Non-shift telescoping-radius one-way transmission

A technology of one-way transmission and retractor, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., which can solve the problems of short arc distance and no transmission, etc., and achieve the effect of easy control and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

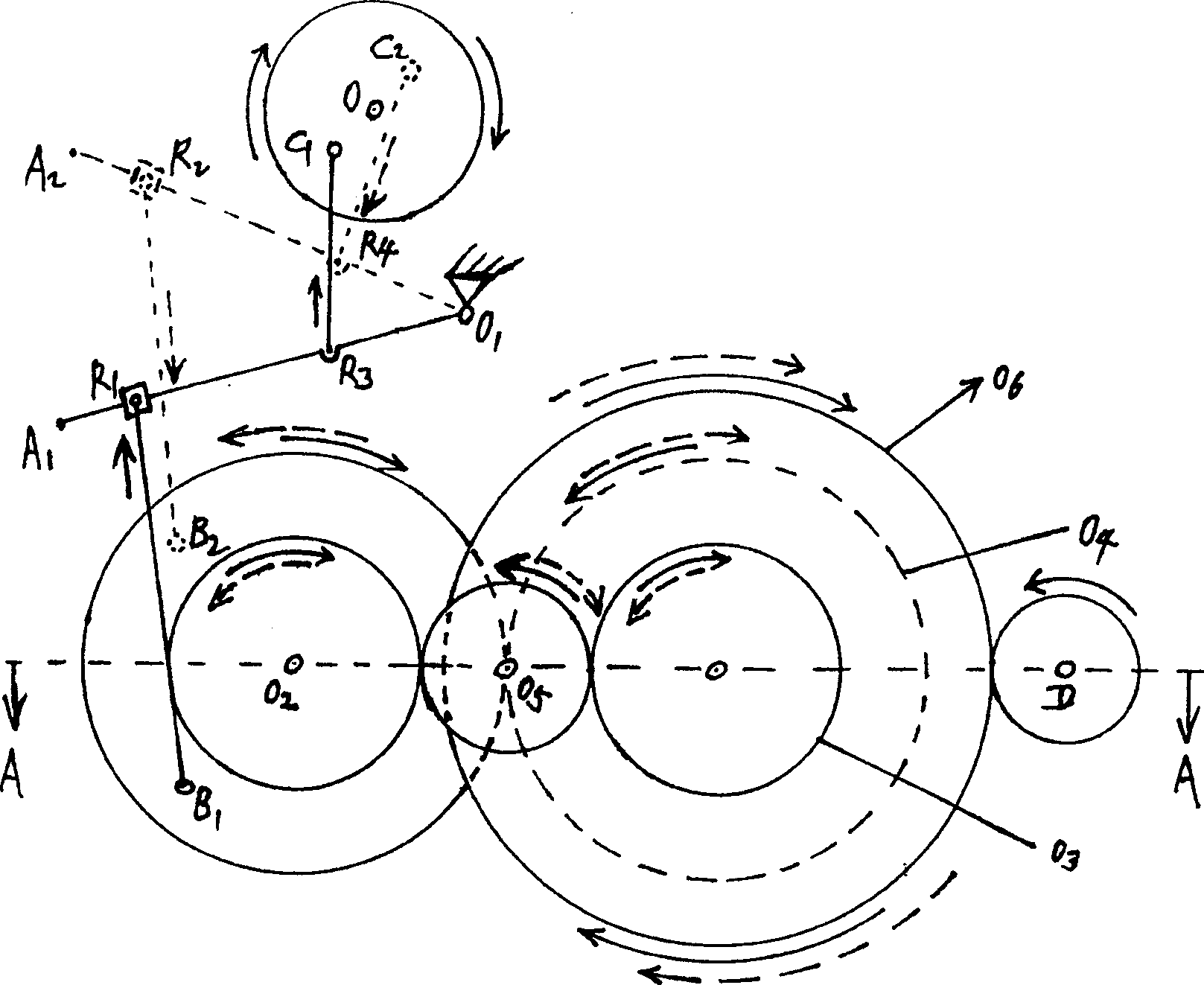

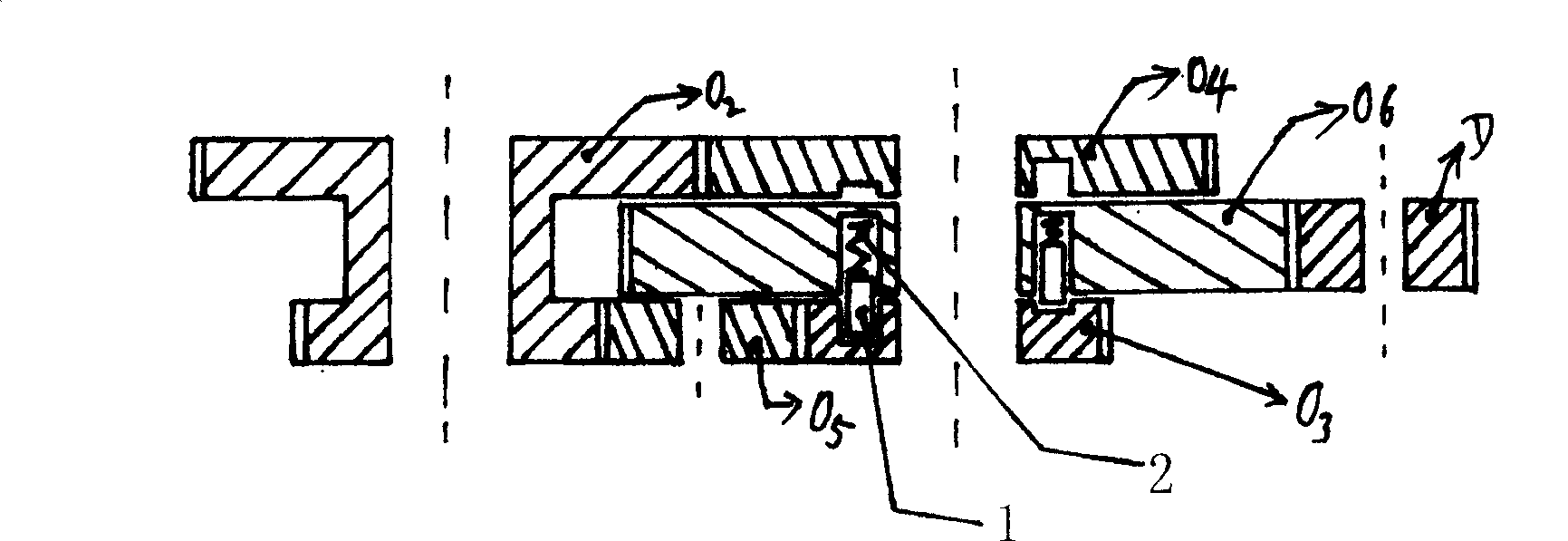

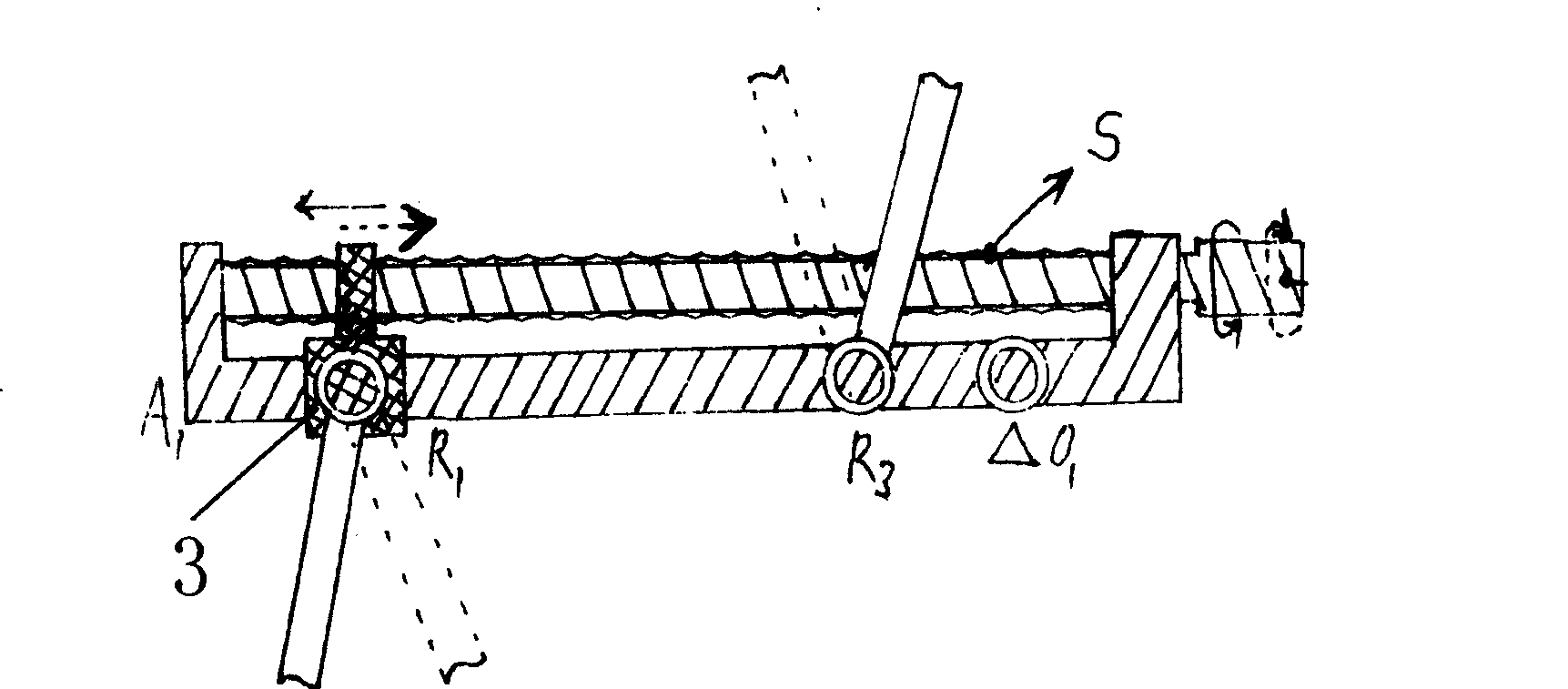

[0015] Accompanying drawing is a kind of specific embodiment of the present invention.

[0016] The gearless telescopic radius one-way transmission of the present invention includes a radius expander, a one-way rotator and a power circle O; the one-way rotator includes three single gears O 3 , O 4 , O 6 , gear O 6 located in gear O 3 with gear O 4 between and the shafts of the three are on the same straight line, the gear O 6 is the power take-off wheel; in gear O 6 Four blind holes are respectively arranged on both sides of the two sides, and the blind holes on both sides are on the same circle, and a slider 1 is arranged through a spring 2 in the blind hole; the gear O 3 with gear O 4 Both and Gear O 6 There are three arc-shaped grooves from deep to shallow on the adjacent side, and the arc-shaped grooves of the two gears are in opposite directions and are opposite to the gear O. 6 The trajectories of the blind holes on both sides are consistent; in addition, there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com