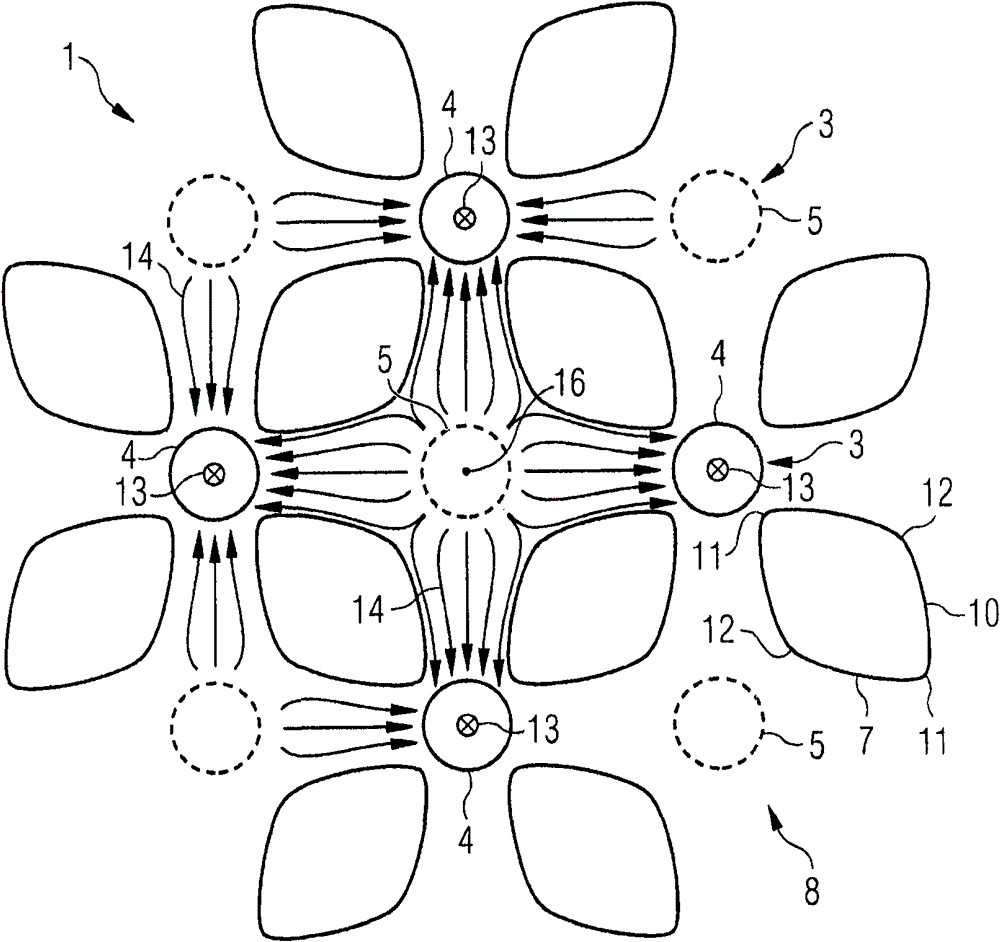

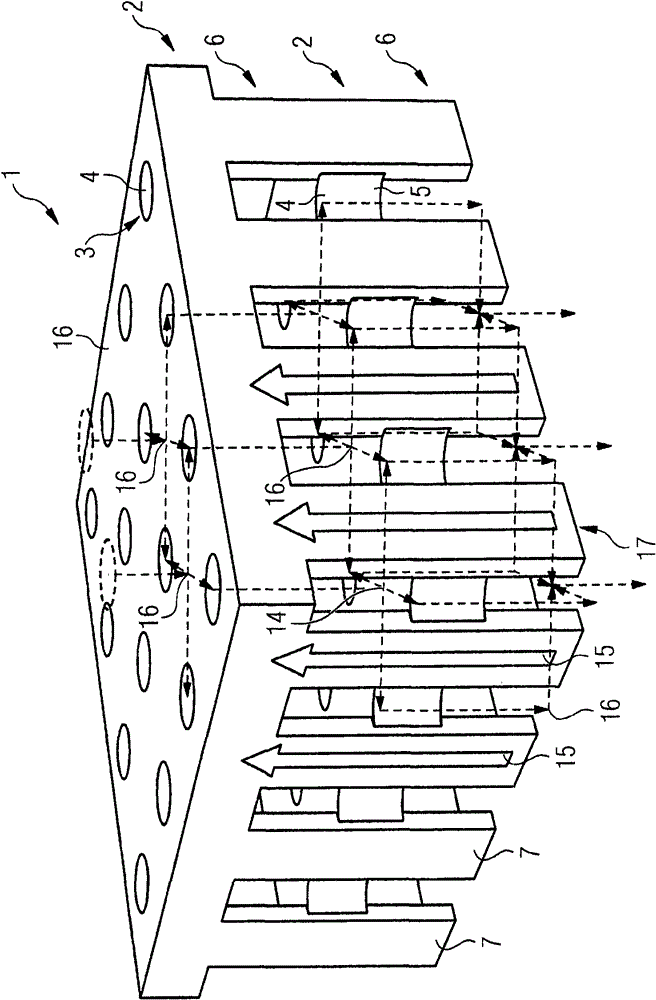

[0026] as available from Figures 1 to 3 It can be seen from the figure that the multi-impact composite structure has a plurality of orifice layers 2 in which a plurality of through-holes 3 are arranged in the form of a grid. The cooling fluid flows through the through-holes 2 , which thus each have an inflow side 4 and an outflow side 5 .

[0027] In addition, the multi-impact composite structure 1 has a plurality of web layers 6, which are respectively arranged between two adjacent perforated plate layers 2, so that the multi-impact composite structure 1 has Sandwich structure composed of layer 2 and tab layer 4. The web layer 6 is formed from a plurality of webs 7 which, like the through-holes 3 , are likewise arranged in a grid-like manner and with their longitudinal direction perpendicular to the perforated plate layer 2 . Each web 7 thus bridges the distance between two adjacent orifice layers 2 , so that heat can be transferred from one orifice layer 2 to the other vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com