Blowing/suction-type carbon powder collecting device for throughflow horizontal generator unit

A technology for generating sets and collecting devices, applied in the directions of cleaning methods and utensils, removing smoke and dust, chemical instruments and methods, etc., can solve the problems of contamination of stator windings and excitation windings, short service life, and rising surface temperature of slip rings, etc. Temperature, improve dust removal effect, reduce quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

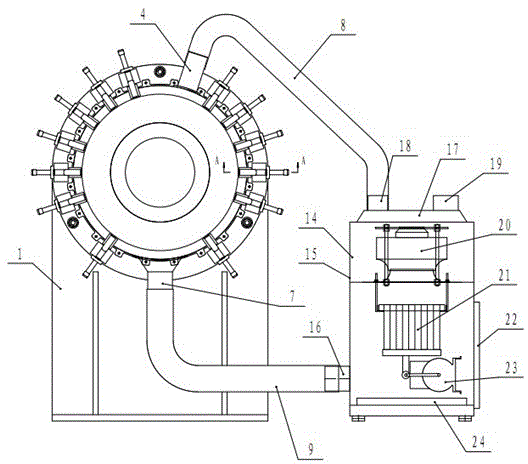

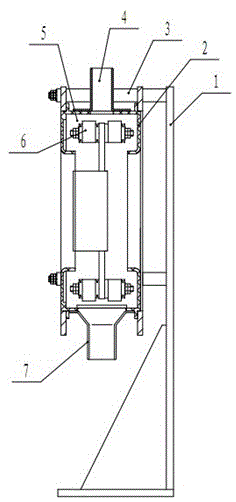

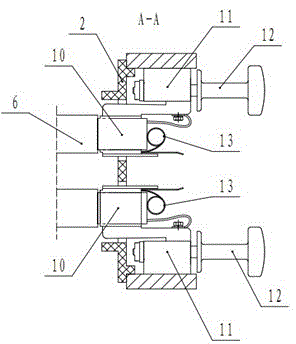

[0019] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

[0020] Such as Figure 1-3 As shown, the present invention cooperates with the slip ring and the carbon brush assembly to form a device that provides excitation current to the excitation device on the rotor. In this embodiment, the carbon brush assembly 11 is composed of two groups of charged detachable carbon brush brush boxes 12, carbon brushes 10, and a constant pressure coil spring 13 arranged at the end of the carbon brush 10 arranged in front and rear. The carbon brushes 10 in the brush box 12 are respectively used as current input or output terminals, respectively contacting the slip ring 6 on the rotor, and the slip ring 6 is connected to the positive and negative electrodes of the excitation device to form a closed current loop. Betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com