Adapter connector, printed board connector and base station remote unit

A technology for transfer connectors and printed boards, applied in the direction of connection, electrical components, coupling devices, etc., can solve the problems of inconvenient maintenance of circuit boards, achieve the effects of improving work efficiency, convenient assembly and maintenance, and reducing disassembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing.

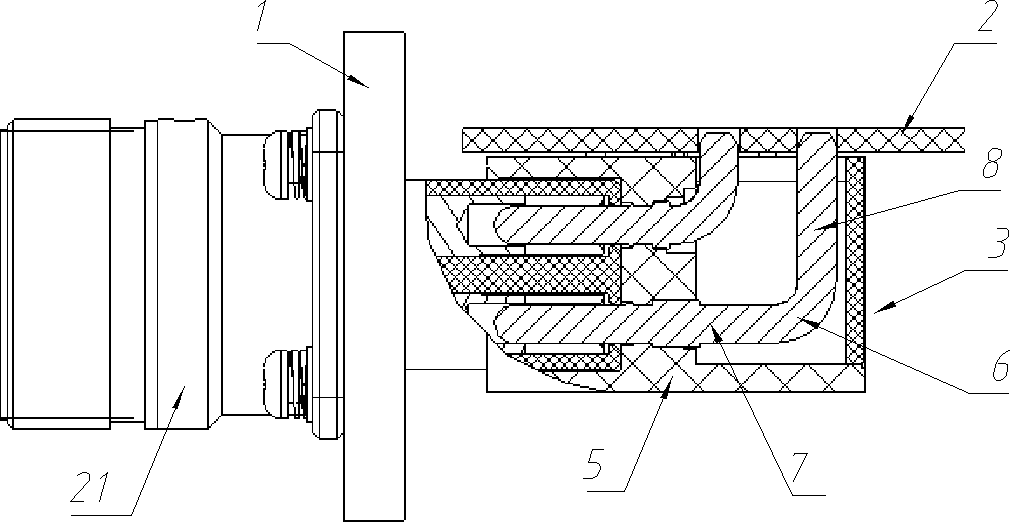

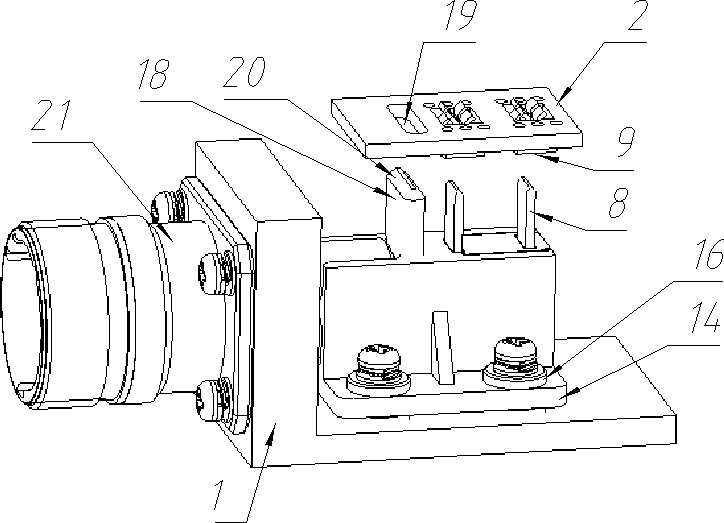

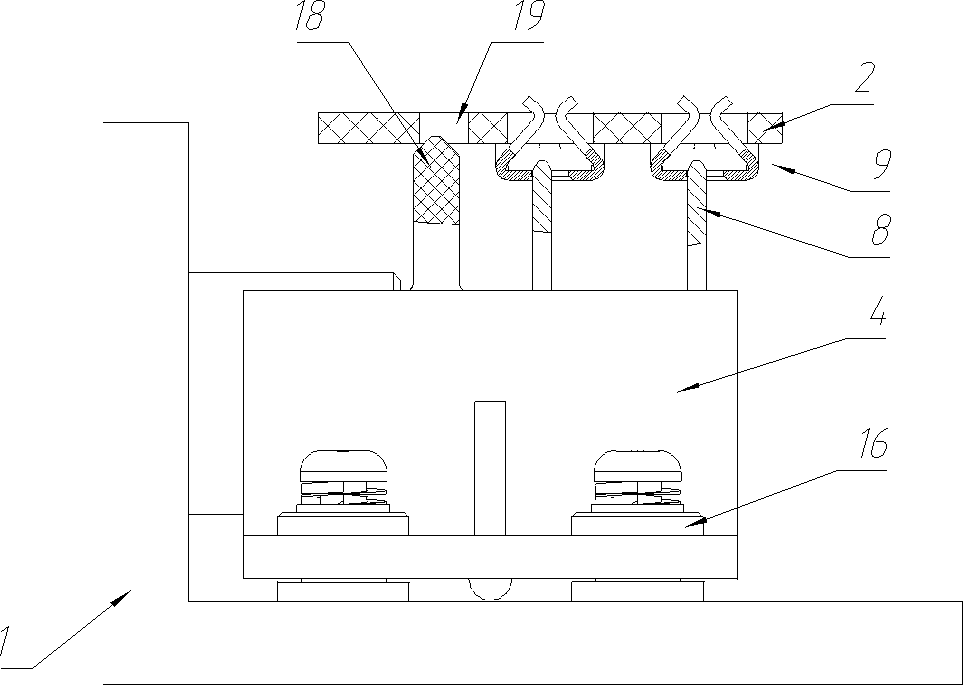

[0056] An embodiment of the remote unit of the base station in the present invention is as Figure 2~Figure 13 As shown, including RU box 1, RU box 1 is provided with printed board 2 and printed board connector 3, and the side wall of RU box 1 is provided with connector mounting holes, and box connector 21 is connected from the outside It is inserted into the RU box 1 through the connector installation hole and fixed on the side wall of the RU box 1 by screws and the flange on the box connector 21 .

[0057] The printed board connector 3 includes a transfer base 4, the transfer base 4 forms a transfer connector, includes an insulator 5 and a contact 6 arranged in the insulator 5, and the contact 6 includes a contact for conducting with the printed board 2 The printed board connecting portion 8 and the socket connecting portion 7 for plugging into the box connector 21 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com