Device for preheating cement raw material for manufacturing cement clinker

A technology for cement raw meal and cement clinker, which is applied in the field of cement raw meal installations, can solve the problems that the cement raw meal cannot be fully heated, the number of driving equipments is too large, and the cement raw meal is not thorough enough, etc. The effect of heating and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

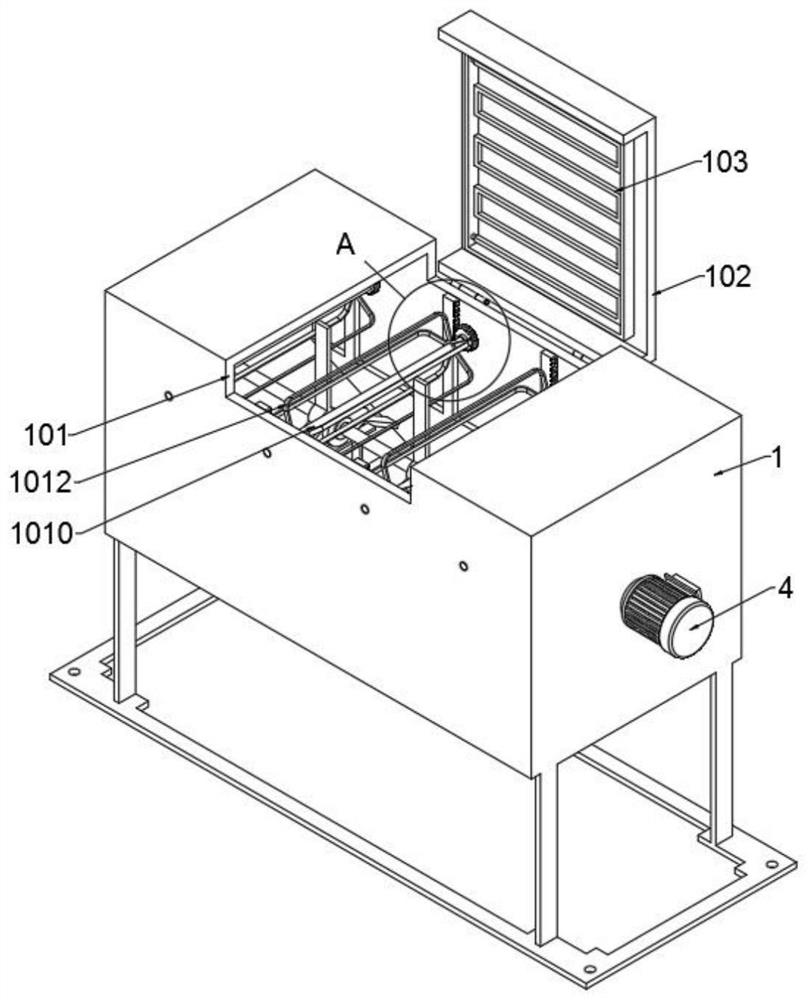

[0030] Example: please refer to Figure 1 to Figure 8 :

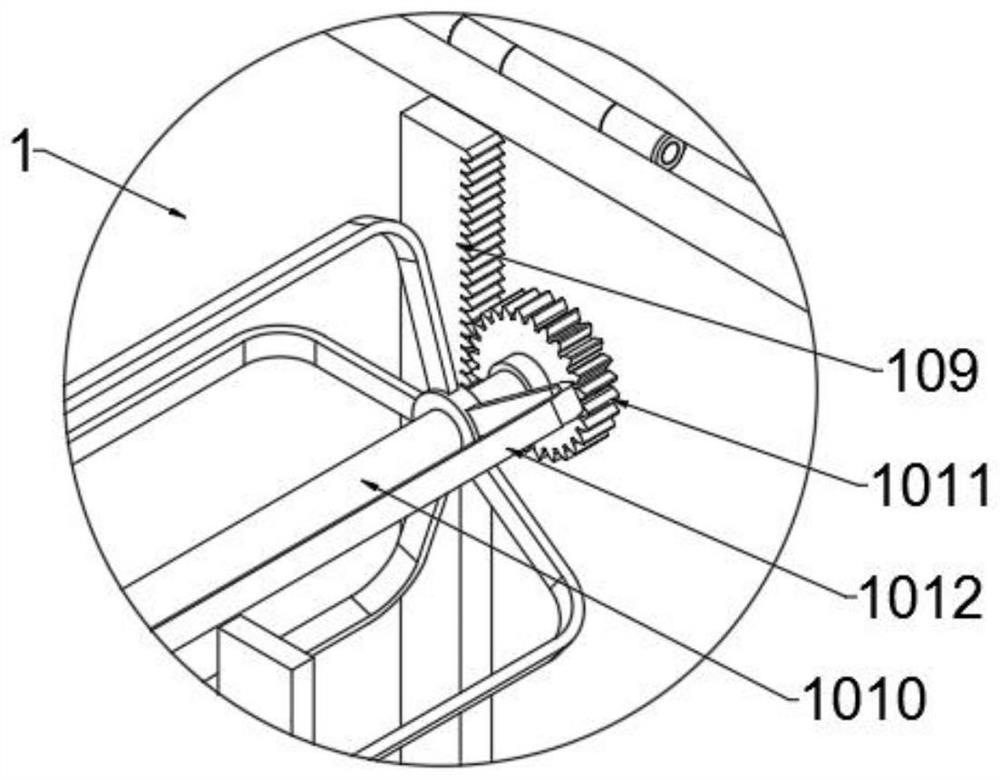

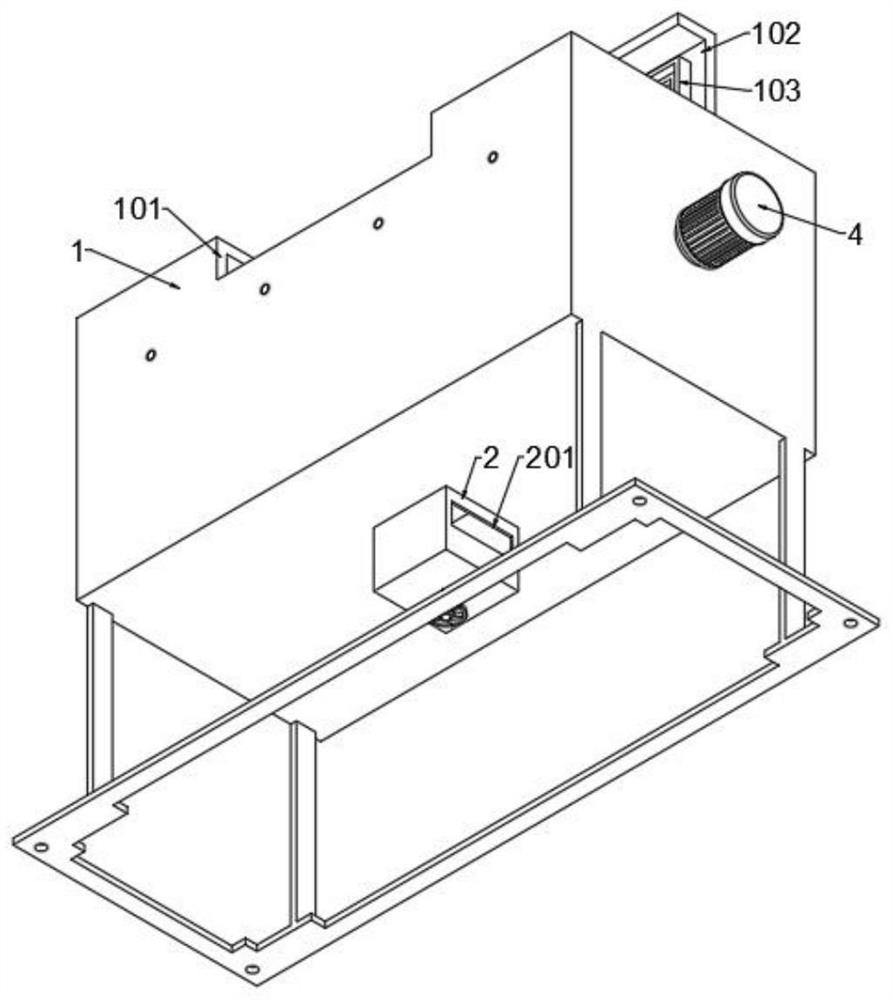

[0031] The present invention proposes a device for preheating cement raw meal for manufacturing cement clinker, comprising: a treatment box 1, the treatment box 1 is a rectangular structure, and a support frame is arranged at the bottom of the treatment box 1; the treatment box 1 The inner left end of 1 is rotatably installed with a rotating rod 3; the right side of the processing box 1 is provided with a motor 4; the right end of the rotating rod 3 is connected with the output shaft of the motor 4; the middle of the bottom of the processing box 1 is provided with a discharge box 2, and the discharge box 2 is a rectangular structure, and the rotating rod 3 is driven by the motor 4 to rotate, so that the rotating rod 3 drives the vertical stirring frame 1012 to rotate to mix the cement raw meal.

[0032] Furthermore, according to embodiments of the present invention, such as figure 1 As shown, a feeding chute 101 is op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com