Copper wire tower having supporting device used for removing vanadium impurity in titanium tetrachloride

A support device and copper wire tower technology, which is applied in the field of non-ferrous metal smelting, can solve the problems of easy damage to the cleaning pool, splashing of copper wire balls, poor safety, etc., and achieve the effects of avoiding environmental pollution, easy operation, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

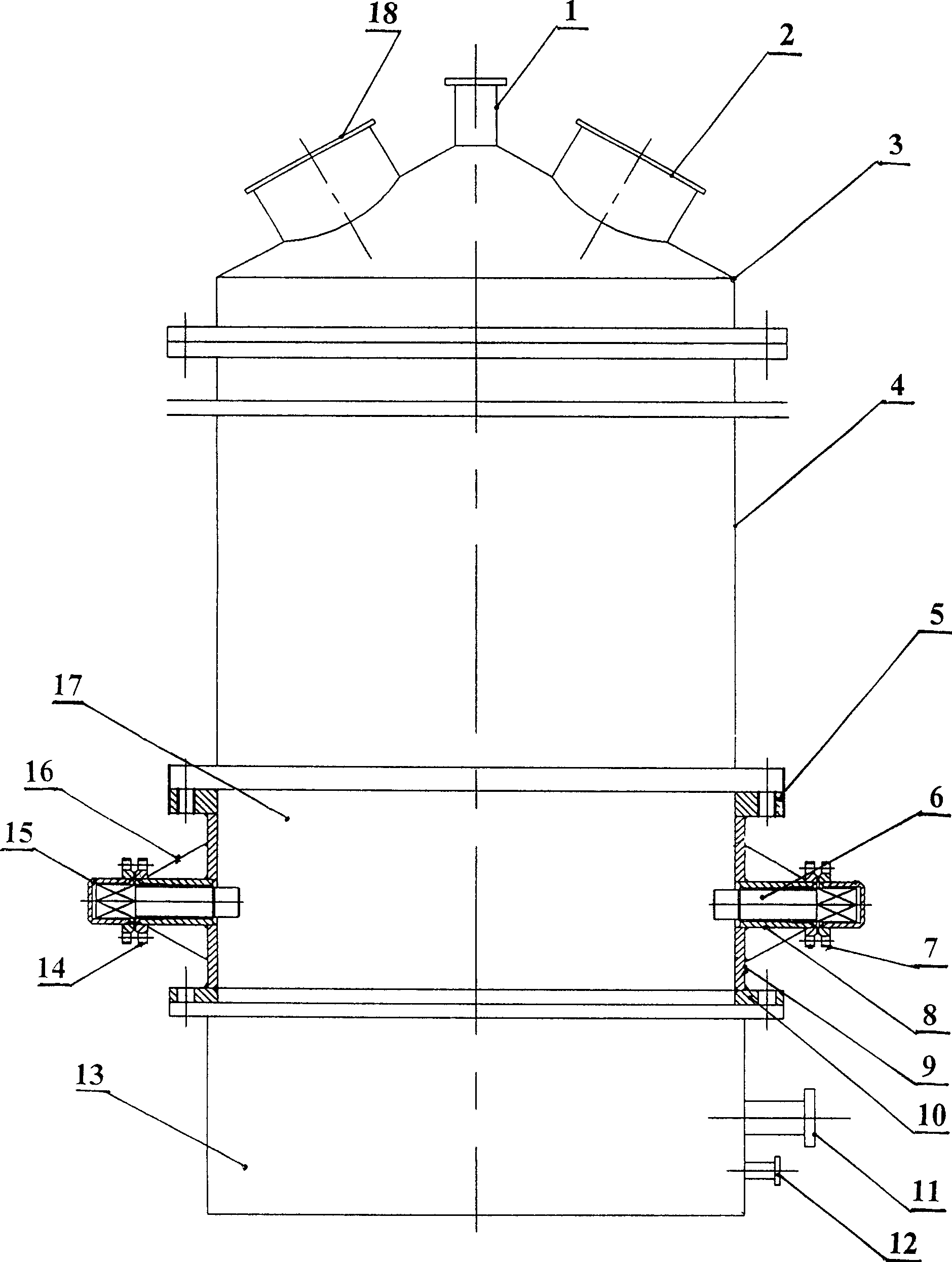

[0009] The specific implementation of the copper wire tower with supporting device of the present invention will be further described below in combination with the examples of the above-mentioned drawings.

[0010] The example of the copper wire tower with the supporting device of the present invention includes a tower top 3 , a tower body 4 , a supporting device 17 and a tower bottom 13 . A steam pipe 1 is arranged on the top 3 of the tower, and the steam pipe 1 is connected to the cooling equipment outside the tower, and the gas in the tower is condensed and recovered to obtain the product. One side of the steam pipe 1 is provided with a copper wire ball feeding pipe 2, and the copper wire ball enters the tower through its nozzle. The other side of the steam pipe 1 is provided with a waste gas discharge pipe 18, which is connected to the equipment of the three wastes treatment system outside the tower. Generally, the pipe is in a normally closed state, and it is opened when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com