Locking sheet, push-and-pull locking mechanism and connector with push-and-pull locking mechanism

A locking mechanism and locking piece technology are applied in the direction of connection, two-part connection device, and parts of the connection device, which can solve the problems of inconvenient operation and influence on work efficiency, and achieve the reduction of disassembly steps, the convenience of operation, and the improvement of The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

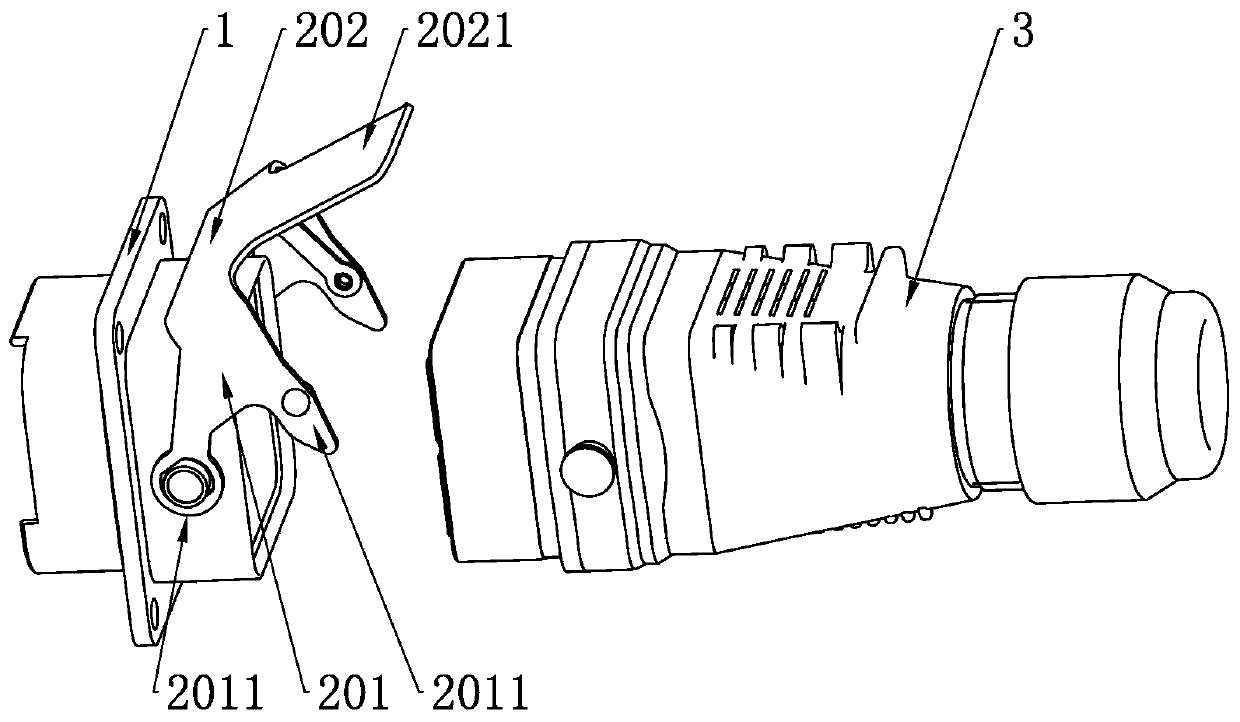

[0035] see figure 2 , a locking piece, has two connecting arms 201 oppositely arranged, a bridging portion 202 connecting the aforementioned two connecting arms 201, each end of the connecting arm 201 has a bending portion 203, and the bending portion is connected to the The end of the arm forms a groove 204 for snapping into the first protrusion 101 on the socket housing 1 or the second protrusion 301 on the plug housing 3 . The bridging portion 202 extends laterally and slopes downward to form a matching portion 205 , and the bent portion and the matching portion are located on two sides of the bridging portion. The two sides of the mating portion close to the bridging portion respectively extend downward to form a connecting portion 206, and the connecting portion 206 is provided with a shaft for passing through so as to install the locking piece on the socket housing 1 or the plug in a rotatable connection. The through hole 207 on the housing 3; the end of the matching p...

Embodiment 2

[0037]On the basis of Embodiment 1, the present invention proposes a push-pull locking mechanism, which includes a locking piece 2, a rotating shaft, an elastic member, a moving piece, and a limiter. The locking piece 2 includes two connecting arms 201 arranged opposite to each other. 1. The bridging portion 202 connecting the aforementioned two connecting arms, the end of each connecting arm 201 forms a bent portion 203, and the bent portion and the end of the connecting arm form a first protrusion for limiting the socket housing. or the second protruding groove 204 on the plug housing; the bridging portion 202 extends laterally and slopes downward to form a matching portion 205, and the two sides of the matching portion close to the bridging portion respectively extend downward to form a through hole 207 The connection part 206. The rotating shaft is used to pass through the through hole 207 of the connecting part and the step 302 on the socket housing or the plug housing, s...

Embodiment 3

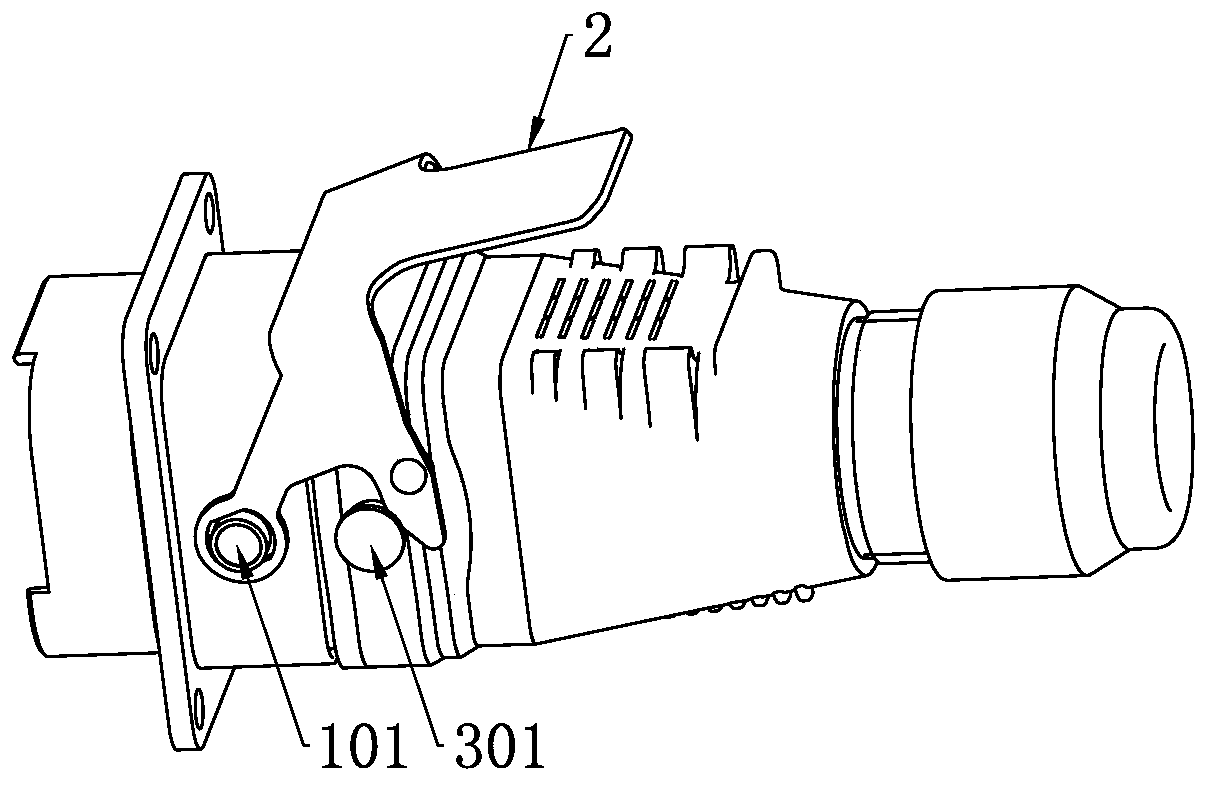

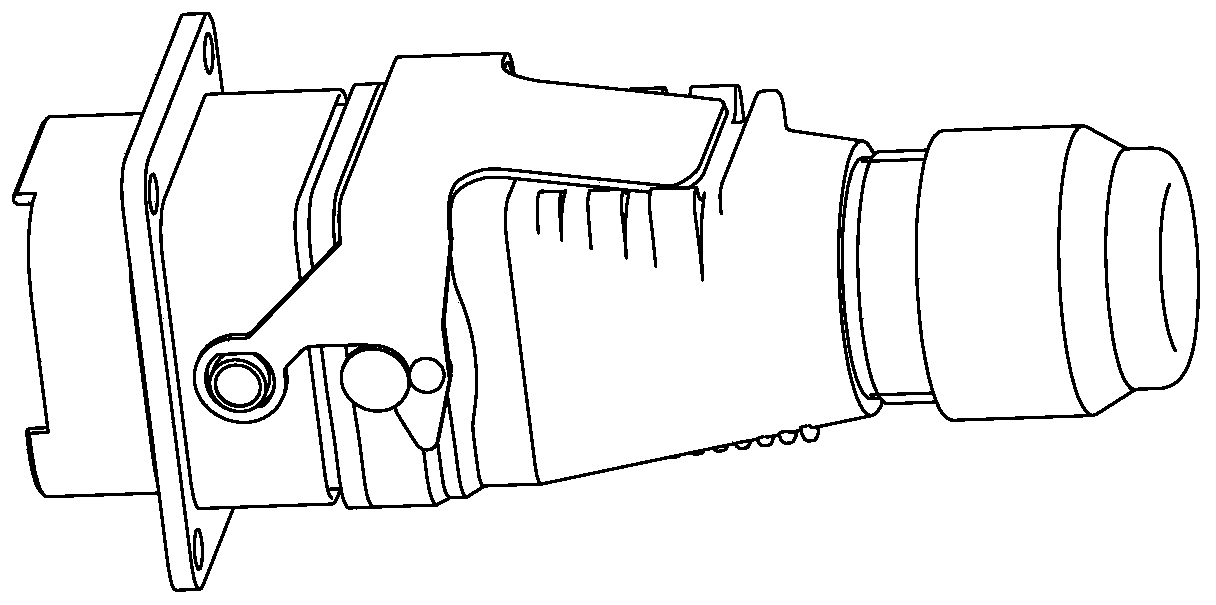

[0042] see image 3 and Figure 4 , on the basis of Embodiment 2, the present invention proposes a connector using a push-pull locking mechanism, including a socket, a plug and a push-pull locking mechanism. Both sides of the socket housing 1 are provided with first protrusions 101, and the plug The housing is provided with a step 302 , and the push-pull locking mechanism includes a locking plate 2 , a pin shaft 4 , a torsion spring 6 , a sleeve 7 and a block 8 . The push-pull locking mechanism is integrally installed on the plug housing, that is, the pin shaft 4 passes through the step 302, the through hole 207 and the torsion spring 6 to install the locking piece 2 on the plug housing 3 in a rotatable connection, and the lock The two connecting arms 201 of the tight piece 2 are respectively located on two sides of the plug housing, and the groove 204 faces the first protrusion 101 on the same side of the socket housing. The two force arms of the torsion spring 6 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com