Supersonic atomizer for preparing iron-based spherical metal powder through crucible gas atomization method

A gas atomization method and metal powder technology, which is applied in the field of metal powder material preparation, can solve the problems of small metal powder particle size, uneven airflow, narrow particle size distribution, etc., and achieve reduced turbulence and uniform airflow velocity distribution , the effect of narrow particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

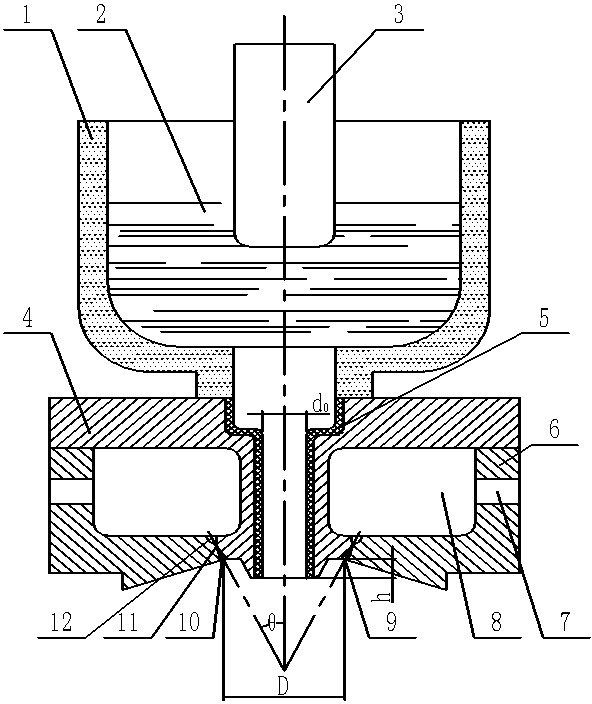

[0017] Specific Embodiment 1: This embodiment describes a supersonic atomizer for preparing iron-based spherical metal powder by using the crucible gas atomization method. The supersonic atomizer includes a crucible 1, a plunger 3, an upper Cover 4, catheter tube 5, lower cover 6, air inlet 7, air cavity 8 and laval type annular seam 9;

[0018] The upper cover 4 is provided with a central shoulder hole, the catheter 5 is installed in the central shoulder hole, the lower part of the upper cover 4 is provided with a lower cover 6, the upper cover 4 and the lower cover 6 is sealed and connected, the space between the upper cover 4 and the lower cover 6 forms an air cavity 8, and the side of the lower cover 6 is provided with an air inlet 7 communicating with the air cavity 8; A Laval-shaped annular seam 9 is formed between the inner sides, and the Laval-shaped annular seam 9 is coaxial with the central shoulder hole of the upper cover 4;

[0019] The upper end surface of the up...

specific Embodiment approach 2

[0020] Specific embodiment two: a supersonic atomizer for preparing iron-based spherical metal powder by crucible gas atomization method described in specific embodiment one, between the upper cover 4 and the lower cover 6 and between the crucible 1 and the Sealing rings are used to seal between the upper covers 4, and bolts are used to connect them respectively.

specific Embodiment approach 3

[0021] Embodiment 3: Embodiment 1 is a supersonic atomizer for preparing iron-based spherical metal powder by crucible gas atomization method, and the catheter 5 is made of graphite or ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com