Oil cooler

An oil cooler and oil cooling technology, which is applied to indirect heat exchangers, heat exchanger shells, heat exchanger types, etc., can solve the problems of oil cooler heat dissipation performance degradation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

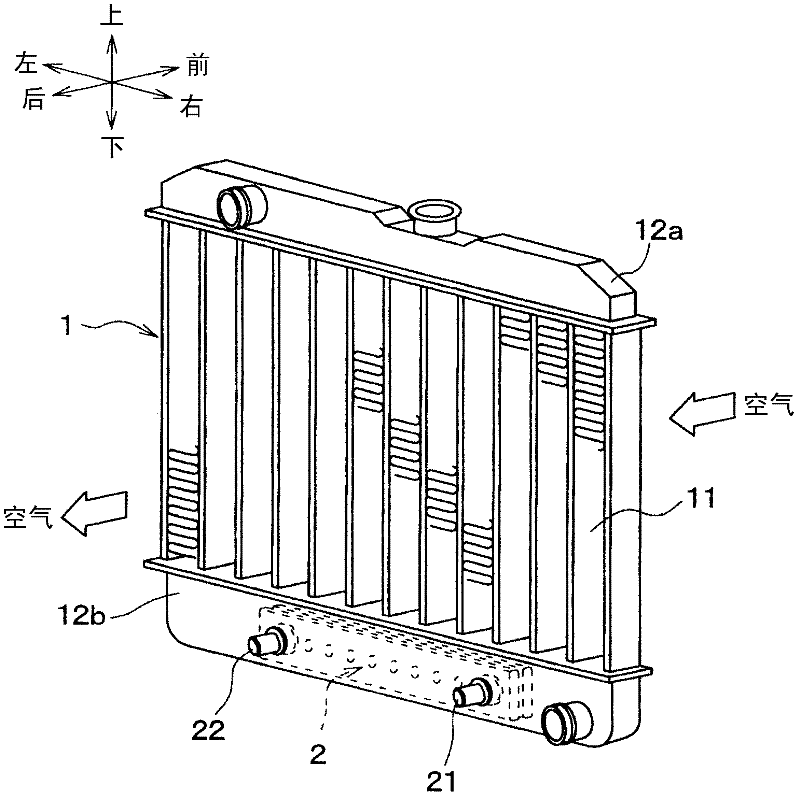

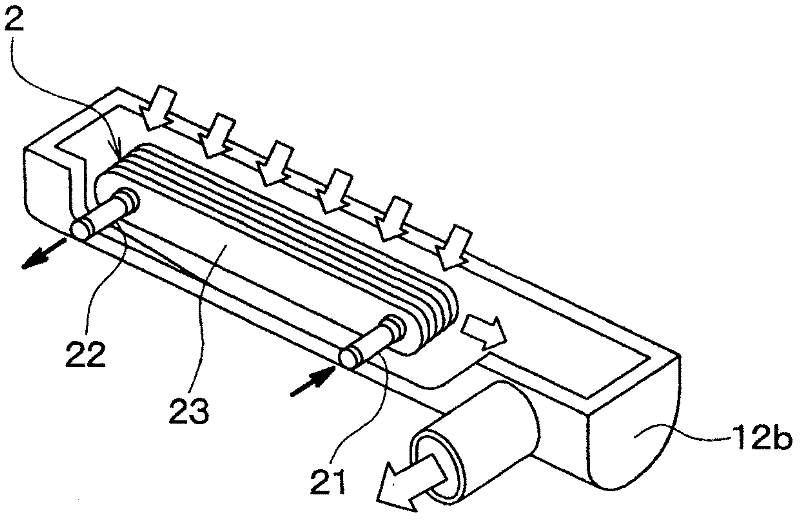

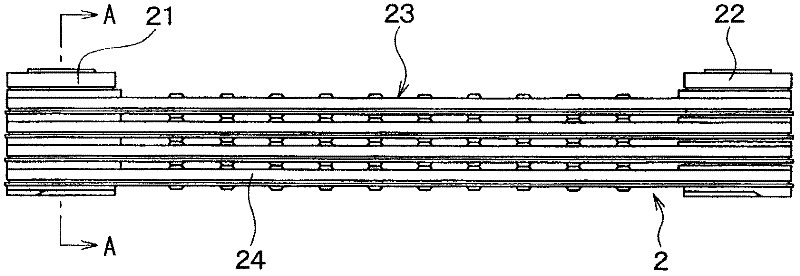

[0036] figure 1 It is a perspective view showing the radiator 1 incorporating the oil cooler 2 of this embodiment. Such as figure 1 As shown, the radiator 1 of this embodiment has a plurality of radiator pipes 11 made of aluminum through which the engine cooling water flows, and aluminum pipes 11 arranged on both ends in the longitudinal direction of the radiator pipes 11 and communicating with the plurality of radiator pipes 11 . Made of the first radiator tank 12a and the second radiator tank 12b.

[0037] The first radiator tank 12 a is connected to the longitudinal upper ends of the plurality of radiator pipes 11 , and distributes engine cooling water to the plurality of radiator pipes 11 . In addition, the second radiator tank 12 b is connected to the lower ends in the longitudinal direction of the plurality of radiator pipes 11 , so that the engine cooling water flowing out from the plurality of radiator pipes 11 is collected.

[0038] In the second radiator tank 12b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com