Starting devices for internal combustion engines

A technology of a starting device and an internal combustion engine, which is applied to the starting of an engine, a starting device with a mechanical power reserve, and an electric motor for an engine. Improved wear and reduced mechanical loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

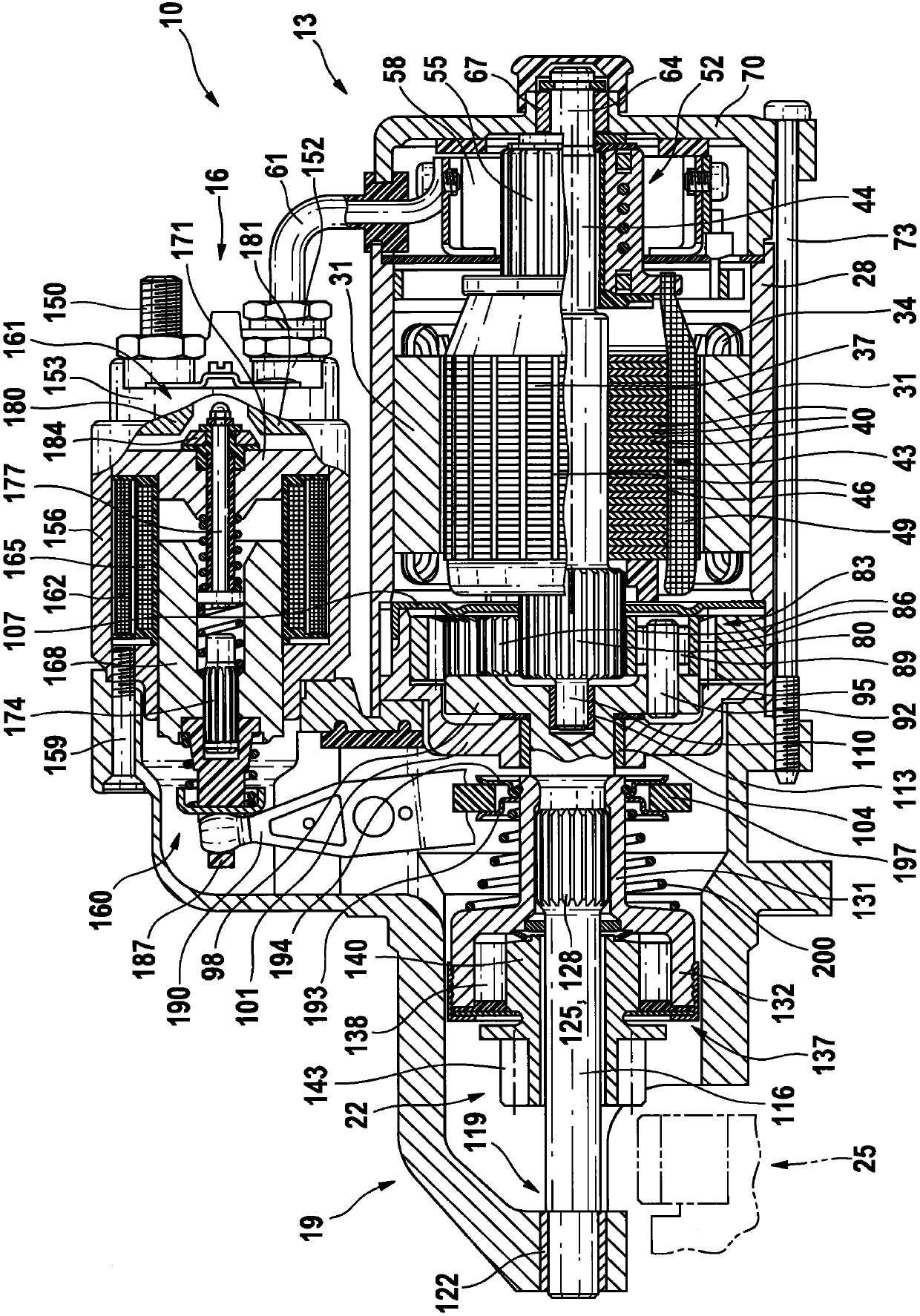

[0024] by figure 1 The representation of the starter device 10 shown in longitudinal section can be obtained.

[0025] according to figure 1 The starter device 10 has, for example, a starter motor 13 and a pre-engagement actuator 16 , which is designed here as a relay or starter relay. The starter motor 13 and the pre-engagement actuator 16 are fastened to a common drive end bearing cover 19 . The starter motor 13 is functionally used when the starter pinion 22 is engaged to figure 1 When in the ring gear 25 of the internal combustion engine, not shown, the starter pinion 22 is driven.

[0026] The starter motor 13 has a pole tube 28 as a housing, which supports on its inner circumference a plurality of pole shoes 31 , which are each wound by a field winding 34 . The pole shoe 31 in turn surrounds an armature 37 which has an armature core 43 formed from laminations 40 and an armature winding 49 arranged in a plurality of slots 46 . The armature core 43 is pressed against ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com