Circumferential seam type supersonic nozzle for metal gas atomization

A supersonic nozzle and gas atomization technology, which is applied in liquid injection devices, injection devices, etc., can solve the problems of gas energy loss, shock waves, and large turbulence, so as to reduce energy loss and turbulence, reduce effect of chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

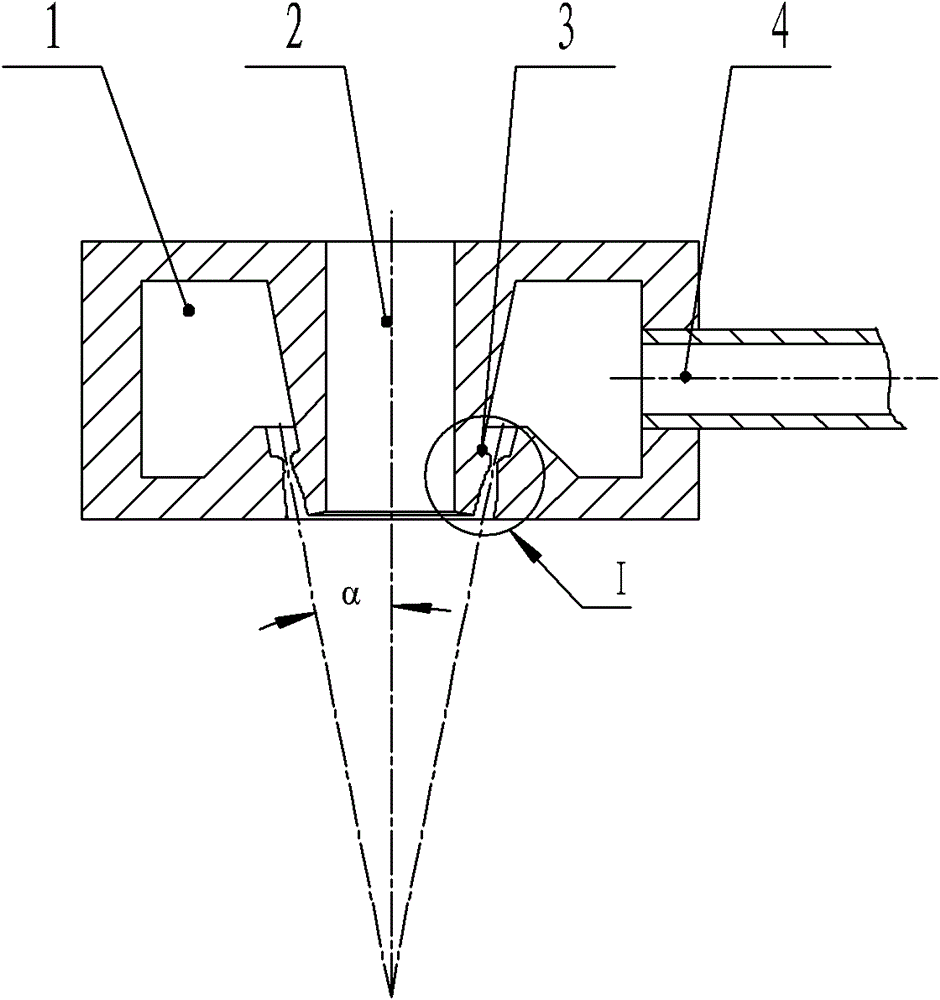

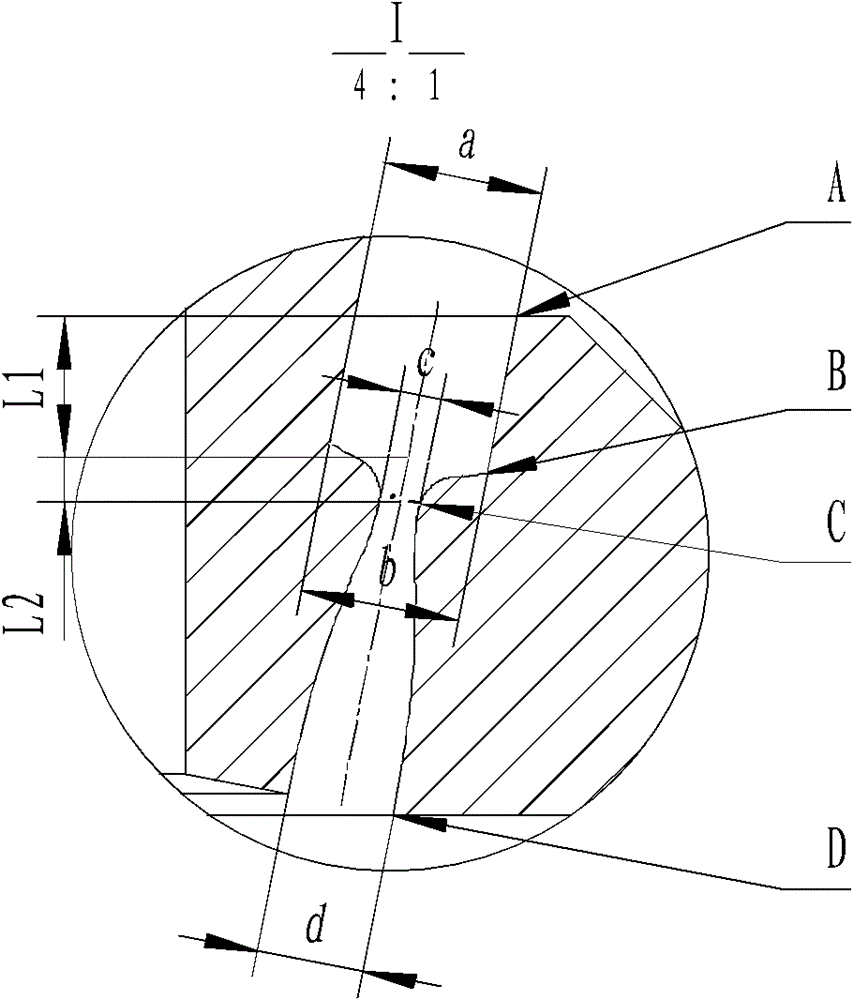

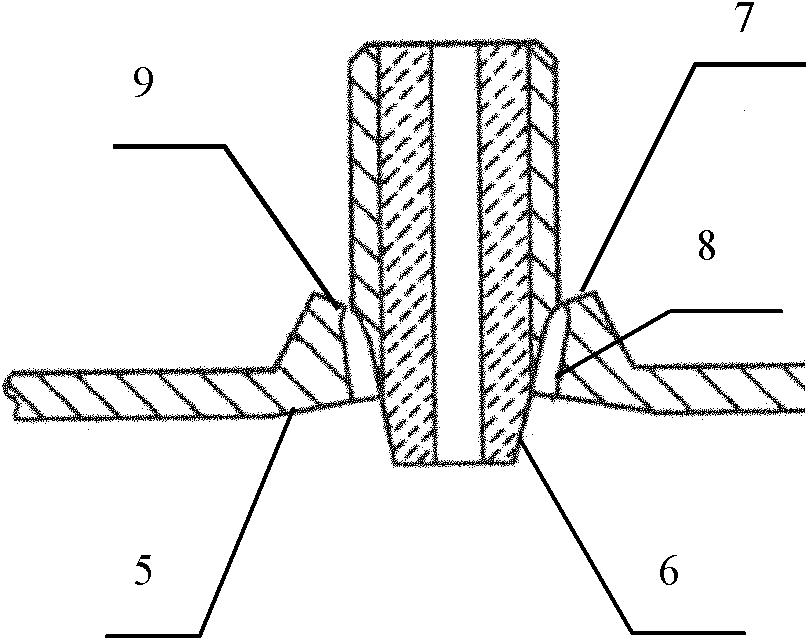

[0044] In this embodiment, the FeNi30 alloy melt flows out of the nozzle at a temperature of 1650°C. The ratio of the throat slit width c of the gas nozzle to the exit slit width d is 1:1.7, and the stable section L 1 The ratio to a is 1:1, the ratio of the stable section a to the throat c is 5:1, and the length of the contraction section is L 2 The ratio to b is 1:2, and the angle α is 15°. The atomizing gas is nitrogen, the atomizing pressure is 4.0MPa, and the pressure in the atomizing chamber is 0.1MPa. The particle size distribution curve of the metal powder is as follows Figure 5 As shown, the SEM photo of the metal powder is as follows Figure 6 shown. The average particle diameter of the produced powder is 27.1 μm, 10 wt% is less than 11.2 μm, and 90 wt% is less than 60.6 μm.

Embodiment 2

[0046] The material is 17-4PH stainless steel melt, which is sprayed from the diversion nozzle at a temperature of 1600°C, and the inner diameter of the diversion nozzle is 4.0mm. The ratio of the throat slit width c of the gas nozzle to the exit slit width d is 1:3, and the stable section L 1 The ratio to a is 1:2, the ratio of the stable section a to the throat c is 4:1, and the length of the contraction section is L 2 The ratio to b is 1:2, and the angle α is 20°. The atomizing gas is nitrogen, the atomizing pressure is 3.5MPa, and the pressure in the atomizing chamber is 0.1MPa. The SEM photo of 17-4PH stainless steel powder is as follows Figure 7 shown. The powder achieved an average particle diameter of 22.1 μm, with 16 wt% smaller than 9.1 μm and 84 wt% smaller than 41.7 μm.

Embodiment 3

[0048] In this embodiment, the ratio of the throat slit width c of the gas nozzle to the exit slit width d is 1:2, and the stable section L 1 The ratio to a is 1:2, the ratio of the stable section a to the throat c is 5:1, and the length of the contraction section is L 2 The ratio to b is 1:2, and the angle α is 20°. The atomization gas is argon, the atomization pressure is 2.0MPa, and the pressure in the atomization chamber is 0.1MPa. The atomization temperature of CuSn20 alloy melt is 1200℃. The SEM photo of CuSn20 powder is as Figure 8 shown. 10 wt% of the atomized powder is less than 5.6 μm, 90 wt% is less than 25.2 μm, and the average diameter D50 is 13.6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com