Anti-explosion motor casing processing device and processing technology

An explosion-proof motor and processing device technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of difficult control of drilling and tapping depth, cumbersome operation, low processing efficiency, etc., to achieve controlled drilling and tapping accuracy, improved assembly accuracy, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

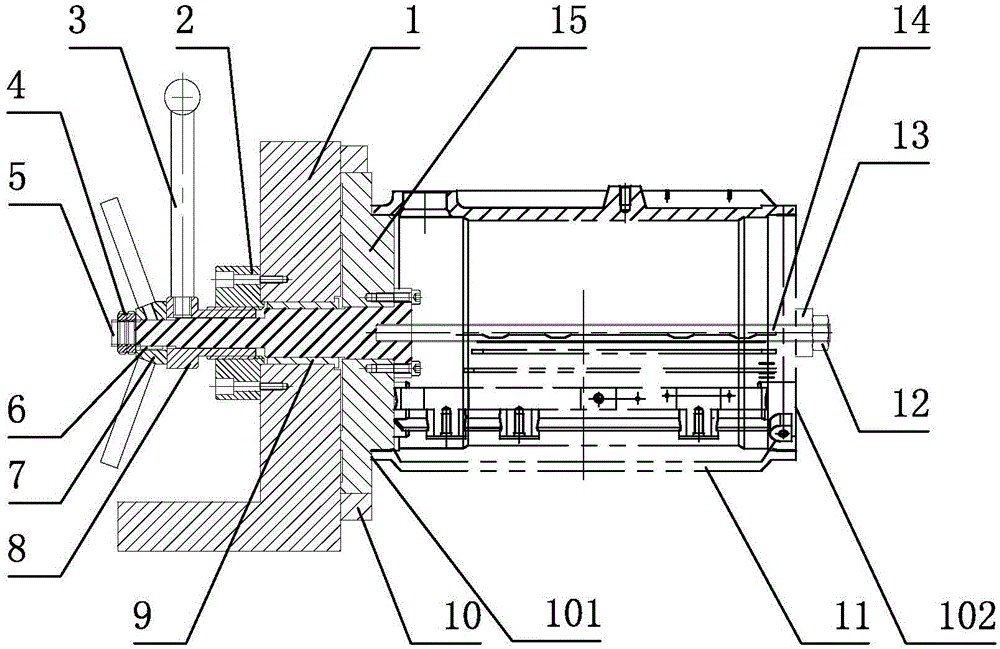

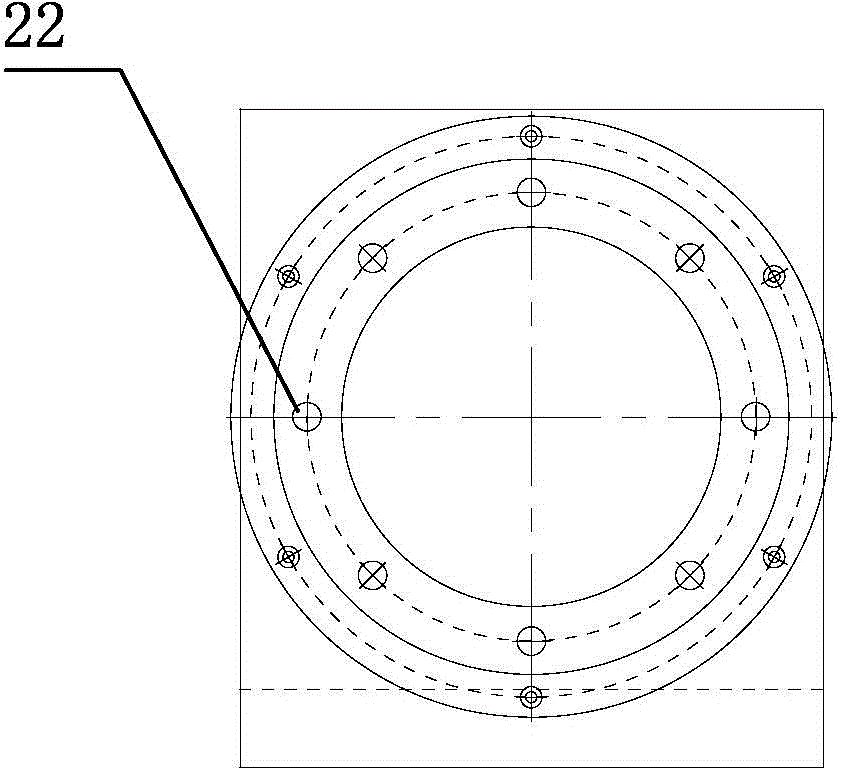

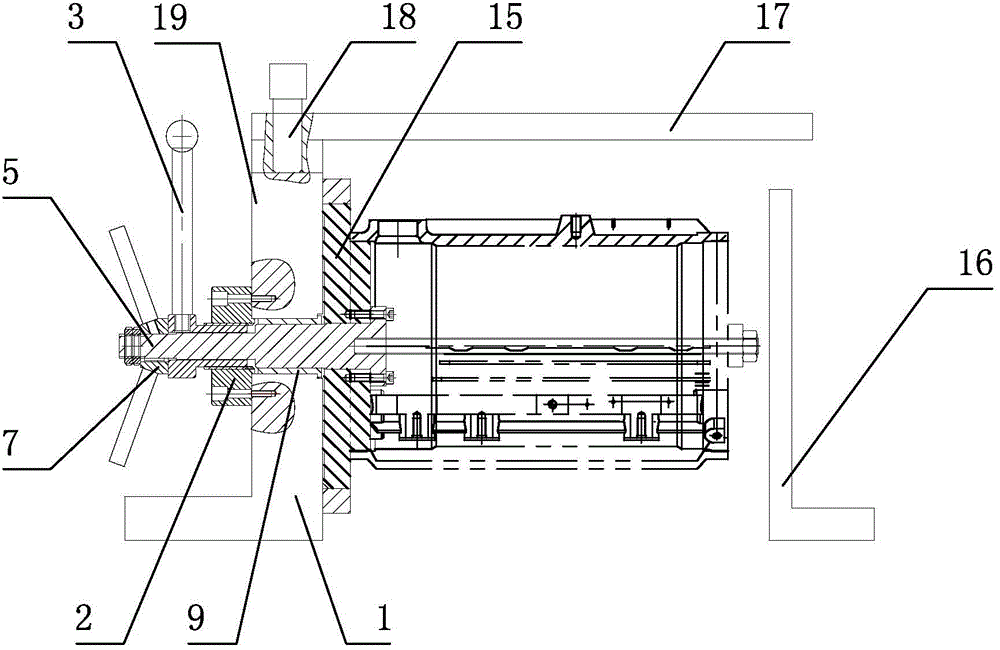

[0027] Such as figure 1 As shown, the explosion-proof motor casing processing device includes milling tooling and drilling tooling. The milling tooling includes a positioning mandrel 5, and the positioning mandrel 5 is sequentially fitted with a positioning plate 15, an L-shaped seat plate 1, and a T-shaped seat plate from back to front. Nut 2, T-shaped screw rod 8 and back cap 7, T-shaped nut 2 is fixed on the L-shaped seat plate 1, a sliding sleeve 9 is arranged in the L-shaped seat plate 1 to cooperate with the positioning mandrel 5, and the T-shaped screw rod 8 and the T-shaped The nut 2 is threaded, and the handle 3 is fixed on the T-shaped screw 8. The loosening and locking of the T-shaped screw 8 is facilitated by the handle 3. The back of the T-shaped screw 8 is provided with a back cap 7, and the back cap 7 cooperates with the T-shaped screw 8. Locking the positioning mandrel 5, the back cap 7 is also provided with an operating handle for rotating the back cap 7. By a...

Embodiment 2

[0034] Processing a Finnish Type 16 explosion-proof high-efficiency energy-saving motor shell, the material is gray iron HT200, the wall thickness is 10mm, the inner hole and the mouth size are required to be ±0.05mm, and the distance from the two bottom feet to the center is 116 (0 / -0.3)mm , the flatness is 0.06mm, the distance from the side of the foot to the center is 101.5±0.1mm, and the dimensional tolerance of the shape and drilling position is in accordance with the ISO2768-f standard.

[0035] 1. Using a C6180 machine tool, three claws support the inner hole of the 11N end 102 of the workpiece, level the D end 101 outer circle blank, control the starting point of machining at 24±0.5mm, the turning process stop Ф265(+0.05 / 0)mm, and the depth of 28(+ 0.5 / 0) mm.

[0036] 2. Use the C6180 machine tool to position with the 101 stop at the D end. After tightening, the diameter of the N end 102 of the car is Ф265 (+0.05 / 0) mm, the depth is 28 (+0.5 / 0) mm, and the inner hole i...

Embodiment 3

[0040] Process a Finnish type 18 explosion-proof high-efficiency energy-saving motor shell, the material is gray iron HT200, the wall thickness is 10mm, the inner hole and the mouth size are required to be ±0.05mm, and the distance from the two bottom feet to the center is 134.9 (0 / -0.3)mm , the flatness is 0.06mm, the distance from the side of the foot to the center is 117.5±0.1mm, and the dimensional tolerance of the shape and drilling position is in accordance with the ISO2768-f standard.

[0041] 1. Using a C6180 machine tool, three claws support the inner hole of the N-end 102 of the workpiece 11, level the outer round blank of the D-end 101, control the starting point of machining at 24±0.5mm, and turn the process stop Ф297 (+0.05 / 0)mm, deep 33 (+0.5 / 0)mm.

[0042] 2. Use the C6180 machine tool to position with the 101 stop at the D end. After tightening, the diameter of the N end 102 of the car is Ф265 (+0.05 / 0) mm, the depth is 30 (+0.5 / 0) mm, and the inner hole is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com