Multi-stirring-shaft vacuum vapor deposition furnace special for powder

A multi-stirring, air-phase technology, applied in pressure vessels/vacuum vessels, gaseous chemical plating, pressure vessels used in chemical processes, etc., can solve the problem of low efficiency, insufficient contact with the converter, and low vacuum degree of the fluidized fluidized furnace, which is difficult to meet product quality Demand and other issues, to achieve the effect of easy operation, firm bonding, and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

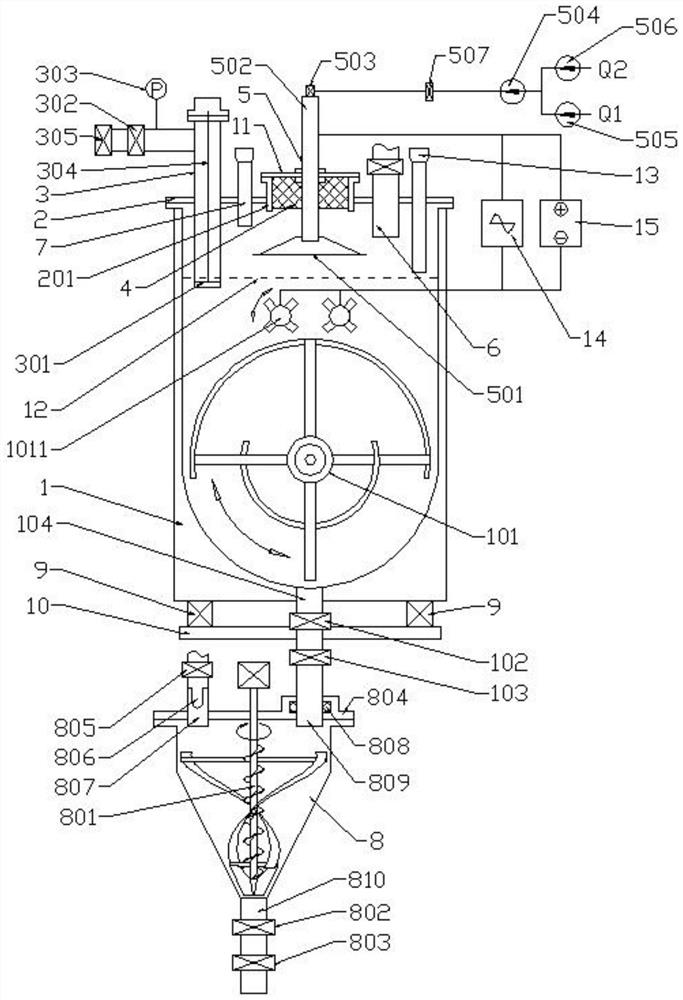

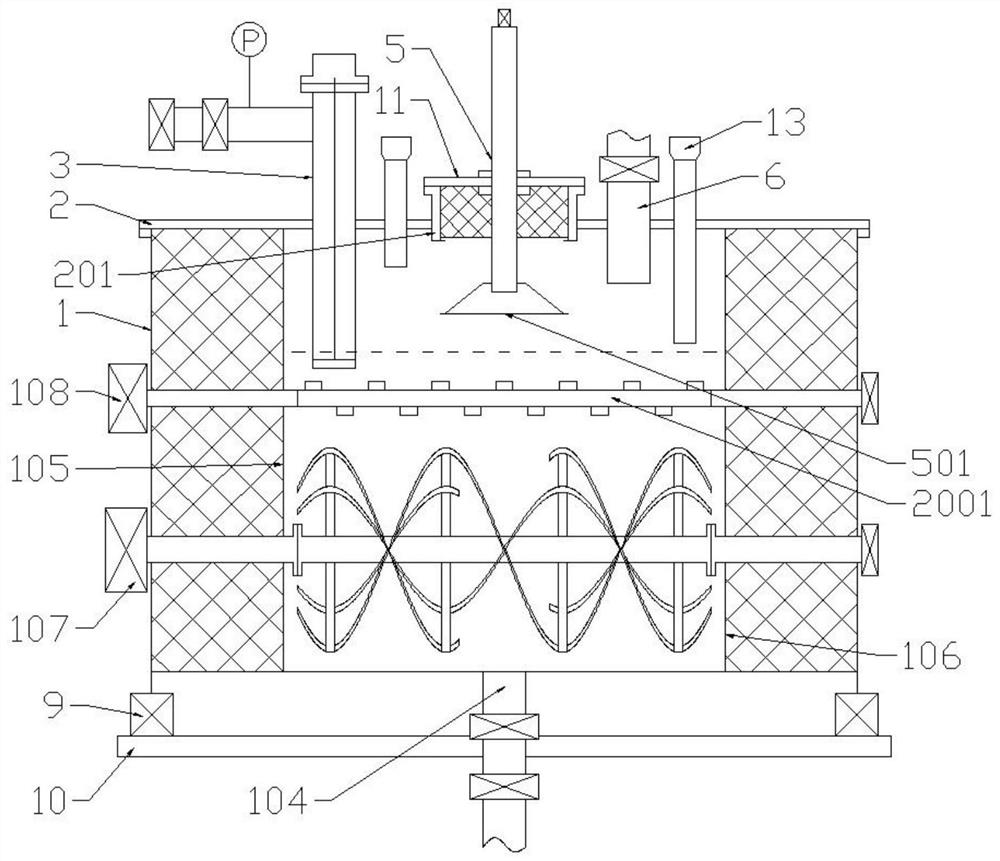

[0036] Such as figure 1 As shown, a multi-shaft vacuum vapor deposition furnace dedicated to powder includes a heating furnace body, a cooling furnace body 8, a load cell 9, and a vacuum channel and an exhaust channel 4 arranged on the furnace cover 11 of the heating furnace body. , upper electrode 5, feed pipe 6, temperature measuring component 7, including furnace body 1 and furnace cover 11. The heating furnace body is connected with the cooling furnace body 8 through a discharge pipe 104 .

[0037] Such as figure 1 As shown, the furnace shaft 1 is a container, and this embodiment is a trough-shaped container welded by a U-shaped trough and two end plates. Such as figure 2As shown, the heating furnace body is provided with a low-speed stirring shaft 101 and a high-speed stirring shaft 1011, both of which run through the end plates at both ends of the U-shaped groove and are connected with the driving devices 107 and 108 outside the end plates. A partition 105 and a par...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the heating element is electromagnetic heating, the outer side of the U-shaped groove housing is provided with an insulating layer, and the outer side of the insulating layer is provided with an electromagnetic induction heating device.

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that the upper electrode is arranged on the upper end of the furnace body, and the upper electrode plate is arranged corresponding to the upper and lower sides of the high-speed stirring shaft to form the working area of the upper and lower electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com