Automatic dyeing device and control method thereof

An automatic dyeing and controller technology, applied in the field of biochemical dyeing, can solve the problems of large amount of reagents, small application range, uneven coverage of dye solution, etc., to reduce the phenomenon of uneven dye solution, improve dyeing efficiency and precision, Ease of daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

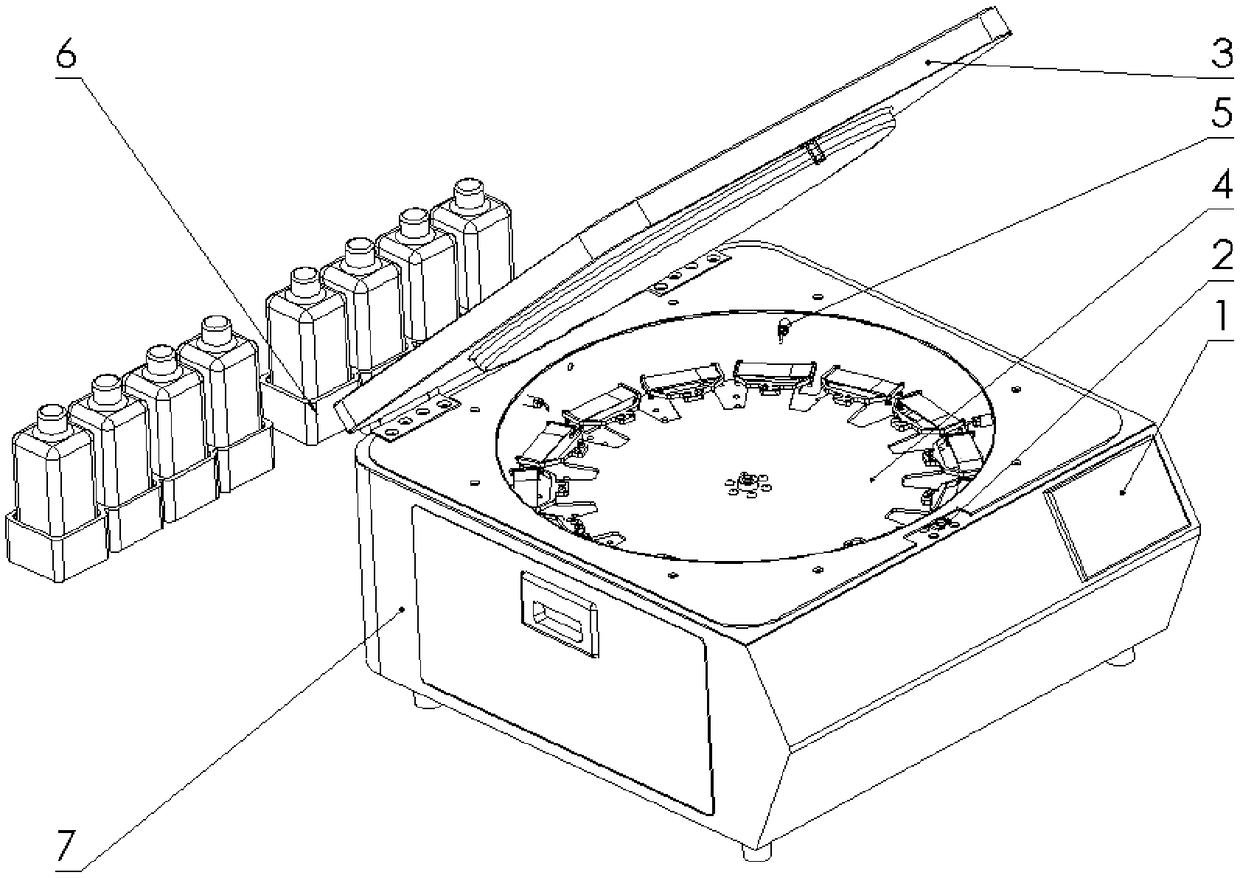

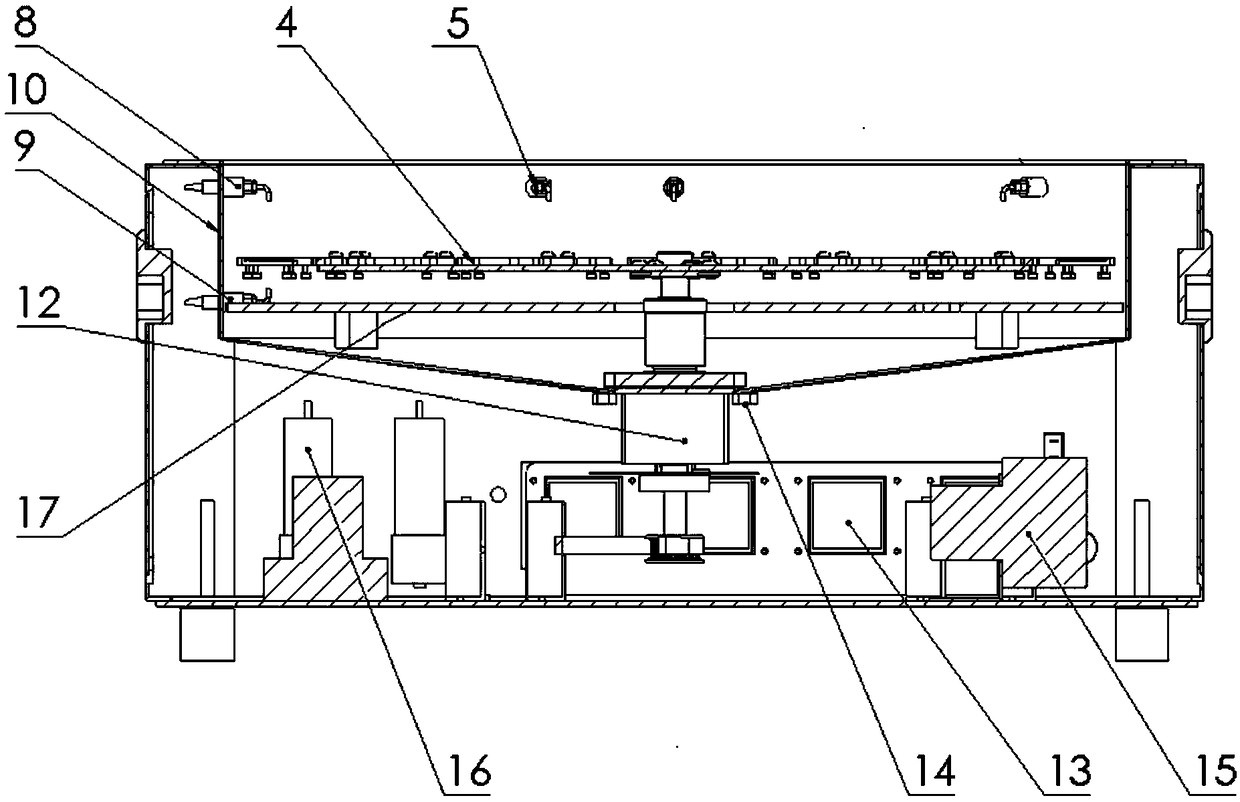

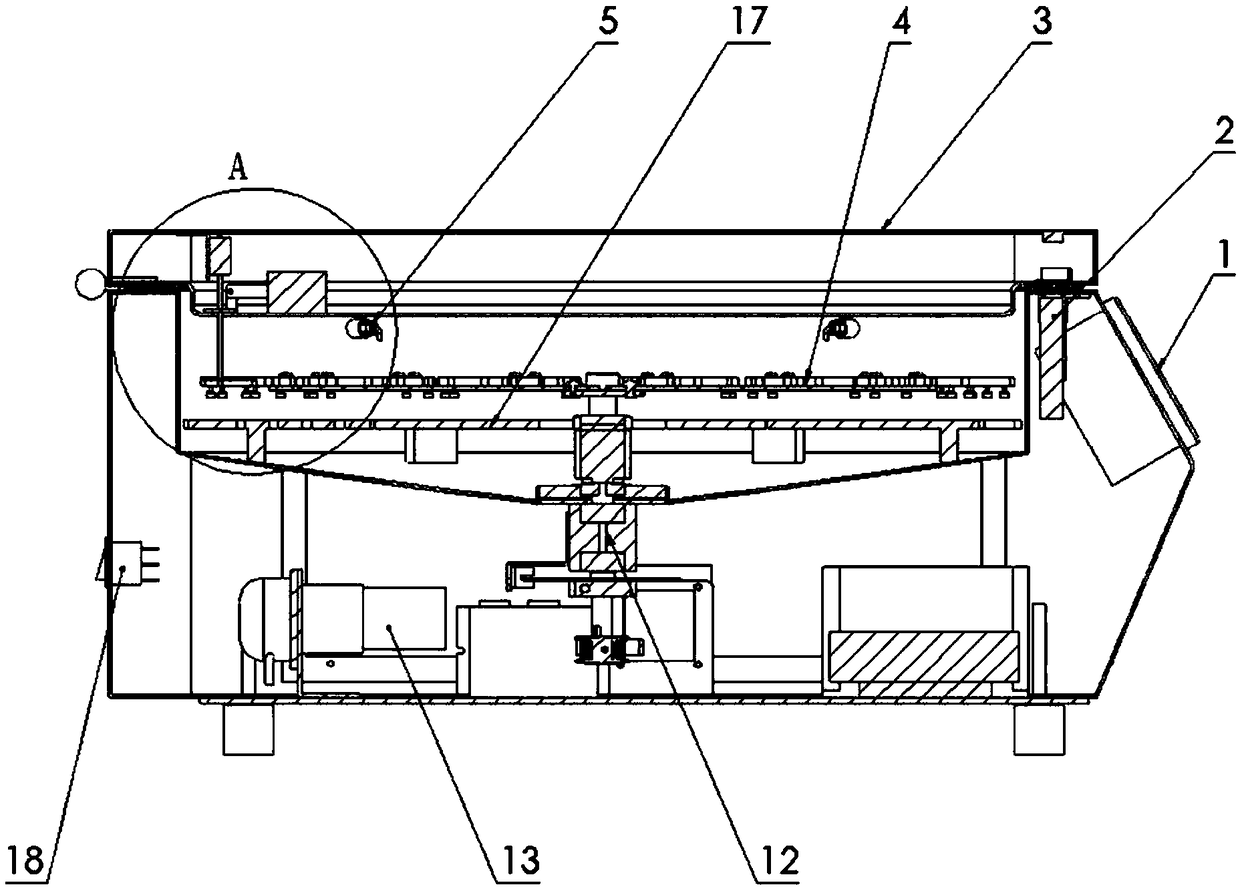

[0050] Such as Figure 1-6 As shown, the automatic dyeing device of the present invention includes a housing 7, a cover 3, a dripping mechanism installed in the housing 7 for dripping and dyeing a sample, a detection mechanism for detecting the position and quantity of the sample, and A cleaning mechanism inside the cleaning device, a rotating mechanism for centrifuging samples, and a reagent detection mechanism for detecting the amount of reagents installed on the outside of the housing 7. The housing 7 is provided with a cover lock 2 and a cover lock 2 Used to lock the position of the cover plate 3 so that the housing 7 forms a closed space; the dripping mechanism includes a plurality of dripping nozzles 5 and a dye peristaltic pump 13, which passes through the dripping pipeline and the dripping nozzle 5 Connection; the detection mechanism includes a sensor support 20, a sensor 19, a protective baffle 23, and a pushing component 22 mounted on the cover 3, the sensor support 2...

Embodiment 2

[0067] On the basis of Embodiment 1, a display screen 1 is installed on the housing 7, and the controller is electrically connected to the display screen 1. The display screen adopts a touch screen to facilitate the user to select an experiment mode.

[0068] When pipeline maintenance is required, take a pipeline connected with a reagent bottle as an example. The dye peristaltic pump 13 is turned over to recover the reagents in the pipeline into the reagent bottle. After the recovery is completed, the dye peristaltic pump 13 is stopped and then turned on The solenoid valve communicated with the cleaning water pump 16, the cleaning liquid enters the dyeing liquid pipeline to flush the pipeline.

[0069] A liquid level sensor is inserted in the reagent bottle to monitor the remaining amount of the reagent in the reagent bottle, and is electrically connected to the controller and the display screen 1 to remind the user to replace the reagent in time.

Embodiment 3

[0071] On the basis of embodiment 1, a heating assembly is also provided in the housing 7 for heating the interior of the housing 7. The heating assembly includes a heater and a temperature sensor, and the heater and the temperature sensor are electrically connected to the controller. When the reagent needs Jarvan, start the heater to heat the reagent in the pipeline. After the temperature sensor detects that the reagent is heated to a preset threshold temperature, the dye solution peristaltic pump 13 is started to work, and the reagent is sprayed from the drip nozzle 5.

[0072] Furthermore, the controller can be programmed to preset a variety of experiments, and the reagent types and experimental requirements can be modified according to the needs of users.

[0073] The device can increase or decrease the number of the dripping nozzle 5, the dye peristaltic pump 13 and other components according to the experimental requirements, and the types of reagents are not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com