Plasma generation device and method based on multi-stage magnetic field and multi-section spray pipe

A plasma and generation device technology, applied in the field of ion plasma generation devices, can solve the problems of difficult control of plasma jet trajectory, difficulty in improving electromagnetic acceleration effect, unfavorable optimization of magnetic field configuration, etc., to ensure ignition reliability and electric field acceleration capability , Improve the effect of trajectory control and electromagnetic acceleration, smooth start and improve the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

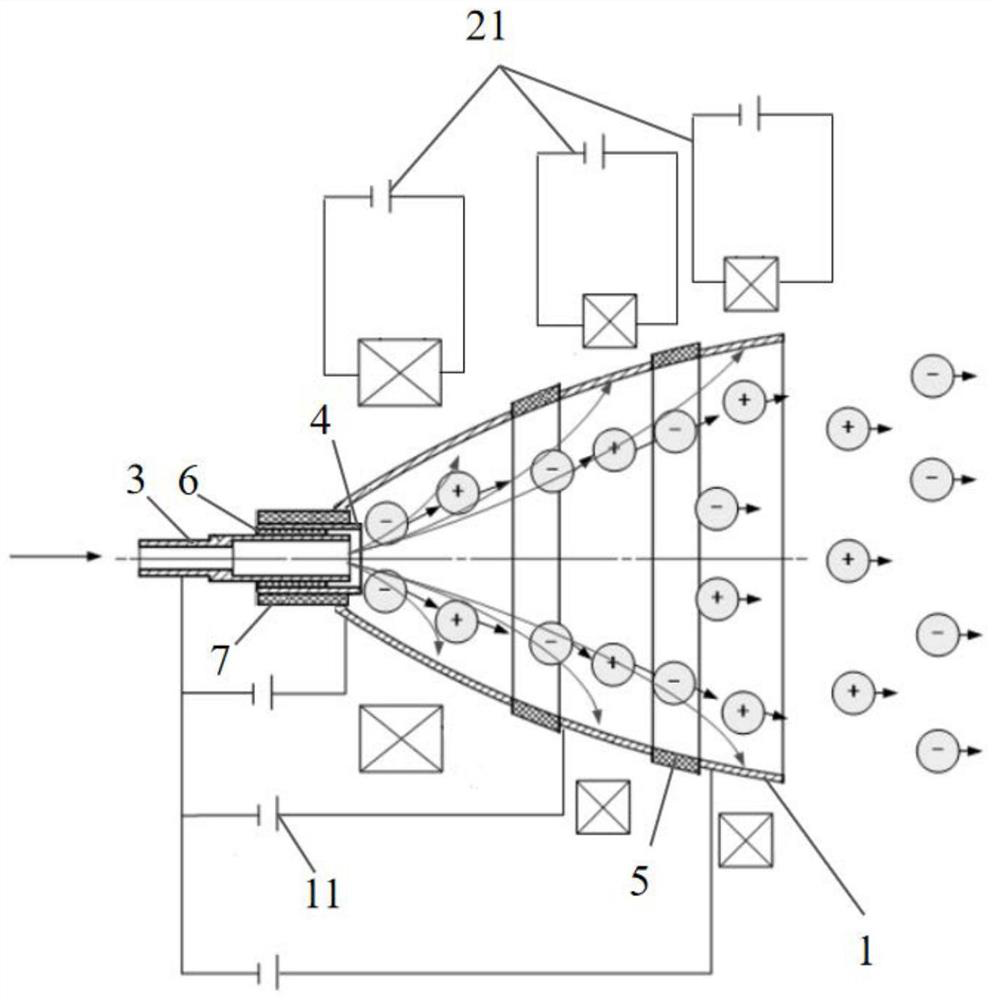

[0050] see figure 1 , the present invention is a plasma generation device based on a multi-level magnetic field and a multi-section nozzle, including a working fluid supply distribution unit and a plasma generation acceleration unit, and the entire plasma generation device is a coaxial structure.

[0051] The working fluid supply and distribution unit includes a working fluid distributor 3 coaxially arranged from inside to outside, a second insulator 6, a transition electrode 4 and a third insulator 7; the working fluid passed into the working fluid distributor 3 is an inert gas, nitrogen Or air; In this embodiment, the working medium is an inert gas. The working fluid distributor 3 is made of oxide-dispersed strengthened tungsten alloy. Therefore, the working fluid distributor 3 made of this material also has the function of a cathode, and has the characteristics of easy emission of electrons and low starting voltage; the first insulator 5. Both the second insulator 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com