Mutual inductor replacement, loading and transporting auxiliary device

A technology of auxiliary devices and transformers, applied in switch devices, electrical components, etc., can solve the problems of increasing labor intensity and complexity of personnel, increasing transit time, and high risk factors, achieving high promotion and application value, reducing labor intensity, and ensuring personal safety. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0042] see Figure 1 to Figure 8 .

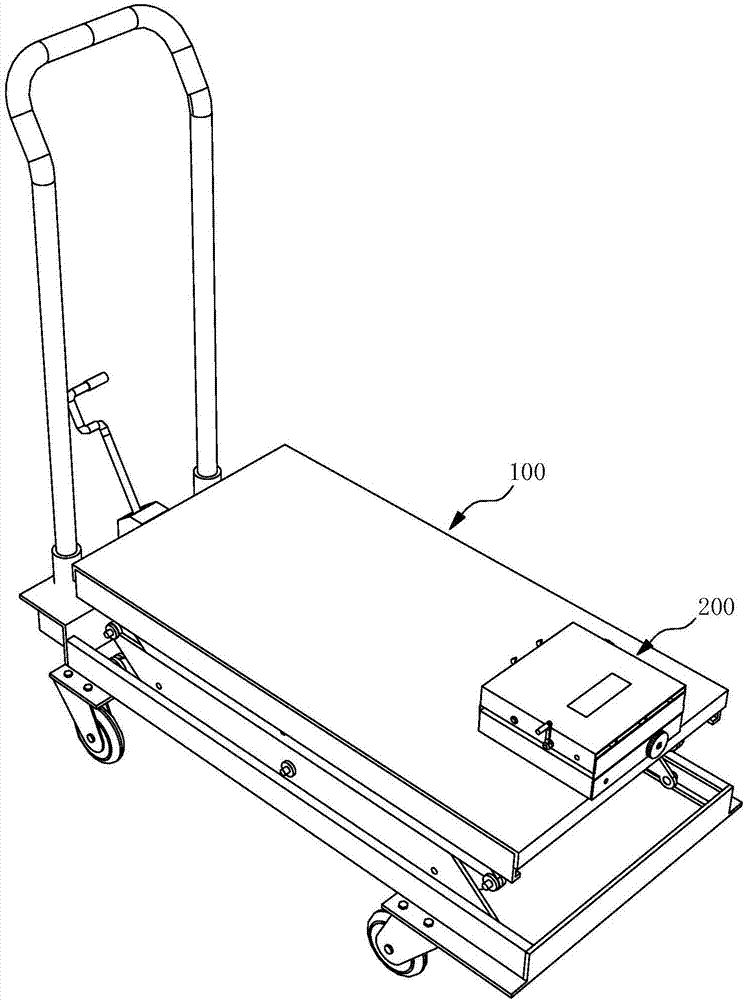

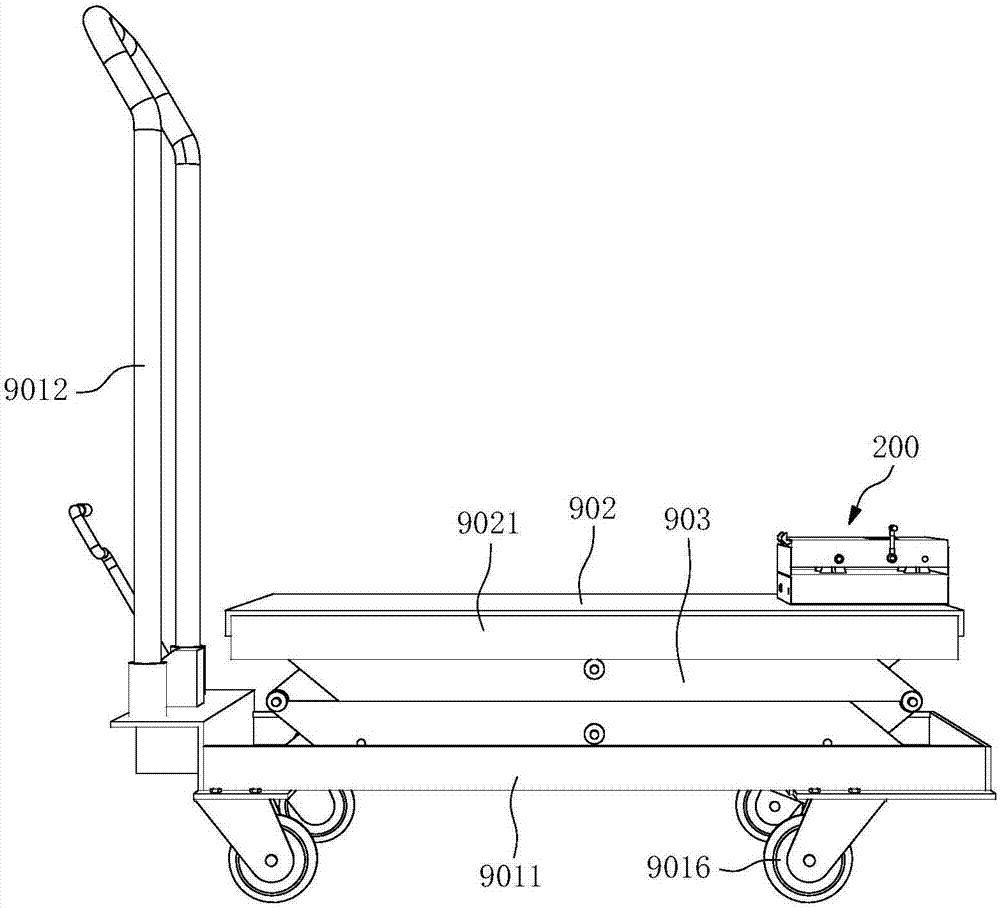

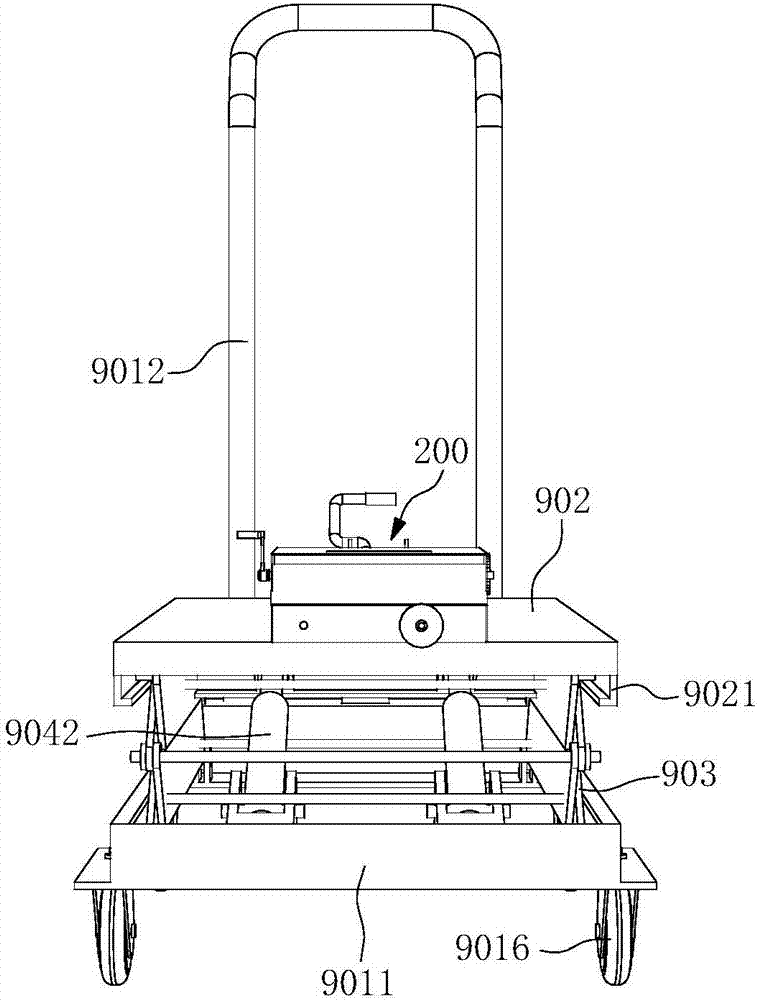

[0043] The auxiliary device for transformer replacement and shipment of the present invention includes a lifting trolley 100 and a position fine-tuner 200;

[0044]The lifting trolley 100 includes a trolley body, a loading platform 902, a main scissor lifting frame 903 and a driving mechanism for driving the main scissor lifting frame 903 to lift, and the main scissor lifting frame 903 The lower end is connected to the cart body, and the upper end is connected to the loading platform 902;

[0045] The position fine adjuster 200 is arranged on the top surface of the loading platform 902, and the position fine adjuster 200 includes the working platform 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com