A rapid tool drop device for a lathe

A technology of falling knife and lathe, which is applied in the field of cutting processing, can solve the problems of difficult accurate calculation of shear force, large vibration, and inability to maintain the spring end face, etc., to avoid differences caused by samples, avoid material waste, and save test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

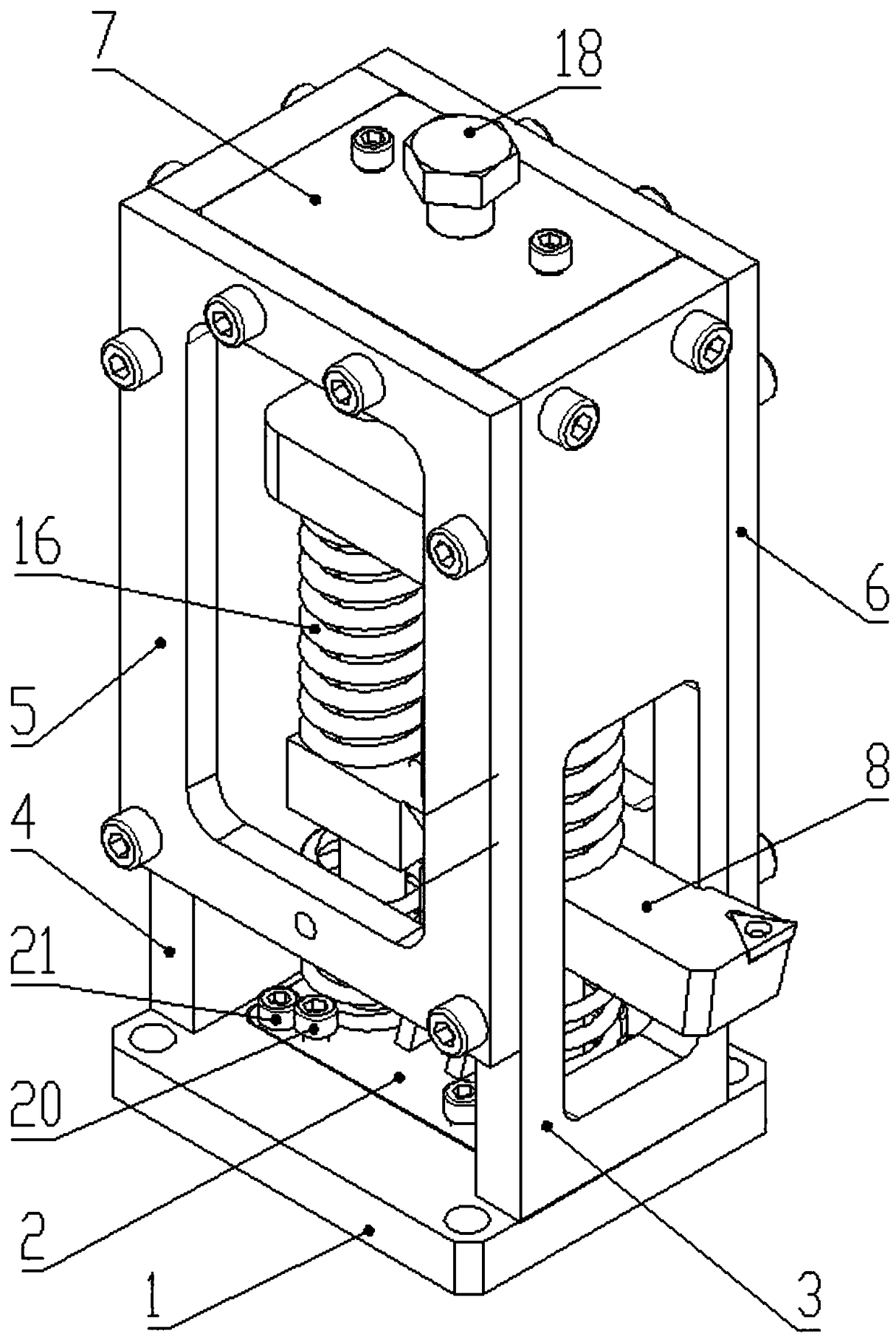

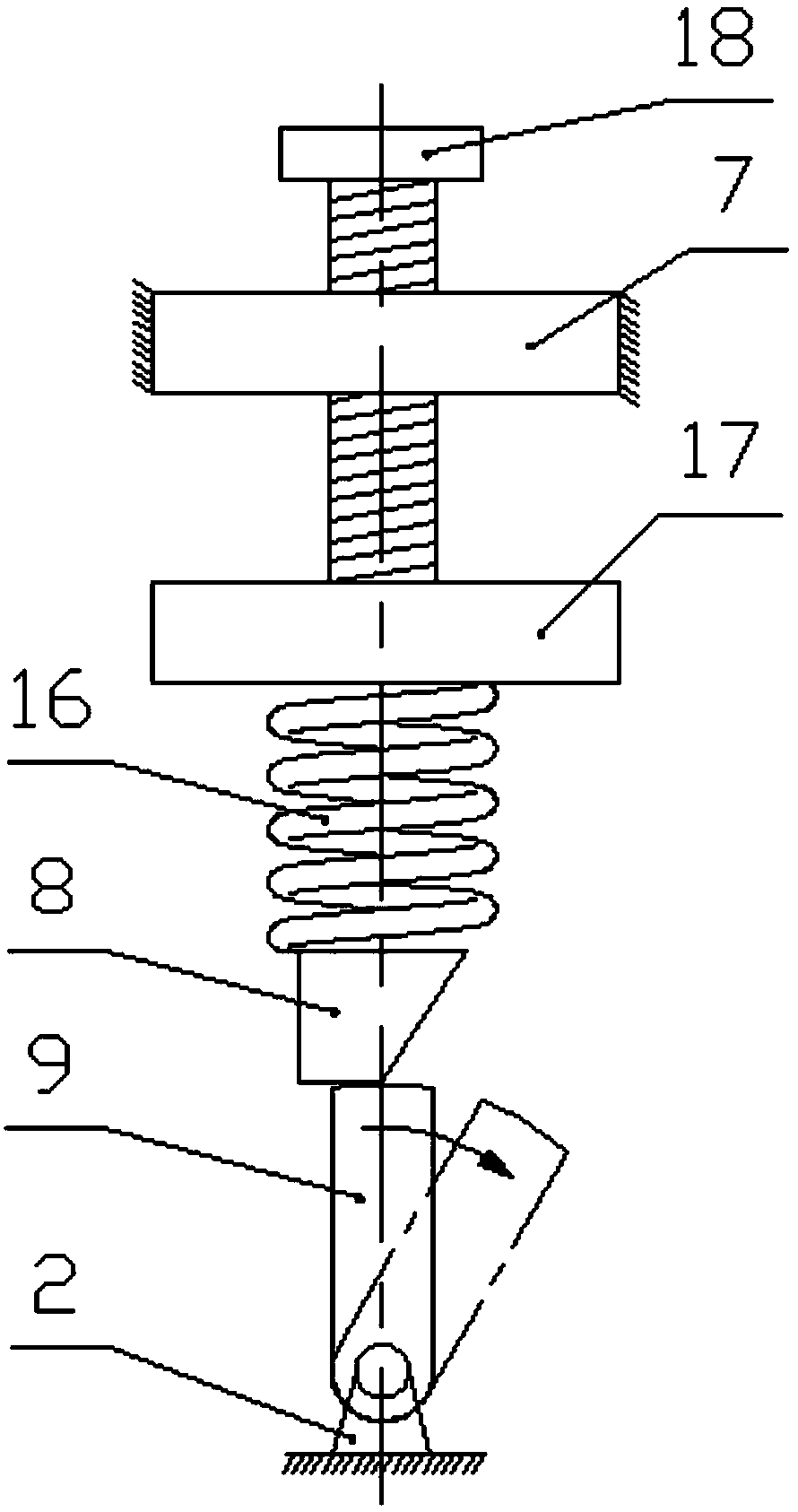

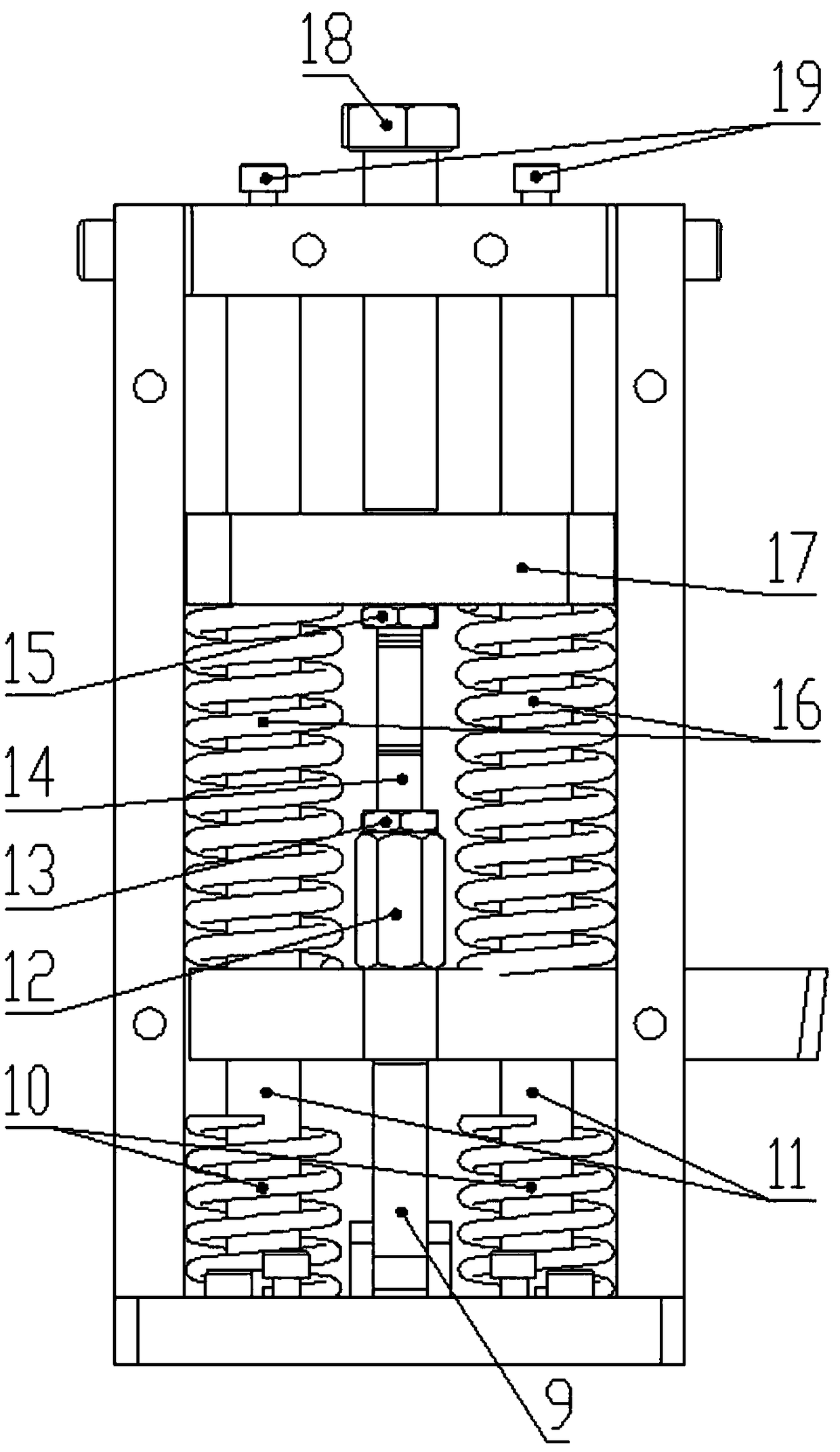

[0032] Such as Figure 1 to Figure 9 Shown, the present invention is a kind of fast tool drop device for lathe, base 1, bottom plate 2, front side plate 3, rear side plate 4, right side plate side 5, left side plate 6, top fixed plate 7, knife bar 8, Cam lever 9, buffer spring 10, cylindrical guide rail 11, adjustment nut 12, first lock nut 13, stud stud 14, second lock nut 15, pressure spring 16, pressure plate 17, compression bolt 18, guide rail fixing Screw 19, height adjustment screw 20, fastening screw 21, bearing pin 22; the device of the present invention is fixed on the lathe through the base 1, the present invention does not limit its fixing method and fixing position, those skilled in the art can choose according to the actual situation , For example, it can be installed on the middle carriage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com