Patents

Literature

35results about How to "Uniform acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

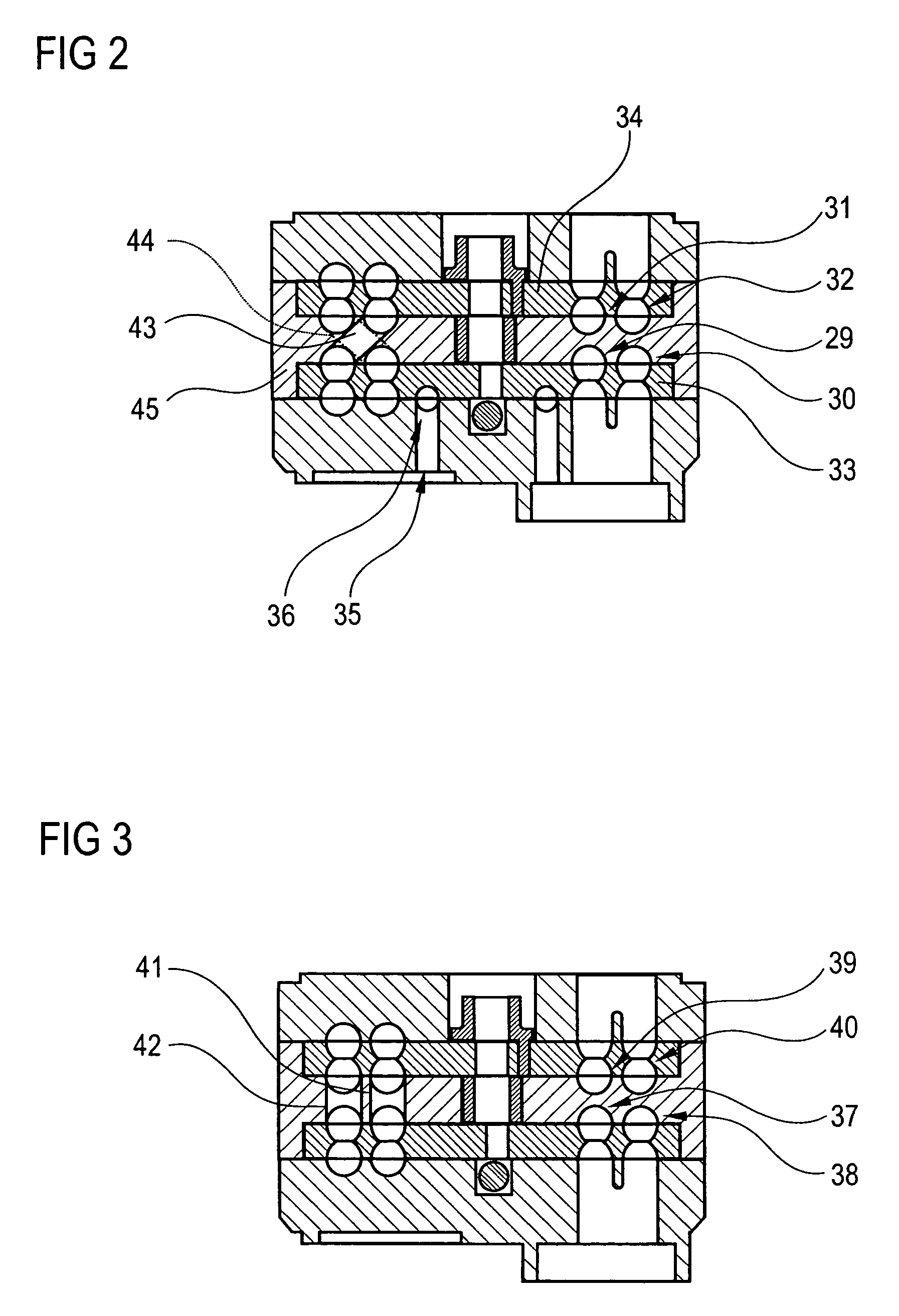

Pressure atomizer nozzle

InactiveUS6045058ASlow disintegrationReduce friction lossBurnersSpray nozzlesNebulizerAtomizer nozzle

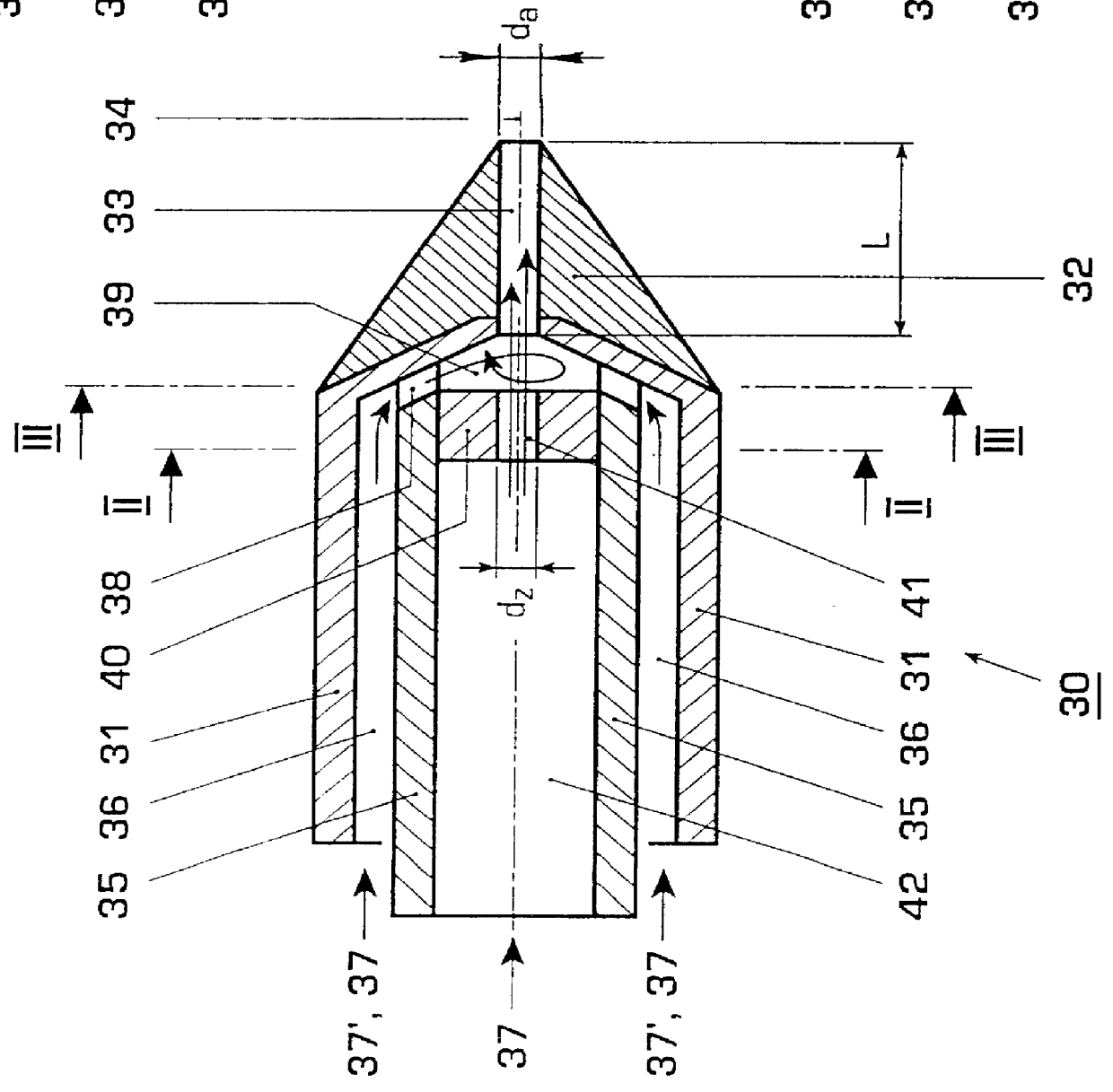

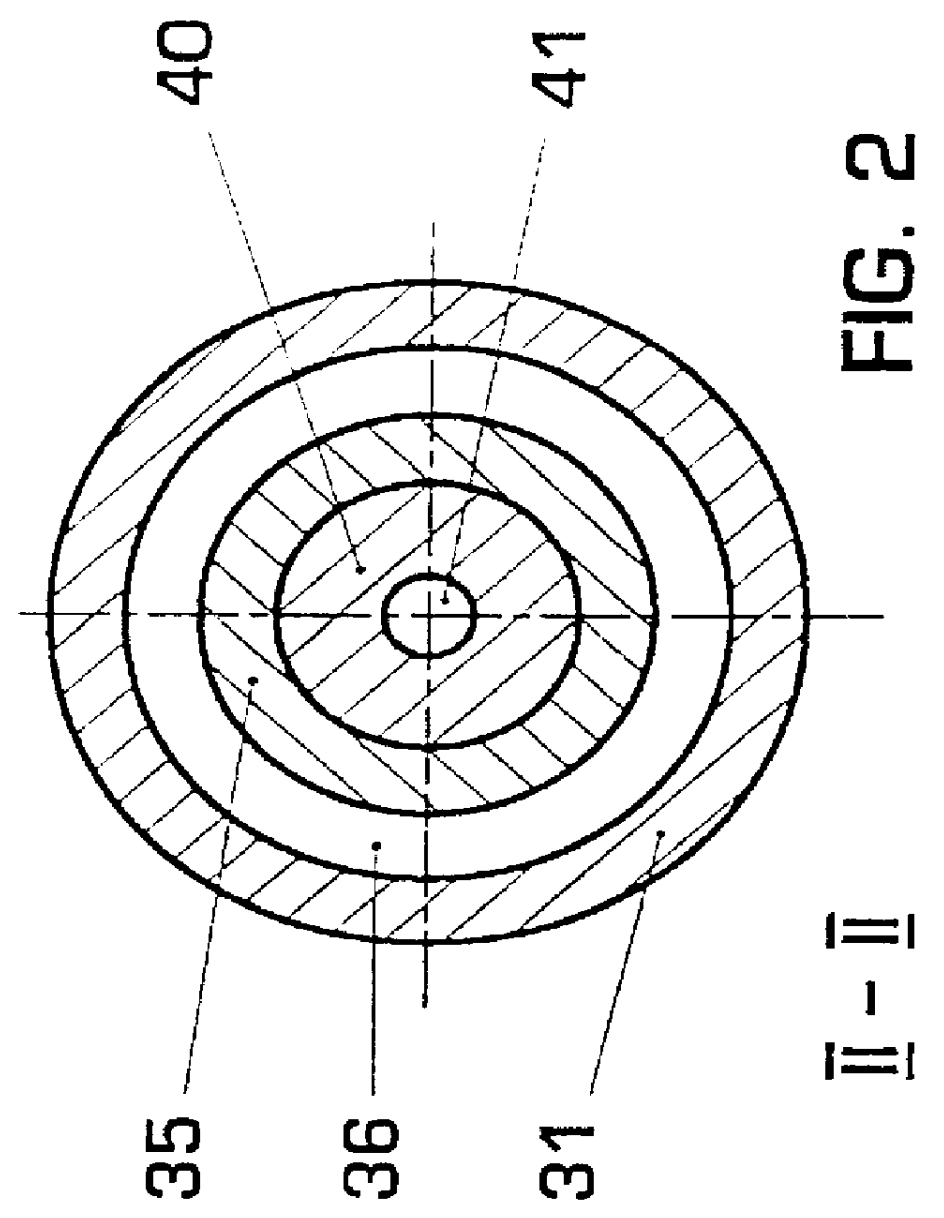

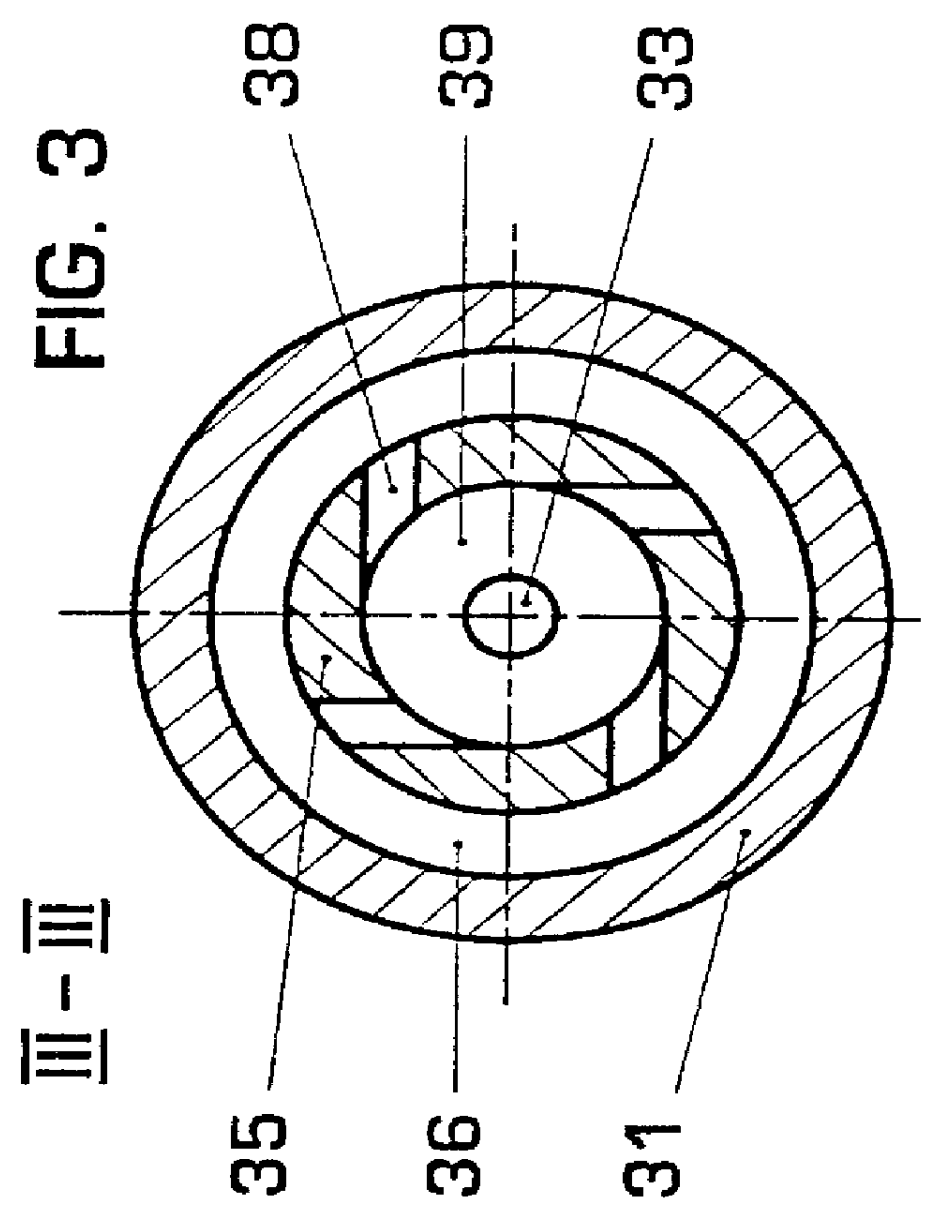

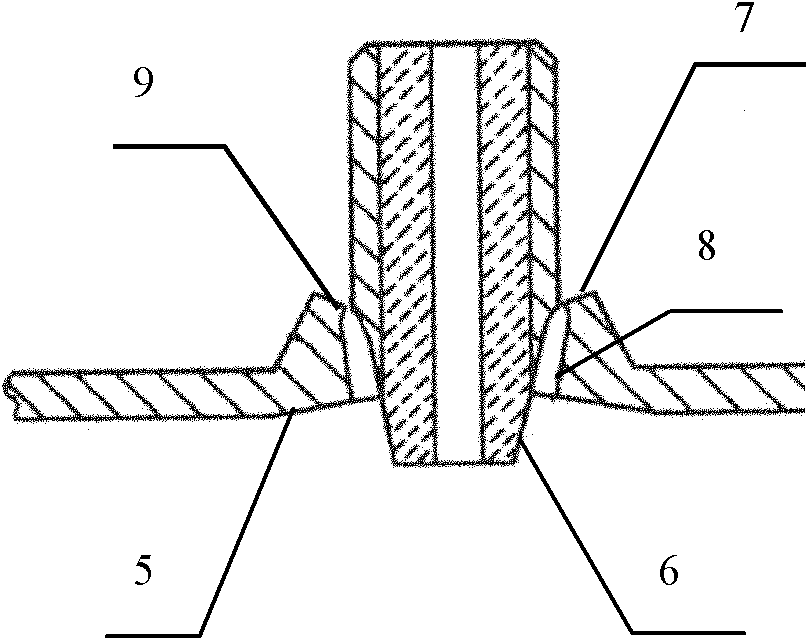

The invention relates to a two-stage pressure atomizer nozzle with a nozzle body (30) having a mixing chamber (39) which is connected to an outside space via a nozzle outlet bore (33), and with a first feed duct (42) with a feed bore (41) for a liquid (37) to be atomized, through which feed bore said liquid (37) can be fed, free of swirling and under pressure, at least one further feed duct (36) for a portion of the liquid (37) to be atomized or for a second liquid (37') to be atomized opening into the chamber (39), through which feed duct said liquid (37, 37') can be fed under pressure and with swirling. The feed bore (41) of the first feed duct (42) lies on one axis (34) with the nozzle outlet bore (33). It is defined in that the outlet-side diameter (da) of the nozzle outlet bore (33) is at most as large as the diameter (dz) of the feed bore (41) and the length (L) of the nozzle outlet bore (33) is at least twice to at most ten times the outlet-side diameter (da) of the nozzle outlet bore (33).

Owner:ANSALDO ENERGIA SWITZERLAND AG

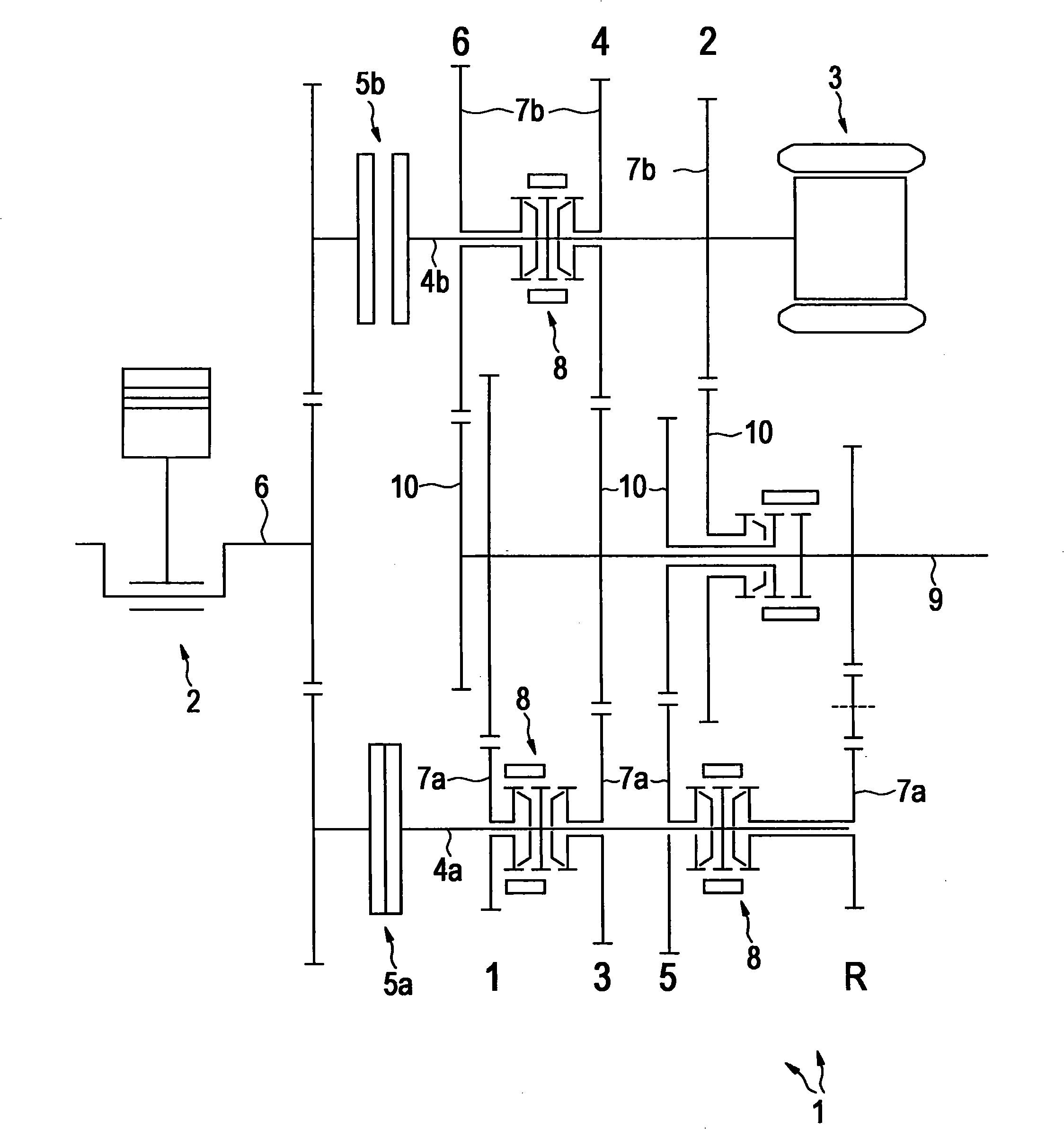

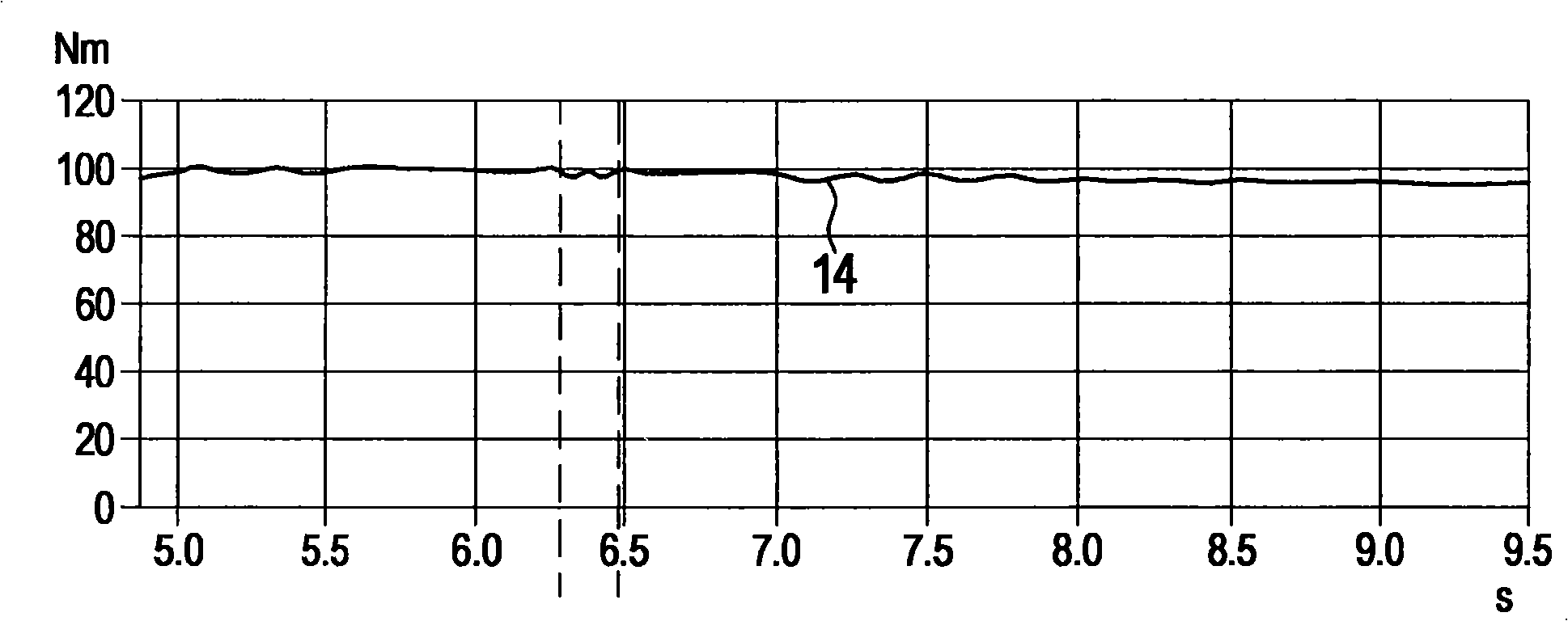

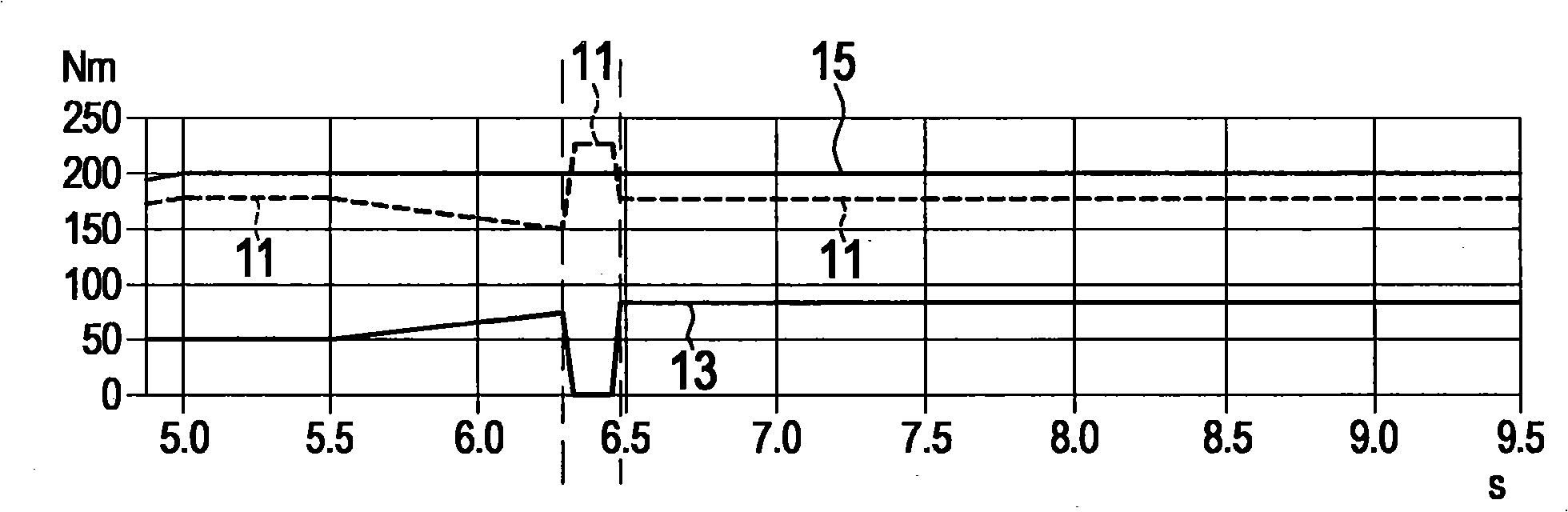

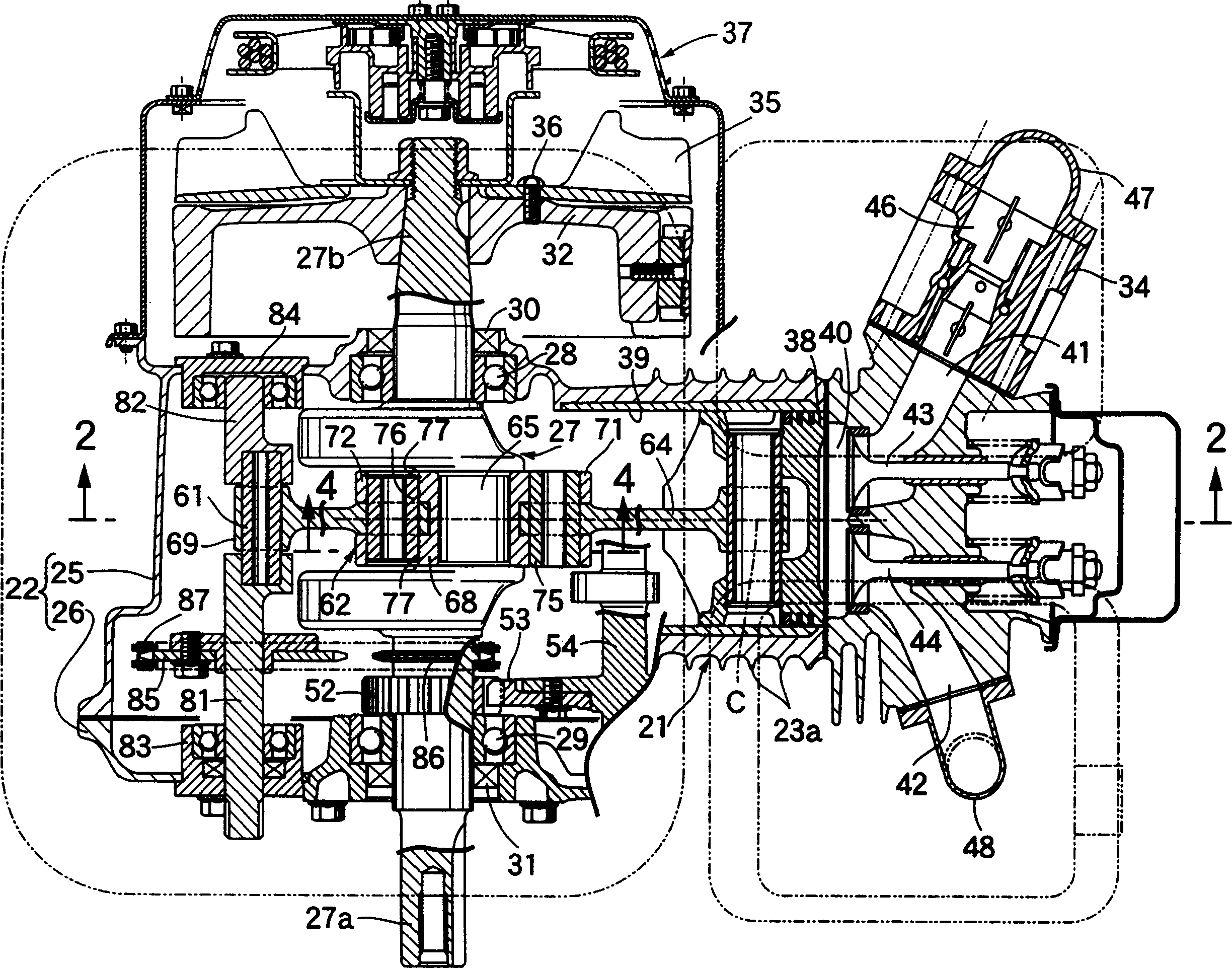

Method for the operation of a hybrid drive train in a motor vehicle

InactiveCN101516708ASmall torqueIncrease torqueToothed gearingsGas pressure propulsion mountingElectric machineControl theory

Owner:SCHAEFFLER TECH AG & CO KG

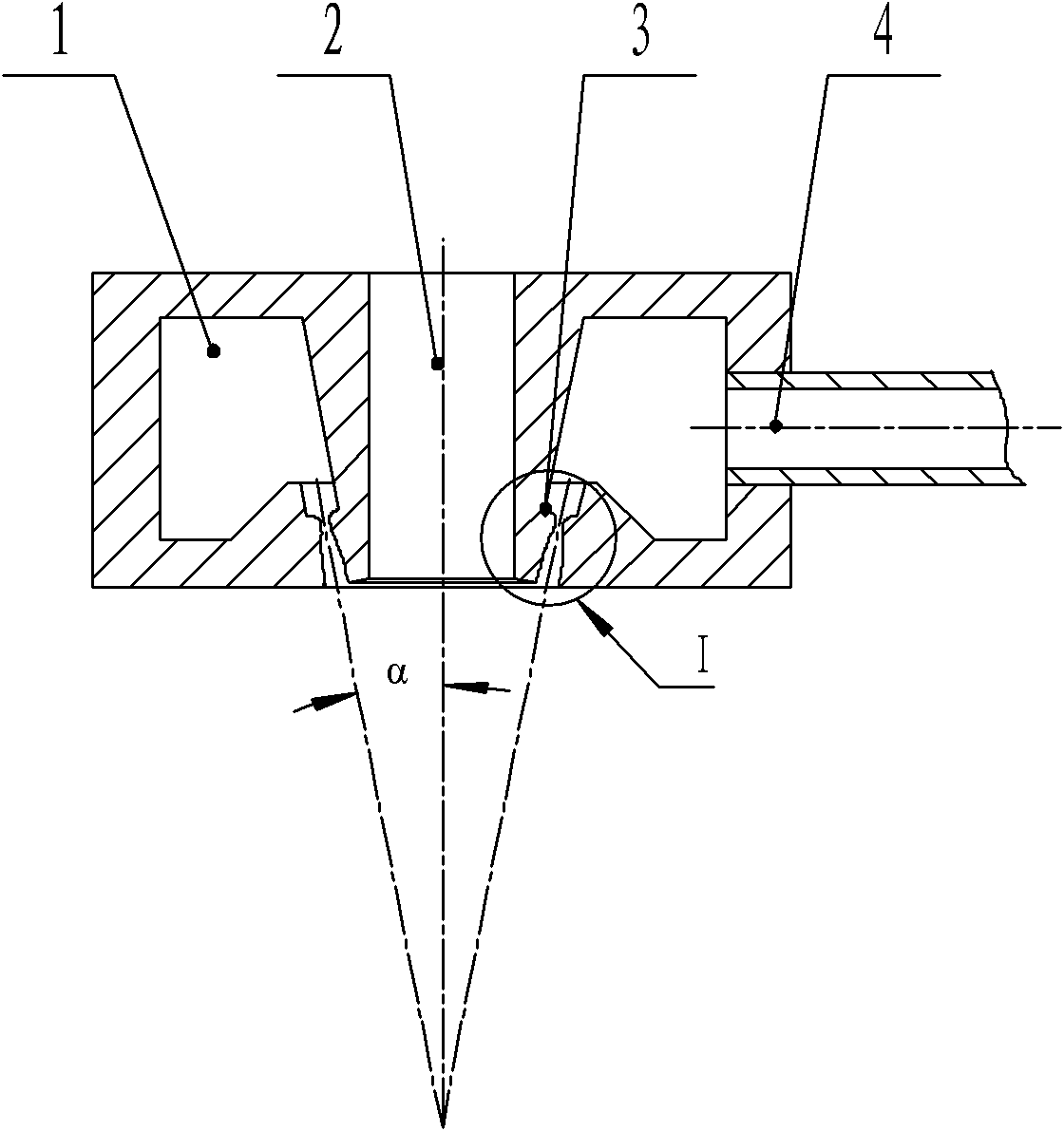

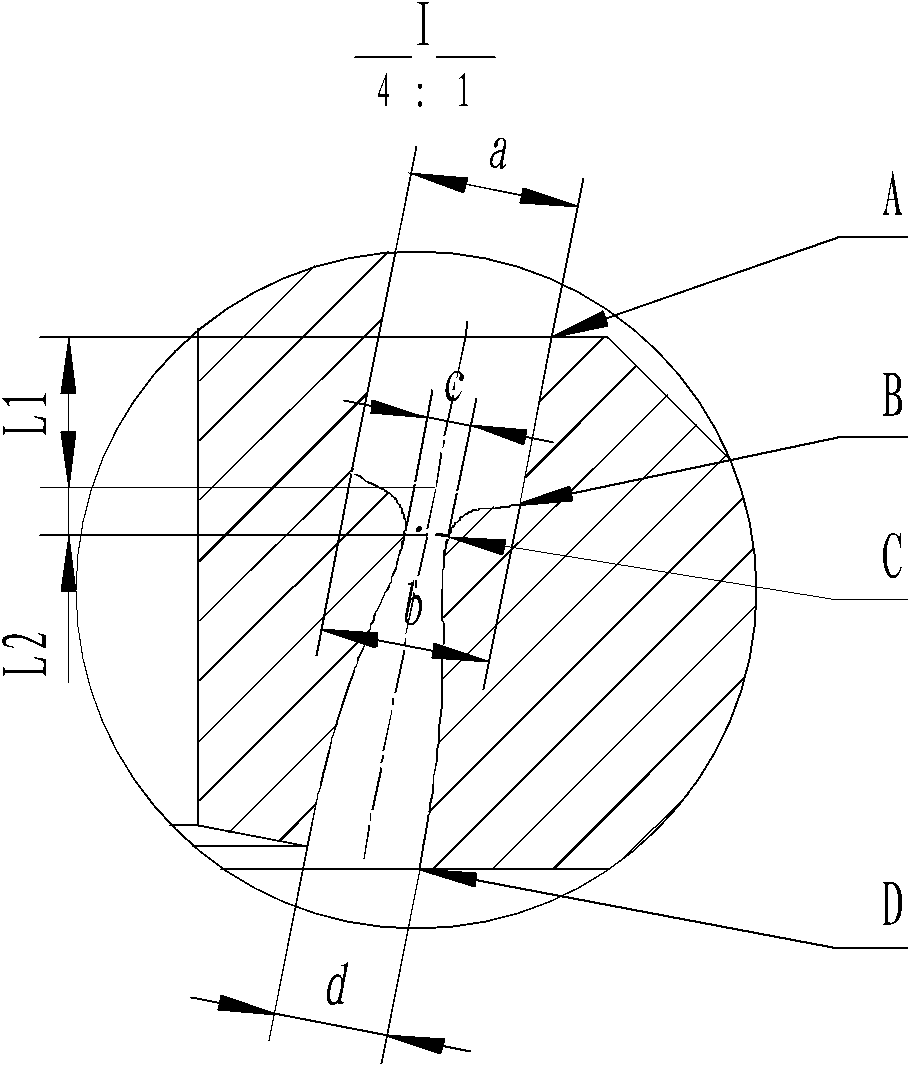

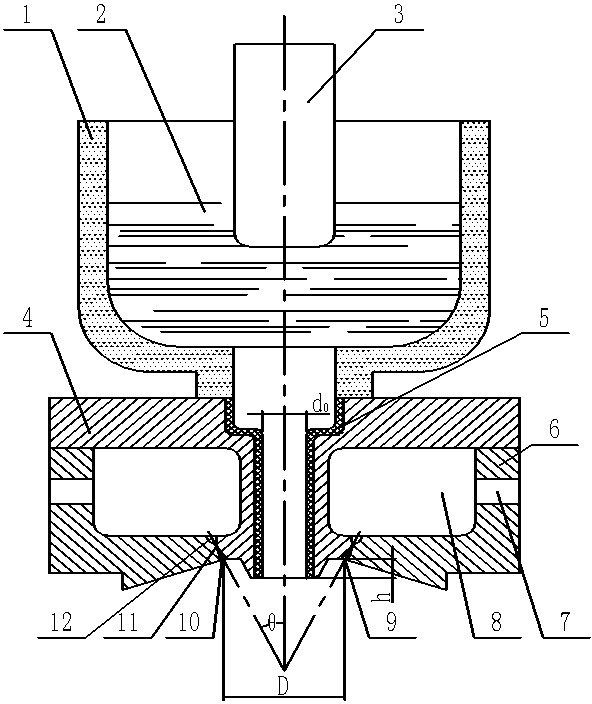

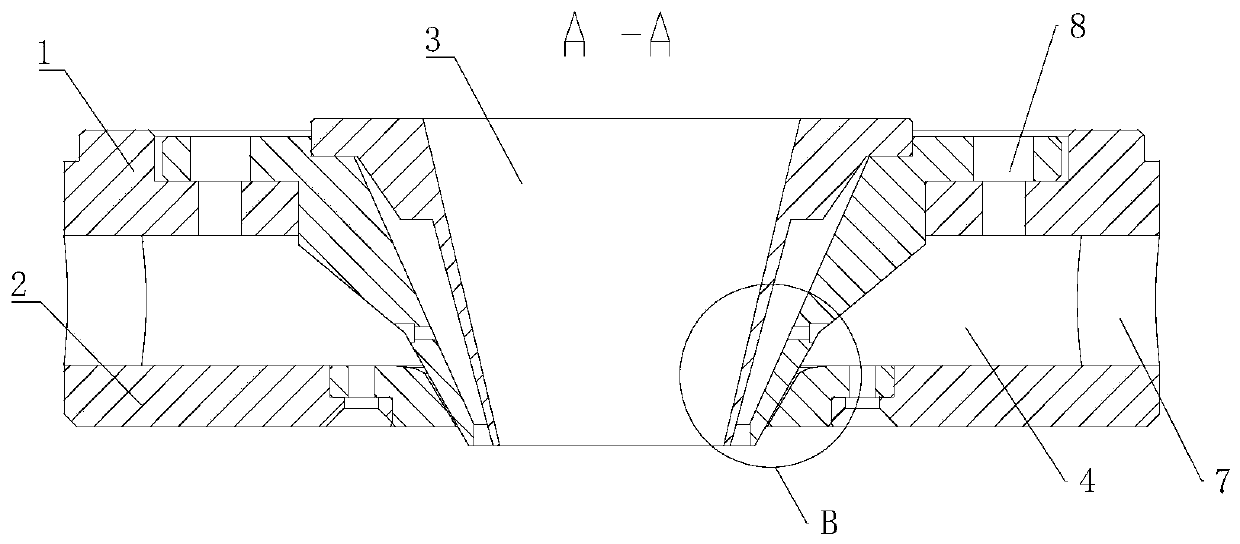

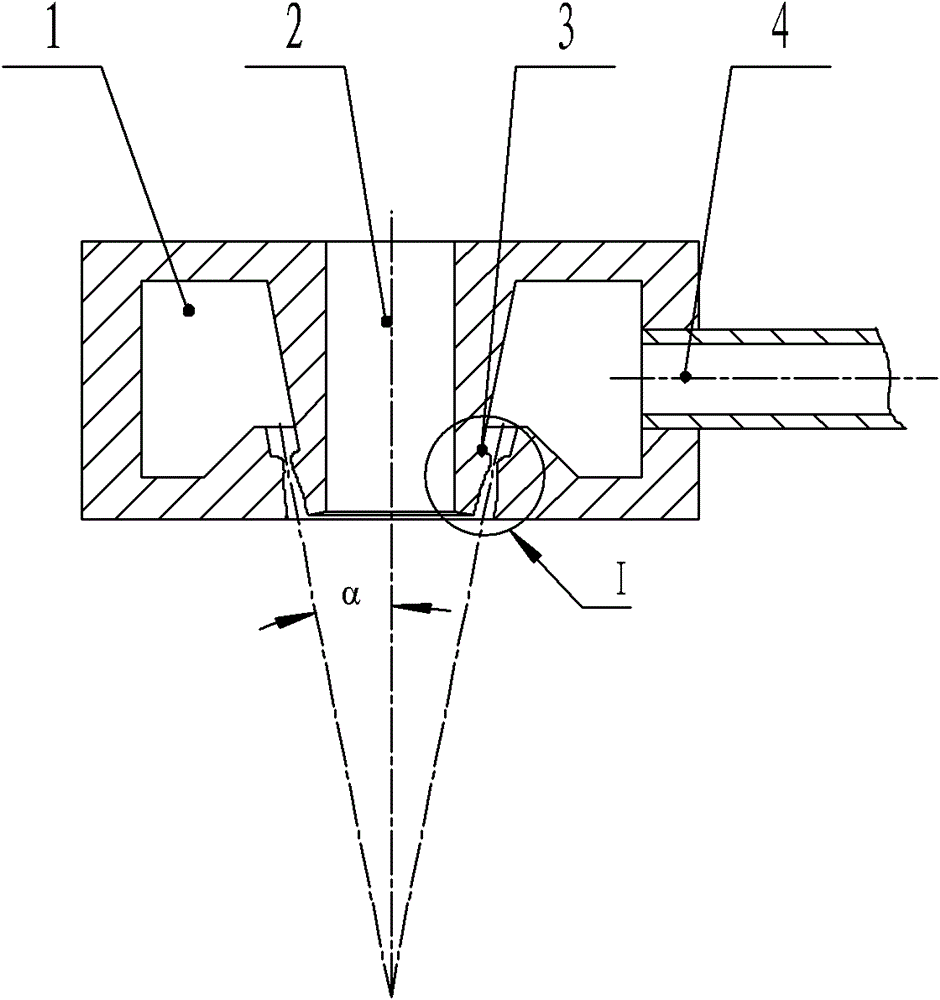

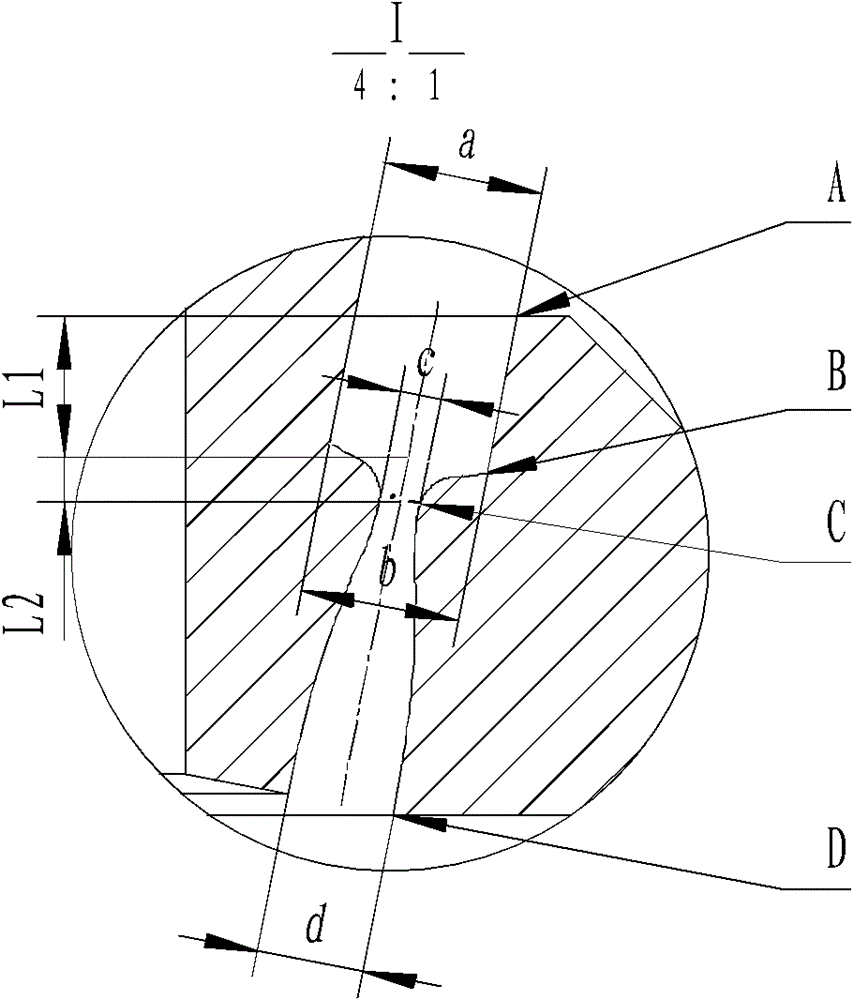

Circumferential seam type supersonic nozzle for metal gas atomization

ActiveCN102581291AUniform velocity distributionReduce turbulenceLiquid spraying apparatusShock waveGas cylinder

A circumferential seam type supersonic nozzle for metal gas atomization comprises a gas inlet pipe (4) connected with an external gas bottle. The gas inlet pipe is connected with an annular gas chamber (1) of the nozzle, the center of the nozzle is provided with a central hole (2), a supersonic gas spray pipe (3) of a circumferential seam structure is formed on the inner chamber wall and the outer chamber wall below the gas chamber and comprises stabilizing sections, contracting sections, throats and diffusion sections, a seam profile consists of symmetric curves, the profile of the whole spray pipe is the seam profile formed by the curves AB, BC and CD to take the axis of central hole (2) as the symmetry axis, the profile rotates by 360 degrees around the axis of the central hole (2) so that a curved surface is obtained, and an included angle alpha ranging from 0 degree to 6 degrees but not equal to 0 degree is formed by an extension line of a central line of each seam passage and the axis of the central hole of the nozzle in the profile of the gas spray pipe (3) passing through the axis of the central hole of the nozzle. The supersonic nozzle for gas atomization has the advantages that gas flow is uniform, turbulence level is low, and shock waves are absent in a flow field.

Owner:有研增材技术有限公司

Method and device for inspecting containers

InactiveCN101210885AReduce productivitySimple designOptically investigating flaws/contaminationStructural engineeringMechanical engineering

Owner:KRONES AG

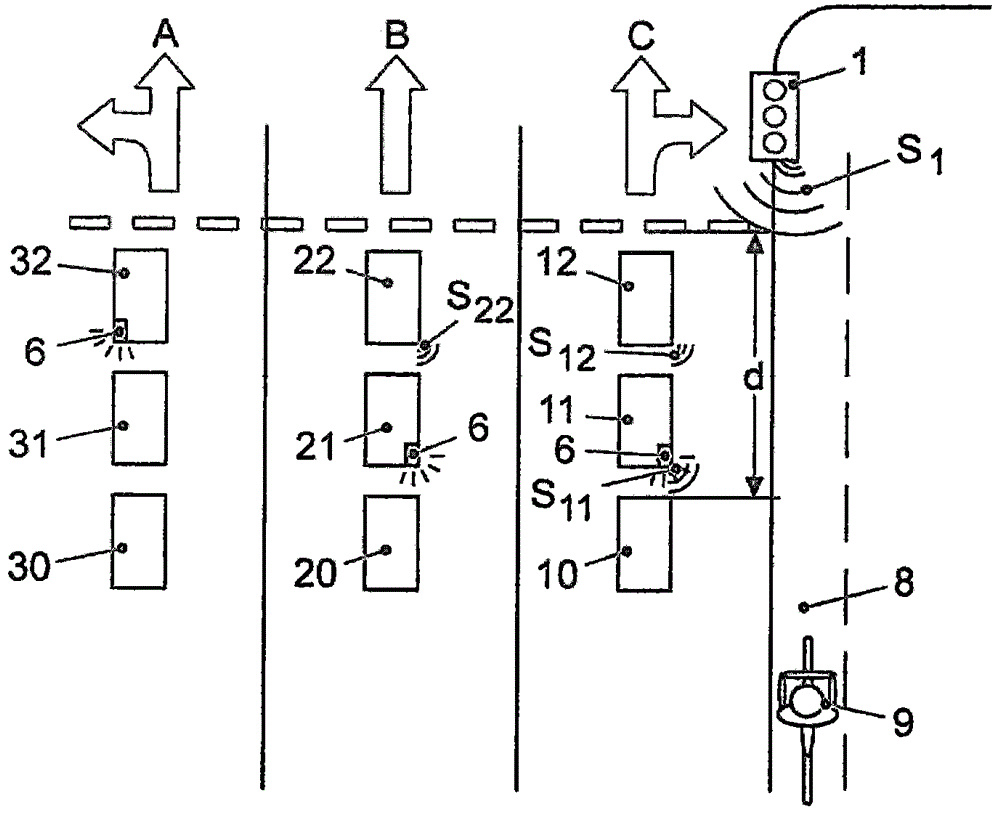

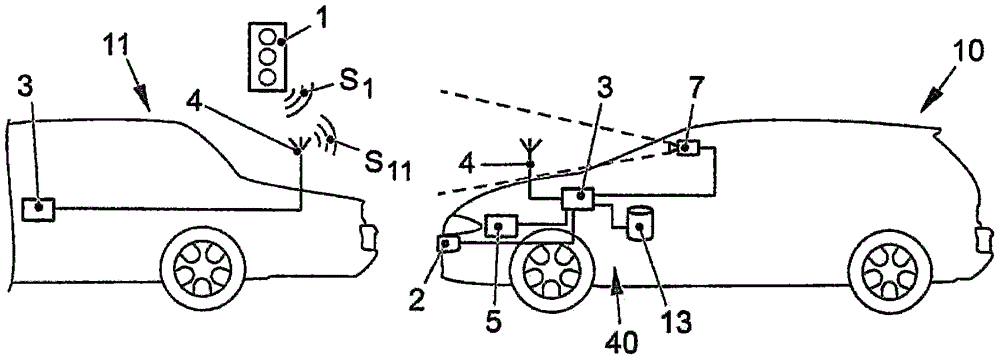

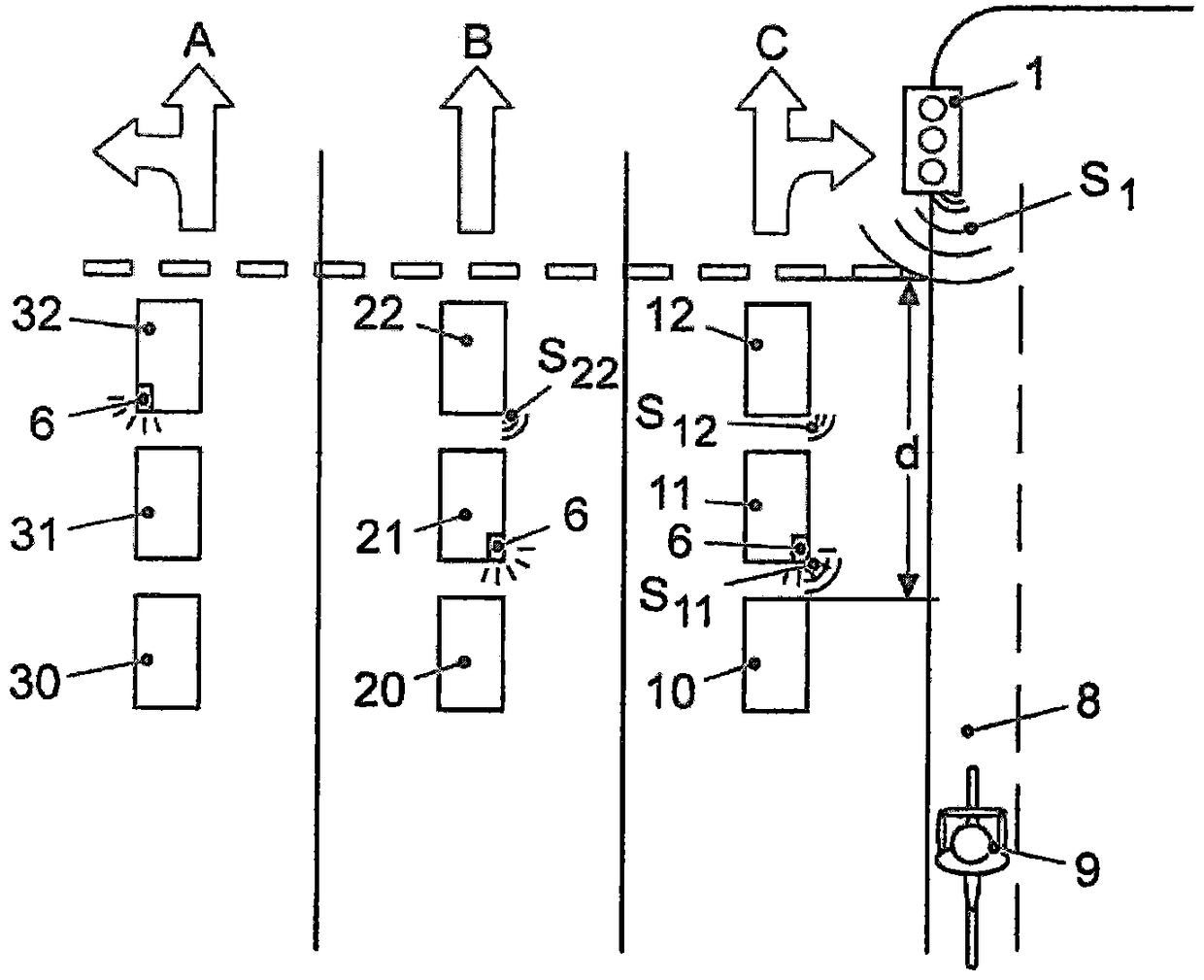

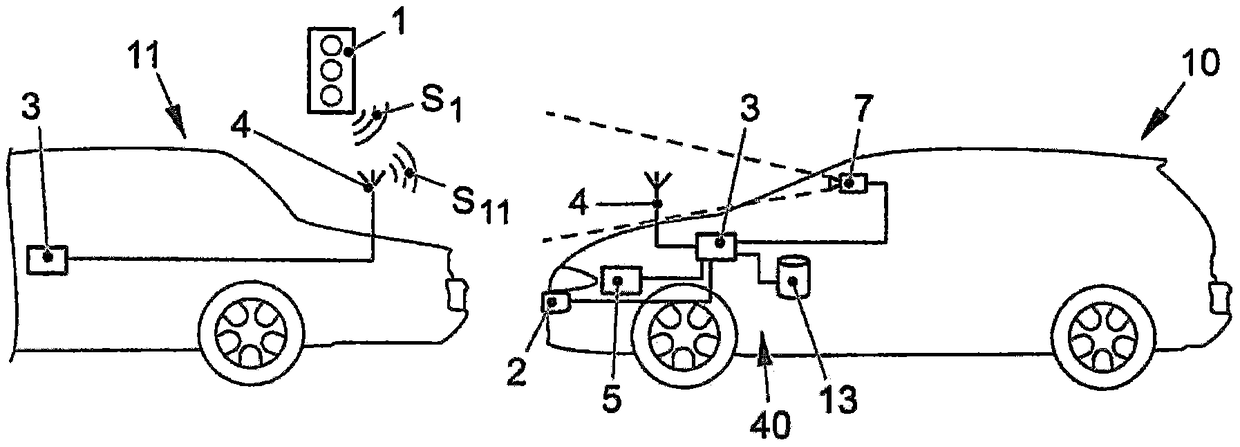

Device and method for accelerating a vehicle at start at a light sign assembly

ActiveCN105882660AAvoid collisionUniform accelerationExternal condition input parametersPlatooningEngineeringLighting system

A means of transport, an apparatus and a method for accelerating a vehicle in the case of a line start at a traffic light system including determining a likelihood of a predefined vehicle being able to pass through the traffic light system during a current or imminent green phase, accelerating the vehicle in accordance with a signal from an electronic towbar system if the likelihood is higher than a predefined threshold value, and accelerating the vehicle to a lesser extent if the likelihood is lower than the predefined threshold value.

Owner:VOLKSWAGEN AG

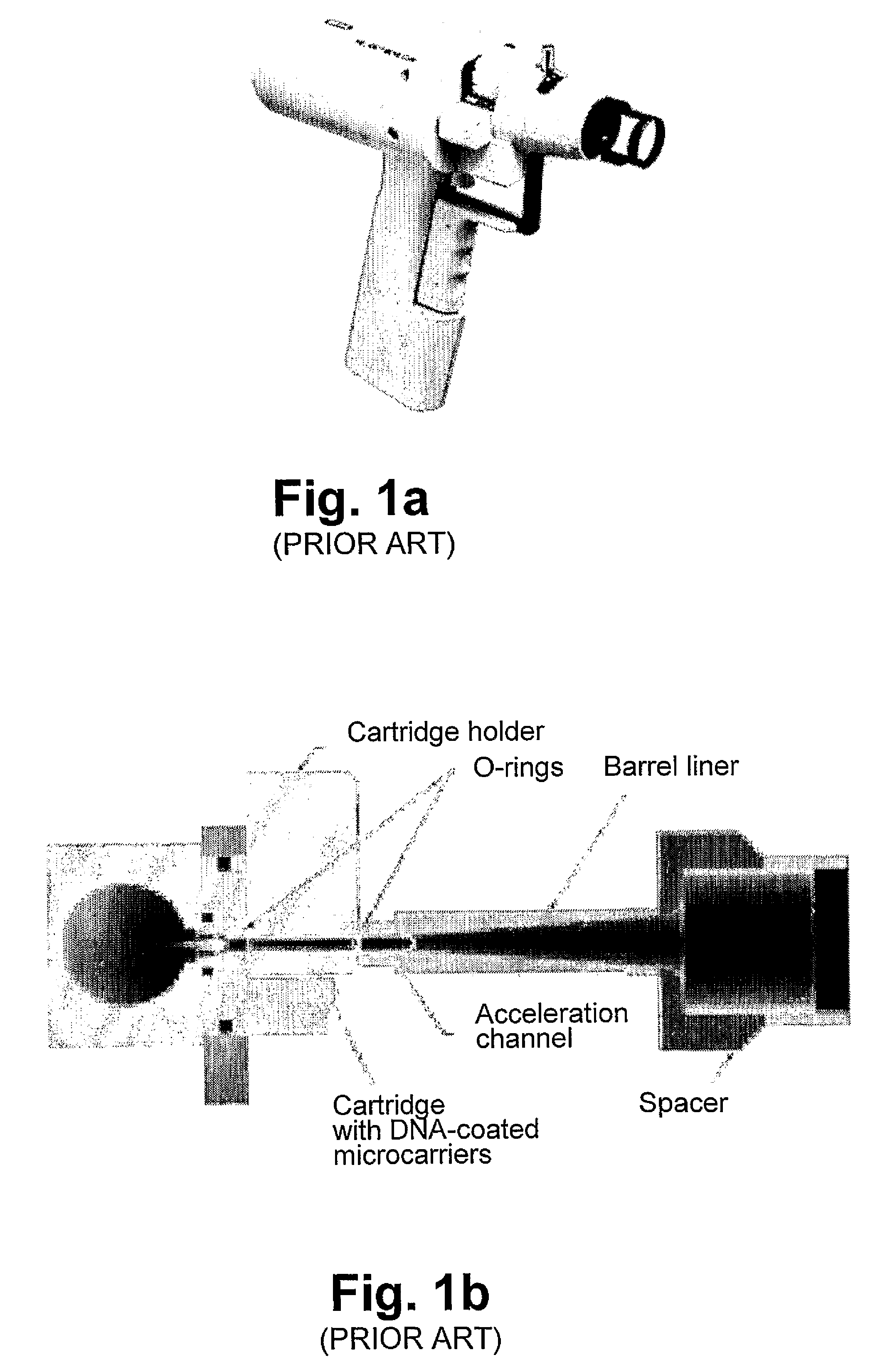

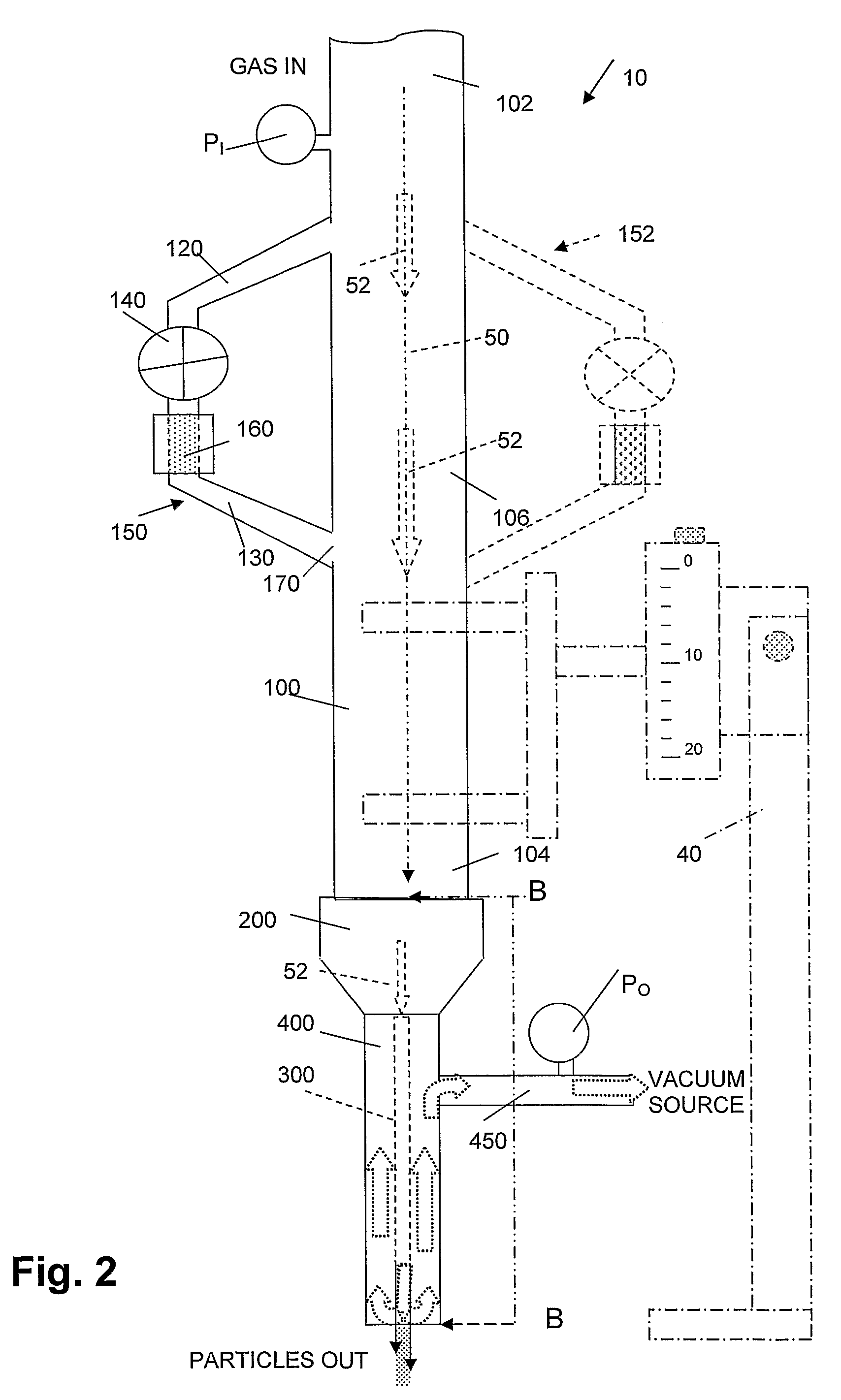

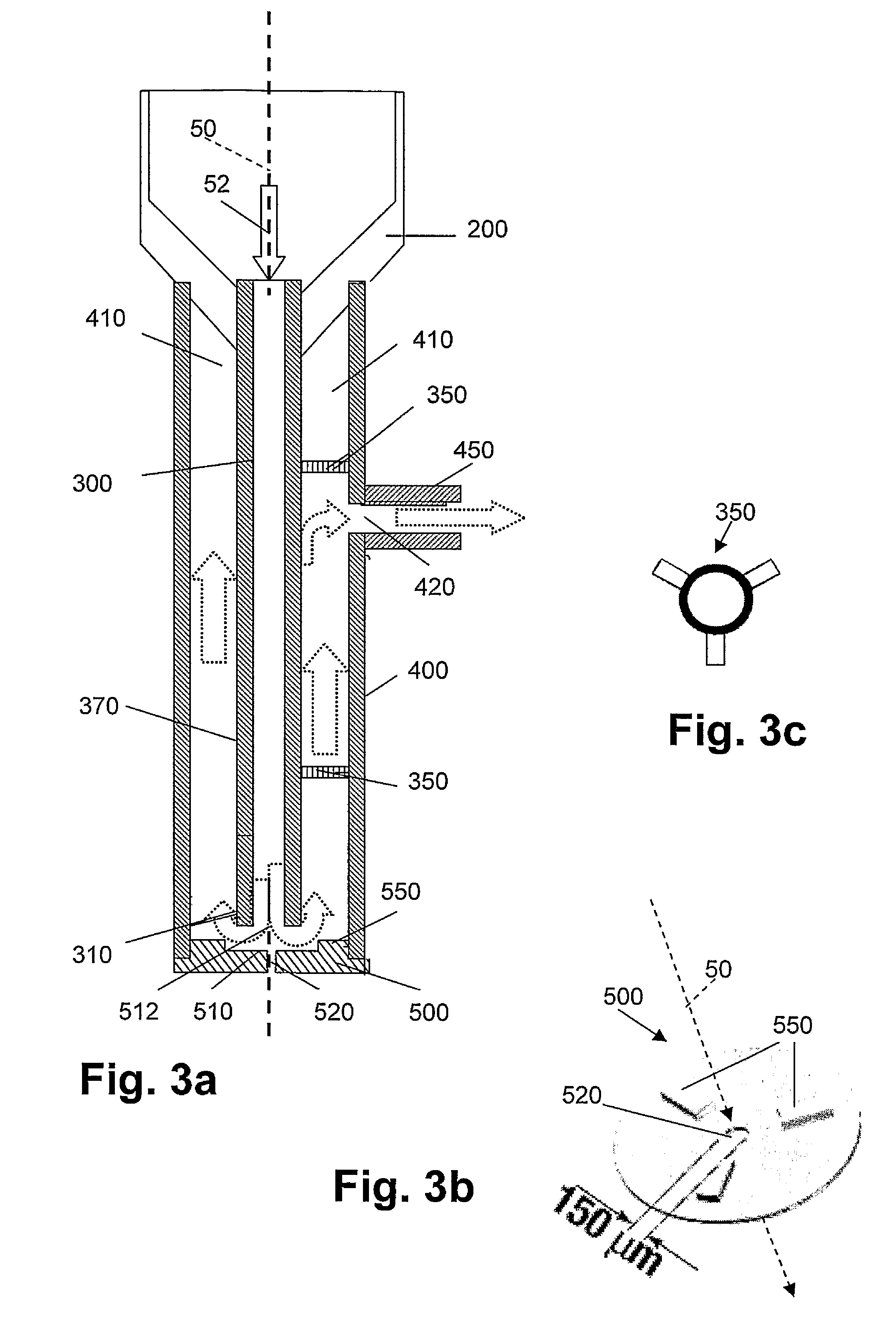

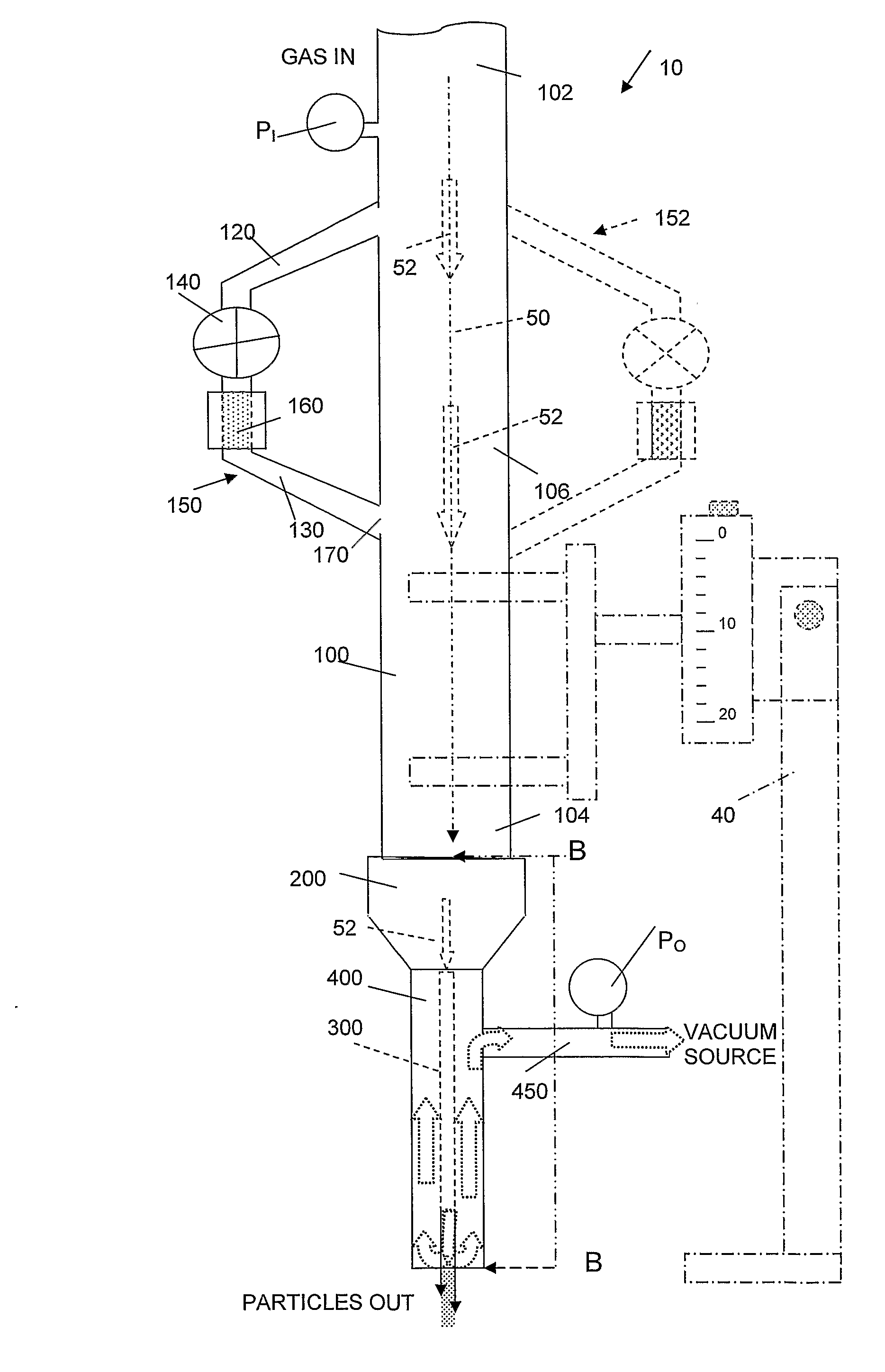

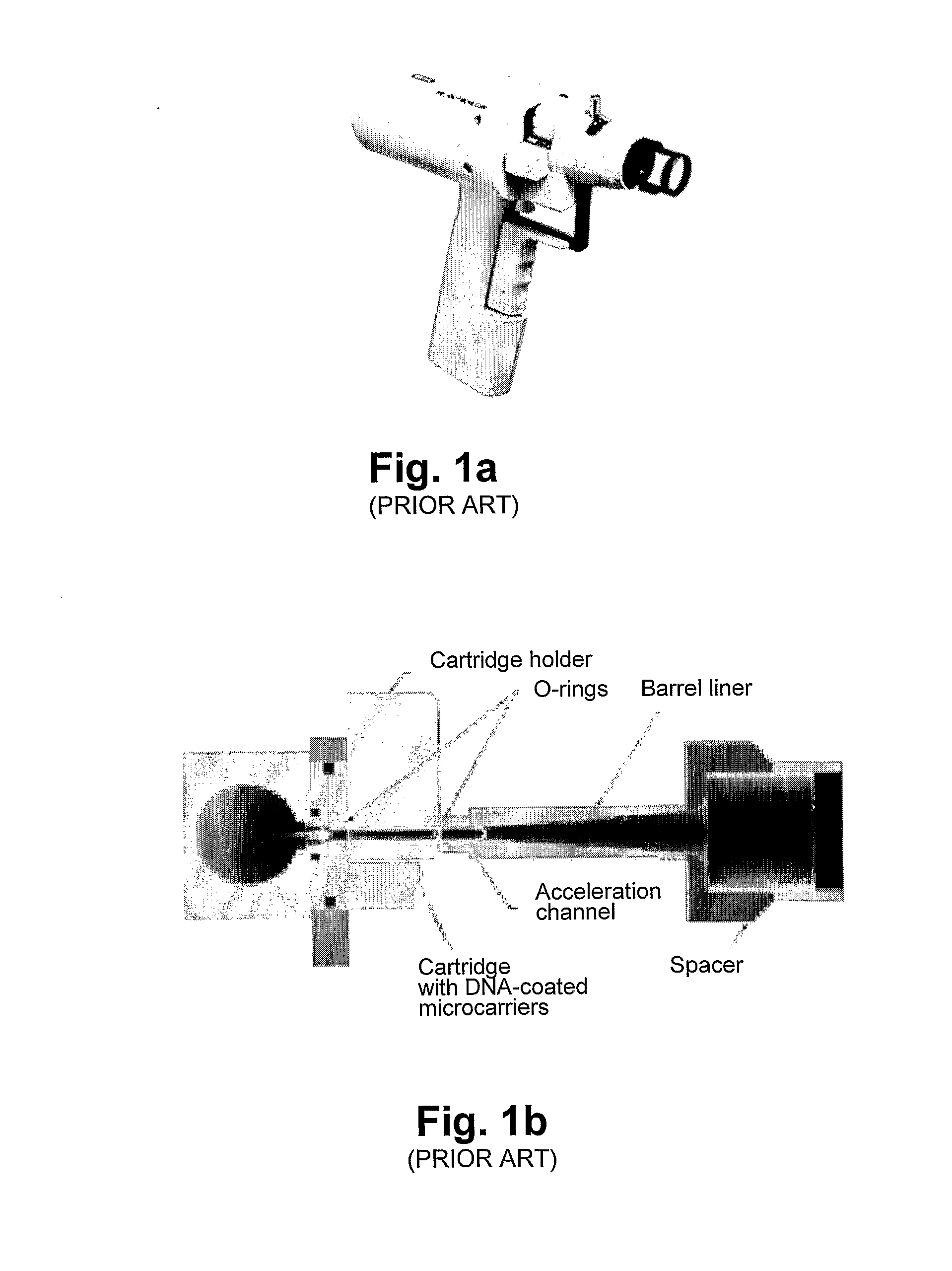

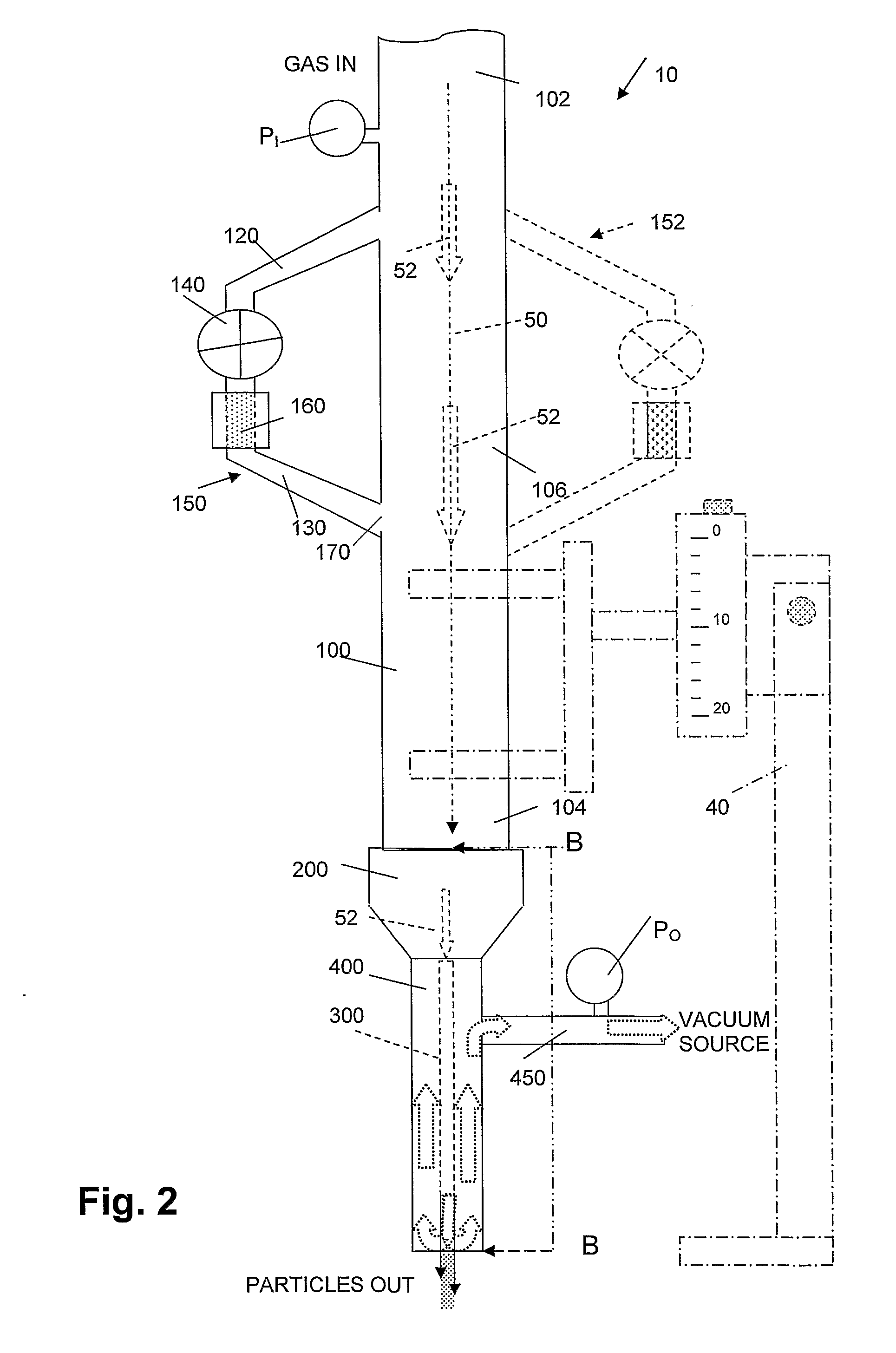

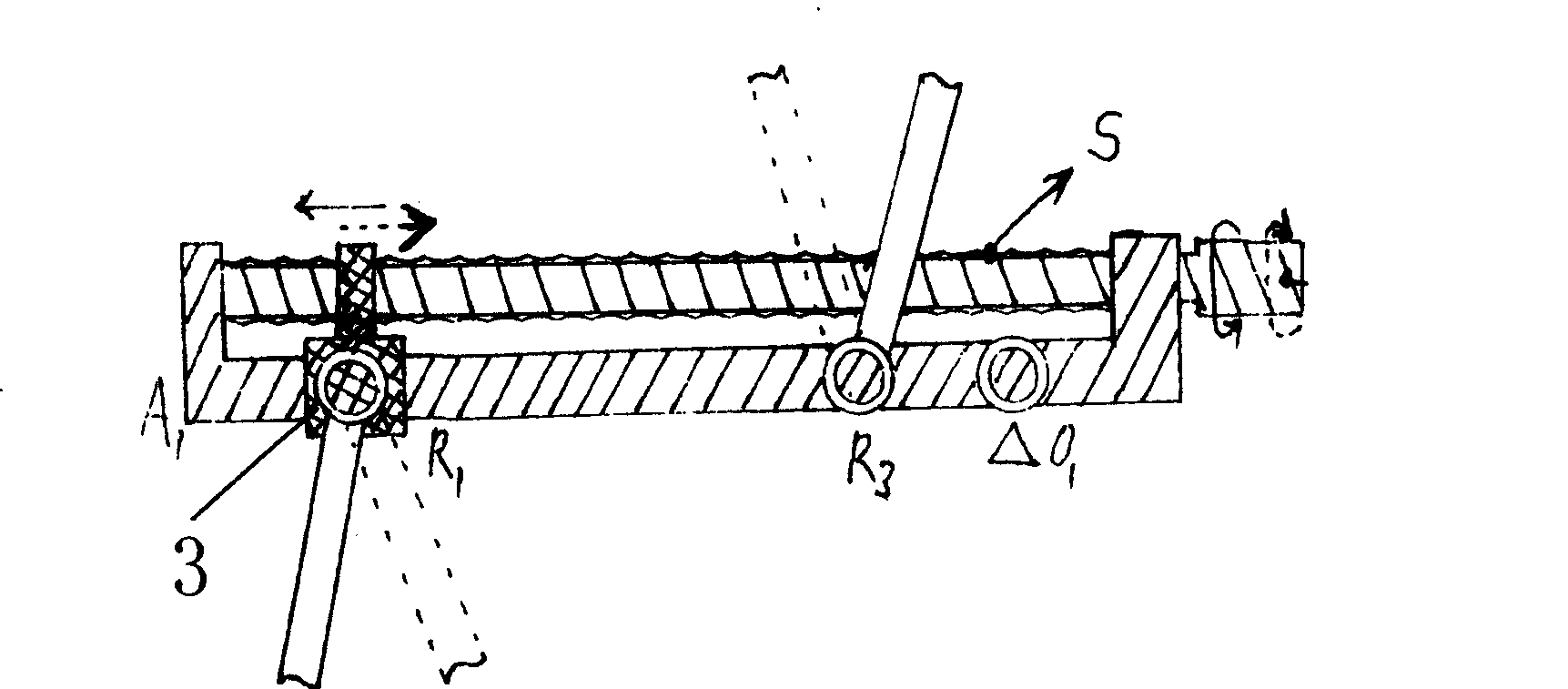

Pneumatic capillary gun for ballistic delivery of microscopic particles into tissue

InactiveUS7892836B2Good reproducibilityEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsAccelerated particleCapillary Tubing

The capillary gun for delivery of ballistic particles to a target includes an inner capillary tube disposed concentrically within an outer capillary tube with the input end of the inner tube connected to a channel through which a continuous flow of high speed helium gas carrying ballistic particles is introduced. The outer capillary tube, which is connected to a vacuum source, has an outlet end that extends slightly beyond the end of the inner tube. A cap placed over the output end of the outer tube has an opening at its center through which the particles exit the device. The vacuum source applies continuous suction to the space between the outer tube and the inner tube, drawing the gas from the output end of the inner tube while the inertia of the accelerated particles causes them to continue in the axial direction through the exit opening for delivery to the target. Multiple particle injectors provide for the concurrent injection of different materials without disruption of the gas flow.

Owner:RGT UNIV OF CALIFORNIA

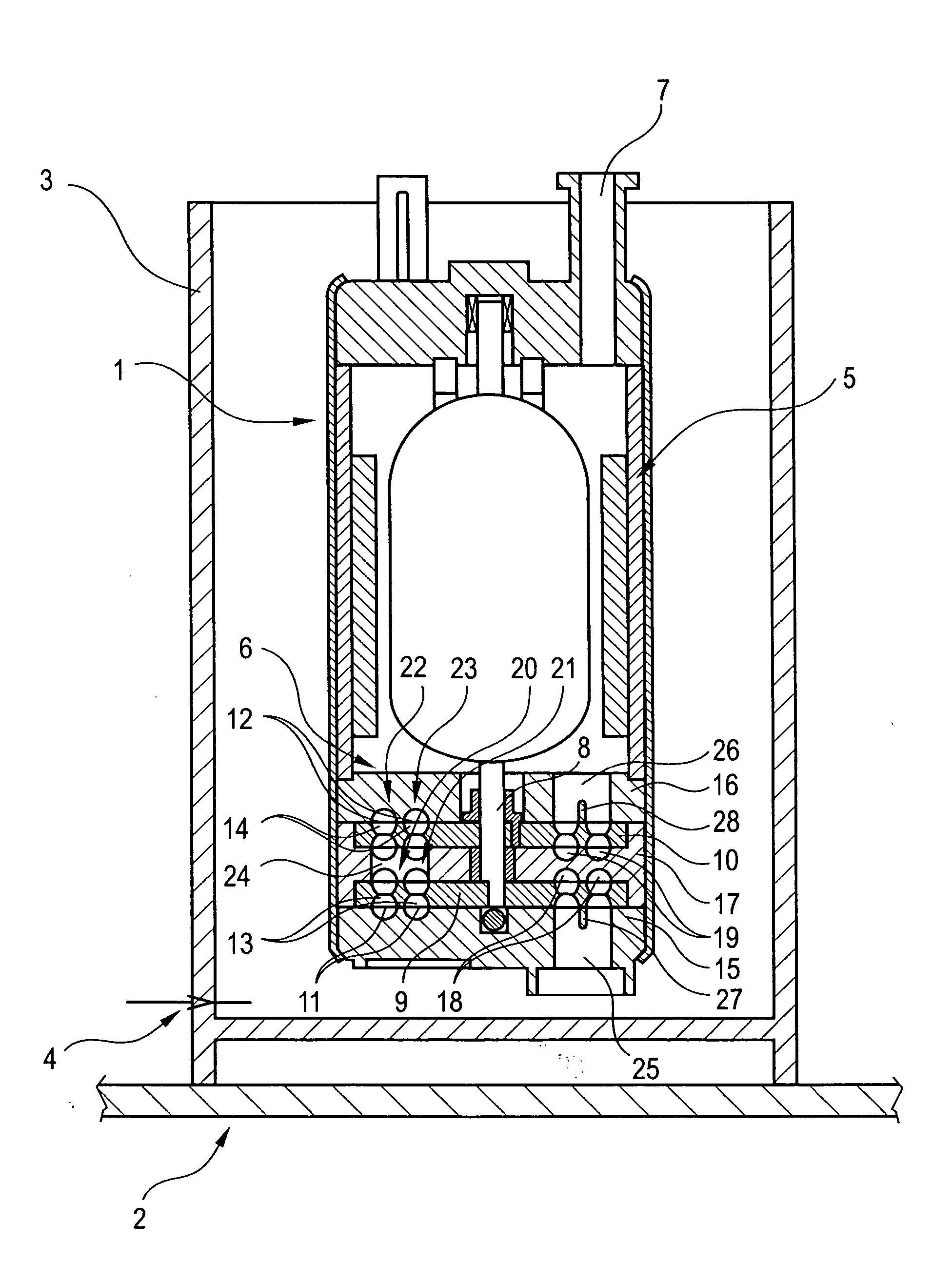

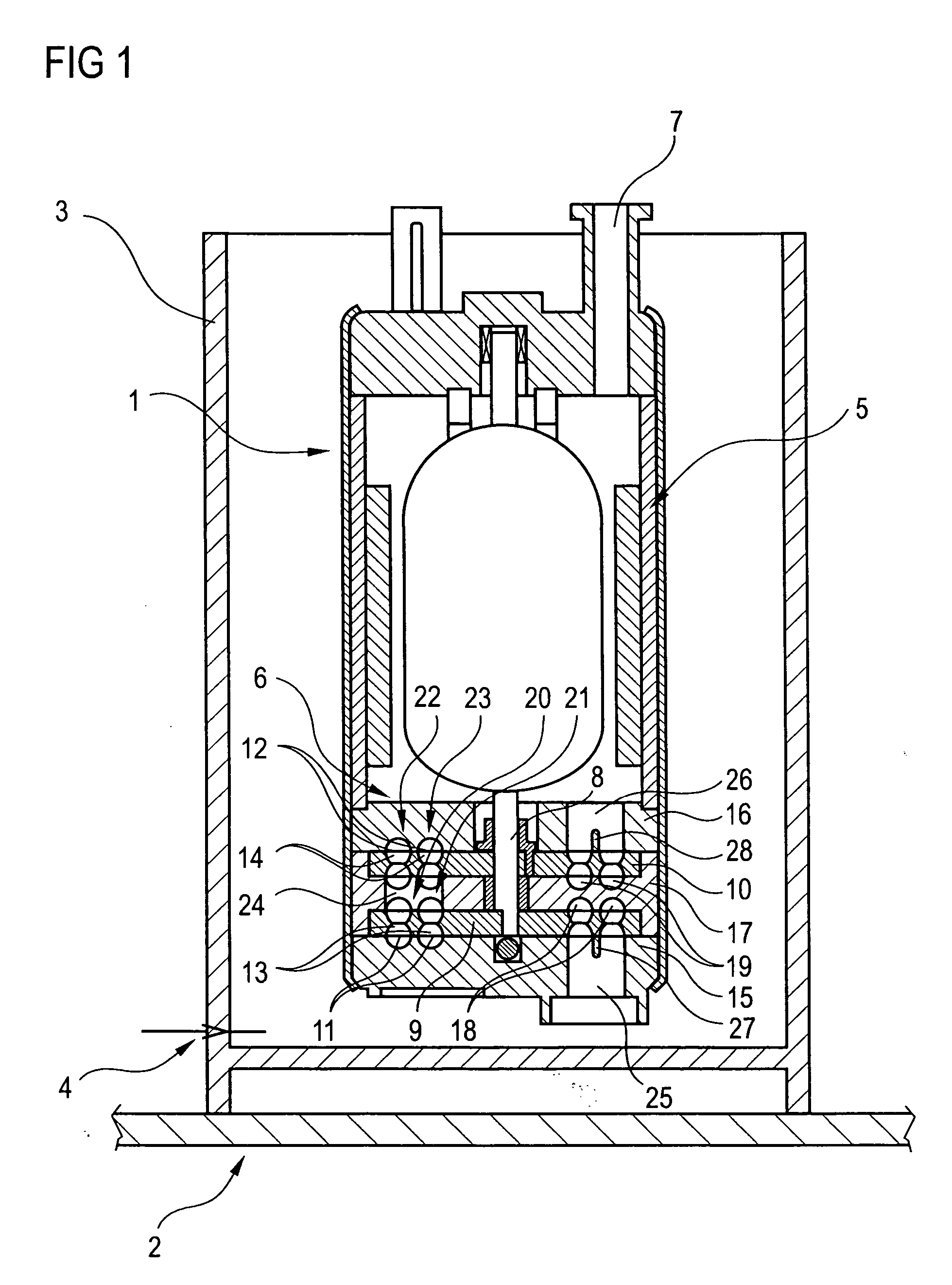

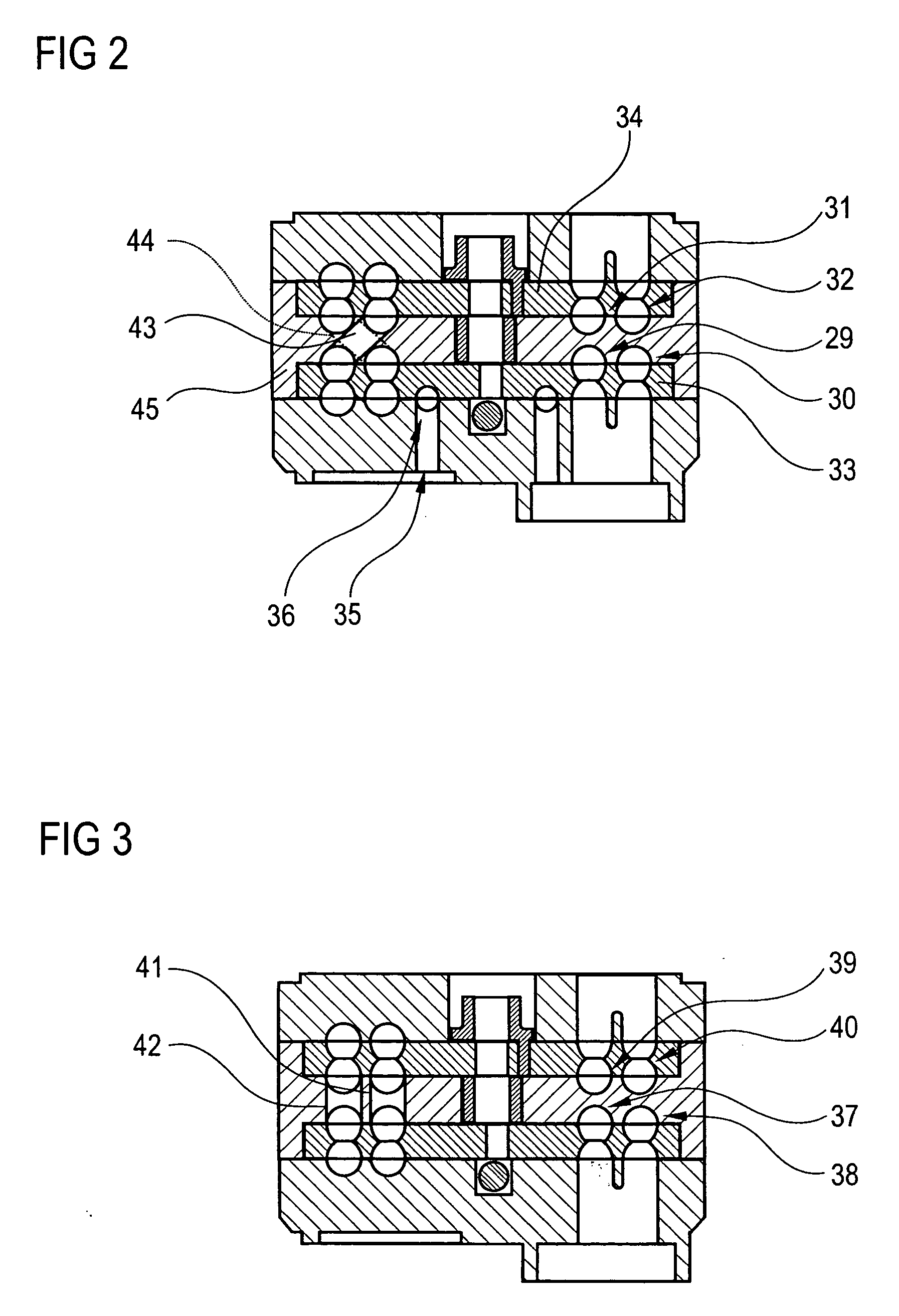

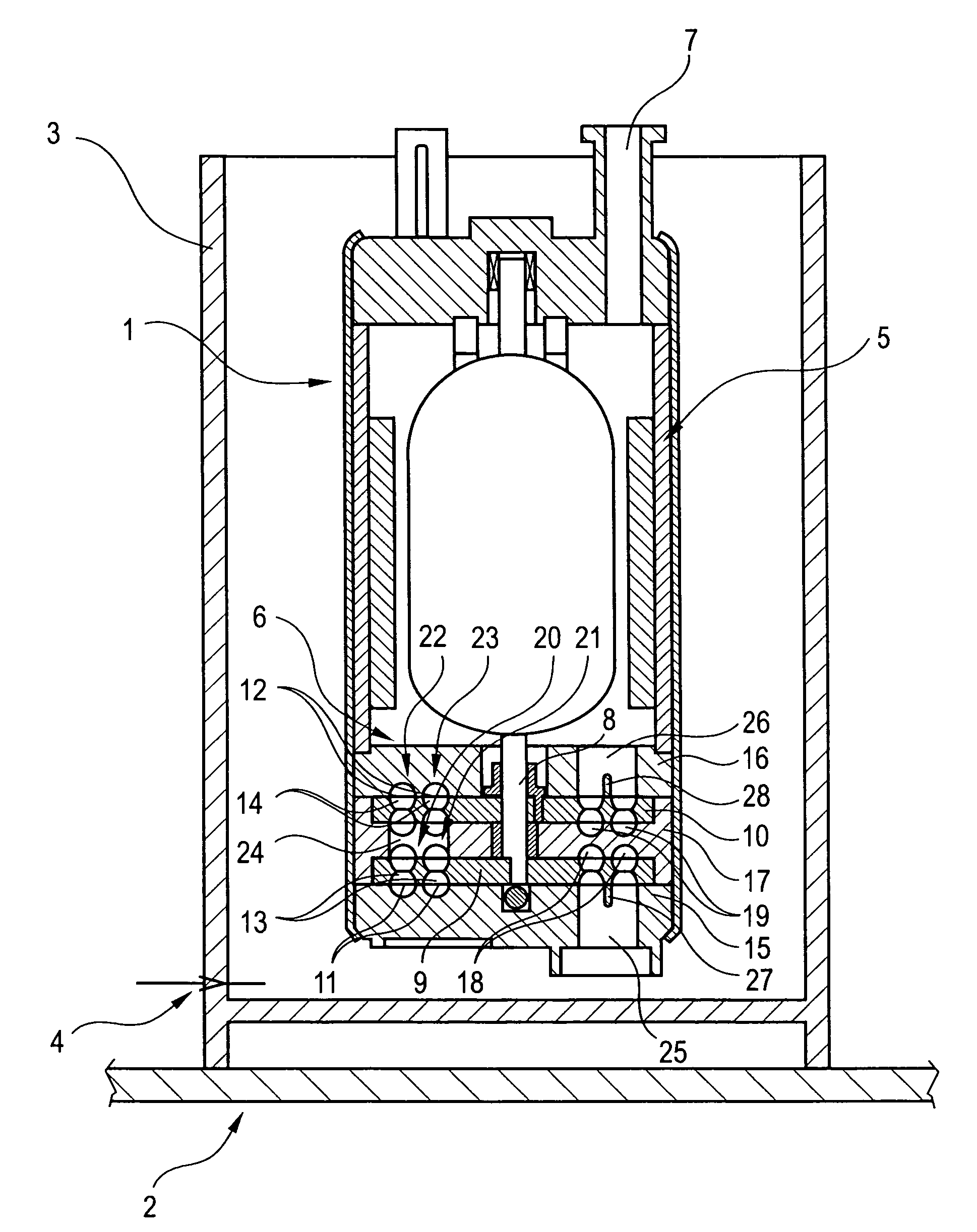

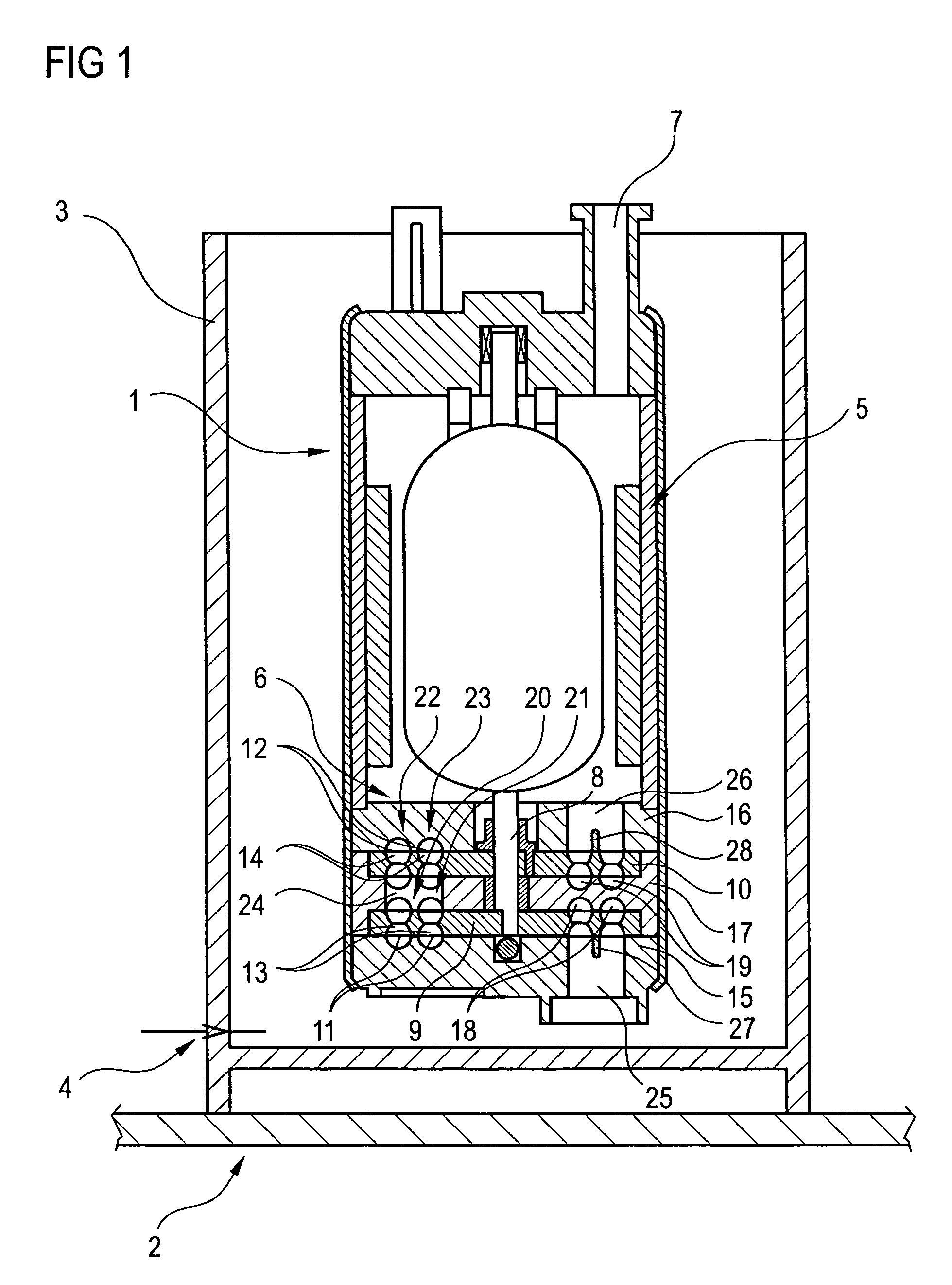

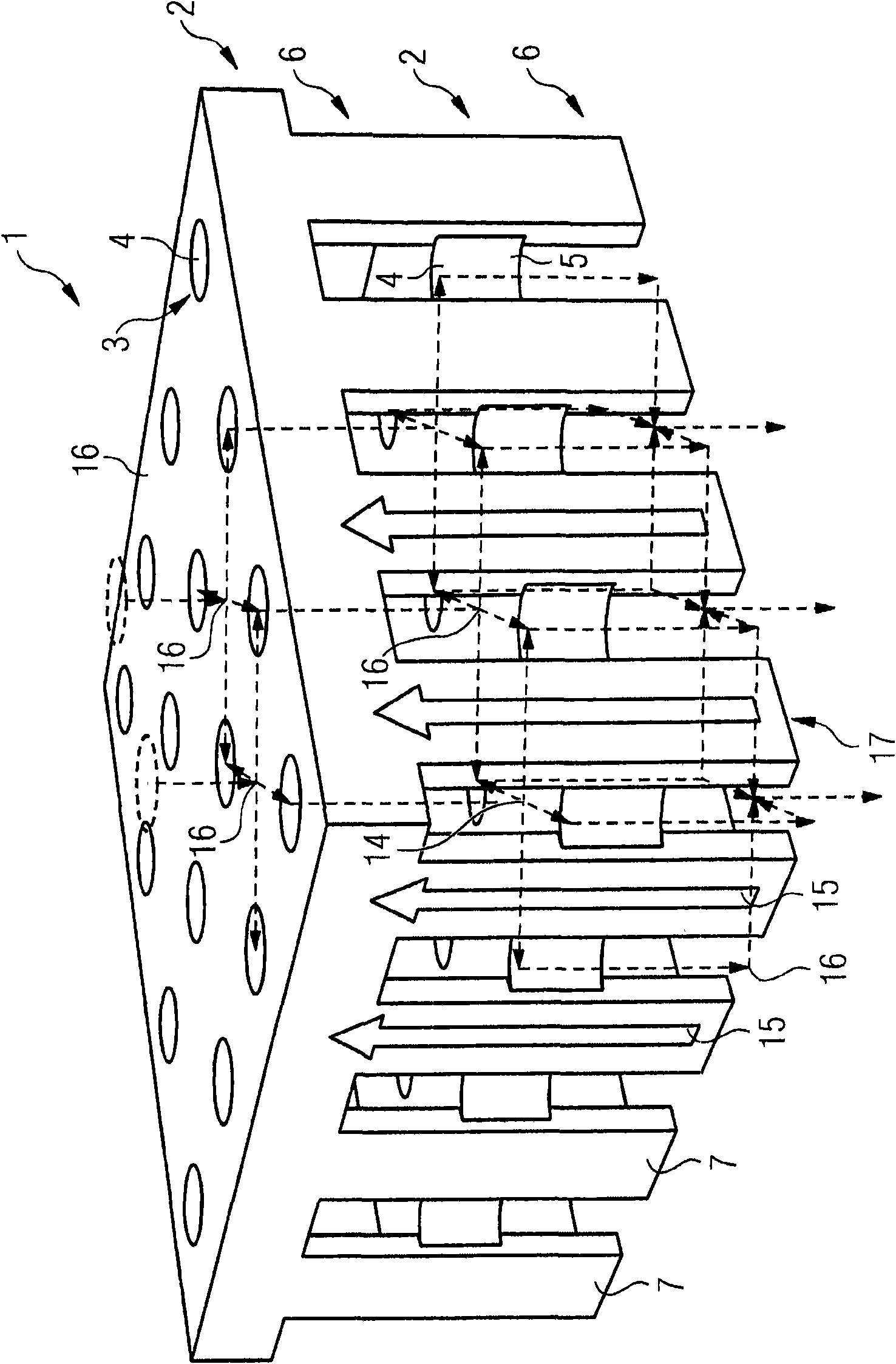

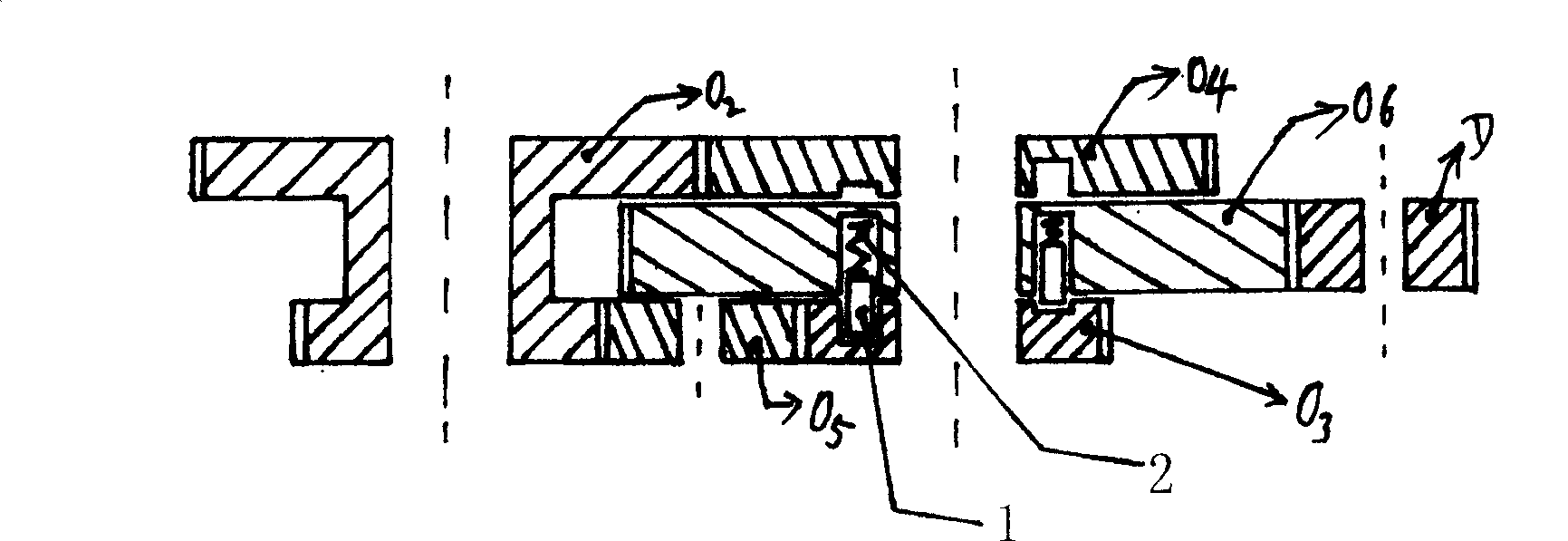

Fuel pump for a fuel tank

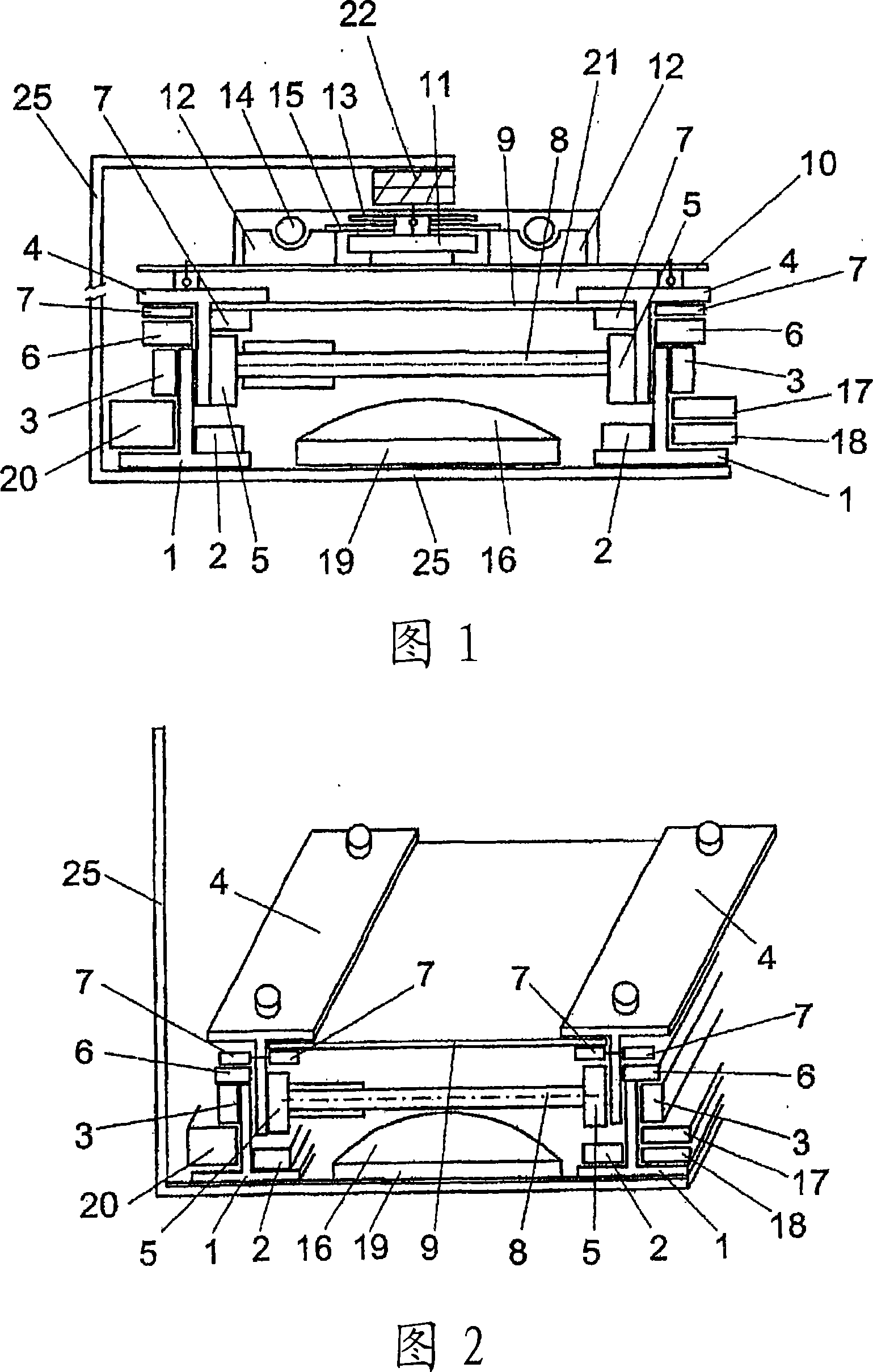

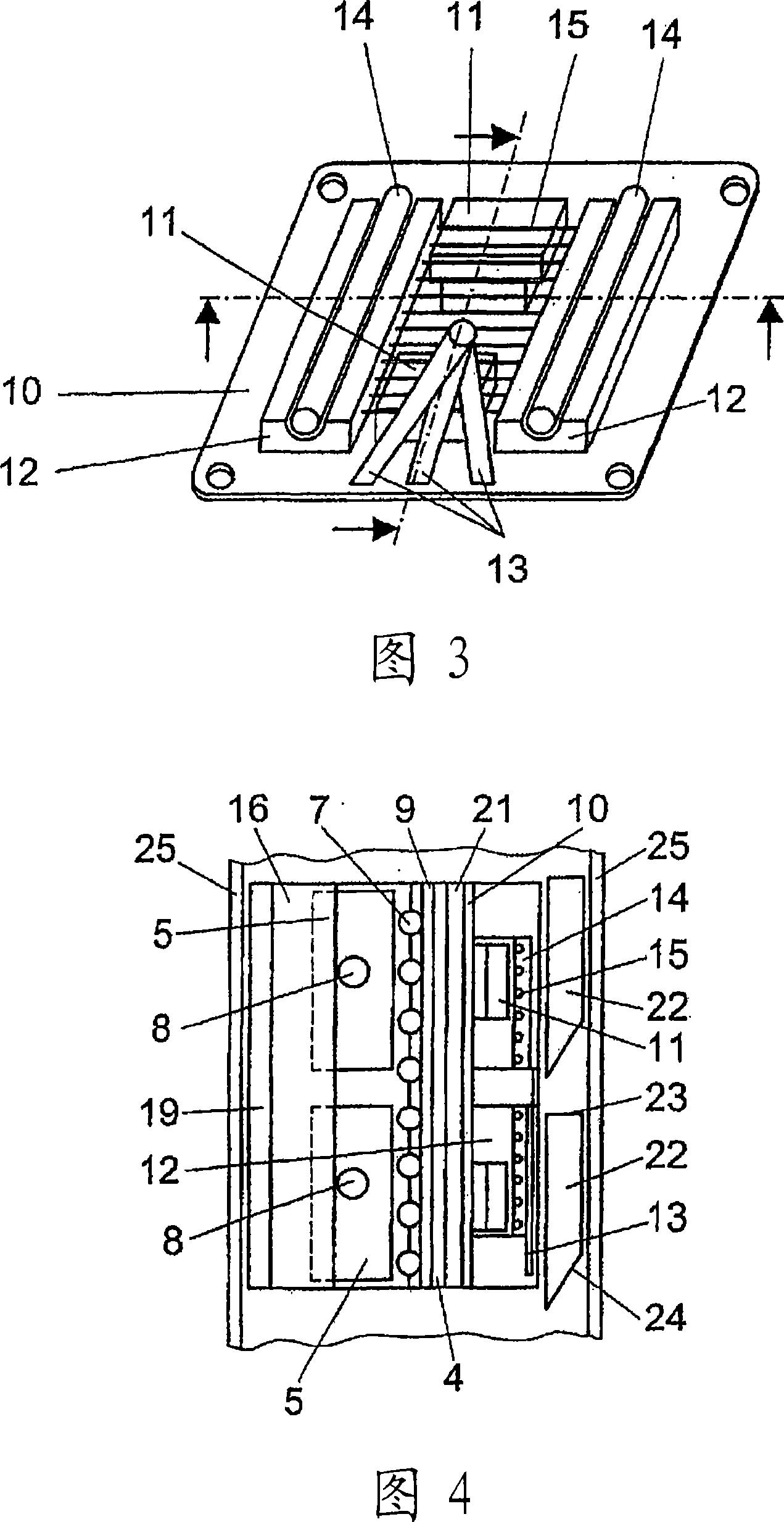

InactiveUS20050074345A1Uniform accelerationEasy to manufacturePump componentsCircumferential flow pumpsImpellerFuel tank

In a fuel pump (6) designed as a side channel pump, in each case two conveying chambers (20-23) one surrounding the other concentrically are arranged on two impellers (9, 10). The conveying chambers (20, 21) of one impeller (9) are connected to an inlet duct (25), while the conveying chambers (22, 23) of the other impeller (10) are connected to an outlet duct (26). A connection (24) of the conveying chambers (20-23) is arranged in a partition (17) keeping the impellers (9, 10) at a distance from one another. As a result, the fuel pump (6) has an especially high volume flow, along with a very high conveying pressure.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Pneumatic Capillary Gun for Ballistic Delivery of Microscopic Particles into Tissue

InactiveUS20080206870A1Improve throughputGood reproducibilityBioreactor/fermenter combinationsBiological substance pretreatmentsAccelerated particleCapillary Tubing

The capillary gun for delivery of ballistic particles to a target includes an inner capillary tube disposed concentrically within an outer capillary tube with the input end of the inner tube connected to a channel through which a continuous flow of high speed helium gas carrying ballistic particles is introduced. The outer capillary tube, which is connected to a vacuum source, has an outlet end that extends slightly beyond the end of the inner tube. A cap placed over the output end of the outer tube has an opening at its center through which the particles exit the device. The vacuum source applies continuous suction to the space between the outer tube and the inner tube, drawing the gas from the output end of the inner tube while the inertia of the accelerated particles causes them to continue in the axial direction through the exit opening for delivery to the target. Multiple particle injectors provide for the concurrent injection of different materials without disruption of the gas flow.

Owner:RGT UNIV OF CALIFORNIA

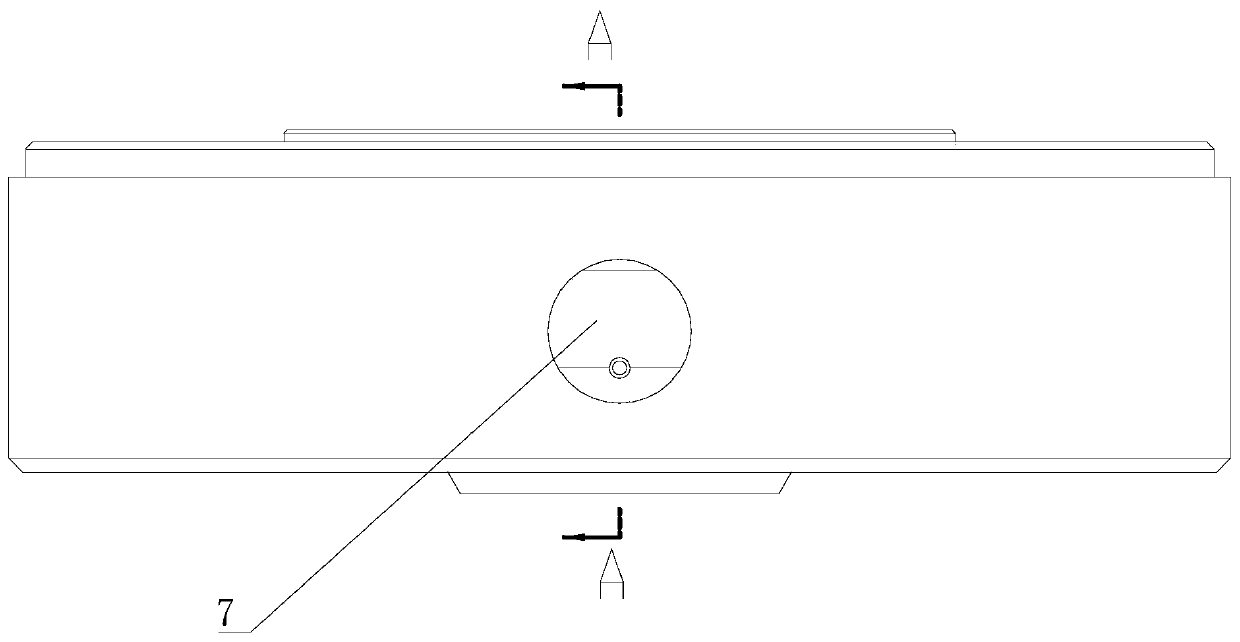

Supersonic atomizer for preparing iron-based spherical metal powder through crucible gas atomization method

The invention discloses a supersonic atomizer for preparing iron-based spherical metal powder through a crucible gas atomization method, and relates to the field of metal powder material preparation.The supersonic atomizer comprises a crucible, a plunger, an upper cover, a liquid guide pipe, a lower cover, gas feeding holes, a gas cavity and a Laval type circular seam; the liquid guide pipe is installed at the center of the upper cover, and the lower cover is arranged under the upper cover; the two gas feeding holes are oppositely formed in the side face of the lower cover; the gas cavity isdefined by the upper cover and the lower cover in a sealed mode and communicates with the upper cover and the lower cover; the Laval type circular seam formed by the upper cover and the lower cover together with the main axis of the atomizer as the center is arranged; and the crucible is filled with molten metal, and after the plunger is removed, the molten metal enters the atomizer through the liquid guide pipe to be atomized by gas flow sprayed out of the Laval type circular seam. The supersonic atomizer has the advantages that the gas flow is uniform and consistent, the turbulence scale issmall, and no impact wave exists in the flow field.

Owner:安徽哈特三维科技有限公司

Fuel pump for a fuel tank

InactiveUS7473069B2Uniform accelerationEasy to manufactureCircumferential flow pumpsPump componentsImpellerFuel tank

In a fuel pump (6) designed as a side channel pump, in each case two conveying chambers (20-23) one surrounding the other concentrically are arranged on two impellers (9, 10). The conveying chambers (20, 21) of one impeller (9) are connected to an inlet duct (25), while the conveying chambers (22, 23) of the other impeller (10) are connected to an outlet duct (26). A connection (24) of the conveying chambers (20-23) is arranged in a partition (17) keeping the impellers (9, 10) at a distance from one another. As a result, the fuel pump (6) has an especially high volume flow, along with a very high conveying pressure.

Owner:CONTINENTAL AUTOMOTIVE GMBH

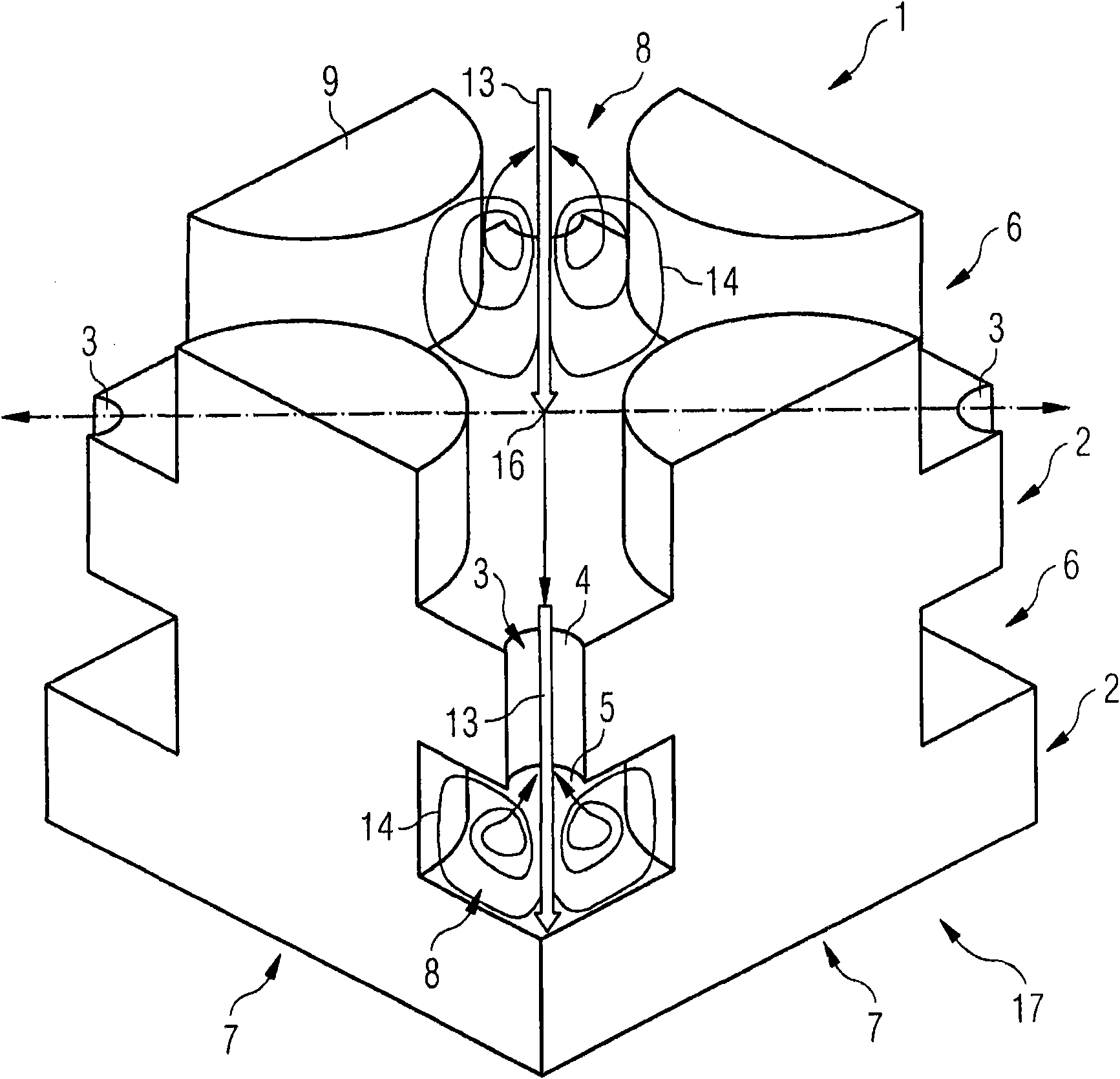

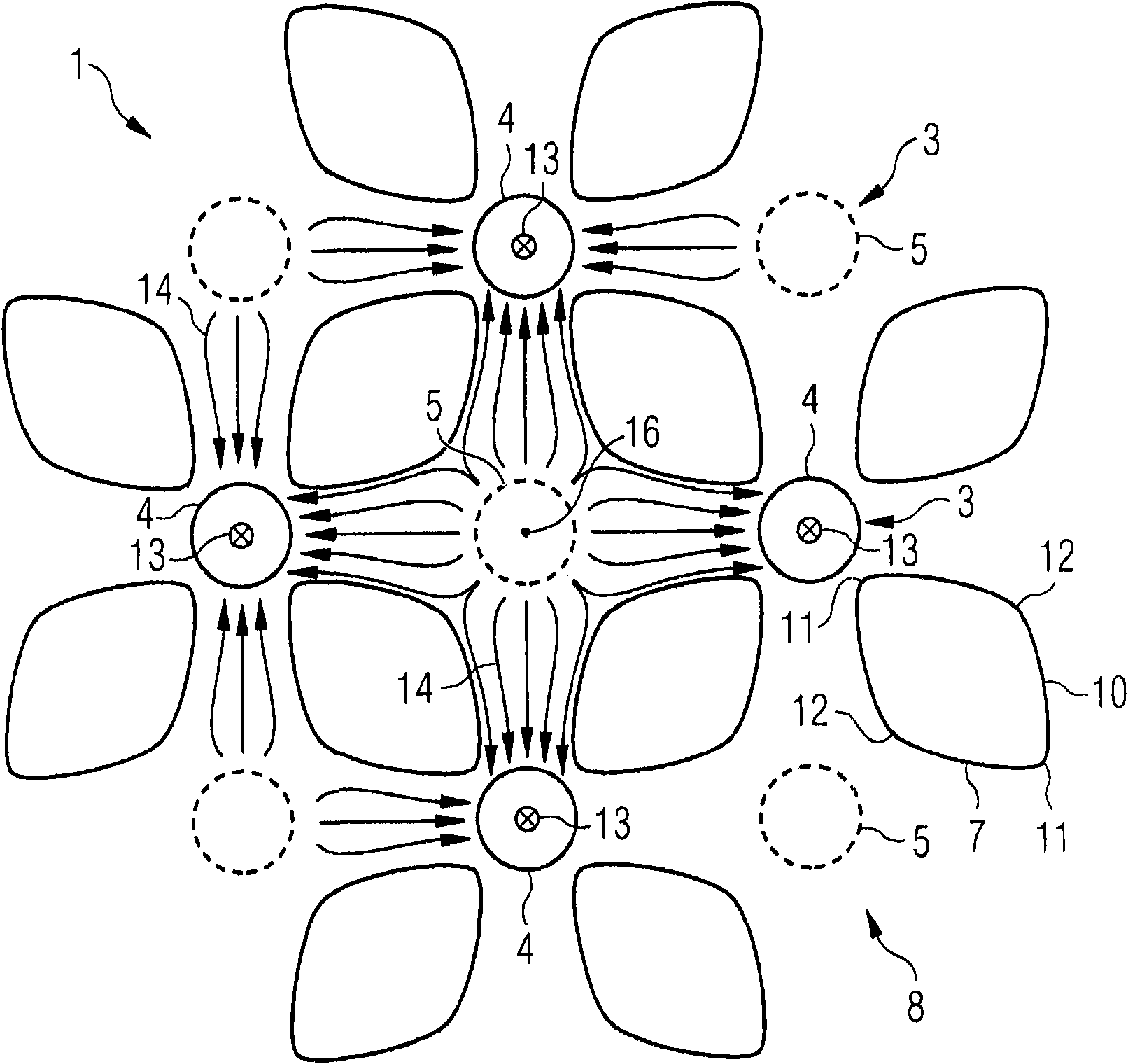

Multi-impingement-surface for cooling a wall

InactiveCN101787904AHigh degree of geometryUniform accelerationContinuous combustion chamberEngine manufactureHeat flowEngineering

The invention relates to a multi-impingement-surface for cooling a wall, capable of planedly and conductively contacting with the surface of a wall to be cooled and comprising a plurality of pore plate surfaces and a plurality of splicing surfaces. The pore plate surfaces comprises a plurality of straight through holes as the pore plate constructions distributed on the surface of the pore plate surfaces and the splicing surfaces and the pore plate surfaces are alternatively stacked and the slicing plates are distributed on the surface of the pore plate layer and correspondingly spliced with the pore plate layer, wherein each splice of one splicing layer is respectively aligned with one of the splice of other splicing layers and each straight through hole of one pore plate layer is staggered relative to the other straight through hole of the adjacent pore plate layer, therefore the multi-impingement-surface is loaded by the pressure using a cooling fluid at a flat side and the cooling fluid flows through the straight through hole and the middle clearance between the splice and the pore plate layer and thus the heat flow from the wall is discharged along with the cold flow.

Owner:SIEMENS AG

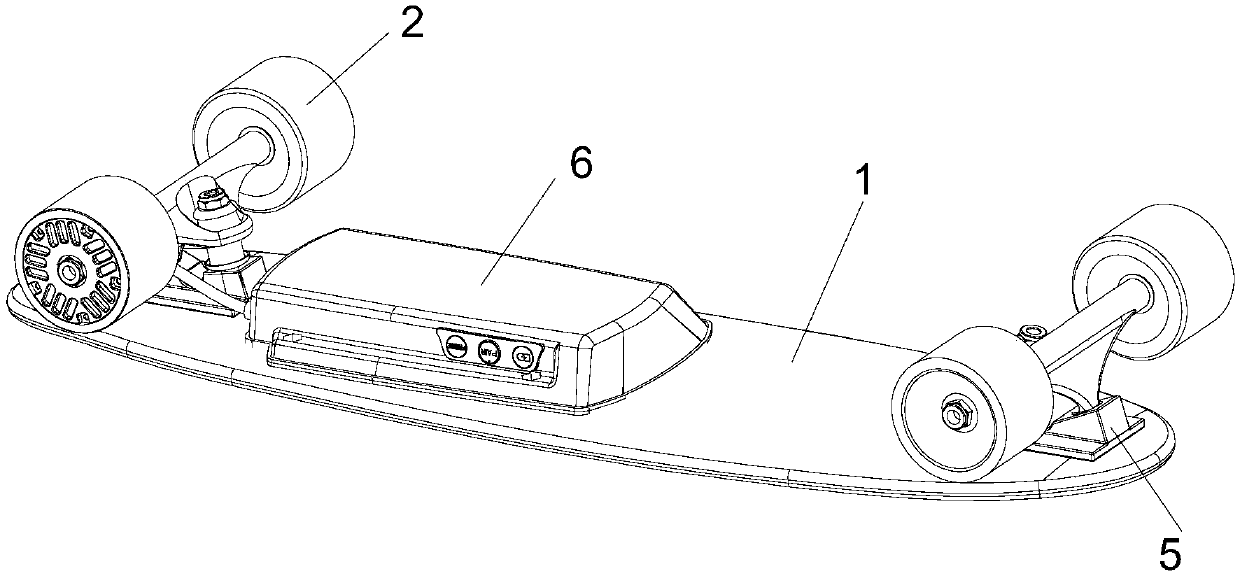

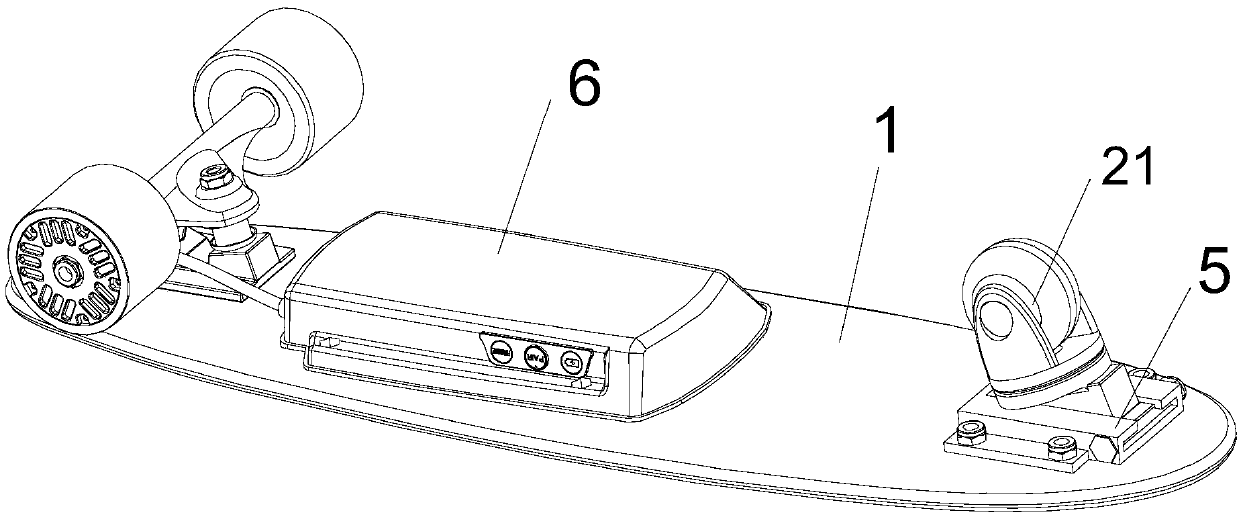

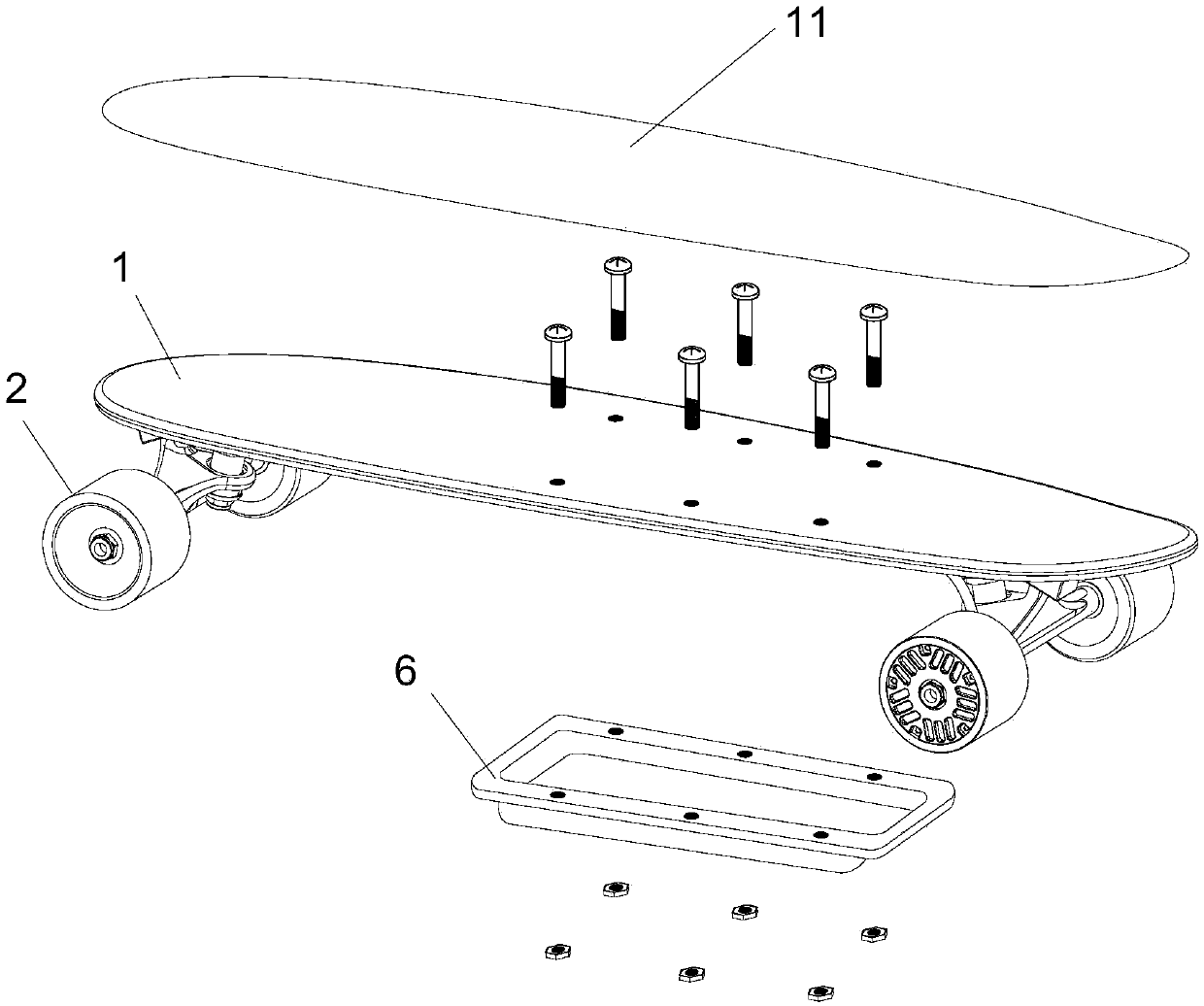

Electric scooter

PendingCN110465070AIncrease the sliding experienceUniform accelerationSkate-boardsRoller skatesElectricityEngineering

The invention discloses an electric scooter. The scooter comprises a skateboard, pulleys, a controller, a brake, a power supply and a driving motor. A photoelectric switch is arranged on the skateboard. The pulleys are connected to the lower surface of the skateboard. The power supply and the controller are connected to the skateboard. The driving motor is connected with the pulleys and drives thepulleys to rotate. The driving motor, the power supply, the brake and the photoelectric switch are electrically connected with the controller and controlled by the controller. The power supply is electrically connected with the photoelectric switch, the brake and the driving motor. The acceleration and the braking of the skateboard are controlled by treading the photoelectric switch. The better sliding experience can be provided for a slider.

Owner:岳阳市爱达兴智能科技有限公司

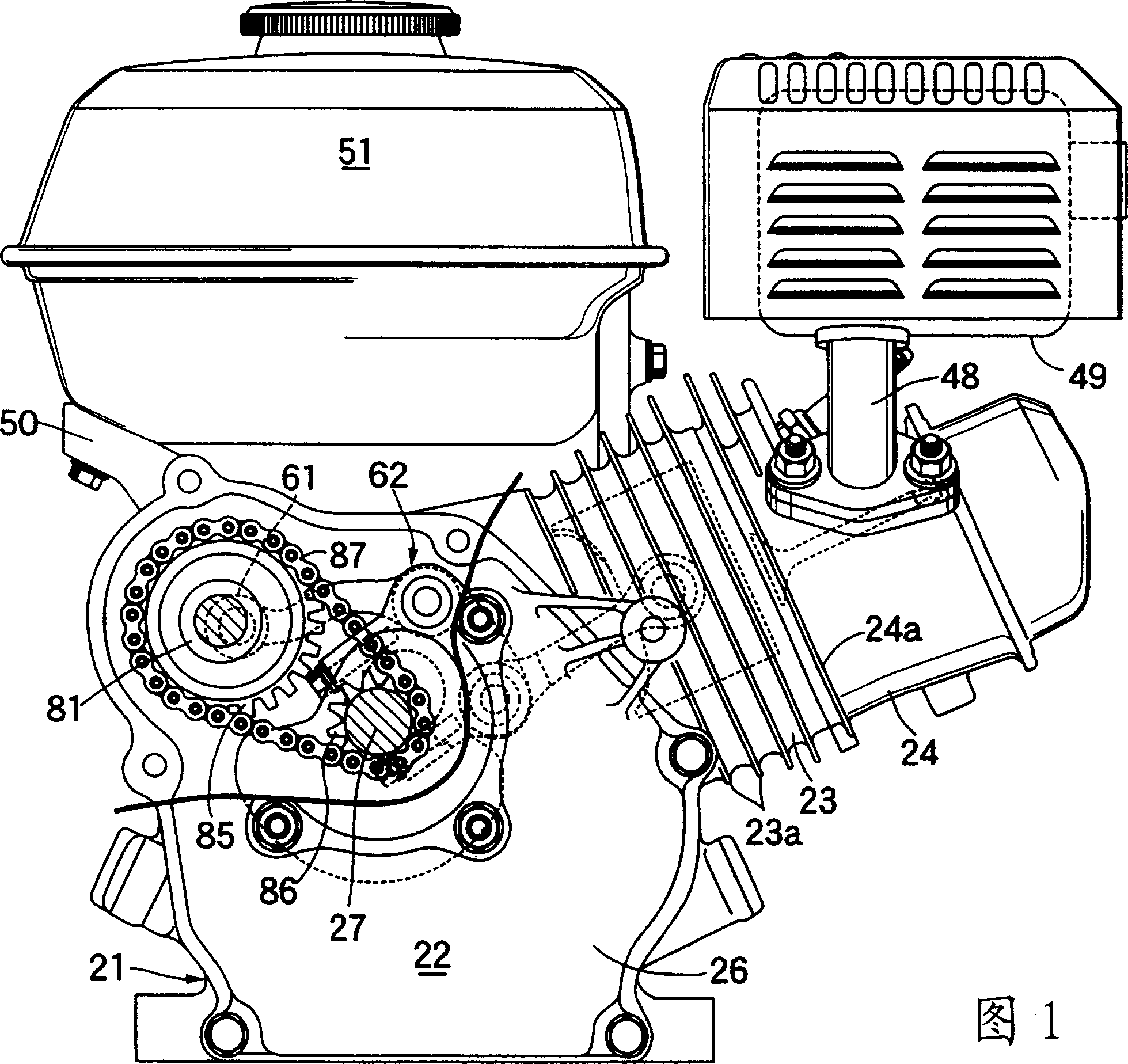

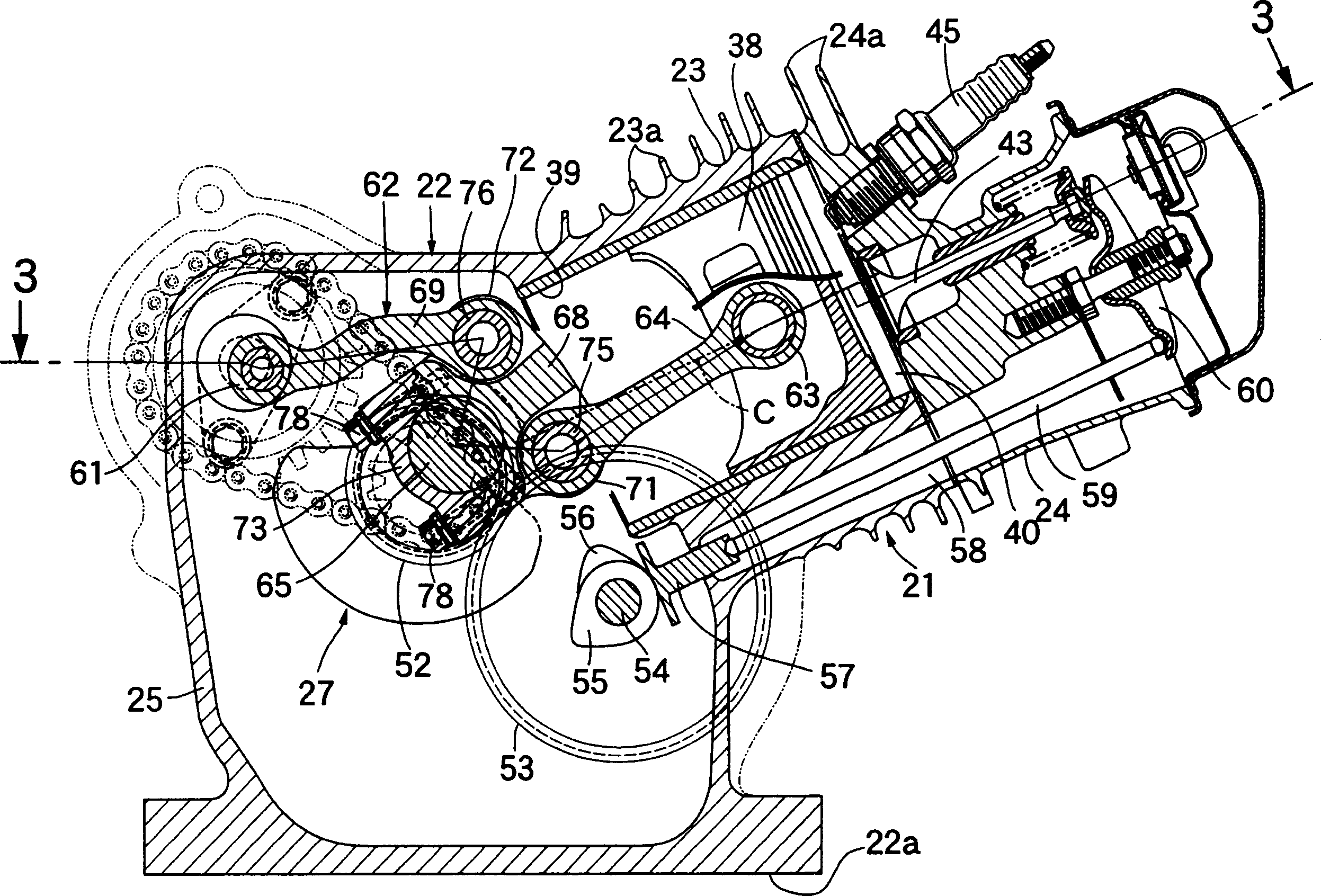

Engine

InactiveCN1445445AReduce frictionSuppress the impact soundCombustion enginesEngine controllersEngineeringCrankshaft

The invention relates to an engine in which the piston stroke in the expansion stroke is greater than the piston stroke in the compression stroke. In order to ensure that the center of top dead center in each of the intake stroke and exhaust stroke is at the same level as the center of top dead center in the compression stroke, the following dimensions are determined according to the equation expressing the level of the piston pin so that in the intake stroke and The top dead center in each of the exhaust stroke and the top dead center in the compression stroke coincide with each other. These dimensions are: the length of the second arm; the length of the first arm; the length of the control rod; the length of the connecting rod; in the y-axis The length from the axis of the crankshaft to the axis of the rotation axis in the direction; the length from the axis of the crankshaft to the axis of the rotation axis in the direction of the x-axis; the deviation of the cylinder axis from the axis of the crankshaft in the direction of the y-axis; the first arm and the second The angle formed by the arms; the length between the axis of the crank shaft and the crank pin; the length of a straight line connecting the axis of the rotating shaft and the axis of the movable eccentric shaft; and the angle θp when the crank angle is "0".

Owner:HONDA MOTOR CO LTD

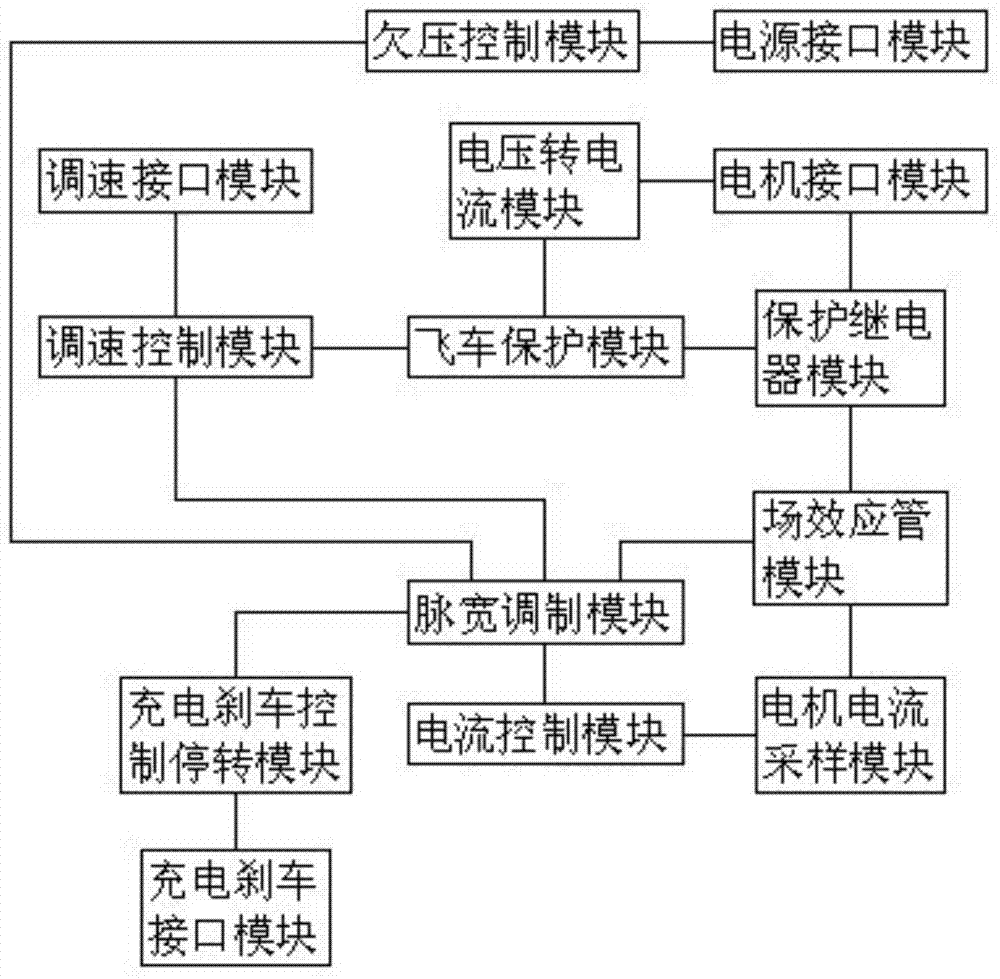

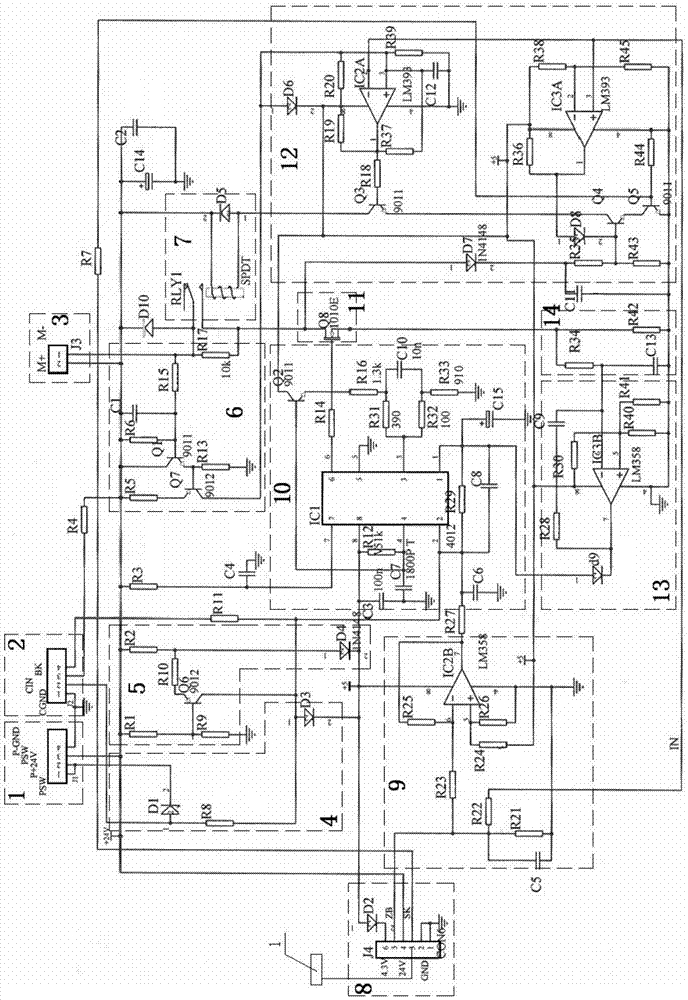

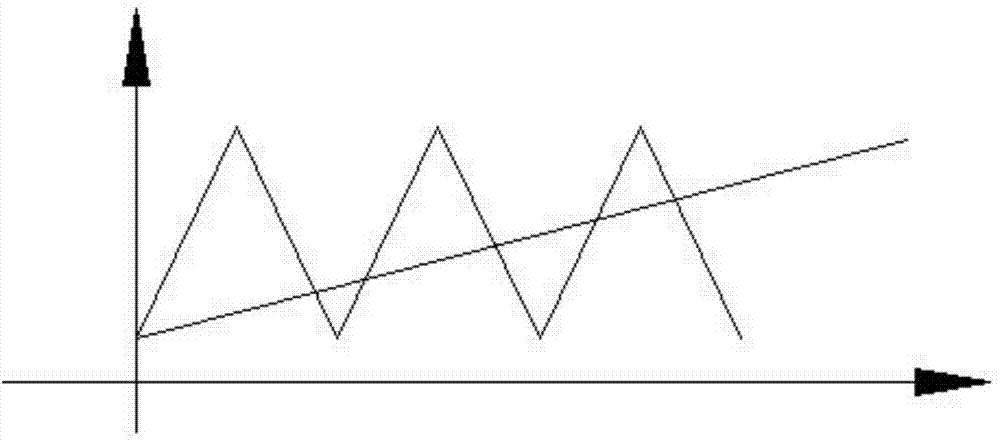

Novel speed adjusting controller for children electromobile

ActiveCN103568866AThere will be no high current outputExtended service lifeSpeed controllerControl signalComputer module

The invention relates to a novel speed adjusting controller for a children electromobile. The novel speed adjusting controller comprises a pulse width modulation module, a power interface module, a motor interface module, a speed adjusting interface module, a charging brake interface module and a field-effect tube module. The output end of the pulse width modulation module is connected with the field-effect tube module which is connected with the motor interface module through a protective relay module, the voltage feedback end of the pulse width modulation module is connected with the speed adjusting interface module through a speed adjusting control module, the power end of the pulse width modulation module is connected with the power interface module, and the voltage feedback end of the pulse width modulation module is further connected with the charging brake interface module through a charging brake control rotation stopping module. According to the novel speed adjusting controller, the modules are organically integrated, the various functions such as duty ratio adjustment, speed adjusting control signal supplementing and correcting, temperature compensation, undervoltage control and galloping protection are achieved, the control process of the children electromobile is safe, safe riding of children is guaranteed, and the service life is prolonged.

Owner:TIANJIN TIANCHU TECH

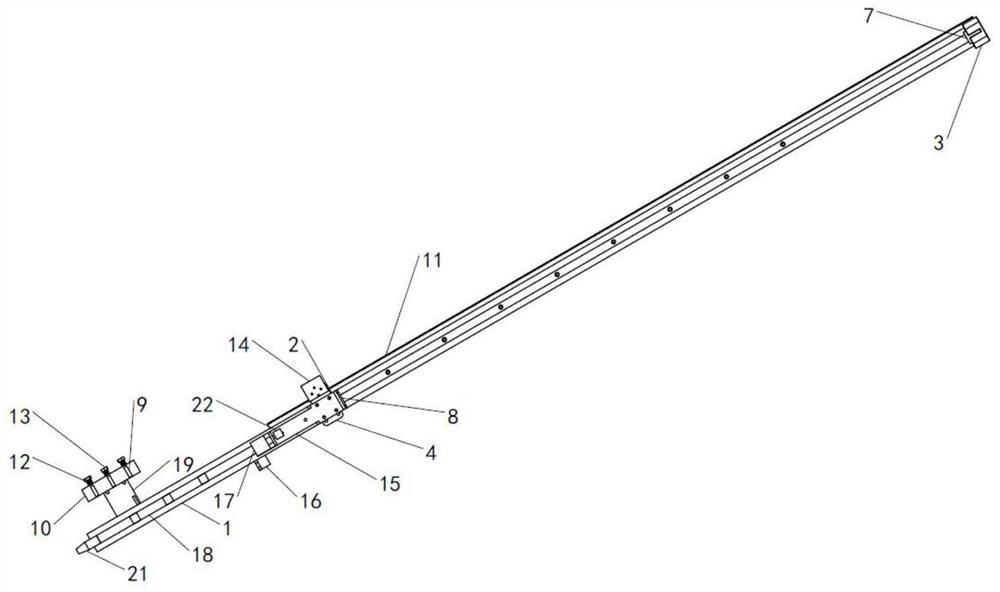

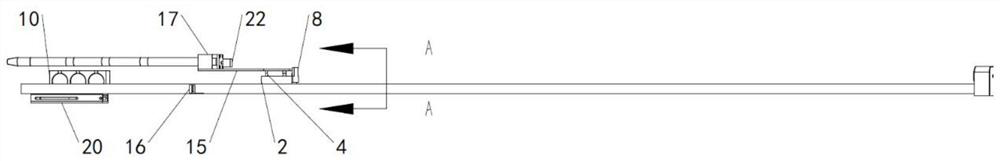

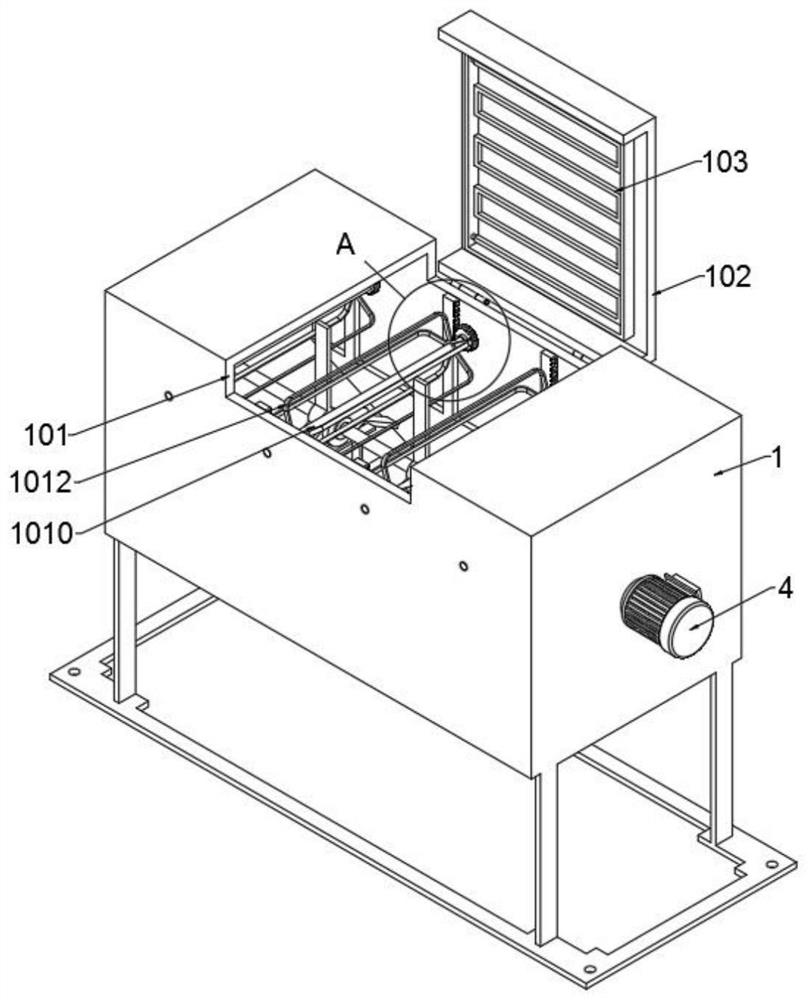

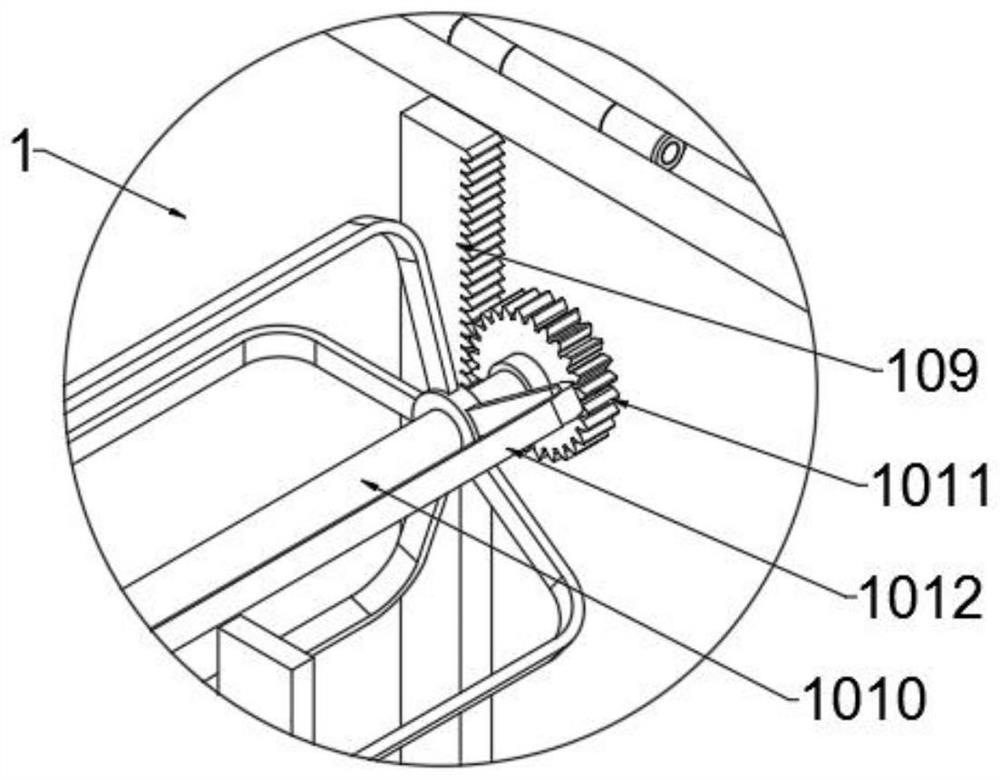

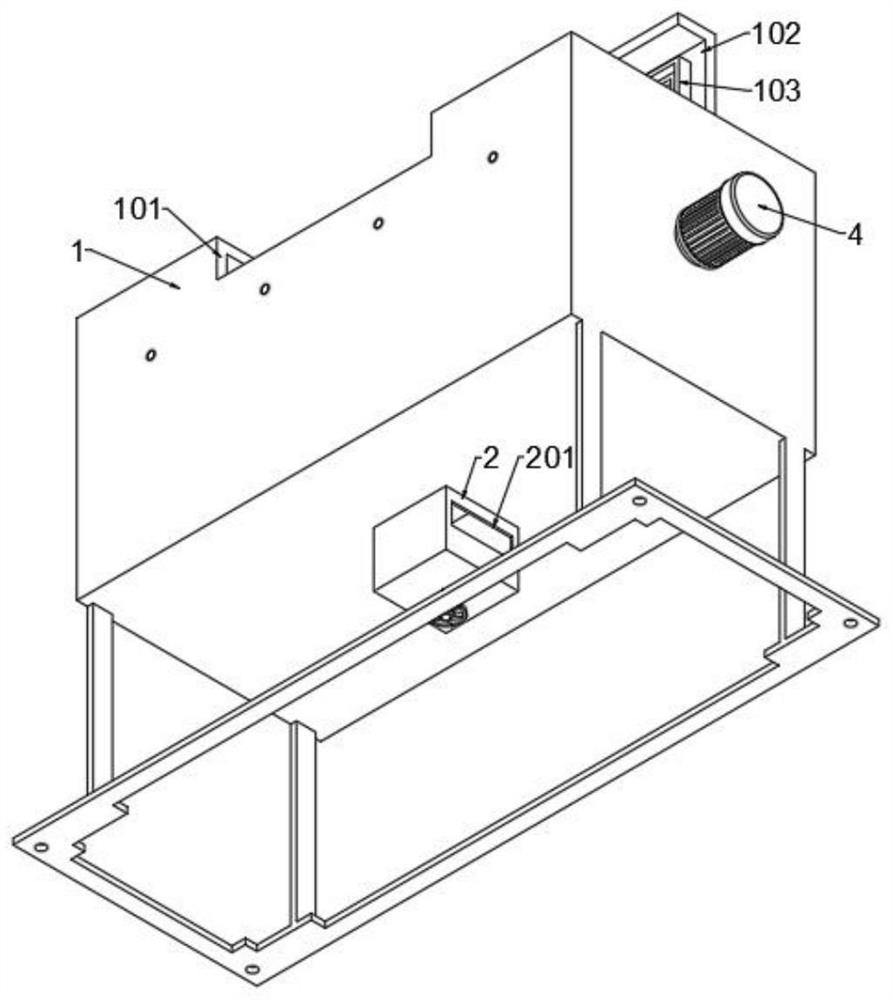

Laboratory simulation forward jet experiment mechanism based on motor acceleration

ActiveCN113820099AUniform accelerationAvoid damageHydrodynamic testingSynchronous motorExperimental laboratory

The invention discloses a laboratory simulation forward jet experiment mechanism based on motor acceleration. The laboratory simulation forward jet experiment mechanism comprises a guide rail, a sliding block, a motor, a motor gear, an electromagnet, an iron sheet, a stopping magnet, a magnet fixing block, a rack, a motor support baffle, a connecting platform, a photoelectric switch, an accelerometer fixing block, a stopping cylinder, a magnet fixing frame, a speed reduction table, a jet nozzle and an accelerometer. Acceleration is carried out through driving of the synchronous motor, inclined ejection can be carried out at a specific speed, and meanwhile the characteristics that ejection is stable and the movement track is stable in the ejection process are achieved. The laboratory simulation forward jet experiment mechanism based on motor acceleration can be widely applied to the field of laboratory simulation equipment.

Owner:SUN YAT SEN UNIV

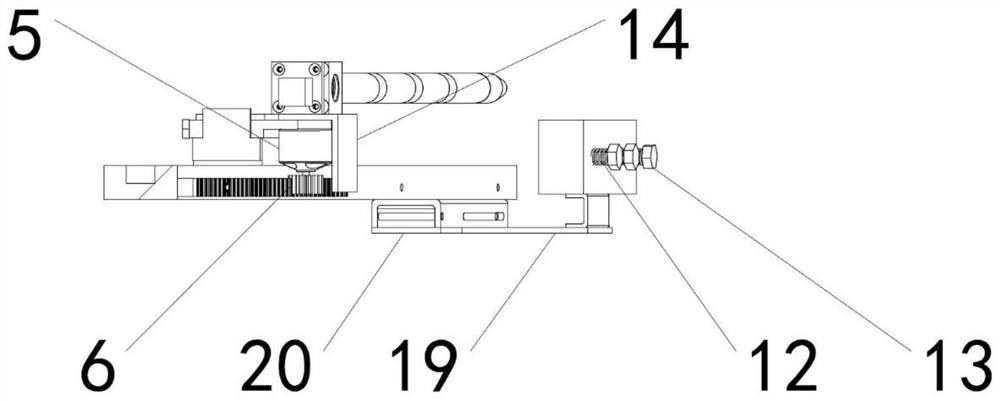

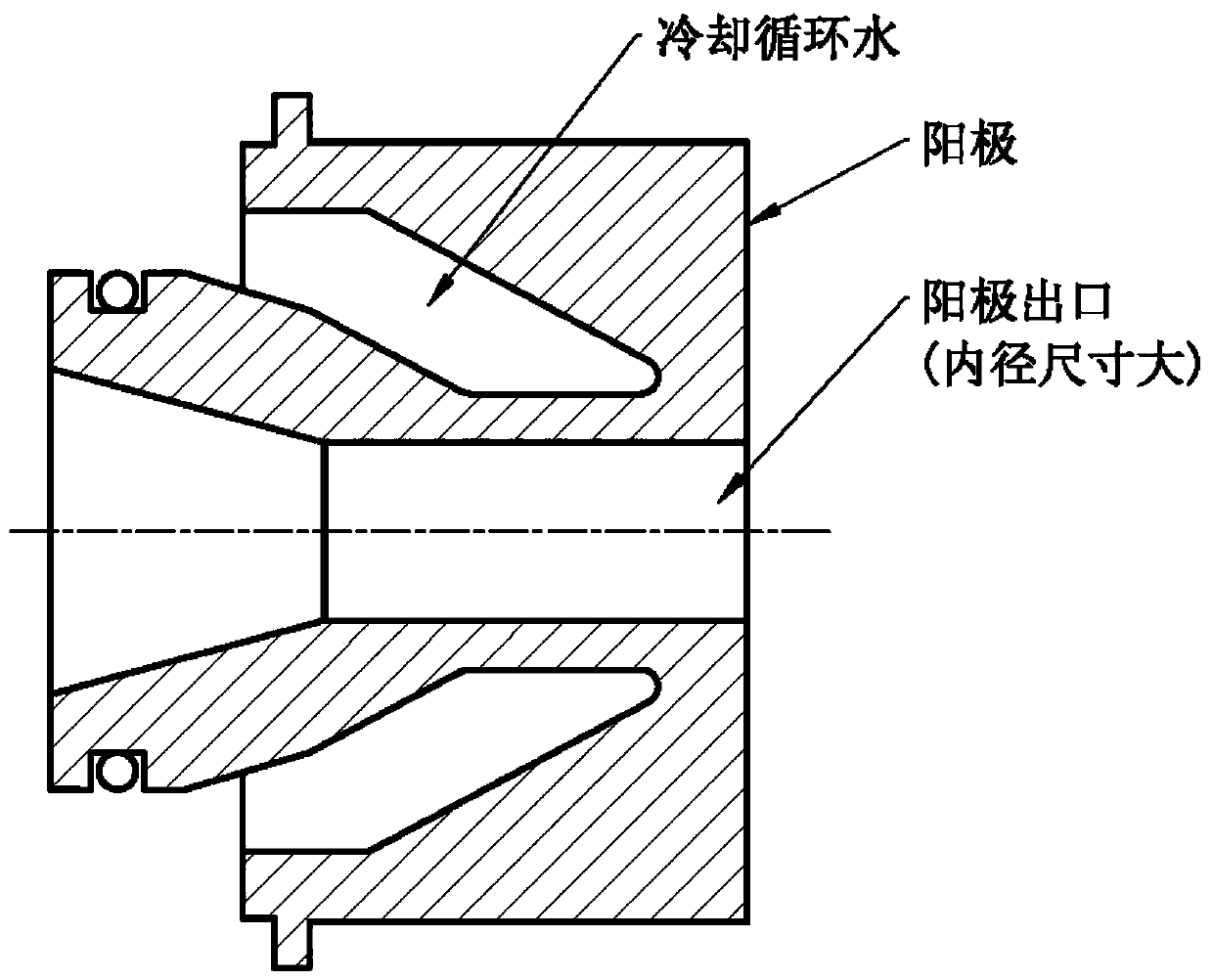

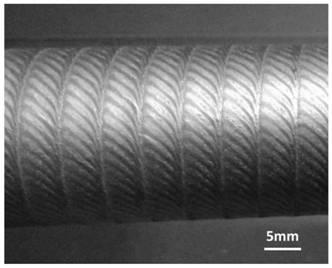

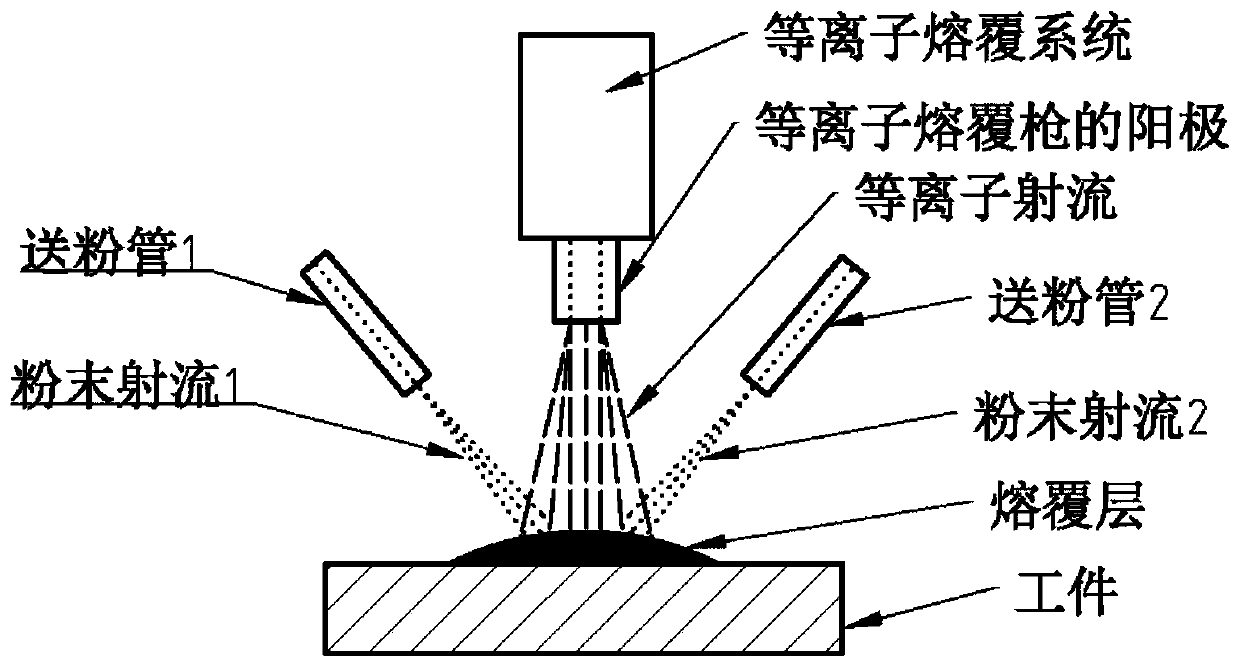

Micro-pore anode used for cluster plasma spray gun and cluster plasma spraying method

The invention provides a micro-pore anode used for a cluster plasma spray gun and a cluster plasma spraying method. The micro-pore anode comprises an anode front part, an anode middle part and an anode rear part, wherein the anode front part is designed with a powder conveying channel and a protective gas conveying channel; the inner diameter of an outlet of the micro-pore anode is limited withina range of 0.5-3 millimeters; micro-pore anode compression effect is utilized to obtain plasma micro jet flow which is focused in energy density and is small in divergence, and a local area on the surface of a to-be-sprayed workpiece is instantaneously molten while the integral temperature of the workpiece is prevented from rising, so that a coating and a basal body generate metallurgical bonding;the powder conveying channel which is in peripheral ring-shaped distribution is used for enabling powder to form tapered powder flow with a pre-designed included angle and small divergence, so that powder is heated and accelerated more uniformly in plasma micro jet flow to obtain a sprayed coating which is uniform in chemical component, is compact in micro structure, and defines metallurgical bonding.

Owner:TIANJIN UNIV

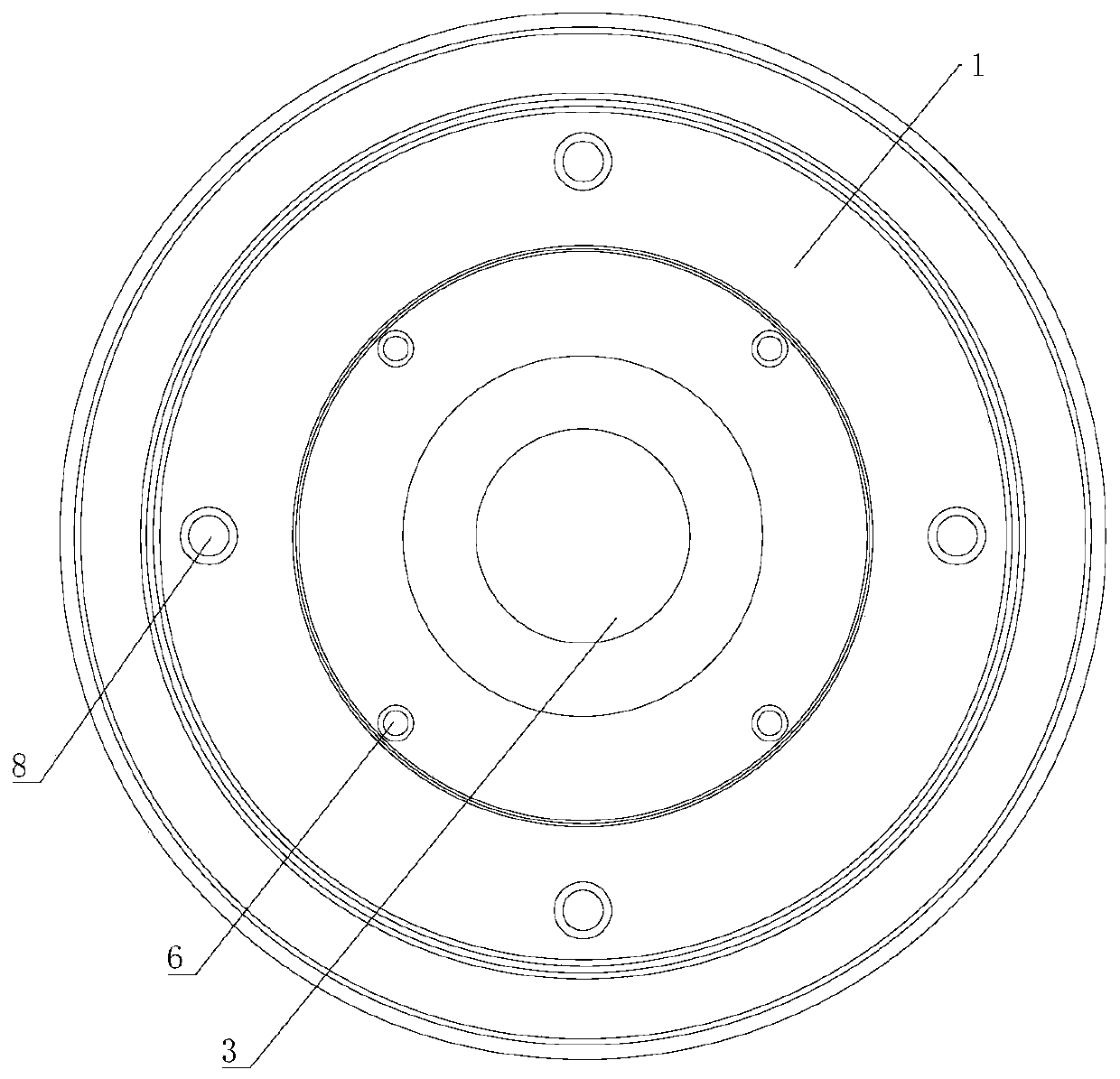

Molten steel atomizing disc, atomizing and pelleting equipment and atomizing and pelleting method

The invention discloses a molten steel atomizing disk, atomizing and pelleting equipment and a atomizing and pelleting method. The molten steel atomizing disc comprises an upper spraying disc body anda lower spraying disc body which are coaxially arranged, conical holes are formed in the upper spraying disc body and the lower spraying disc body correspondingly, an air cavity allowing airflow to pass through and a Laval structure annular gap connected with the air cavity are reserved between the upper spraying disc body and the lower spraying disc body, and the narrow throat of the Laval structure annular gap is located on one side, away from the air cavity, of the Laval structure annular gap. Gas passes through the annular gap of the spraying disc, namely a Laval structure, the gas is accelerated and ejected at high speed; and due to the fact that an included angle is formed between the path through which the gas passes in the spraying process and the central axis of the upper spraying disc body and the central axis of the lower spraying disc body, and the gas cavity and the Laval structure gap which communicates with the gas cavity are both annular, the gas forms a vortex-closedgas cone after being sprayed out through the narrow throat, and molten metal flowing through the cone top is crushed, the gas injection amount is large and uniform, and the steel shot yield is high.

Owner:无锡锋速钢丸有限公司

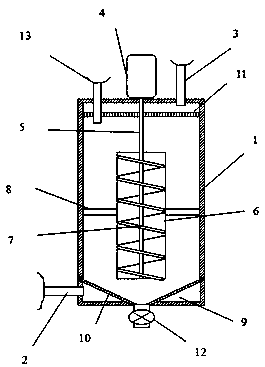

Plastic particle dryer

InactiveCN110671909AFast exchangeUniform accelerationGranular material dryingDrying gas arrangementsDrive shaftElectric machine

The invention discloses a plastic particle dryer which comprises a material bucket and a material turning device. A bottom partition plate for dividing the material bucket into a hot air chamber and amaterial bin is installed at the bottom of the material bucket, the bottom partition plate is provided with a vent hole for communicating the material bin and the hot air chamber, a hot air pipe externally connected to a hot air dryer is installed on the side wall of the hot air chamber, a feed pipe and an air exhaust pipe are arranged above the material bucket, the feed pipe is connected to a negative pressure loader, and the air exhaust pipe is externally connected to an exhaust fan; and the material turning device includes a drive motor, a transmission shaft, a spiral twisted sheet and aninner tube, the drive motor is fixed on a top cover of the material bucket, the transmission shaft equipped with the spiral twisted sheet goes deep into the material bucket, the inner tube is arrangedoutside the spiral twisted sheet in a sleeving manner, and the inner tube is fixed on the material bucket through an inner tube bracket. By means of the manner, the plastic particle dryer is thoroughin turning in the drying process, has no dead corners, and is uniform in heating, fast in gas heat exchange and high in drying efficiency.

Owner:TAICANG JINHAODA NEW MATERIAL CO LTD

Device for preheating cement raw material for manufacturing cement clinker

PendingCN114719618AUniform accelerationGuaranteed to be heatedClinker productionWaste heat treatmentElectric machineryProcess engineering

The invention provides a device for preheating a cement raw material for manufacturing cement clinker, and relates to the technical field of cement production, the device comprises a treatment box body, the treatment box body is a rectangular structure, and a support frame body is arranged at the bottom of the treatment box body; a rotating rod is rotationally mounted at the left end of the interior of the treatment box body; a motor is arranged on the right side of the treatment box body; the right end of the rotating rod is connected with an output shaft of the motor; a discharging box is arranged in the middle of the bottom of the treatment box and is of a rectangular structure. The cement raw material stirring device is provided with the longitudinal stirring mechanism, the transverse stirring mechanism and the vibration screening mechanism, cement raw materials can be fully stirred uniformly through the three mechanisms, the cement raw materials can be fully heated, the processing quality is guaranteed, the three mechanisms work synchronously, the processing efficiency is guaranteed, and the problems that an existing device is single in stirring mode and poor in stirring effect are solved. The stirring is not uniform enough, so that the cement raw material cannot be fully heated, and the raw material treatment is not thorough.

Owner:黄婧

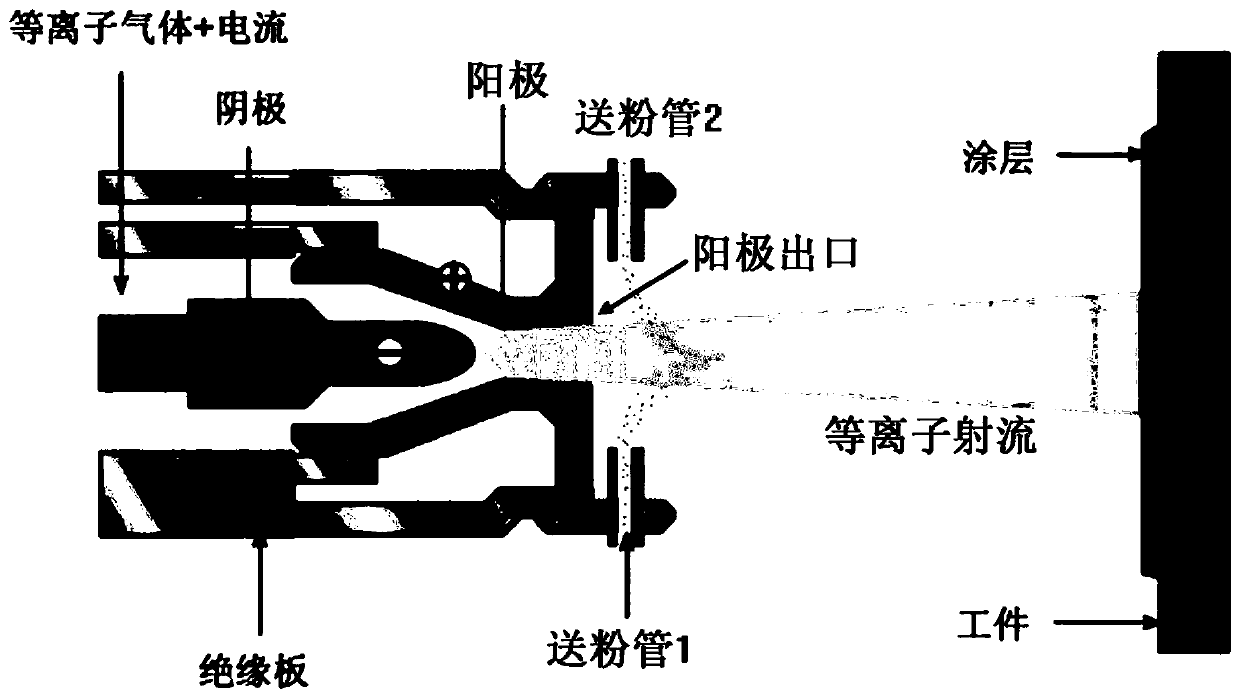

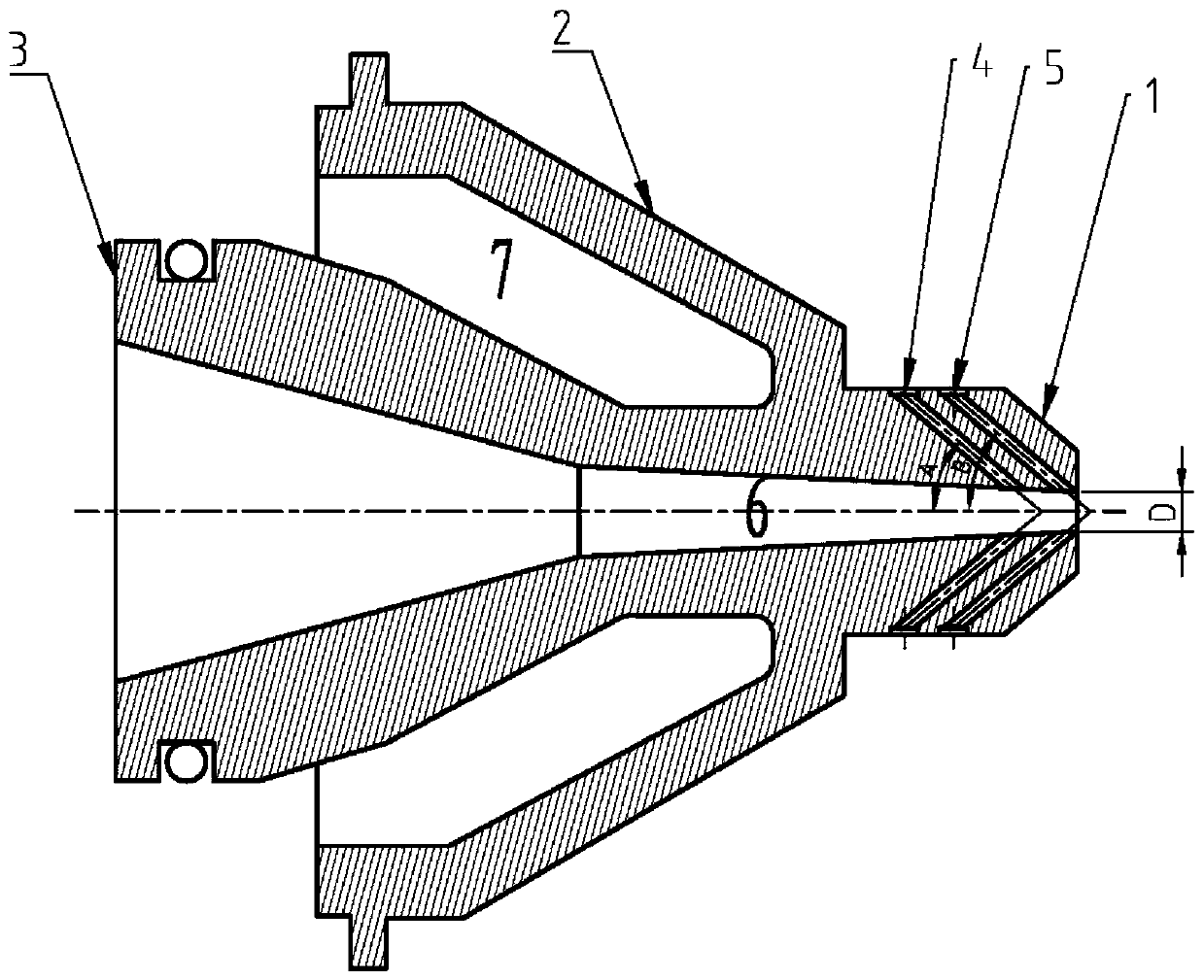

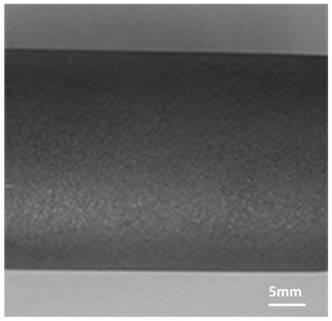

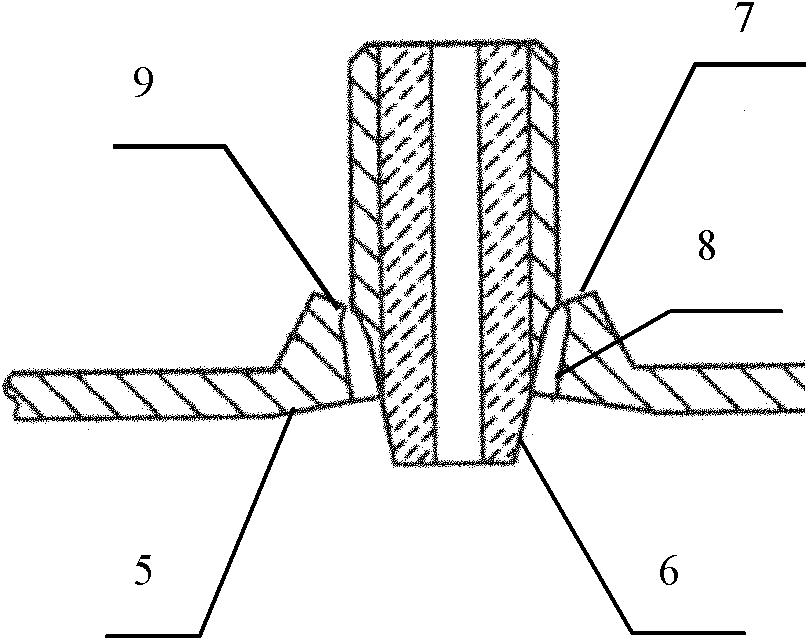

Conical powder feeding device for ultra-high-speed plasma cladding and ultra-high-speed plasma cladding method

InactiveCN111411355AHigh powder feeding rateIncrease productivityMetallic material coating processesPlasma jetUltra high speed

The invention provides a conical powder feeding device for ultra-high-speed plasma cladding and an ultra-high-speed plasma cladding method. The conical powder feeding device comprises a central cylinder, a water-cooled inner spacer, a powder guide spacer, and a protective air spacer and a water-cooled outer spacer which are assembled to the outside from a central shaft. The entrance of the centralcylinder is axially connected with the anode of a cladding gun of a plasma cladding system; the conical powder feeding device delivers the powder to a plasma jet uniformly at a high speed, under themechanical constraint of the outlet oblique conical surface of the powder guide space, a conical powder fluid with a pre-designed angle is formed, and finally the fluid focuses on the central shaft, so as to obtain the powder jet with high concentration, high speed, uniform distribution and small divergence, and under the ultra-high-speed plasma cladding condition of above 10-200m / min relative movement speed of the plasma cladding system and a workpiece, a cladding layer with thin thickness, uniform chemical composition, low surface roughness, low dilution rate and dense microstructure can beobtained.

Owner:TIANJIN UNIV

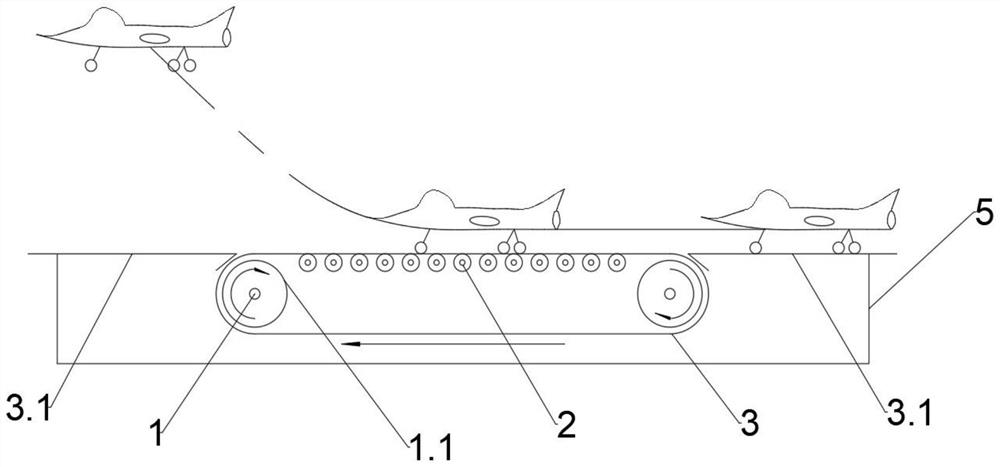

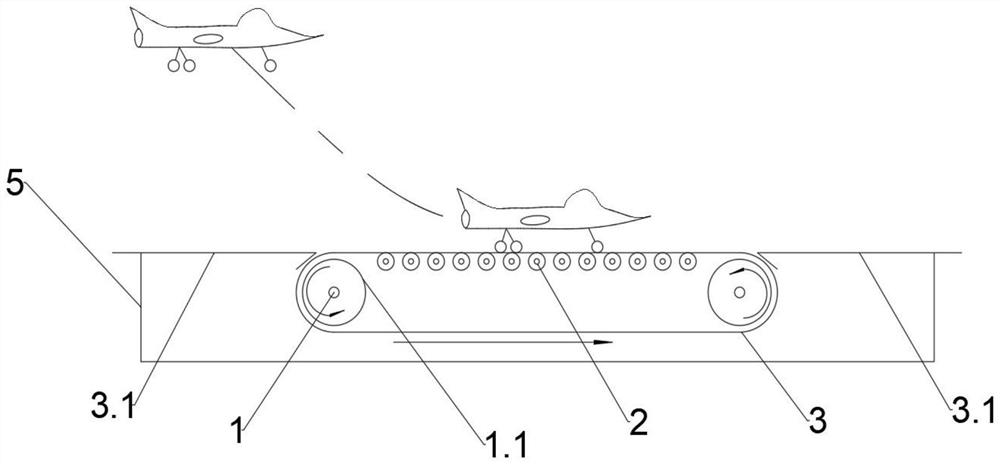

Dynamic runway for taking off and landing of airplane

InactiveCN114435616AImprove securityTakeoff and landingArresting gearLaunching/towing gearDrive shaftElectric machinery

The invention discloses a dynamic runway for taking off and landing of an airplane, which comprises driving shafts, a bearing shaft, a circulating track, an adjustable-speed motor and a truss, the two ends of the truss are provided with the driving shafts which are rotatably connected with the truss, the two driving shafts are horizontally arranged in parallel front and back, and the circulating track which is in transmission connection with the driving shafts is wound on the driving shafts; a bearing shaft which is horizontally arranged in parallel with the two driving shafts is arranged between the two driving shafts, the bearing shaft is arranged in the middle of the circulating crawler belt and used for supporting the circulating crawler belt, a speed regulating motor is fixedly arranged on the truss, and the speed regulating motor is in transmission connection with the driving shafts. According to the invention, the circulating track and the airplane pulley rotate in opposite directions at the same speed, so that the airplane uniformly takes off in an accelerated manner and lands in a decelerated manner during take-off and landing; when the aircraft takes off, a long runway is not needed, and when the aircraft lands, emergency deceleration is not needed, so that the safety of the aircraft in taking off and landing is improved; the device can be used in various takeoff and landing environments with limited runway length, such as aircraft carriers and mountainous airports, and is wide in application range.

Owner:卢伯林

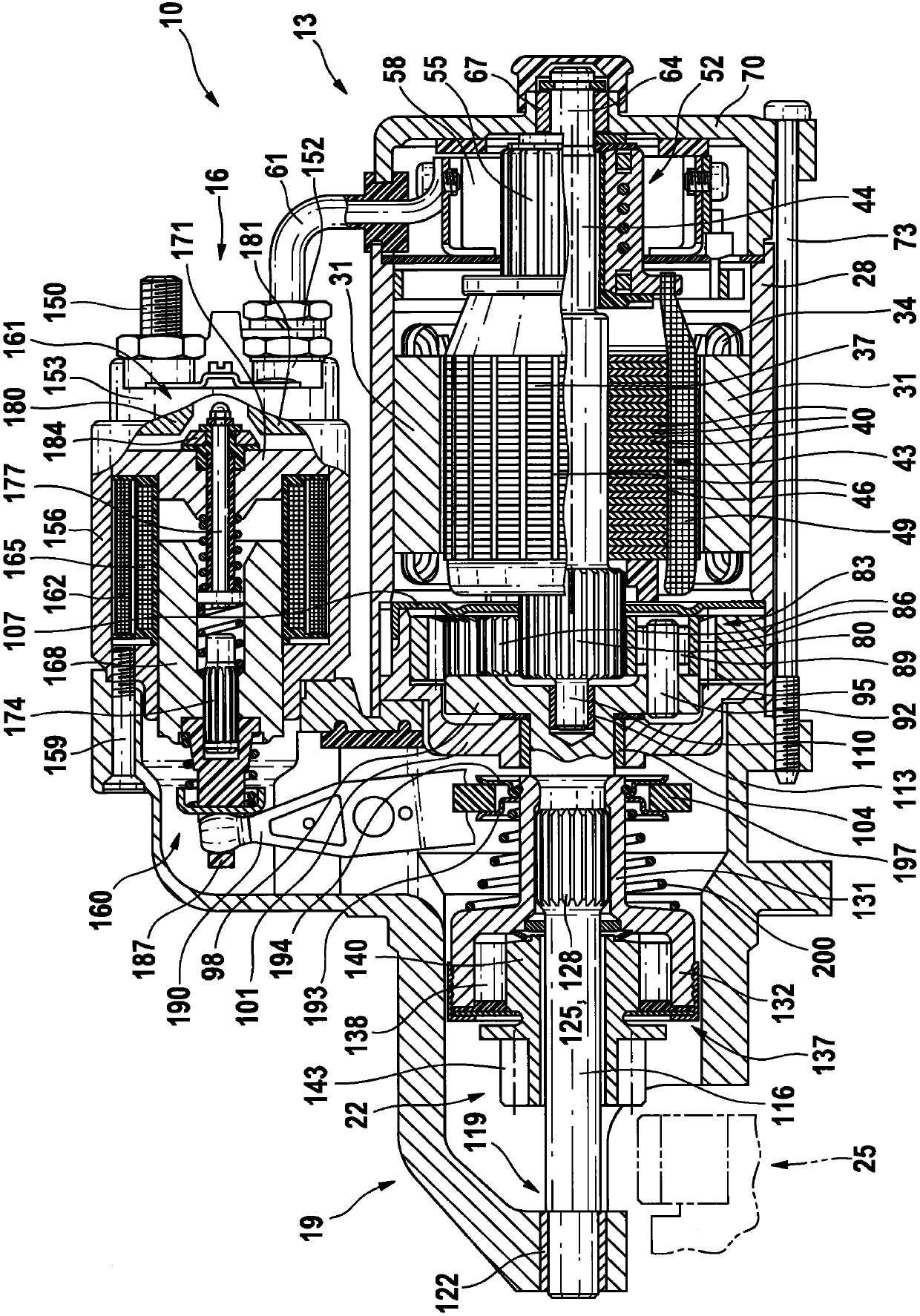

Starting devices for internal combustion engines

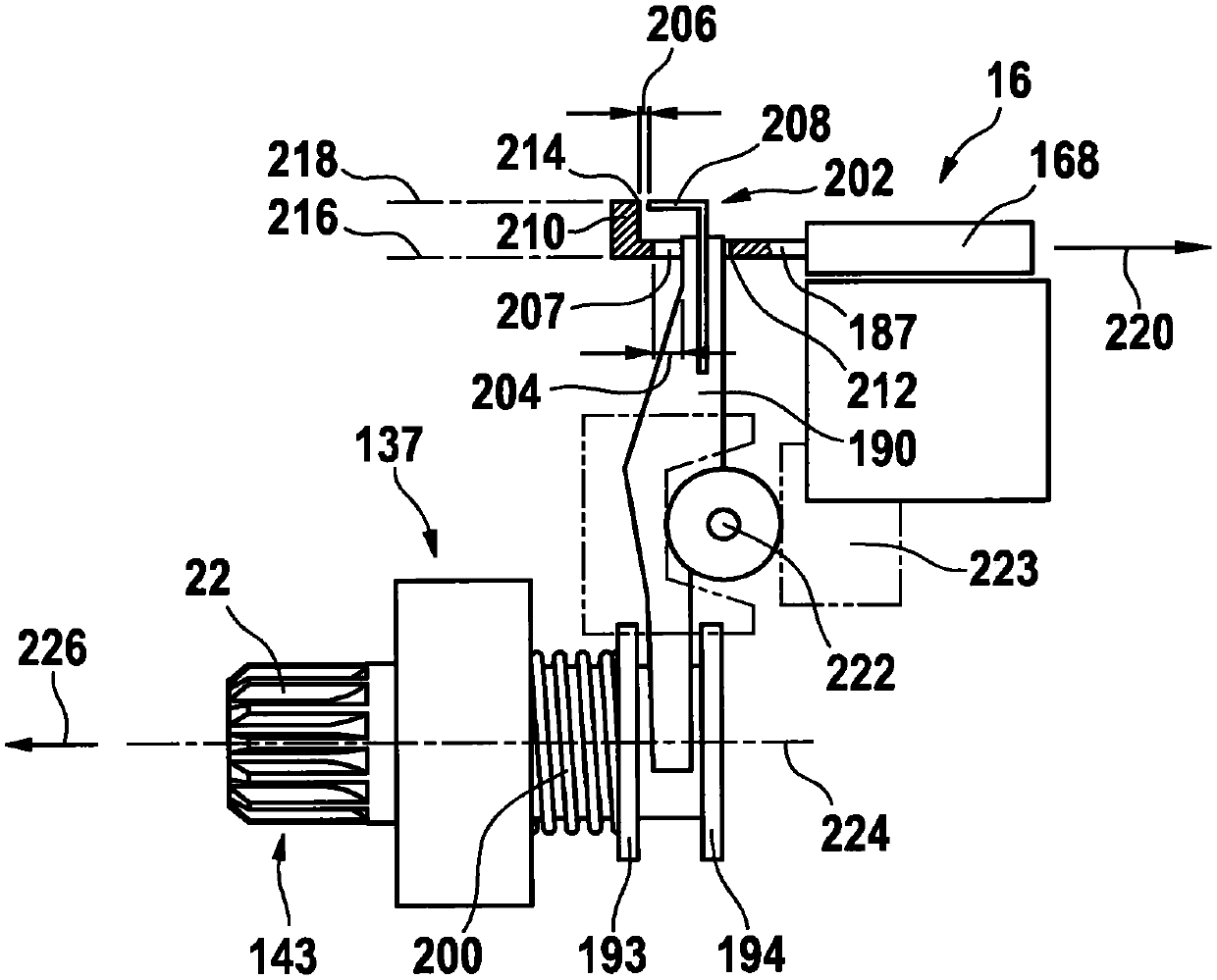

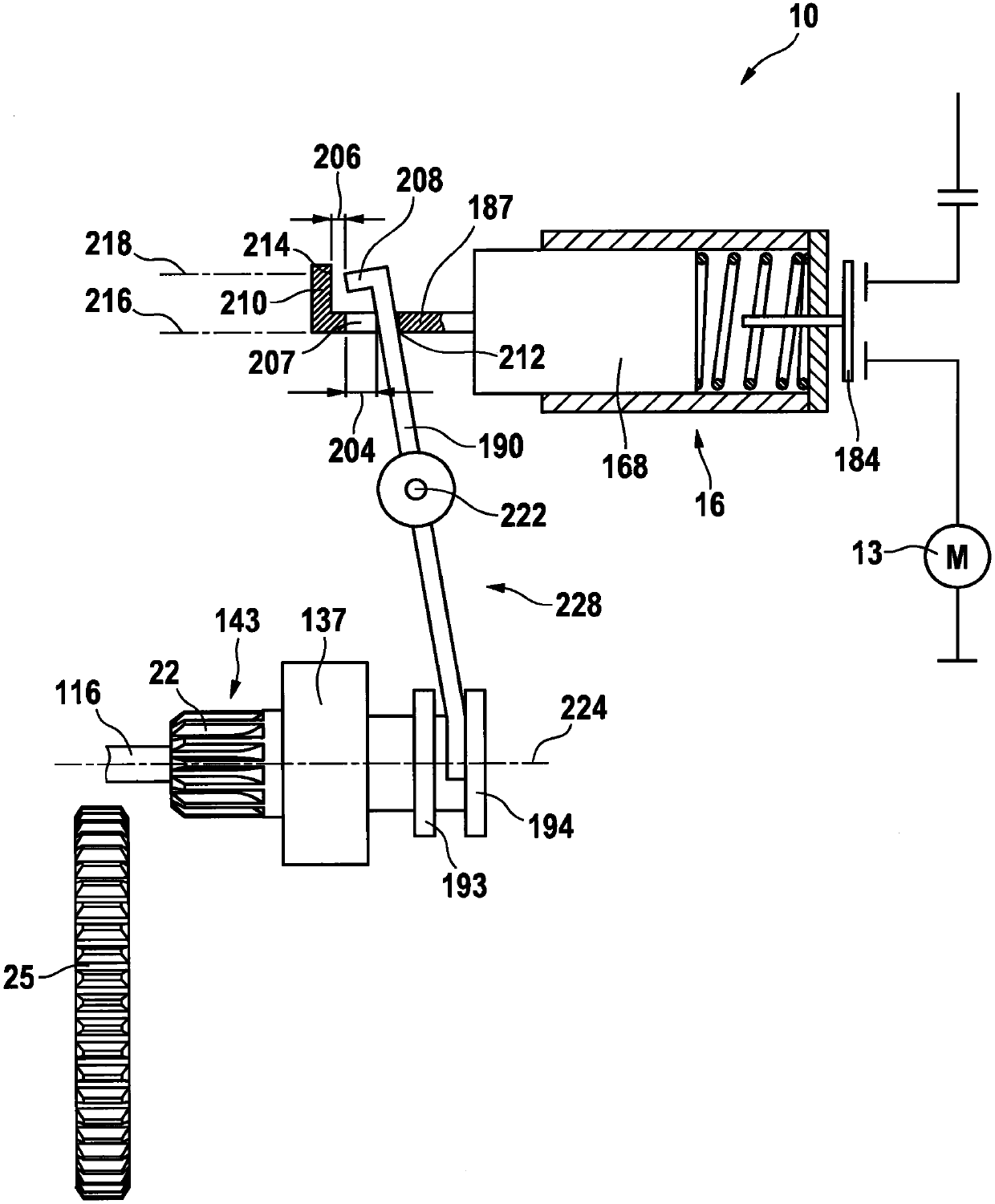

ActiveCN103443445BIncrease the itineraryUniform accelerationPower operated startersElectric motor startersEngineeringInternal combustion engine

The invention relates to a starting device (10) for an internal combustion engine. The starting device (10) comprises a pre-engagement actuator (16) manipulating a pull element (187, 210). The pulling element (187, 210) moves the lever (190) to engage the starter pinion (22) into the ring gear (25) of the internal combustion engine. A first entrainment point (212) and a second entrainment point (214) are formed between said pull element (187, 210) and said lever (190), said first entrainment point (212) and a second entrainment point (212) The two entrainment points (214) lie in different planes (216, 218) from each other.

Owner:SEG AUTOMOTIVE GERMANY GMBH

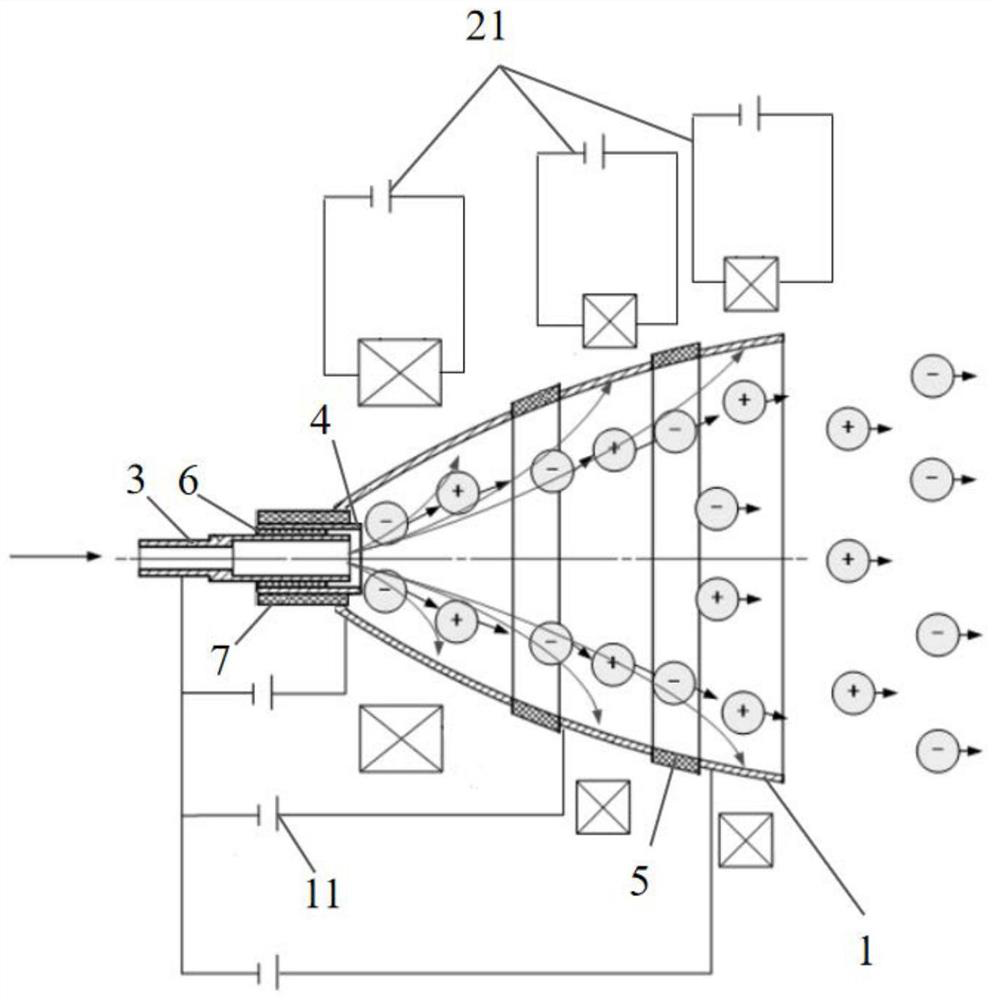

Plasma generation device and method based on multi-stage magnetic field and multi-section spray pipe

PendingCN114352494AFully ionizedReduce thrust lossMachines/enginesUsing plasmaPhysicsSupply & distribution

The invention relates to a plasma acceleration propulsion device, in particular to a plasma generation device and method based on a multi-stage magnetic field and a multi-section spray pipe. The technical problem that the specific impulse and thrust are not ideal due to the fact that a plasma generating device with a single-section spray pipe is not favorable for optimizing the configuration of a magnetic field and the trajectory of plasma jet is difficult to control is solved. The device comprises a working medium supply and distribution unit and a plasma generation acceleration unit, wherein the working medium supply and distribution unit comprises a working medium distributor, a second insulator, a transition electrode and a third insulator which are coaxially arranged from inside to outside; the plasma generation acceleration unit comprises n sections of spray pipes, n-1 sections of first insulators, accelerator electric field power supplies corresponding to the spray pipes, electromagnetic coils corresponding to the spray pipes and electromagnetic field power supplies corresponding to the electromagnetic coils; and the n sections of spray pipes and the n-1 sections of first insulators form a spray pipe assembly. The invention further provides a plasma generation method based on the multi-stage magnetic field and the multi-section spray pipe.

Owner:XIAN AEROSPACE PROPULSION INST

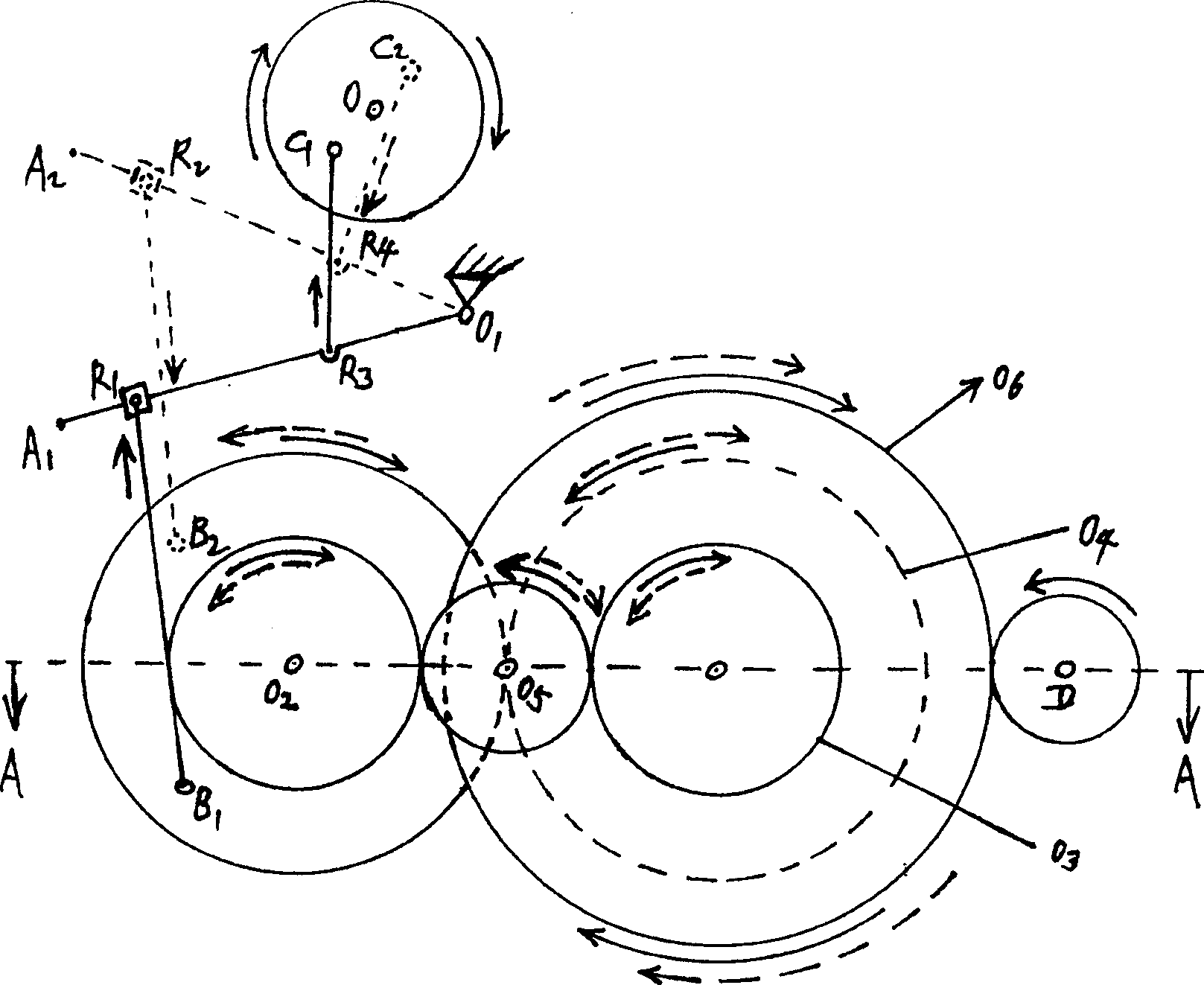

Non-shift telescoping-radius one-way transmission

The invention relates to a no-shift unidirectional transmission with expansion radius, which can accelerate equally and has not the phenomena generated by former shift transmission in changing shift that former shift transmission accelerates unevenly in changing shift and residual tail gas is generated in increasing throttle. The no-shift unidirectional transmission is divided into two parts. One is the expansion machine of radius and the other is unidirectional rotating machine. By two wheels, which are rotating in opposite directions and are not rotating in the same direction permanently, the third wheel is driven to rotate in clockwise or counterclockwise single direction. The expansion machine of radius is matched with the unidirectional rotating machine to achieve the variable speed in common. The invention can be applied in traffic tools such as bicycle, vehicle and so on as the transmission system.

Owner:廉彦芳

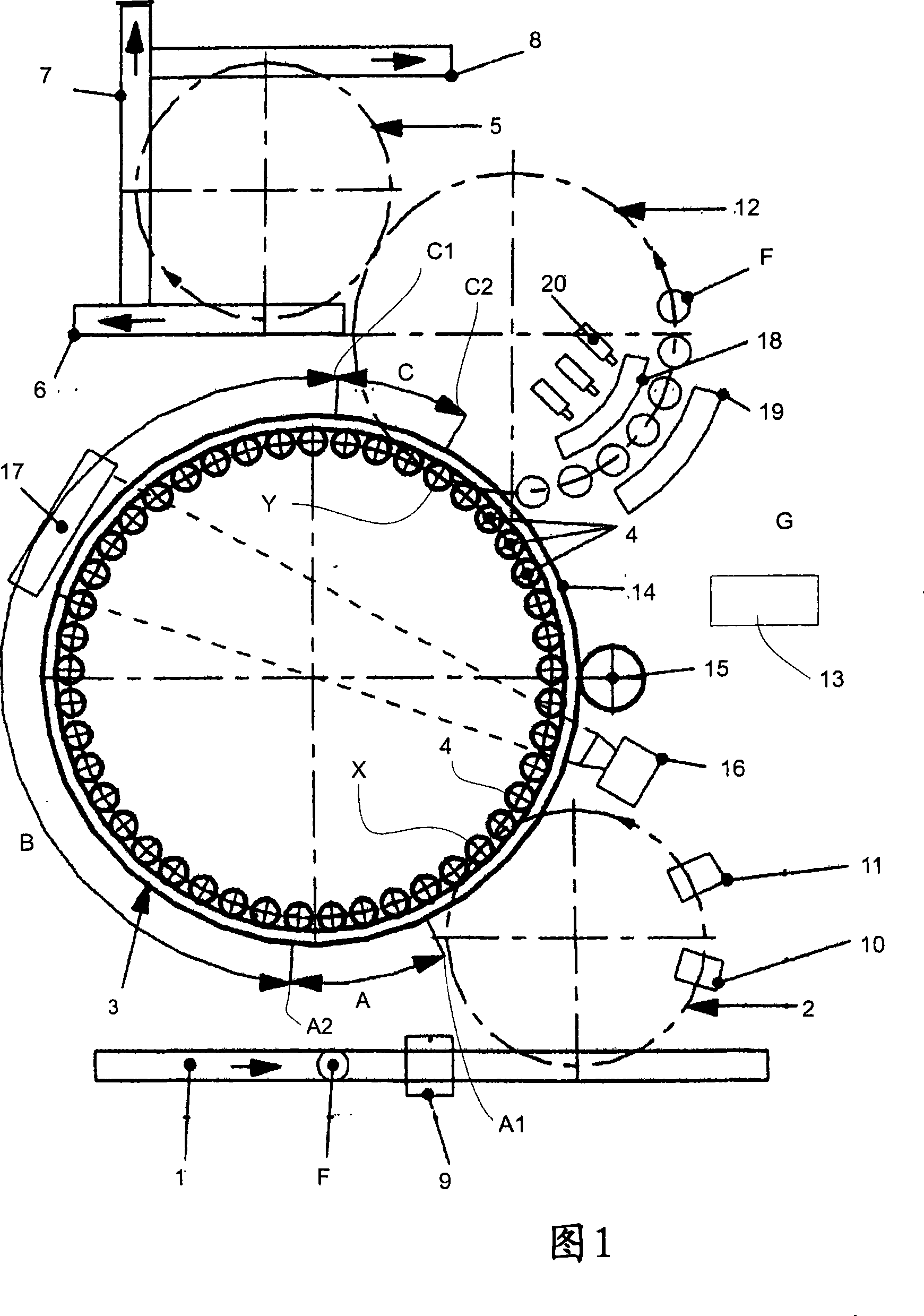

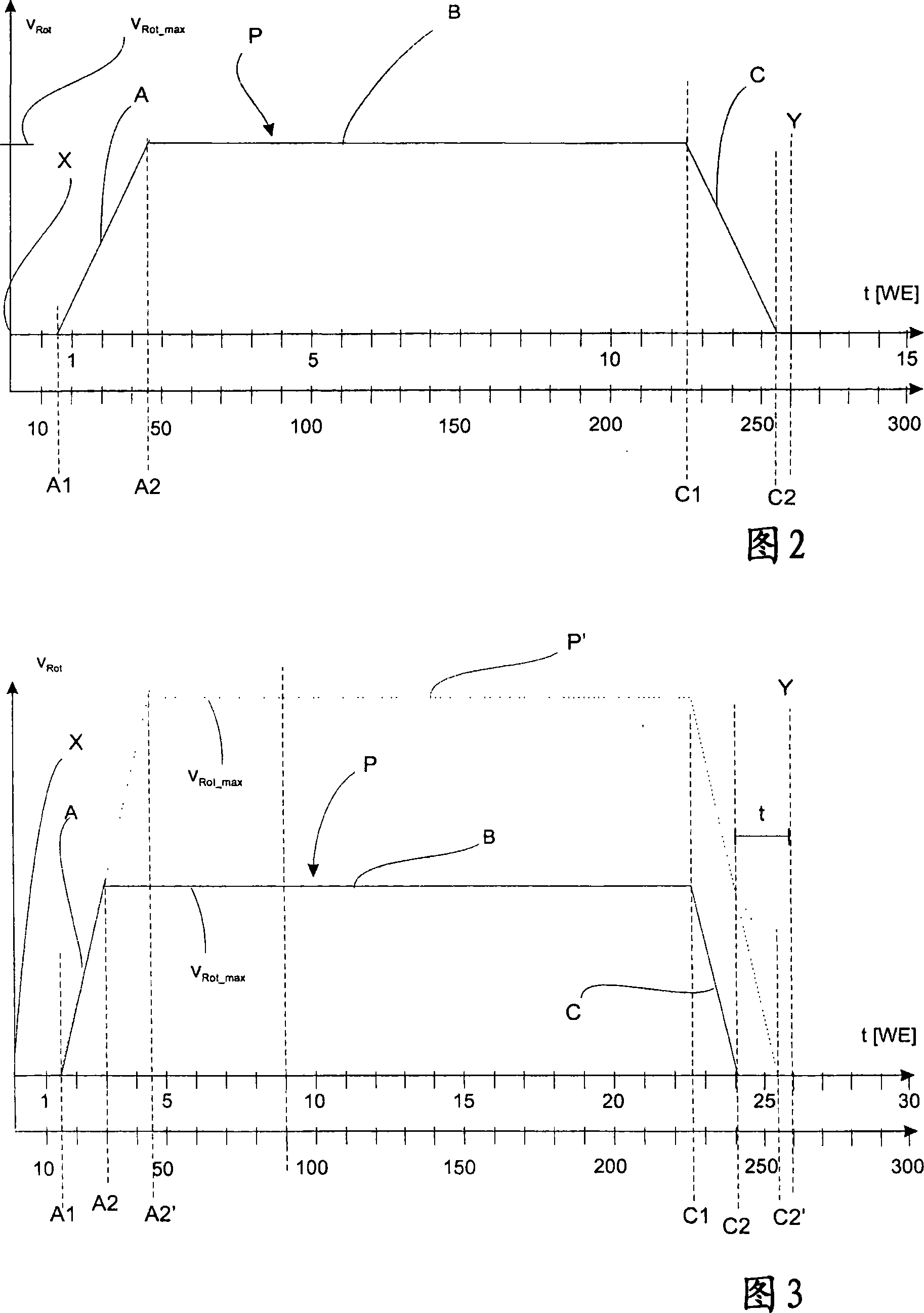

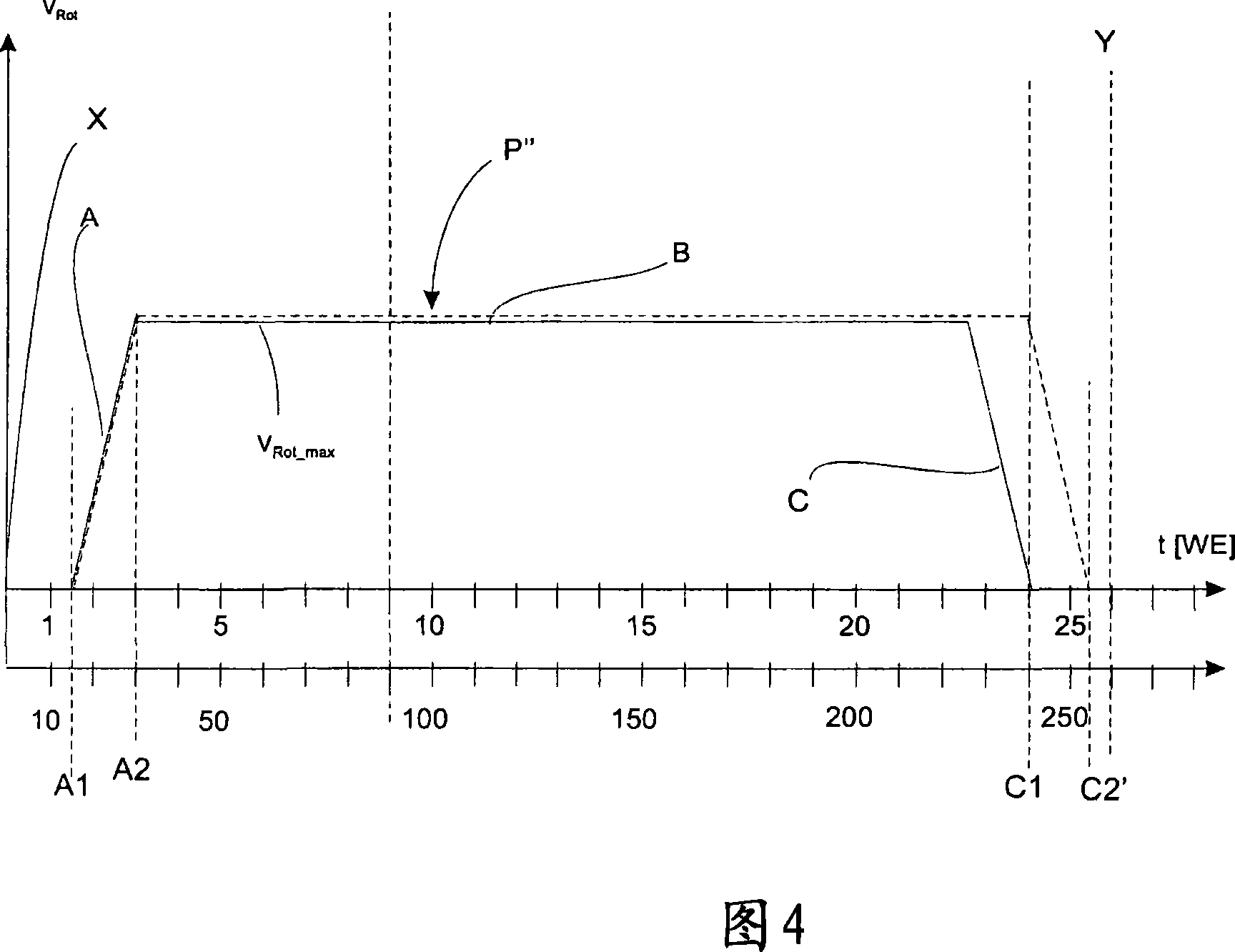

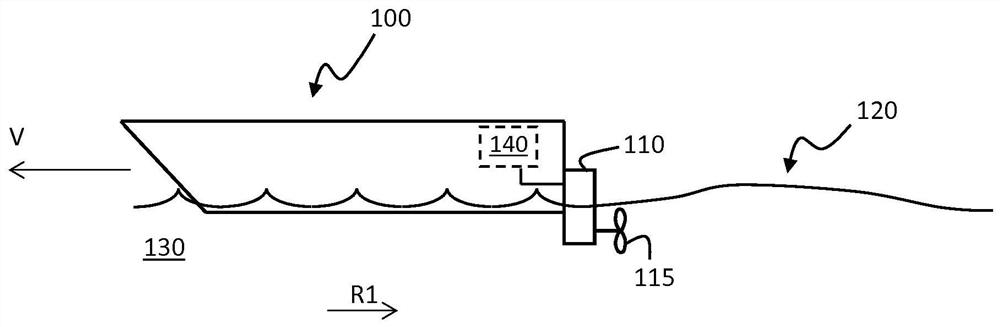

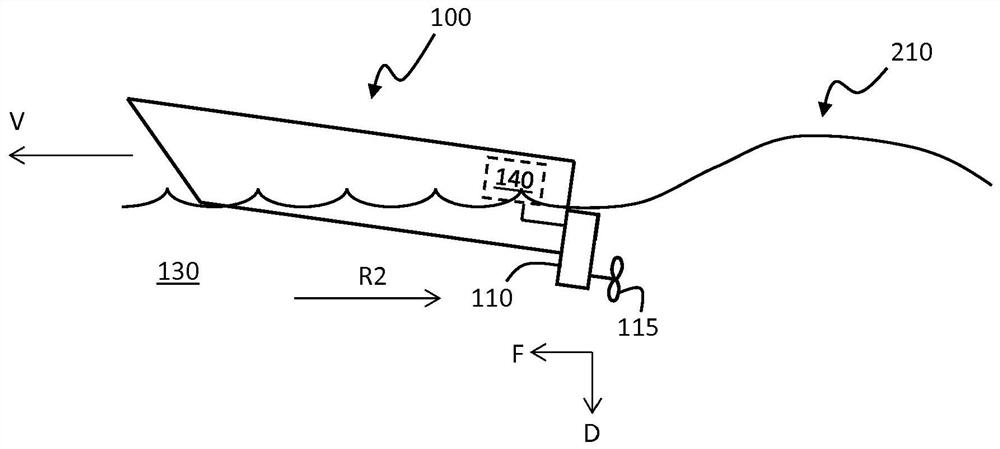

Method and device for accelerating a vehicle when starting at a signal light arrangement

ActiveCN105882660BAvoid collisionUniform accelerationExternal condition input parametersPlatooningSignal lightEngineering

A forward movement, a device and a method for accelerating a vehicle (10) at a signal light device (1) at the start of a queue are proposed. The method includes the following steps: determining the probability that a predefined vehicle (10) can pass the traffic light device (1) during a real-time or upcoming green light phase, as long as the probability is greater than a predefined threshold, corresponding to the electronic The signals (S1, S11, S12, S22) of the traction system accelerate the vehicle (10) and to a correspondingly lesser extent as long as the probability is smaller than a predefined threshold.

Owner:VOLKSWAGEN AG

Circumferential seam type supersonic nozzle for metal gas atomization

ActiveCN102581291BUniform velocity distributionReduce turbulenceLiquid spraying apparatusShock waveGas cylinder

Owner:有研增材技术有限公司

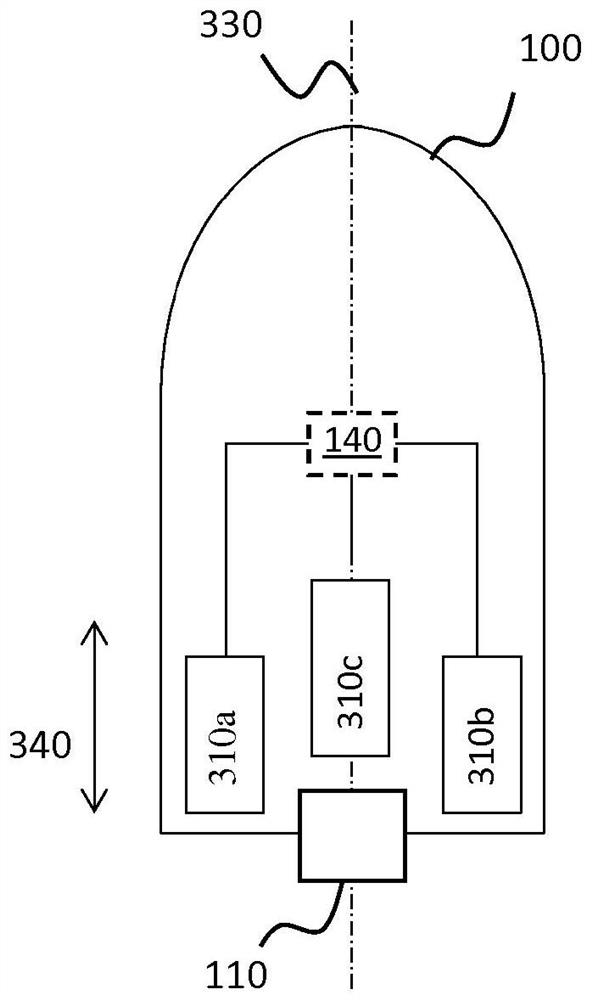

Improved engine control

PendingCN112839867AUniform accelerationAccelerate fastSelf-bailing equipments/scuppersOutboard propulsion unitsMarine engineeringMechanical engineering

The present invention relates to a method for controlling a propulsion operation of a propulsion unit to reach the desired speed of a marine vessel. The method comprises obtaining a target speed configuration indicating the desired speed of the marine vessel, obtaining a current speed value associated with a current speed of the marine vessel, obtaining a fill level value associated with a fill level of one or more ballast tanks of the marine vessel, and controlling the propulsion operation of the propulsion unit to reach the desired speed based on the target speed configuration, the current speed value, and on the fill level value.

Owner:CPAC SYST

Multifunctional modular system for energy transformation

InactiveCN101072703AReduce manufacturing costReduce installation costsSliding/levitation railway systemsRailway transportModularityEngineering

Owner:尤泰姆公司

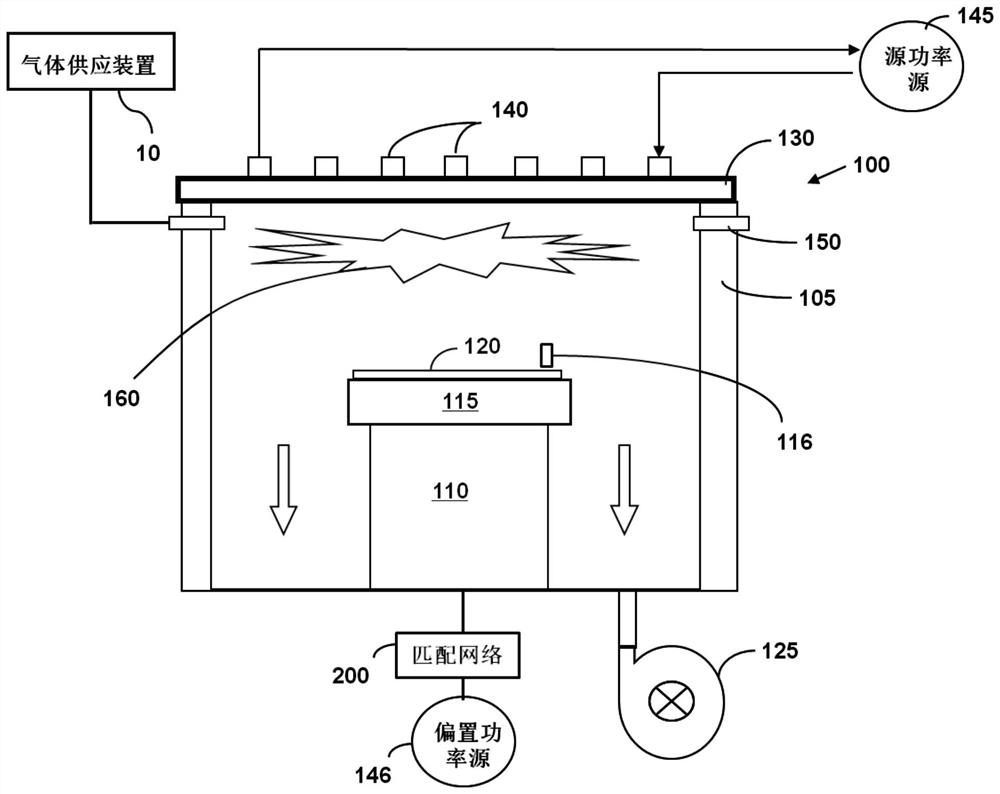

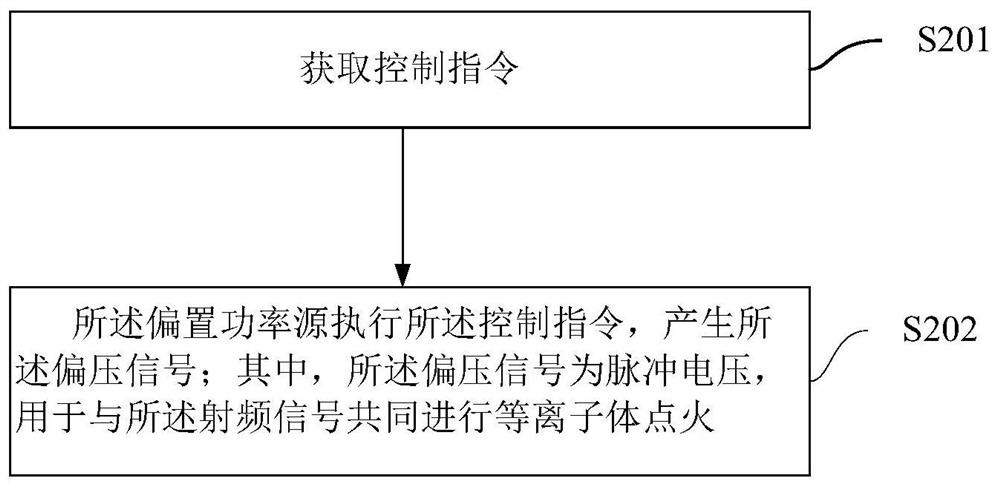

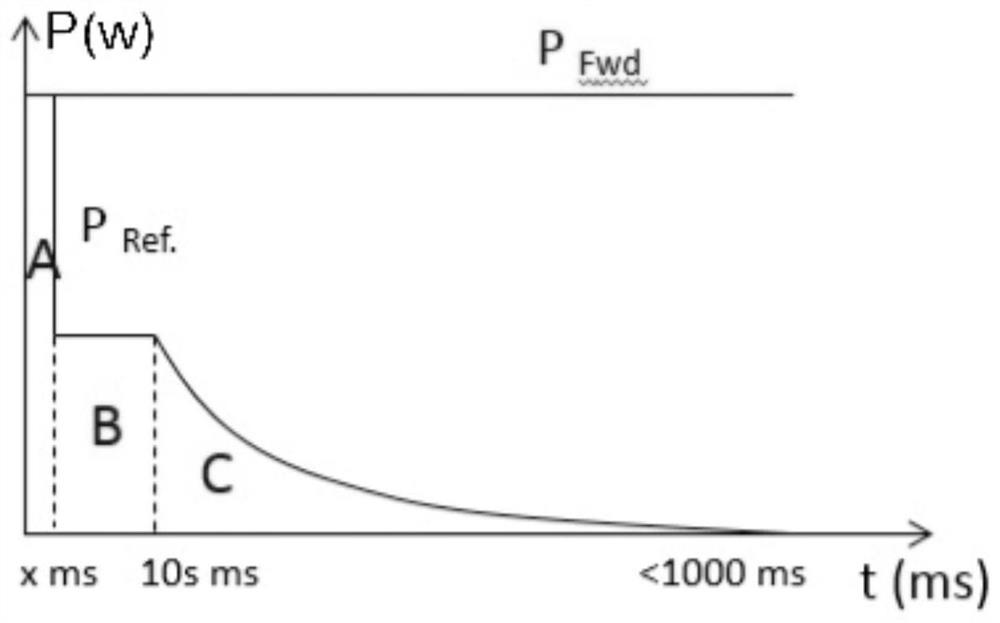

Inductively coupled plasma processing apparatus and ignition control method thereof

PendingCN112509899AUniform accelerationEliminate capacitive couplingElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequency signalInductively coupled plasma

The invention discloses an ignition control method of an inductively coupled plasma processing device. The device is provided with a vacuum processing cavity, a radio frequency power source and a biaspower source, and the radio frequency power source couples a radio frequency signal into the vacuum processing cavity through an inductive coupling coil. The bias power source applies a bias voltagesignal to a base in the vacuum processing cavity through a radio frequency matching network, and the base is used for supporting a substrate to be processed. The method comprises the steps of obtaining a control instruction; and by the bias power source, executing the control instruction to generate a bias voltage signal, wherein the bias voltage signal is a pulse voltage and is used for carryingout plasma ignition together with the radio frequency signal. By applying the method provided by the invention, the starting time of the radio frequency power source and the bias power source is controlled, and the duty ratio and the voltage of the pulse voltage of the bias power source are adjusted, so that the uniform acceleration of the plasma can be realized while the high-efficiency ignitionis realized.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

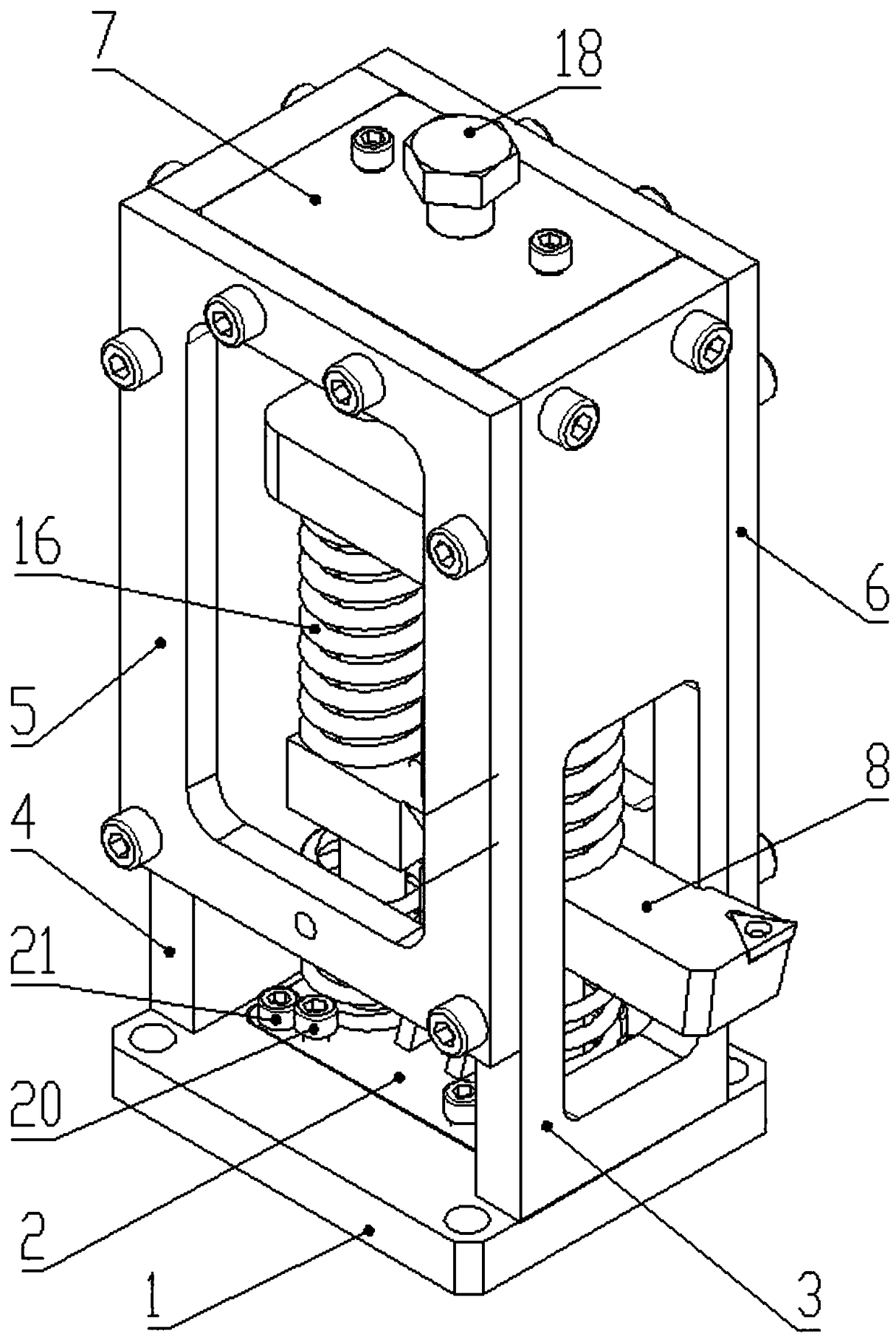

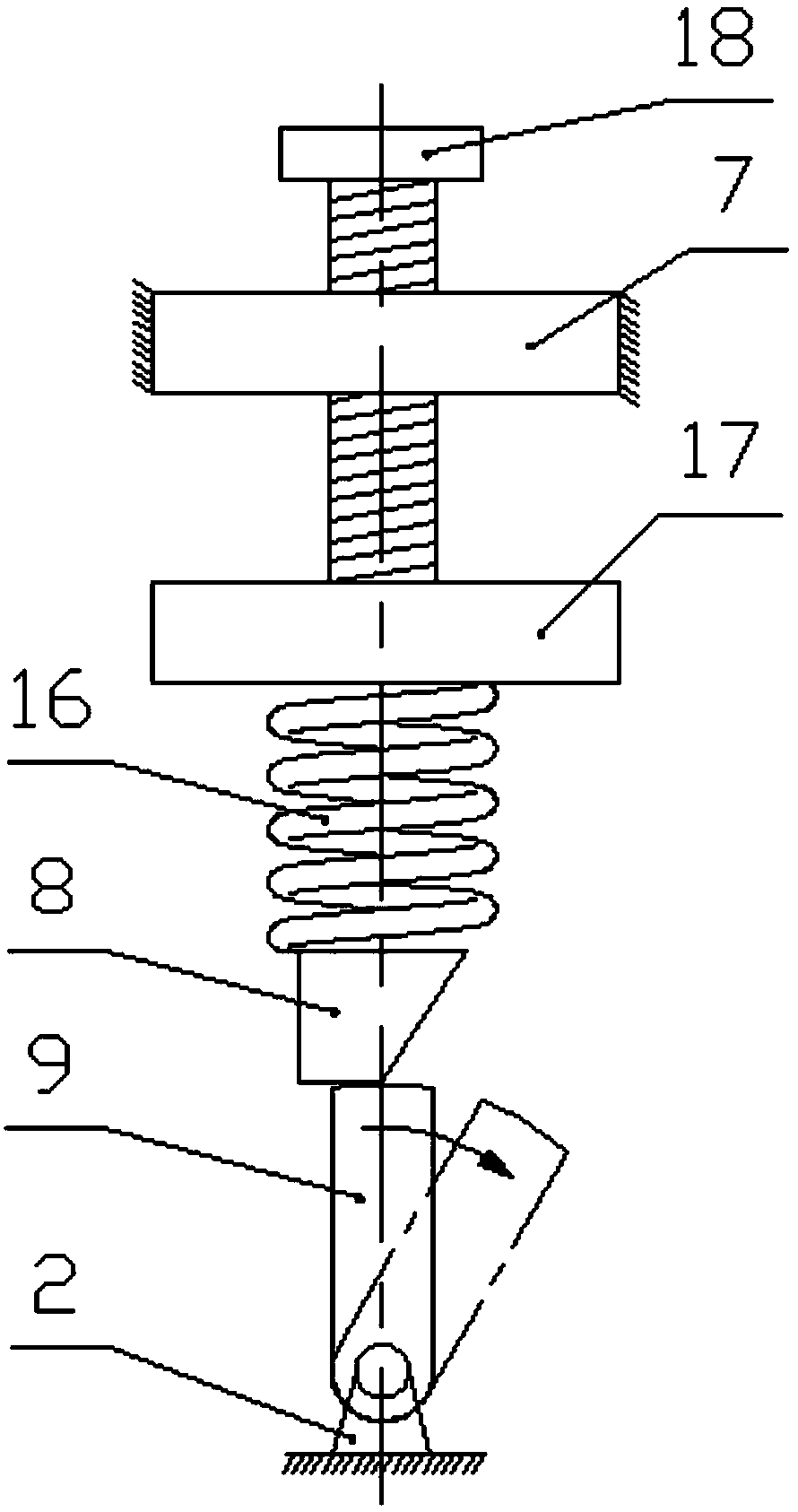

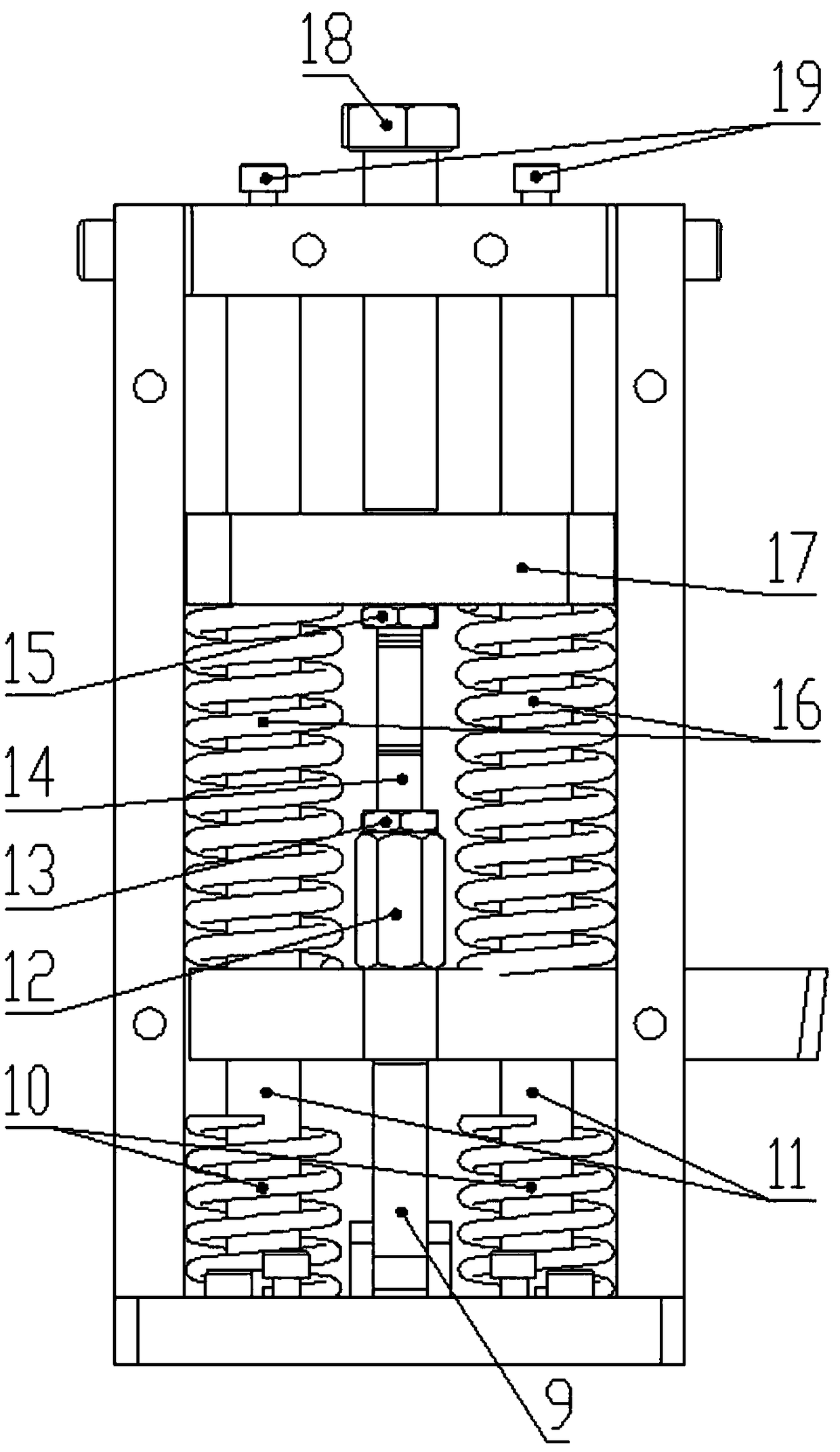

A rapid tool drop device for a lathe

ActiveCN107511492BIncrease contactReduce mistakesAuxillary equipmentMeasurement/indication equipmentsHigh accelerationEngineering

The invention belongs to the technical field of cutting and processing, and provides a rapid tool drop device for a lathe, which includes a base, a bottom plate, a front side plate, a rear side plate, a right plate side, a left side plate, a top fixing plate, a knife rod, a cam rod, a buffer It consists of a spring, a cylindrical guide rail, an adjusting nut, a lock nut, a double-ended stud, a lock nut, a pressure spring, a pressure plate, a pressure bolt and a pin. The cam rod supports the knife rod before the knife falls. When the knife needs to be dropped, the external force makes the cam rod rotate. When the cam rod turns over a certain position, the knife rod loses its supporting force instantly. The tool drops with great acceleration, leaving the cutting area in a short time and freezing the root of the chip. The invention has the advantages of simple structure, low manufacturing cost, safe and convenient operation, small impact, reusable use, short reset time, no interference between the tip of the knife and the workpiece when dropping the knife, no damage to the chip root, and rapid and effective knife dropping.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com