Flange instrument valve sealing testing device

A technology of valve sealing and testing equipment, which is applied in the direction of fluid tightness testing, measuring equipment, and testing of machine/structural components, etc. It can solve problems such as affecting test results, taking a long time, and scrapping flanged instrument valves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

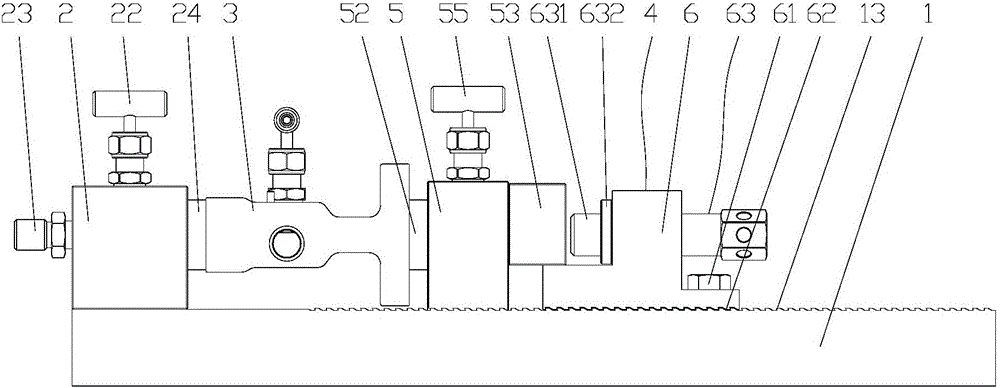

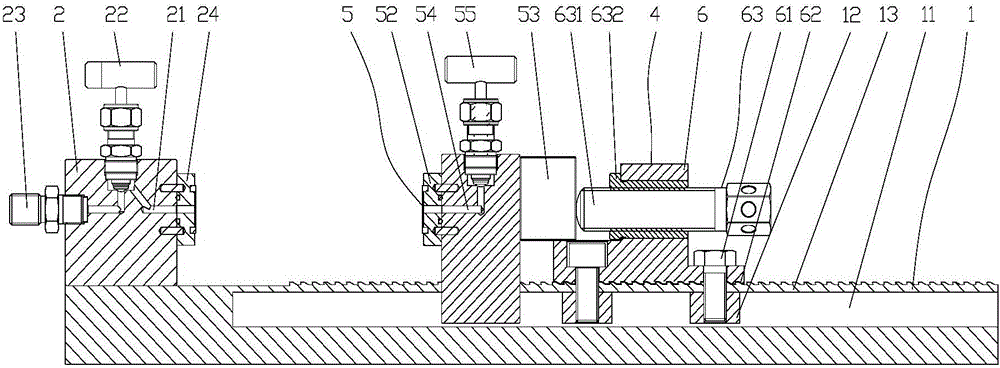

[0039] Such as Figure 5 As shown, when testing the single inlet and outlet flange instrument valve 31, a set of flange instrument valve sealing test device of the present invention is used to connect the inlet and outlet of the single inlet and outlet flange instrument valve 31 to the second sealing cover assembly 24 respectively. The second through hole on the top is communicated with the first through hole on the first sealing cover assembly 52, and then the movable clamp seat 4 is used to tighten and seal.

Embodiment 2

[0041] Such as Image 6 As shown, when testing the double inlet and outlet flange instrument valve 32, two sets of flange instrument valve sealing test devices of the present invention are used. The two sets of flange instrument valve seal test devices have two bases 1, and the two ends of the two bases 1 are Each is connected by a connecting piece 7 to form a whole, and then the two inlets of the double inlet and outlet flange instrument valve 32 are respectively communicated with the second through holes on the two second sealing cover assemblies 24, and the double inlet and outlet method The two outlets of the blue meter valve 32 communicate with the first through holes on the two first sealing cover assemblies 52 respectively, and then respectively go through the two movable clip seats 4 to tighten and seal.

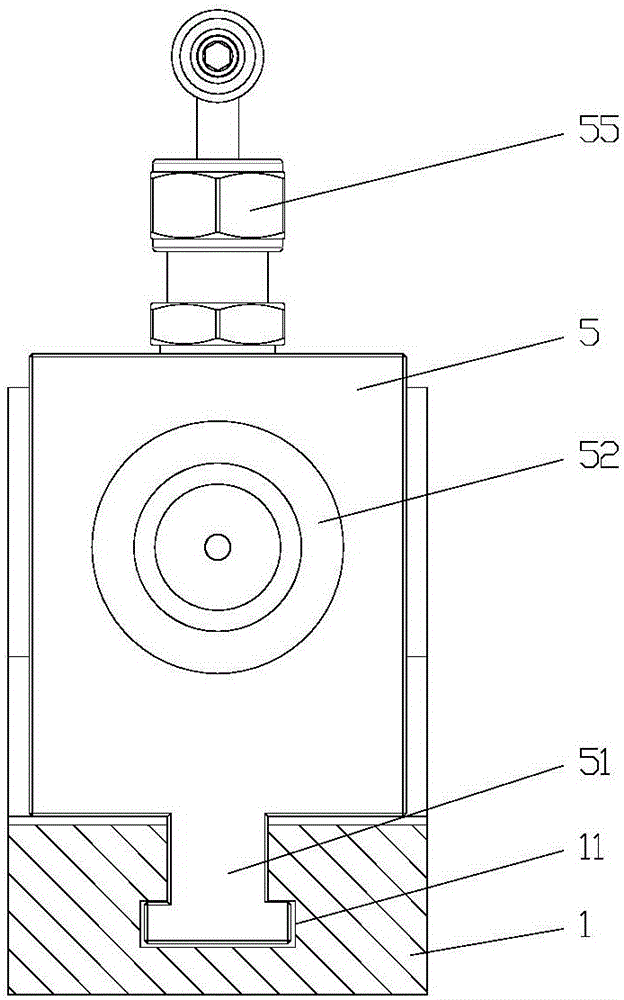

[0042] The present invention adopts the above technical scheme. When installing the flange instrument valve 3 to be tested, the T-shaped part 51 of the movable suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com