Engine

A technology of engine and rotating shaft, which is applied in the direction of engine components, engine control, combustion engine, etc., and can solve problems such as top interference, reduced output power, and insufficient exhaust gas exhausted by the piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

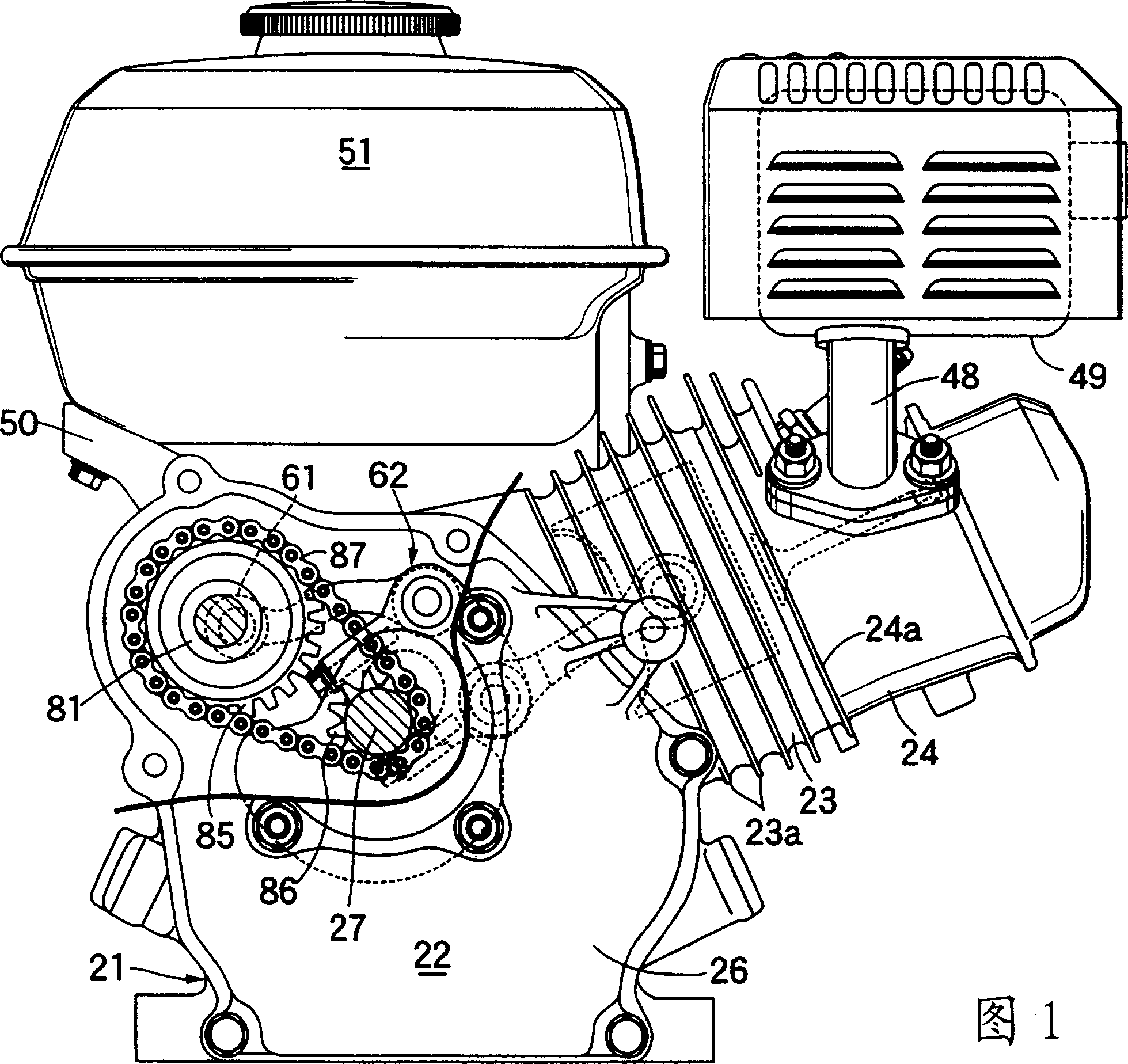

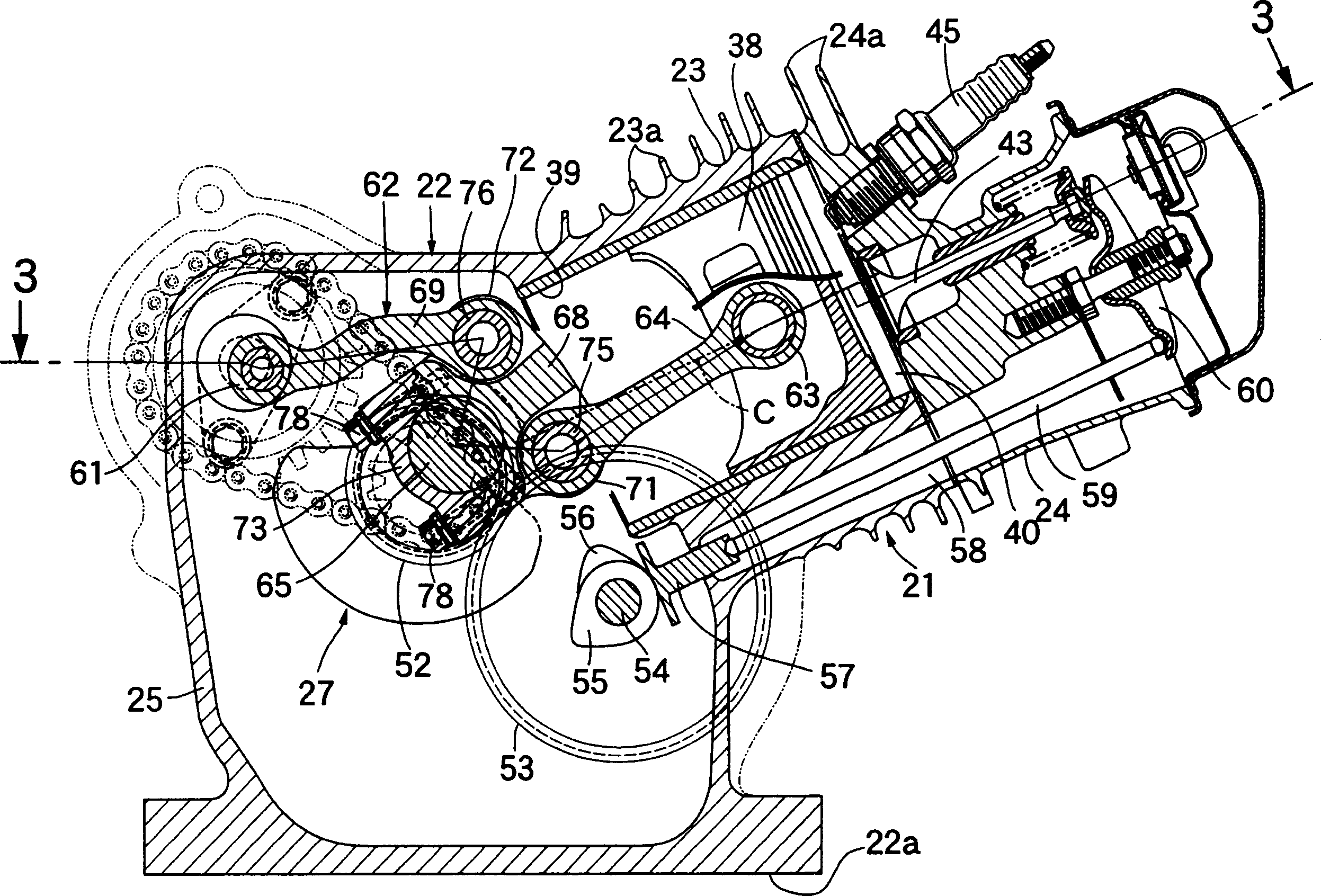

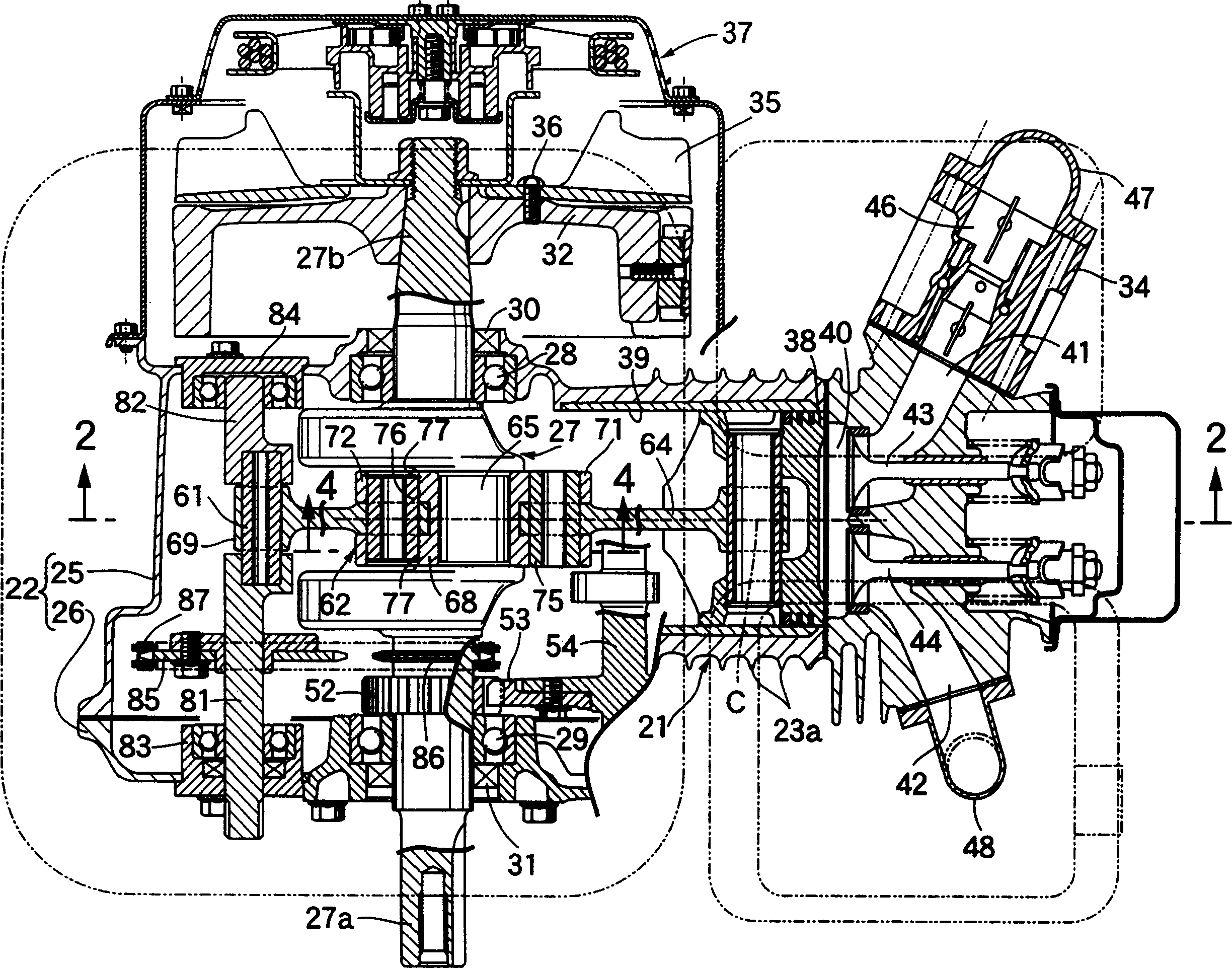

[0046] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 7 . Refer to Figure 1 to image 3 , the engine according to the first embodiment of the present invention is an air-cooled single-cylinder engine for use in such as working equipment or the like, and this engine includes a body 21 consisting of a crankcase 22, from the crankcase 22 and a cylinder block 23 protruding slightly upwards on one side of the cylinder block 22, and a cylinder head 24 connected to a top of the cylinder block 23. On the outer surfaces of the cylinder block 23 and the cylinder head 24, a large number of air cooling fins 23a and 24a are provided. On the base of each of the various working machines is mounted a mounting surface 22 a on the lower surface of the crankcase 22 .

[0047] Crank case 22 comprises: a case body 25, and this case body forms an integral body with cylinder block 23 by casting; One side cover 26, is connected with an open end of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com