Method for increasing fresh tealeaves enzymatic-synthesized theaflavin productive rate

A technology of theaflavins yield and enzymatic synthesis, applied in the direction of tea treatment before extraction, etc., can solve the problem of limiting the quality of black tea, not specifying the conversion rate of theaflavins of tea catechins, and not specifying the four kinds of monomer theaflavins Content and instant green tea powder specifications and other issues, to achieve the effect of increasing yield

Active Publication Date: 2014-04-30

HANGZHOU TEA RES INST CHINA COOP

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Chinese Patent Authorization Publication No. CN102228100B discloses a method for making high theaflavin black tea, which uses foreign instant green tea powder of a certain concentration (0.2%-1%, w / v) sprayed on the surface of withered fresh tea leaves Aqueous solution, and then after traditional rolling, fermentation and drying, black tea with the total amount of theaflavins higher than 2% (w / w); Content of a single theaflavin and specification of instant green tea powder

However, under the conditions of traditional technology, it is not known how to increase the content of four main theaflavins in black tea without adding foreign tea polyphenols or oxidase pathways, thus limiting the quality of black tea in my country

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0039] 1. Experimental materials and methods

[0040] 1.1. Experimental materials

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of tealeaves processing, in particular to a method for increasing the productive rate of theaflavoin formed by converting catechinic acid in fresh tealeaves. The adopted scheme is as follows: storing harvested fresh tealeaves into a soft sealed bag, carrying out vacuum sealing on the bag (controlling the vacuum degree at minus 0.1MPa to minus 0.01MPa), adequately freezing the fresh tealeaves, warming the tealeaves under an ambient temperature which is more than zero (about 4 to 37 DEG C) for 2 to 15h, and promoting the catechinic acid to be enzymatically synthesized into theaflavin. After the reaction is ended, the high-temperature withered fresh tealeaves can be directly processed into bar-shaped red tea, flat red tea or twisted into coiled red tea; the mass percent of four theaflavin monomers (theaflavin, theaflavin-3-gallate, theaflavin-3'-gallate and theaflavin-3,3'-bi-gallate) in a dry sample of the prepared read tea is more than or equal to 2 percent of the total mass percent.

Description

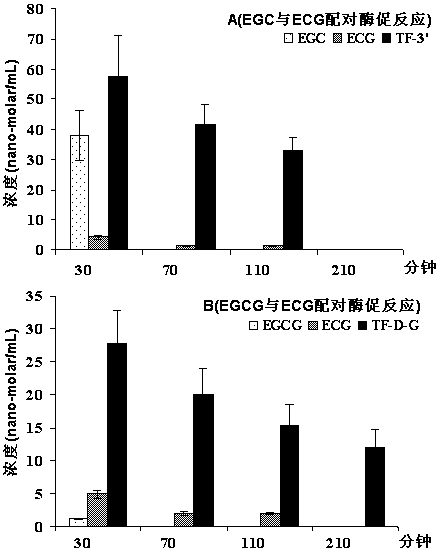

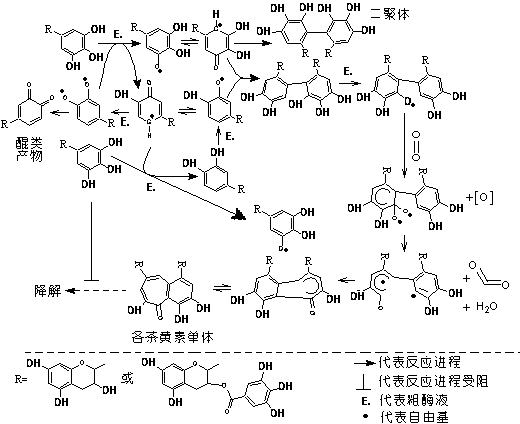

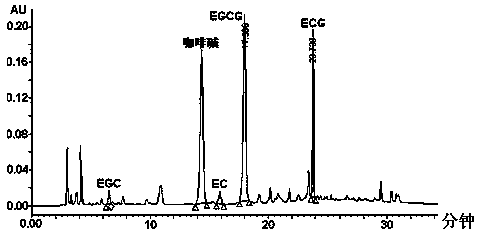

technical field [0001] The invention relates to the field of tea processing, and more specifically, relates to a method for increasing the yield of theaflavins from catechins in fresh tea leaves. Background technique [0002] As a mainstream tea drink in the world, black tea has attracted much attention for its polyphenolic compound theaflavins. Theaflavins were originally identified by Roberts (Roberts A T H. the phenolic substances of manufactured tea (I). J Sci Food Agric, 1957, (8): 72-78) was isolated and identified from black tea extract, and was named because the solid was orange-yellow. tea tree( Camellia Sinensis ) fresh leaves themselves do not contain theaflavins, but under the traditional black tea processing technology, after wilting treatment and kneading or shearing, the destruction of leaf cells in fresh tea leaves promotes endogenous oxidase, oxygen and catechins (such as Epigallocatechin EC, epicatechin gallate ECG, epigallocatechin EGC, epigallocatech...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23F3/06

Inventor 涂云飞张士康杨秀芳朱跃进

Owner HANGZHOU TEA RES INST CHINA COOP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com