Film removing method for high light plate piece

A high-gloss plate and plate technology, applied in the field of auto parts processing, can solve problems such as tape waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

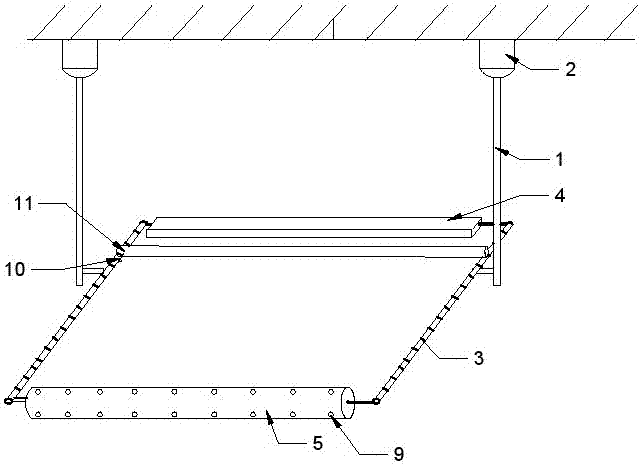

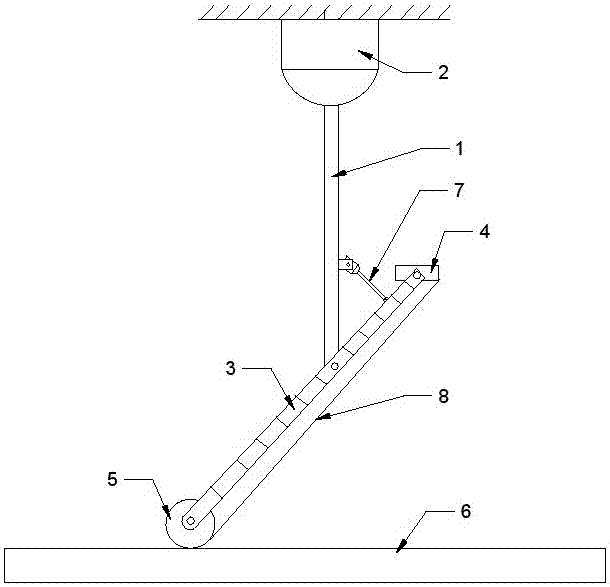

[0020] The reference signs in the drawings of the description include: support rod 1, first cylinder 2, telescopic shaft 3, mucous membrane plate 4, counterweight cylinder 5, high-gloss plate 6, transmission cylinder 7, protective film 8, communication hole 9, cutting Film cutter 10, guide rail 11.

[0021] The film-removing method used for high-gloss boards in this solution includes the following steps:

[0022] Step 1: Prepare the film removal device, which is attached figure 1 , figure 2 As shown: it includes a frame, a stripping mechanism and a support. The support is composed of two struts 1. The upper ends of the two struts 1 are fixedly connected with the first cylinder 2, and the first cylinder 2 slides horizontally on the frame. The lower end of the bracket is connected to the stripping mechanism.

[0023] The stripping mechanism includes a mucous membrane p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com