Screen levelness adjusting mechanism and projection display device

A technology for adjusting mechanism and levelness, which is applied in the field of screen levelness adjusting mechanism and projection display device, can solve the problems of screen tilt, low adjustment efficiency, large installation error of screen length and width, etc., so as to reduce the steps of disassembly and assembly, improve The effect of adjusting efficiency and saving adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further illustrate the screen levelness adjustment mechanism and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

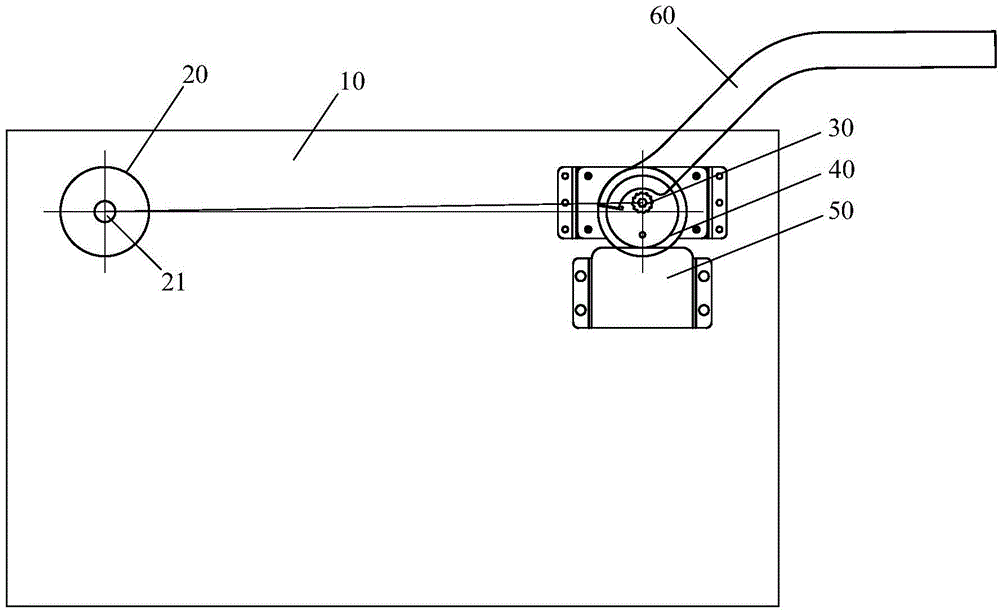

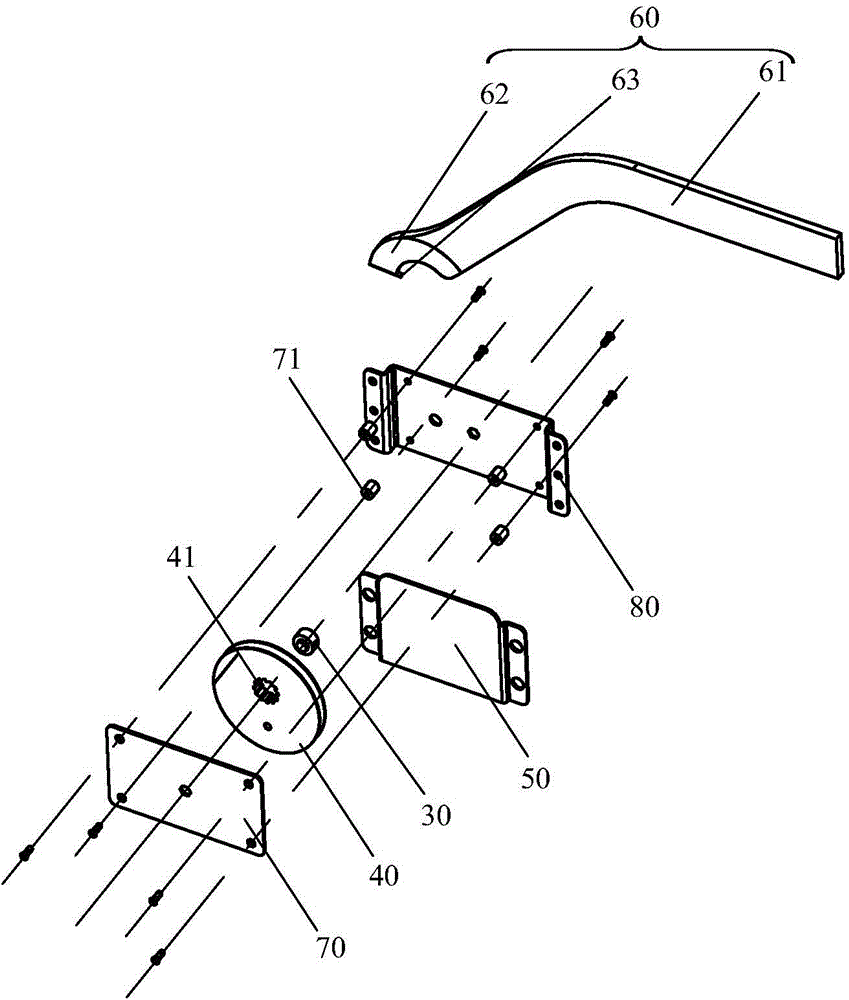

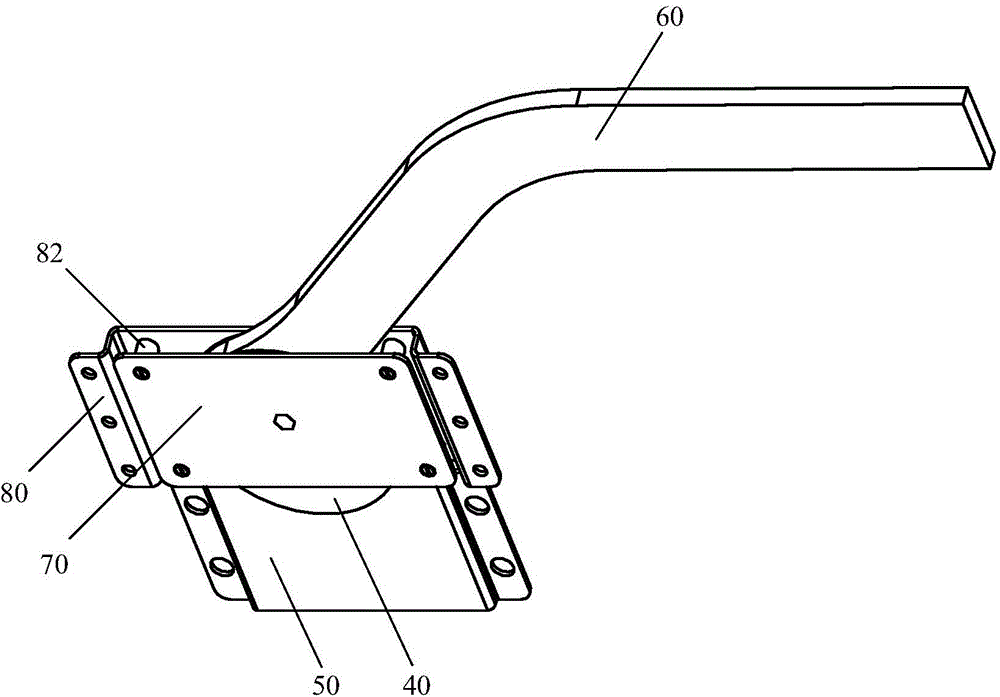

[0042] see Figure 1 to Figure 5 The screen level adjustment mechanism provided by the embodiment of the present invention includes: a reference member 20, a support shaft 30, a cam 40 and a support plate 50, wherein the reference member 20 and the support shaft 30 are installed on the back of the screen 10, and the support shaft 30 and The reference member 20 is located on both sides of the vertical center line of the screen 10, and the support shaft 30 is provided with a retractable pawl assembly; the rotation center of the cam 40 is provided with a shaft hole 41, and the inner surface ring of the shaft hole 41 is provided with a plurality of The ratchet 42 and the cam 40 are sleeved on the support shaft 30 through the shaft hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com