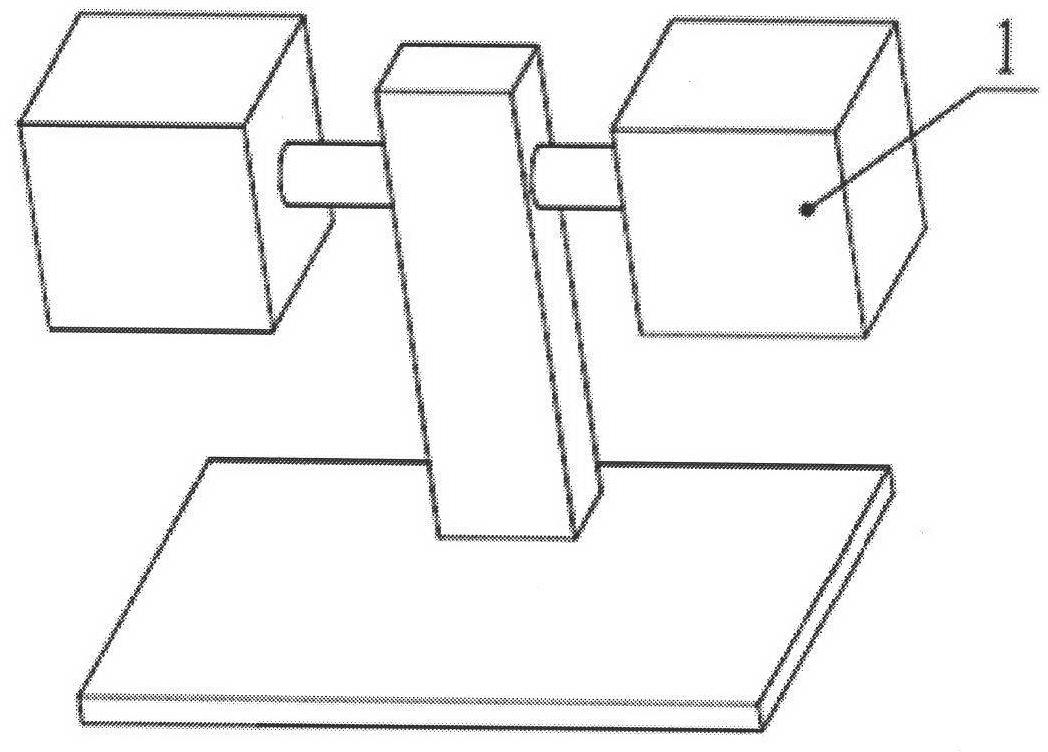

Testing apparatus and testing method for textile resistance of solid state dirt contamination

The technology of a testing device and a testing method, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of being unable to be widely used and difficult to obtain uniform standard dirty cloth, etc., so as to achieve easy disassembly and cleaning, accurate test results, little elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: test fabric is the white down jacket fabric of antifouling finishing

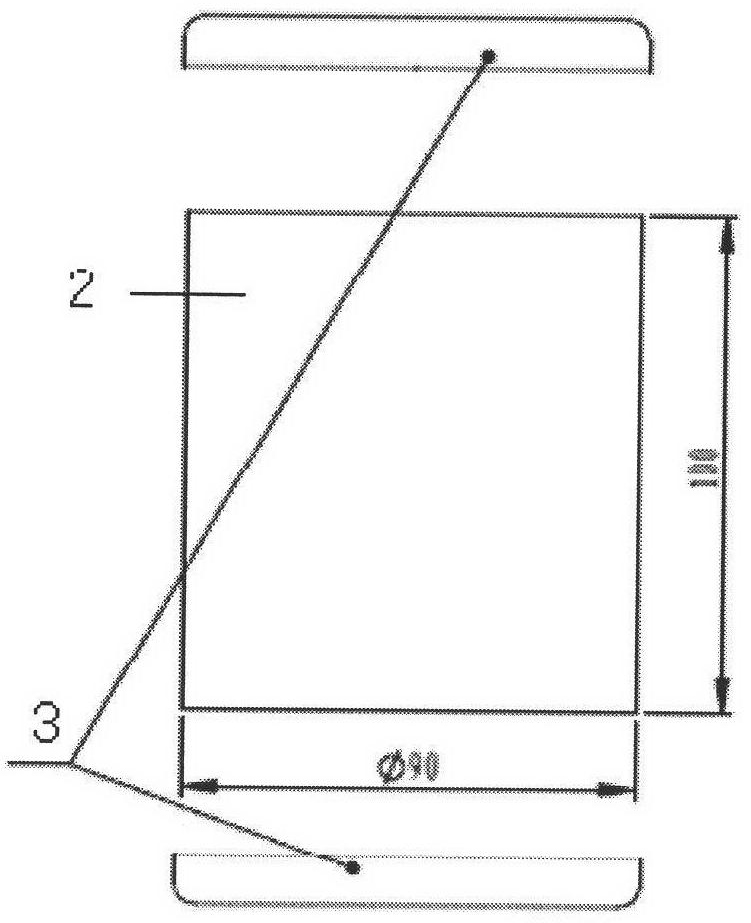

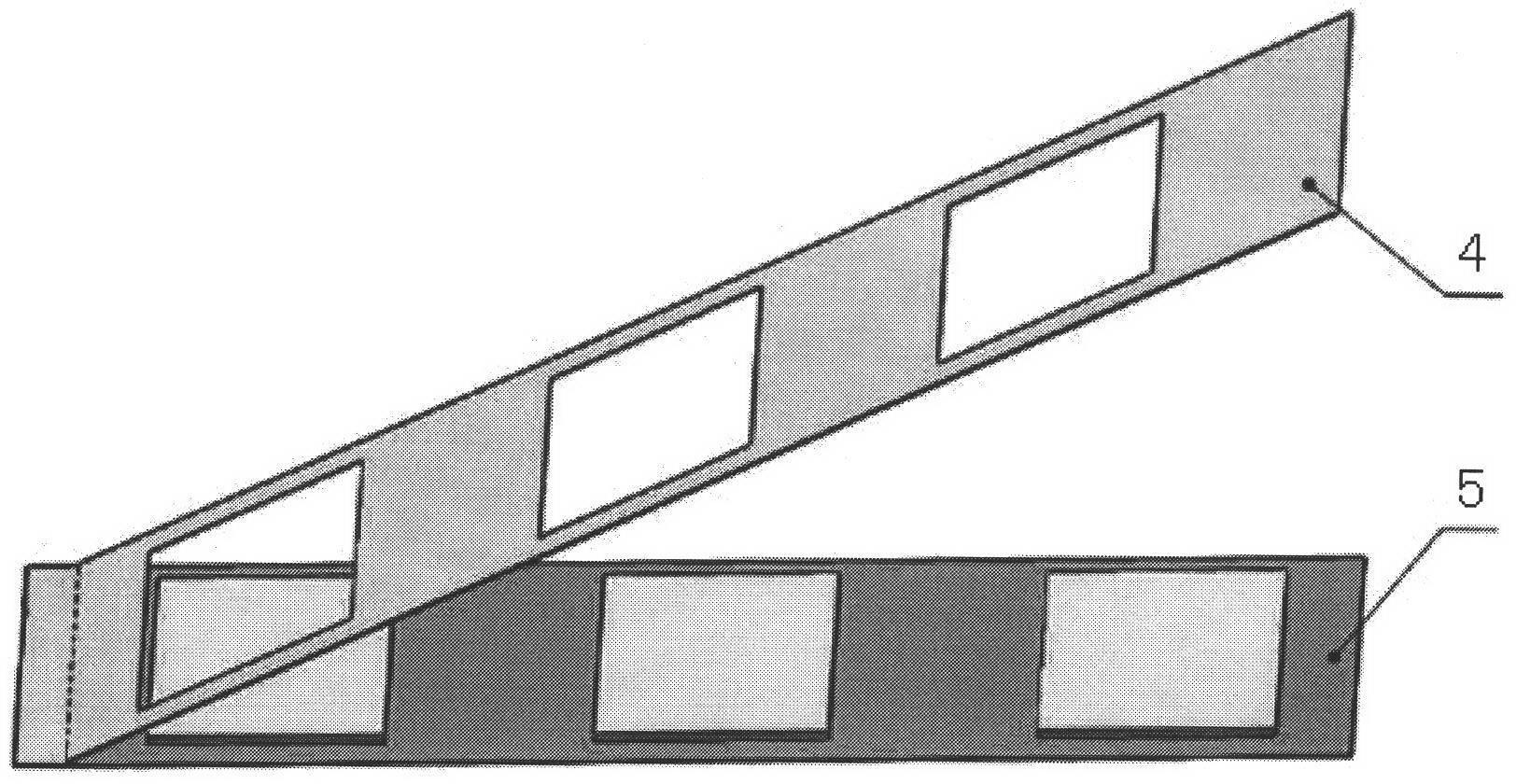

[0033] Take 3 samples with a size of 70mm×100mm and place them on the elastic gaskets of the lower clamping piece respectively, and press the upper clamping piece down on the sample, so that the rectangular hole and the elastic gasket and the sample bite together. Roll the sample fixture into a cylindrical shape along its length and put it into the cylinder, then fasten a cylinder cover with the cylinder body, put the cylinder into the inversion box, close the box cover, and start the inversion box, stop after turning 200r . Take out the sample, blow off the dirt attached to the surface of the sample with a hair dryer, use the original sample as a comparison sample, and use the gray scale for color fastness staining of textiles to evaluate the staining grade of each sample. The staining grades of the three samples are respectively grade 3, grade 3 and grade 3.5, so the grade of antifouli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com