Method and device for inspecting containers

A technology of containers and conveying devices, which is applied in the field of inspection containers and can solve the problems of liquid refilling and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

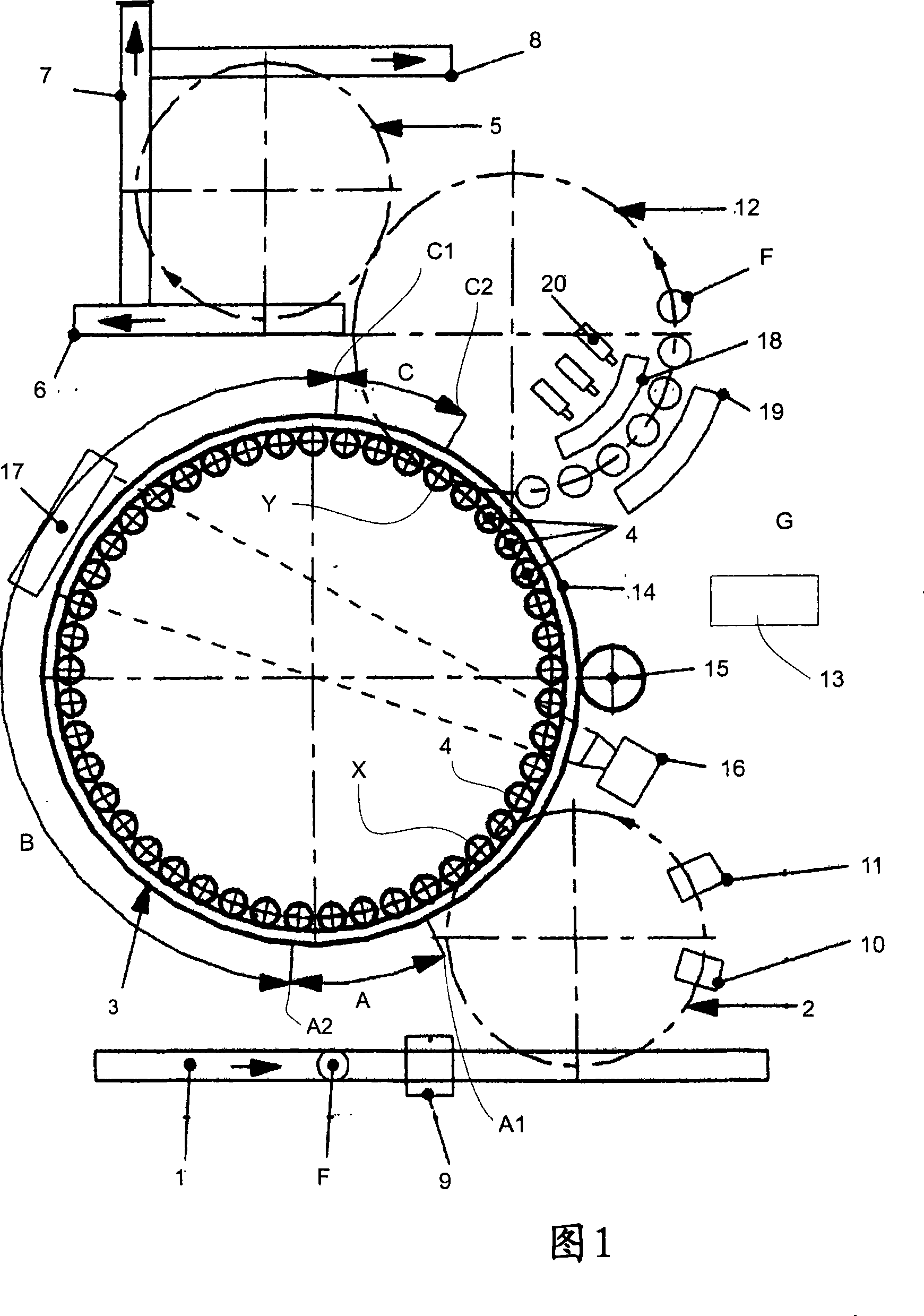

[0036] The device for inspecting filled and sealed containers, in the present case beverage bottles, shown schematically in FIG. 1 is specially designed for inspecting bottles made of transparent or translucent material. The bottles F to be inspected are preferably fed continuously to an inlet star wheel 2 via an inlet conveyor 1 , for example on an upstream bottle filling and sealing machine.

[0037] In this case, before being taken over by the inlet star wheel 2, the bottles pass through a permanently arranged inlet inspection 9, which checks the presence of a seal and, if necessary, also the filling level. In order to avoid excessive acceleration of the container, which in turn could lead to contamination of the testing device by liquid escaping from the unsealed bottle, these defectively sealed bottles F are not gripped by the inlet star wheel 2 but only in the tangential direction Pass through and lead to a rear collection point. Do the same with overfull or underfilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com