Molten steel atomizing disc, atomizing and pelleting equipment and atomizing and pelleting method

A technology of atomizing disc and molten steel, which is applied in the field of stainless steel shot atomizing and spraying disc, can solve the problems of reducing the proportion of fine particle steel shot and affecting the blowing degree of molten steel, so as to achieve large spraying volume, prevent metal oxidation, and prevent steel shot The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

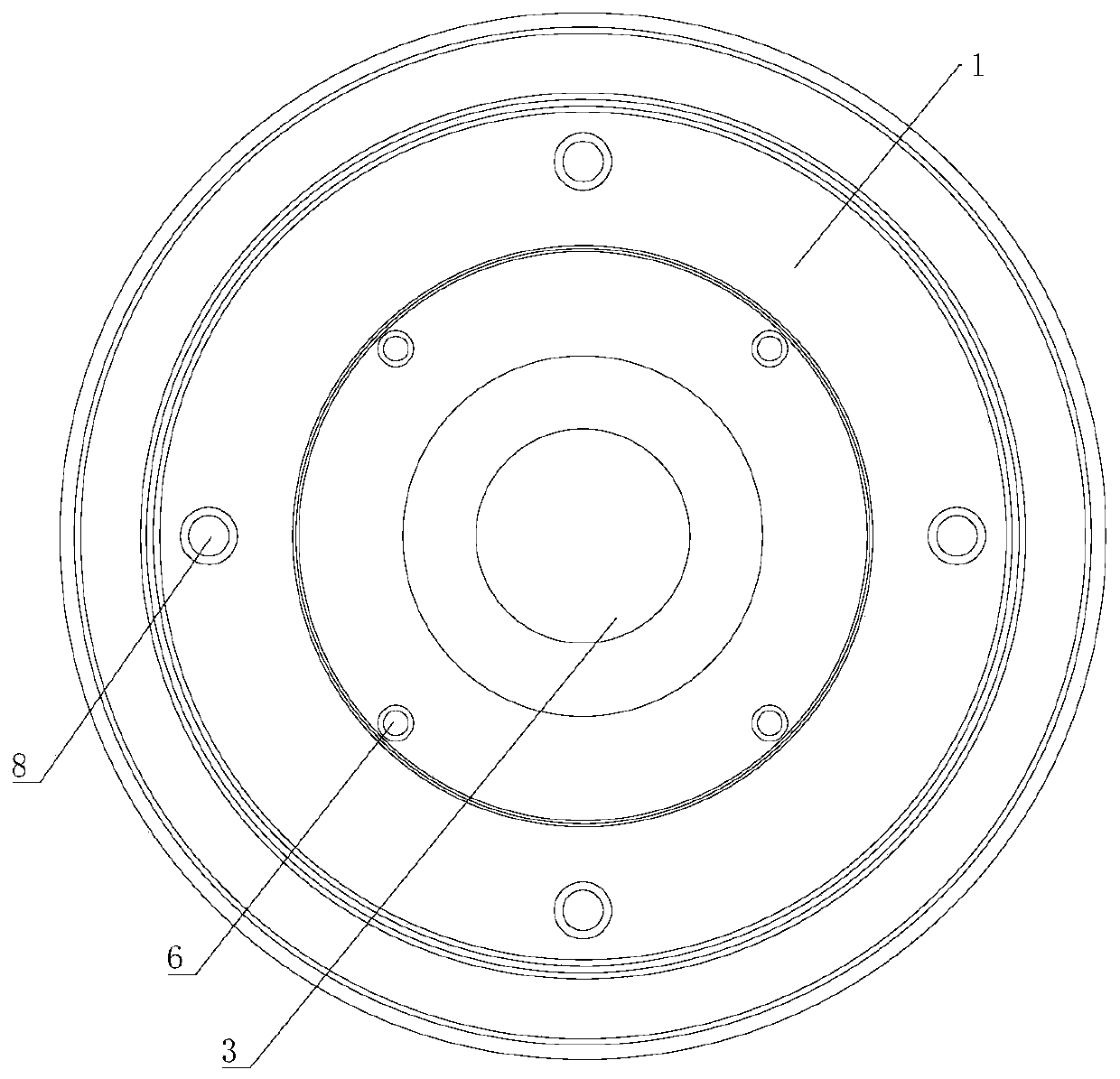

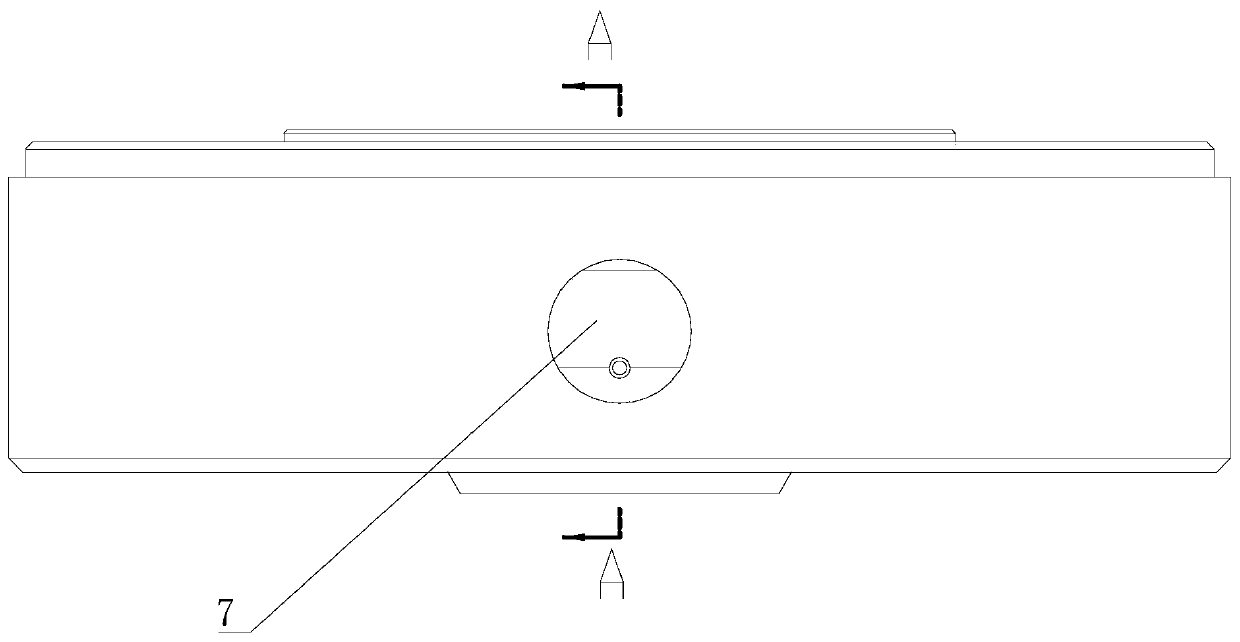

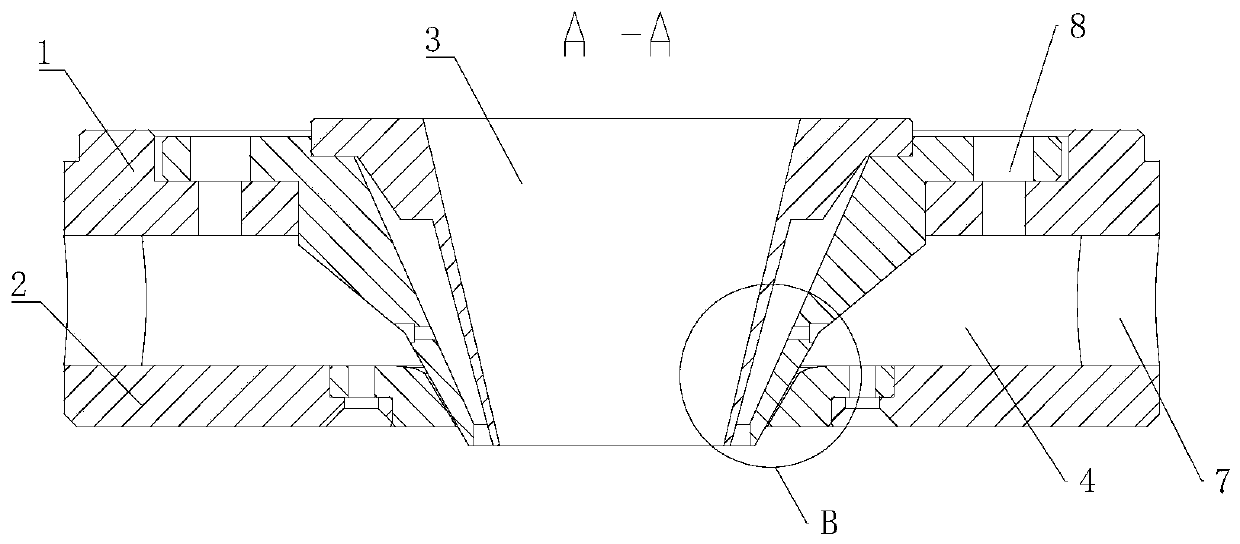

[0027] A molten steel atomization disc, such as figure 1 with 3 As shown, the upper spray plate 1 and the lower spray plate 2 are coaxially arranged. In this embodiment, the upper spray plate 1 and the lower spray plate 2 are both set as circular metal plates, and the upper spray plate 1 and the lower spray plate 2 are Both cone holes 3 are provided, and the two cone holes 3 are coaxial with the upper spray plate 1 and the lower spray plate 2. The cone hole 3 of the upper spray plate 1 falls in the cone hole 3 of the lower spray plate 2. Between the upper spray plate 1 and the lower spray plate 2 are reserved an air cavity 4 allowing air flow to pass, and a Laval structure annular gap 5 connected to the air cavity 4. The air cavity 4 is arranged as an annular hollow cavity, and is arranged coaxially with the upper spray plate 1 and the lower spray plate 2. Such as Figure 4 As shown, the air cavity 4 is close to the center axis of the upper spray plate 1 or the lower spray pla...

Embodiment 2

[0035] A kind of atomized pelletizing equipment, mainly used to manufacture steel shot or steel grit, including the equipment body. The equipment body is provided with an air inlet and a molten steel inlet. For the equipment using the molten steel atomizing disc in embodiment 1 In other words, except for the air inlet, the molten steel inlet, and the molten steel atomizing plate, the necessary components are no different from conventional molten steel output equipment. The air inlet is communicated with the air inlet 7 and is used to input nitrogen into the air inlet 7. As an optimized structure, it can also communicate with the air supplement hole 6 to facilitate the input of gas through the air supplement hole 6. The molten steel inlet is communicated with the cone hole 3 on the upper spray plate 1 and is used to input the molten steel to be atomized into the cone hole 3.

[0036] In this embodiment, the nitrogen output from the air inlet of the atomizing pelletizing equipment ...

Embodiment 3

[0038] An atomized pelletizing method employs the molten steel atomizing disk in Example 1 and the atomized pelletizing equipment in Example 2. Including the following steps:

[0039] S1: Input high-pressure atomized inert gas into the inlet 7; the inert gas in this embodiment is nitrogen, and the nitrogen enters from the inlet 7 on both sides of the upper and lower spray discs 2, which is formed by the linear inlet 7 Enter the air cavity 4 in a tangential direction. After the airflow from the air inlets 7 on both sides enters the air cavity 4, it has a tangential acceleration. The airflow in the air cavity 4 flows in the annular air cavity 4 and is also output to the narrow throat. It is more convenient to form a conical air vortex.

[0040] S2: Input molten metal into the cone 3 of the upward spray plate 1;

[0041] It should be noted that the liquid metal does not start to be input until the airflow enters the air inlet 7 and forms a conical cyclone, so that the liquid metal can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com