Patents

Literature

60results about How to "Work at high speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

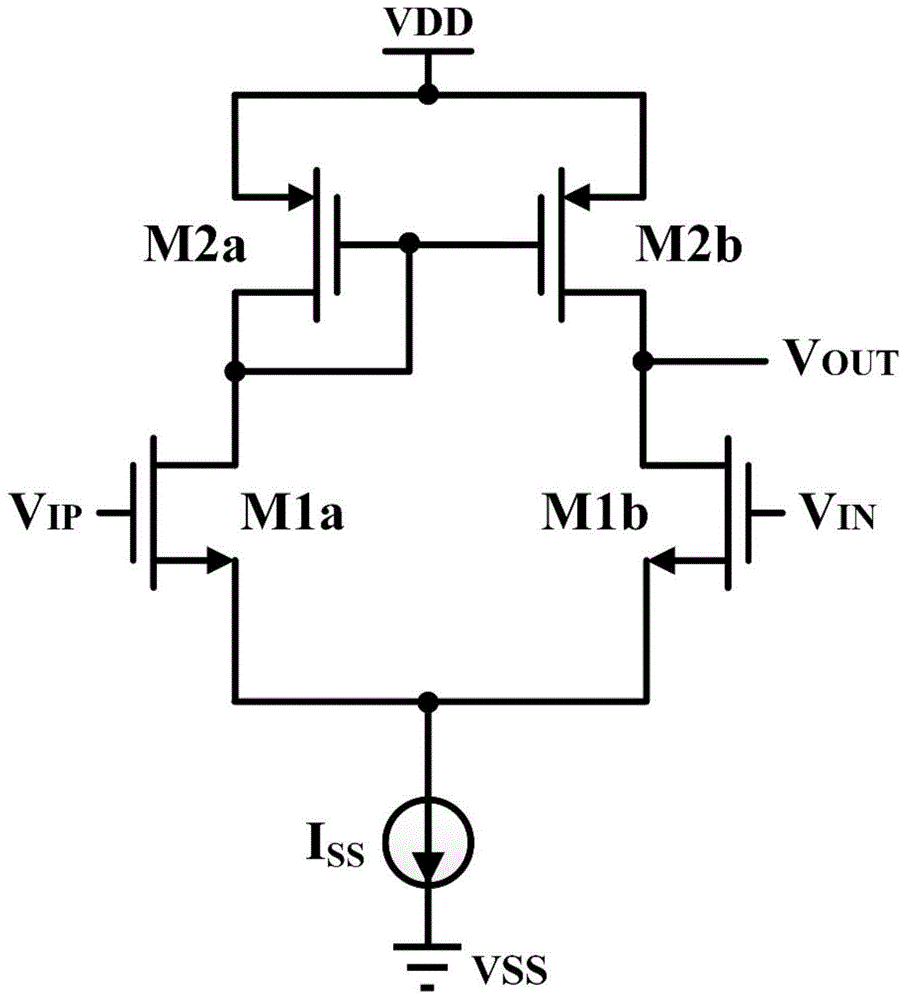

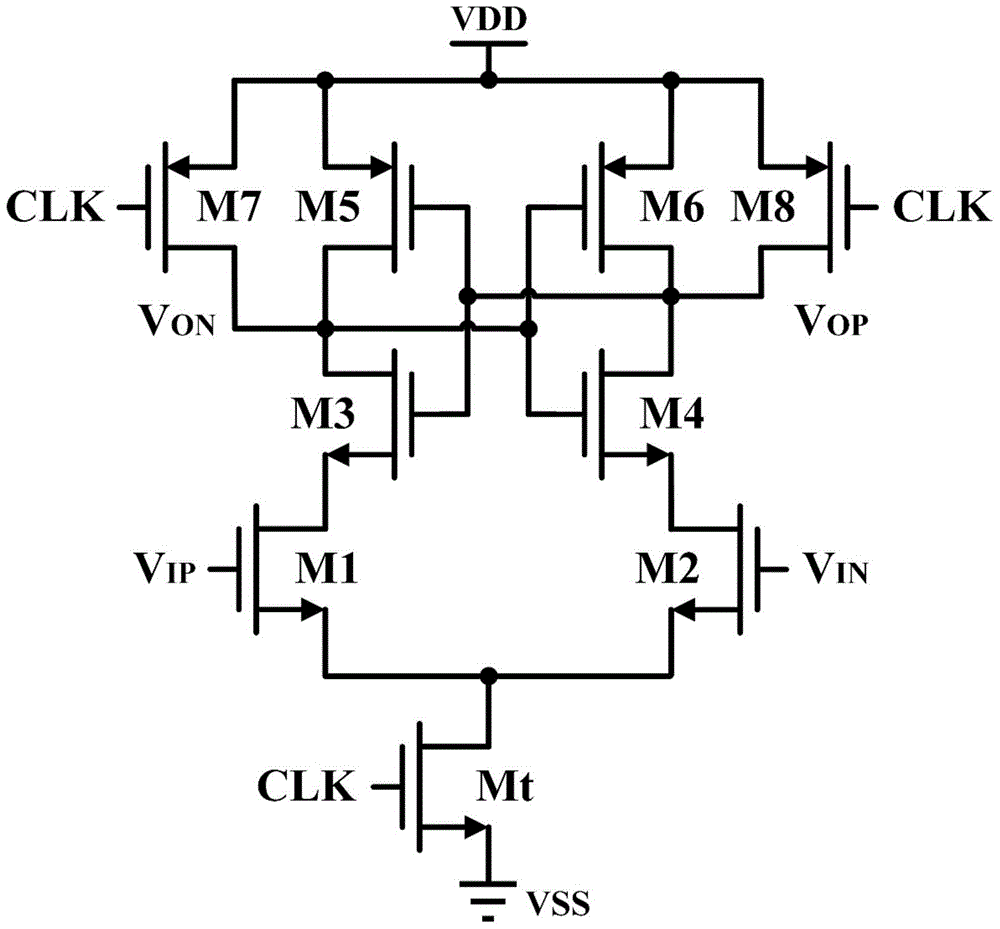

High-speed low-power-consumption dynamic comparator

ActiveCN105680834ATiming is simpleImprove energy efficiencyMultiple input and output pulse circuitsDifferential signalingEngineering

The invention discloses a high-speed low-power-consumption dynamic comparator, comprising a pre-amplification circuit and a regeneration latch circuit; the pre-amplification circuit comprises a clock output end, a first differential signal input end, a second differential signal input end, an output node FN and an output node FP; the pre-amplification circuit is connected with a direct current power, the output node FN synthesizes the output voltage VDD of the direct current power and a first differential input signal to output the first differential input signal, and the output node FP synthesizes the output voltage VDD of the direct current power and a second differential input signal to output the second differential input signal; the regeneration latch circuit is connected with the output node FN and the output node FP of the pre-amplification circuit, and can be used for latching the first differential input signal and the second differential input signal and outputting a first output signal and a second output signal. The dynamic comparator provided by the invention can quickly achieve low power consumption dynamic latching function under the high speed application.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

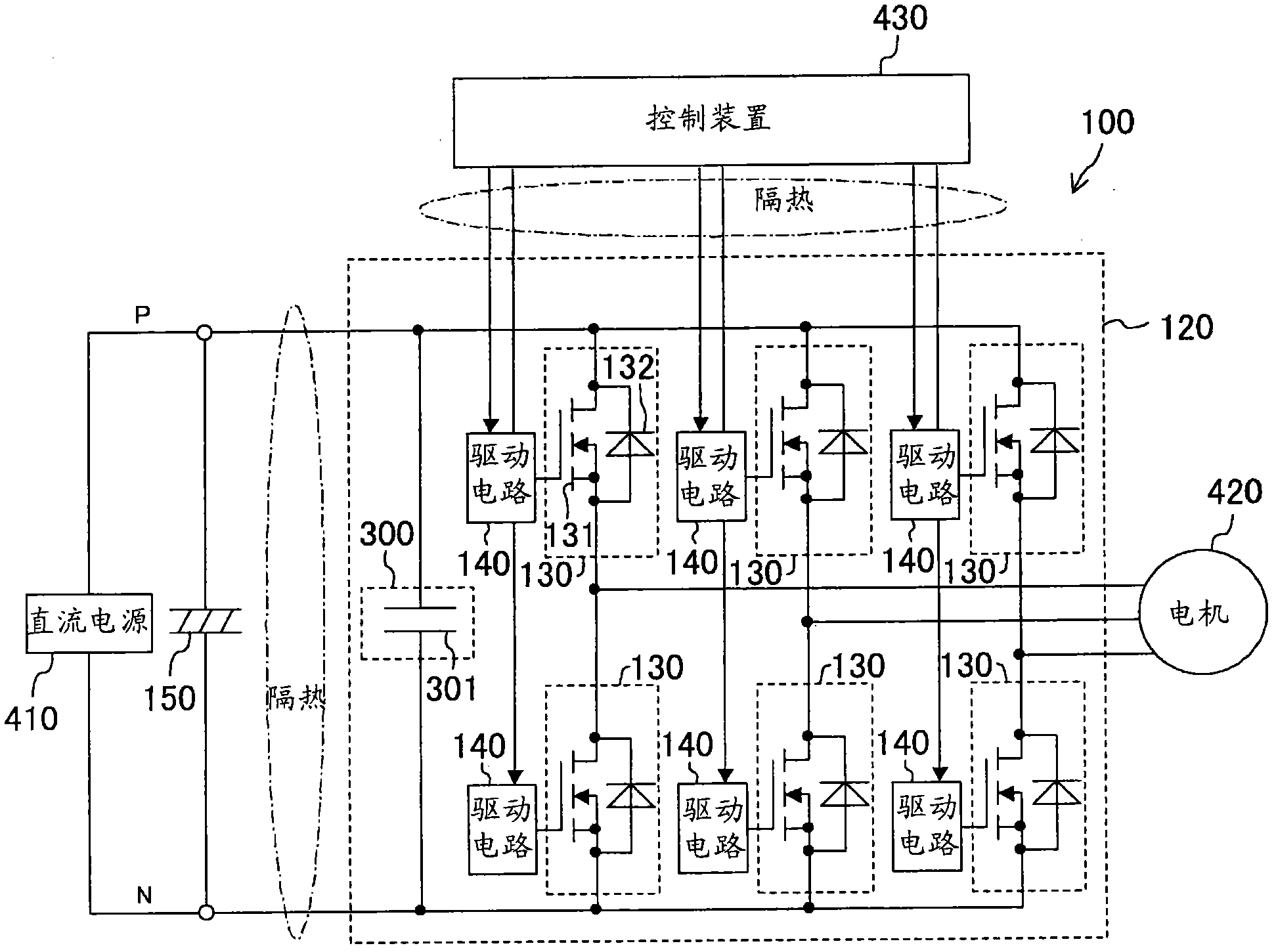

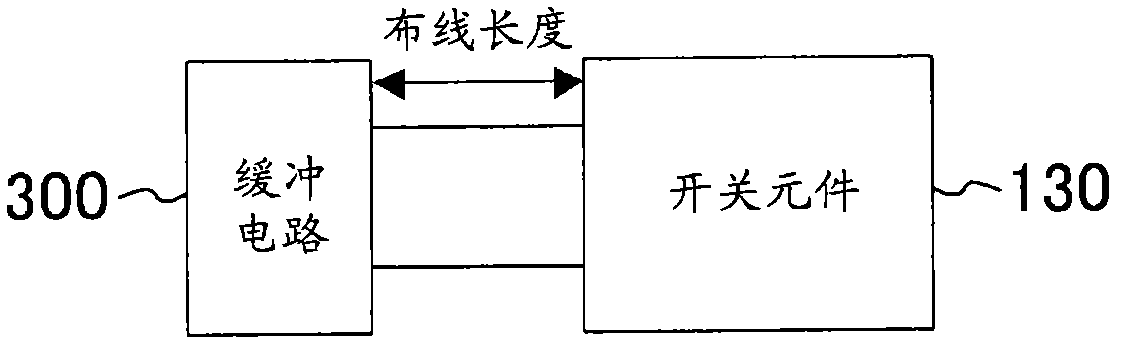

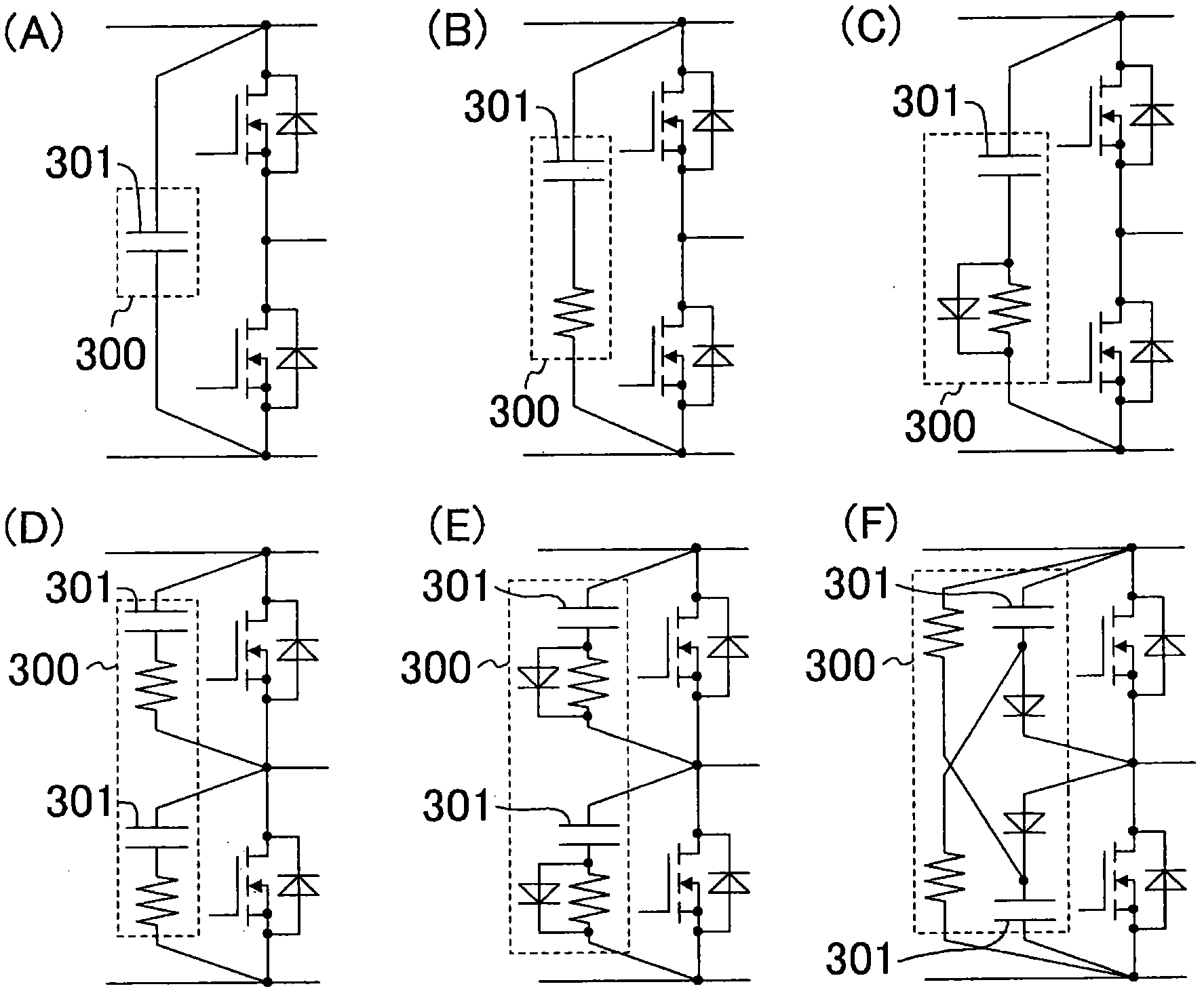

Power conversion device

InactiveCN101965677AEnables power conversionEfficient Power ConversionConversion constructional detailsSolid-state devicesSnubberAC power

Disclosed is a power conversion device that is provided with a switching element (130) that is constituted to be capable of high-temperature operation, and that converts AC power supplied from an AC power source or DC power supplied from a DC power source to AC power of a specified voltage and frequency. A snubber circuit (300) is provided that is constituted to be capable of high-temperature operation and that contains a capacitor (301) that is constituted to be capable of high-temperature operation.

Owner:DAIKIN IND LTD

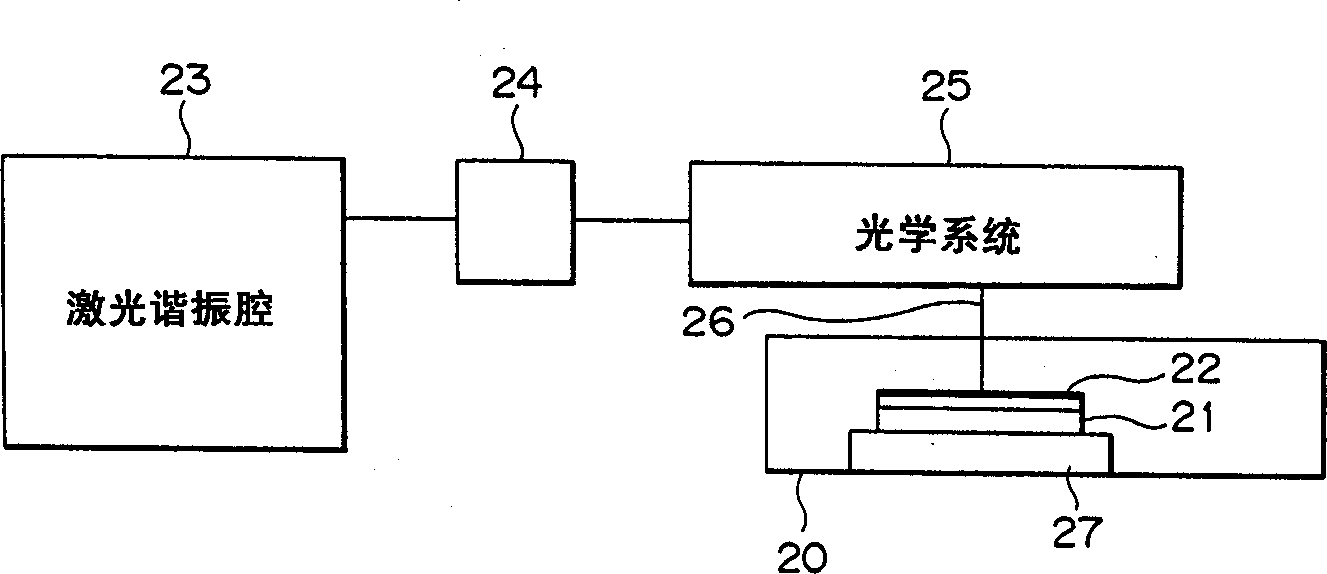

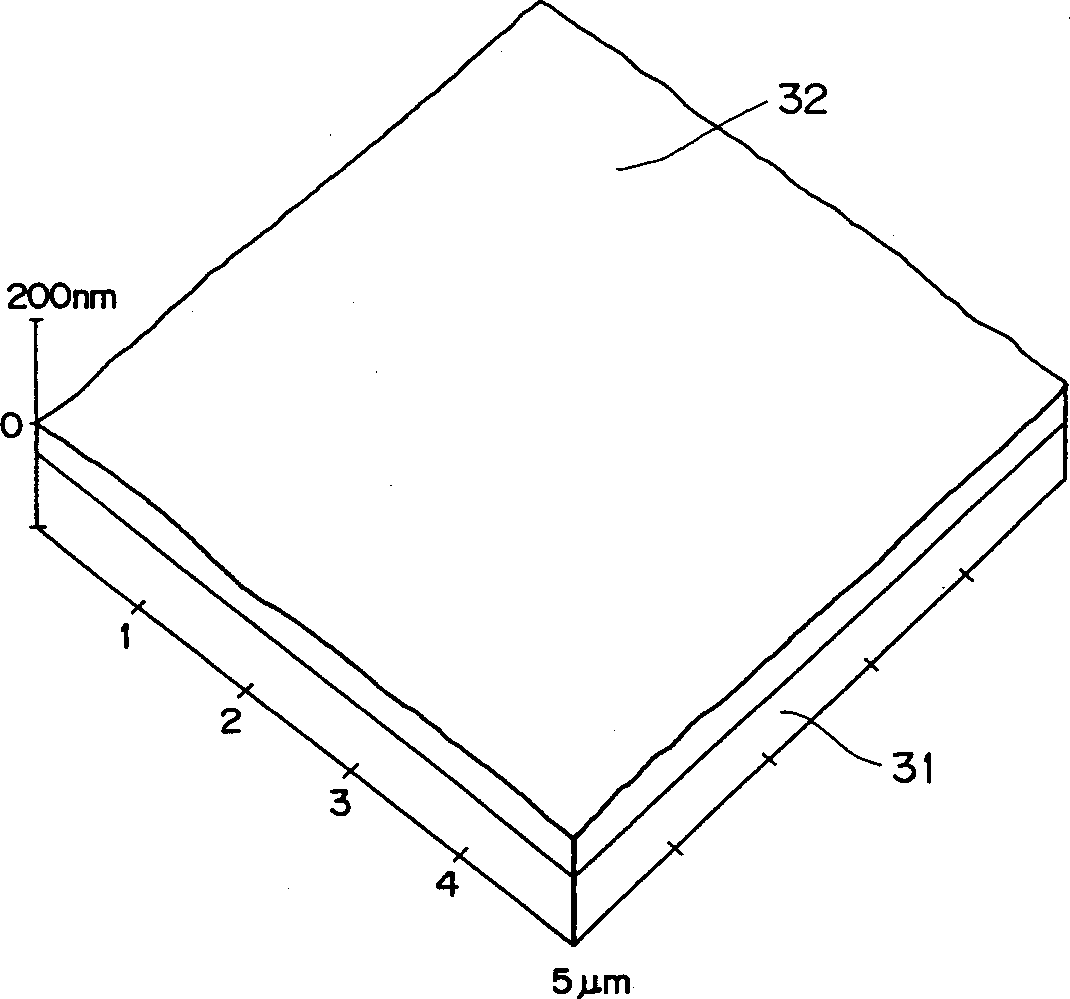

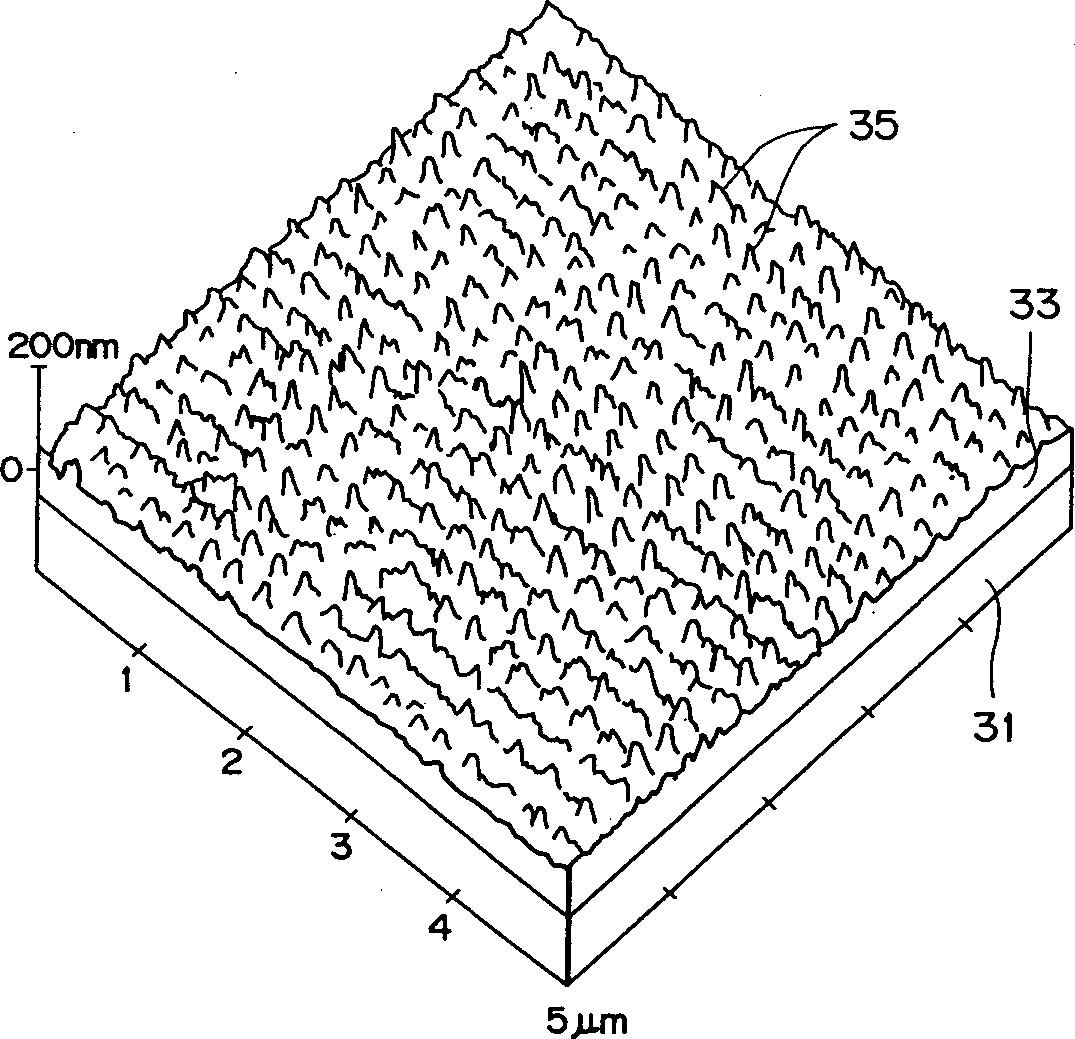

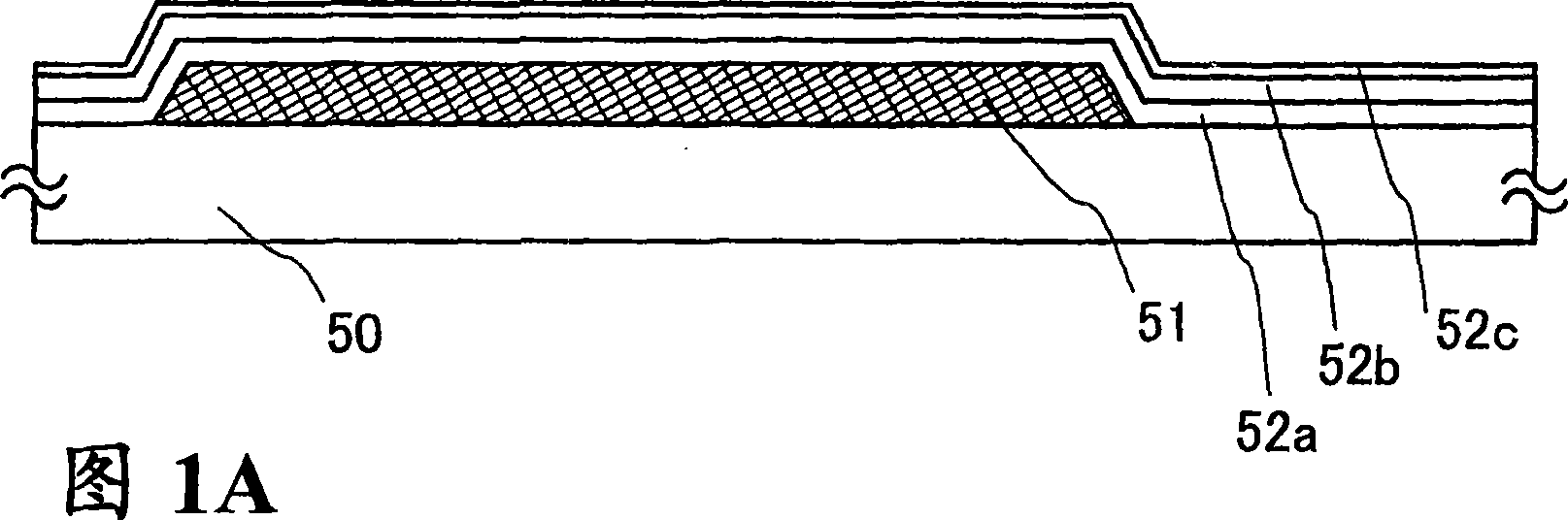

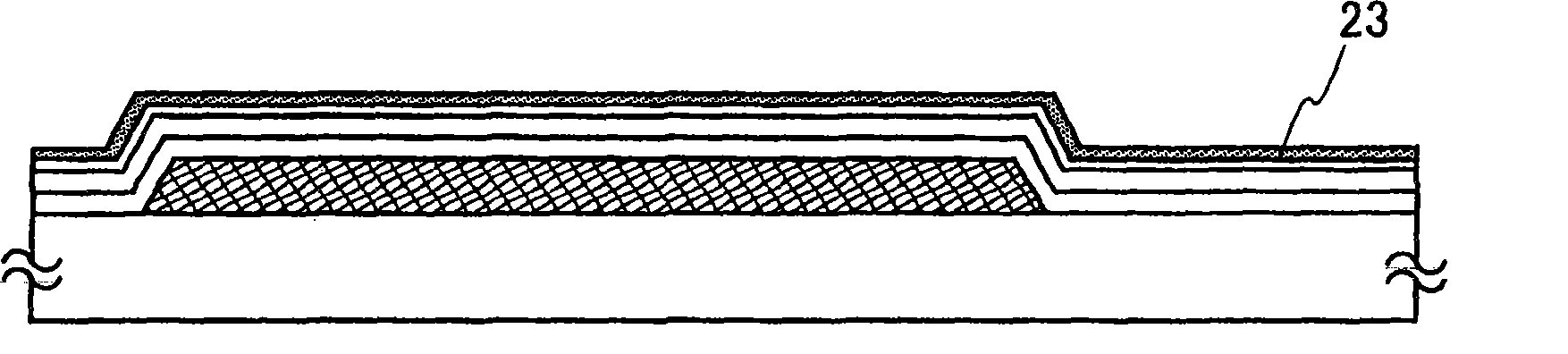

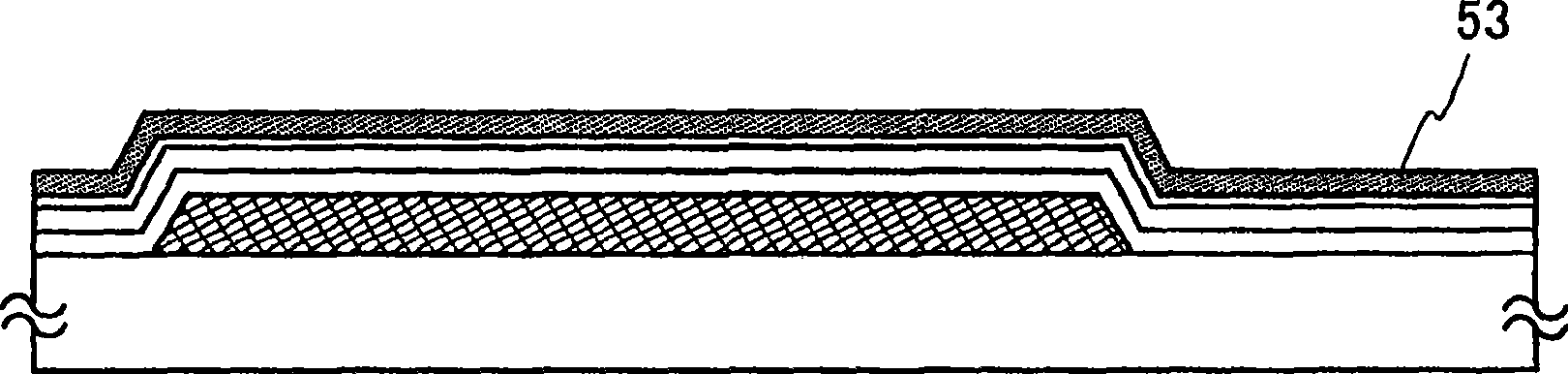

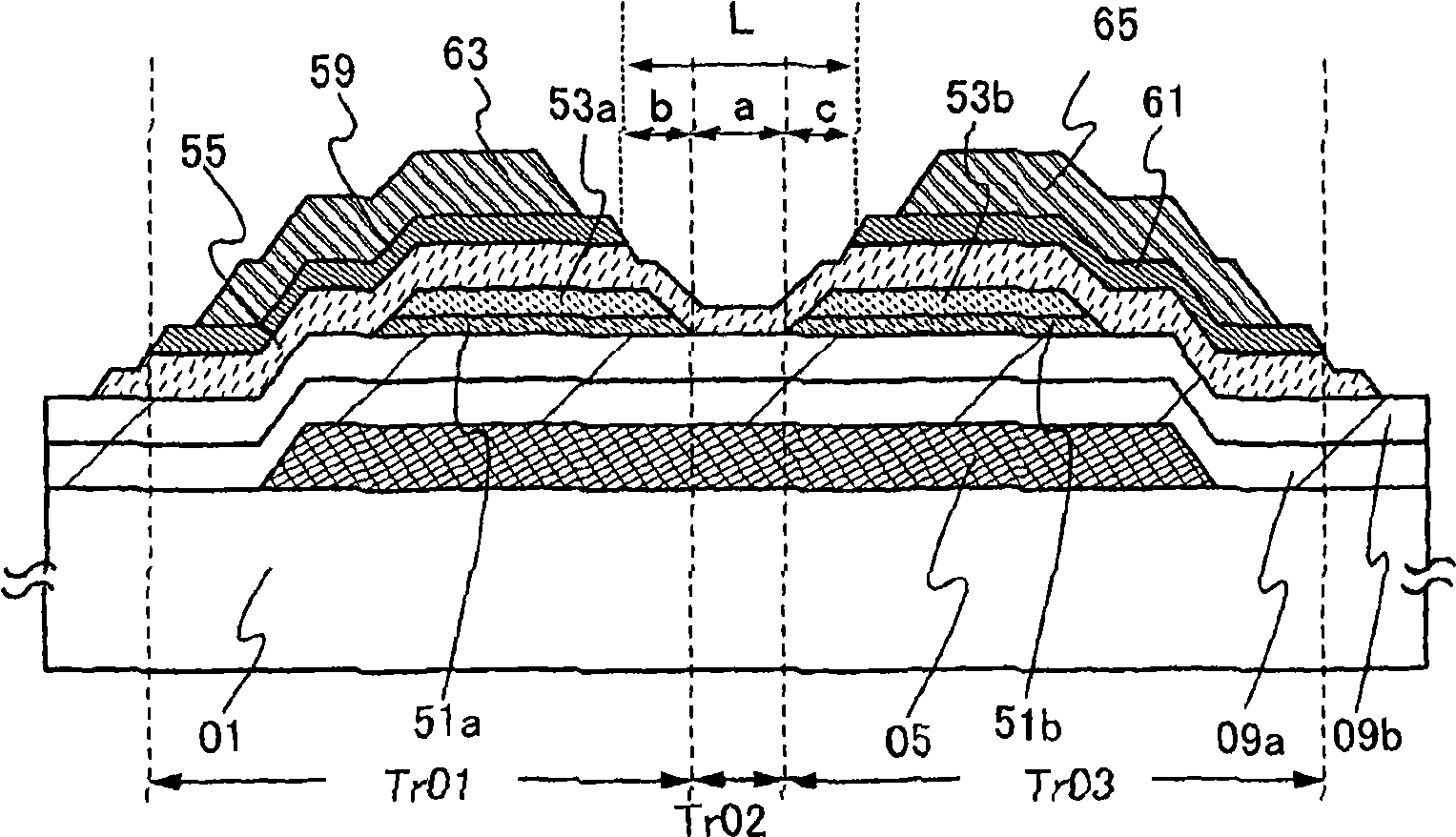

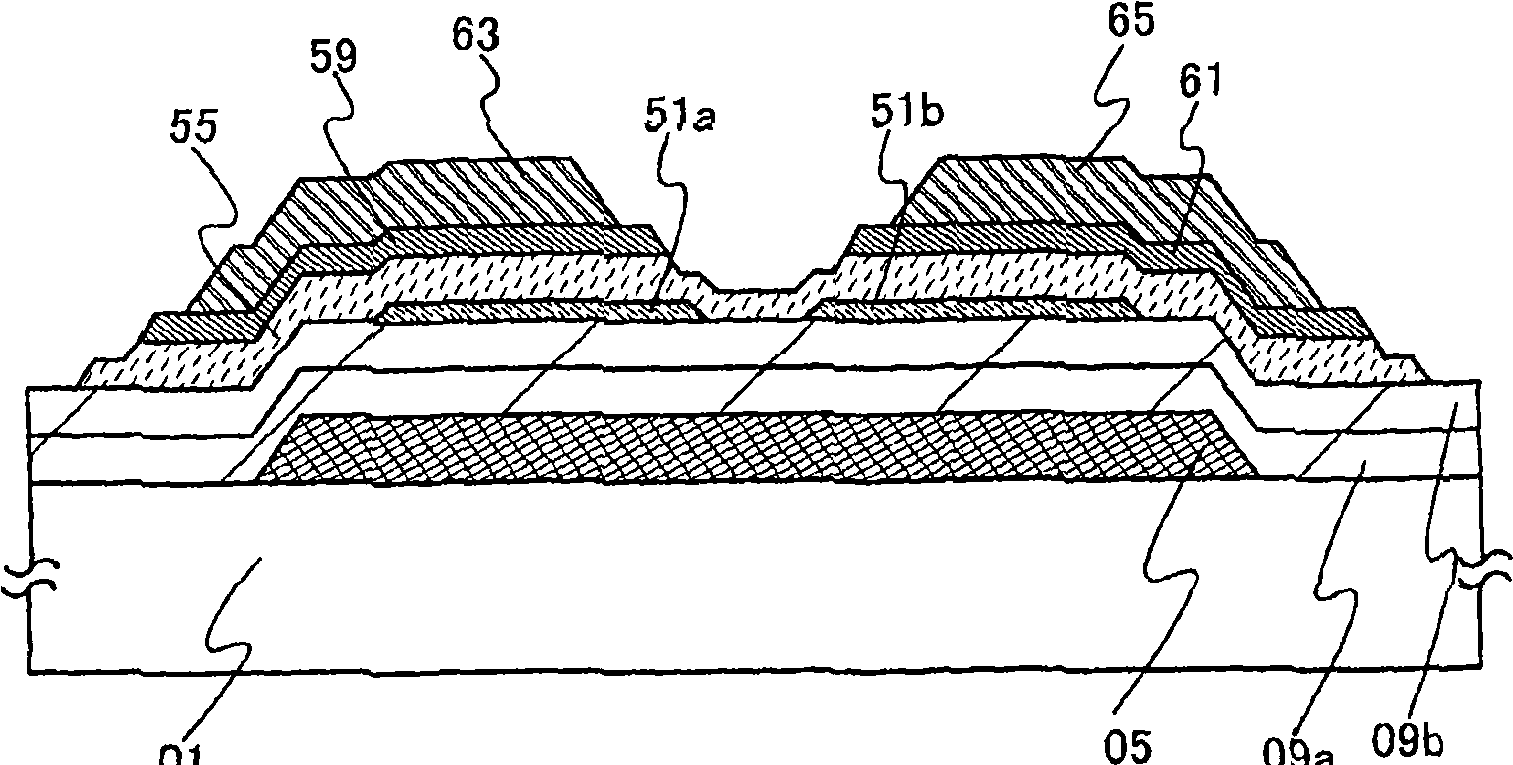

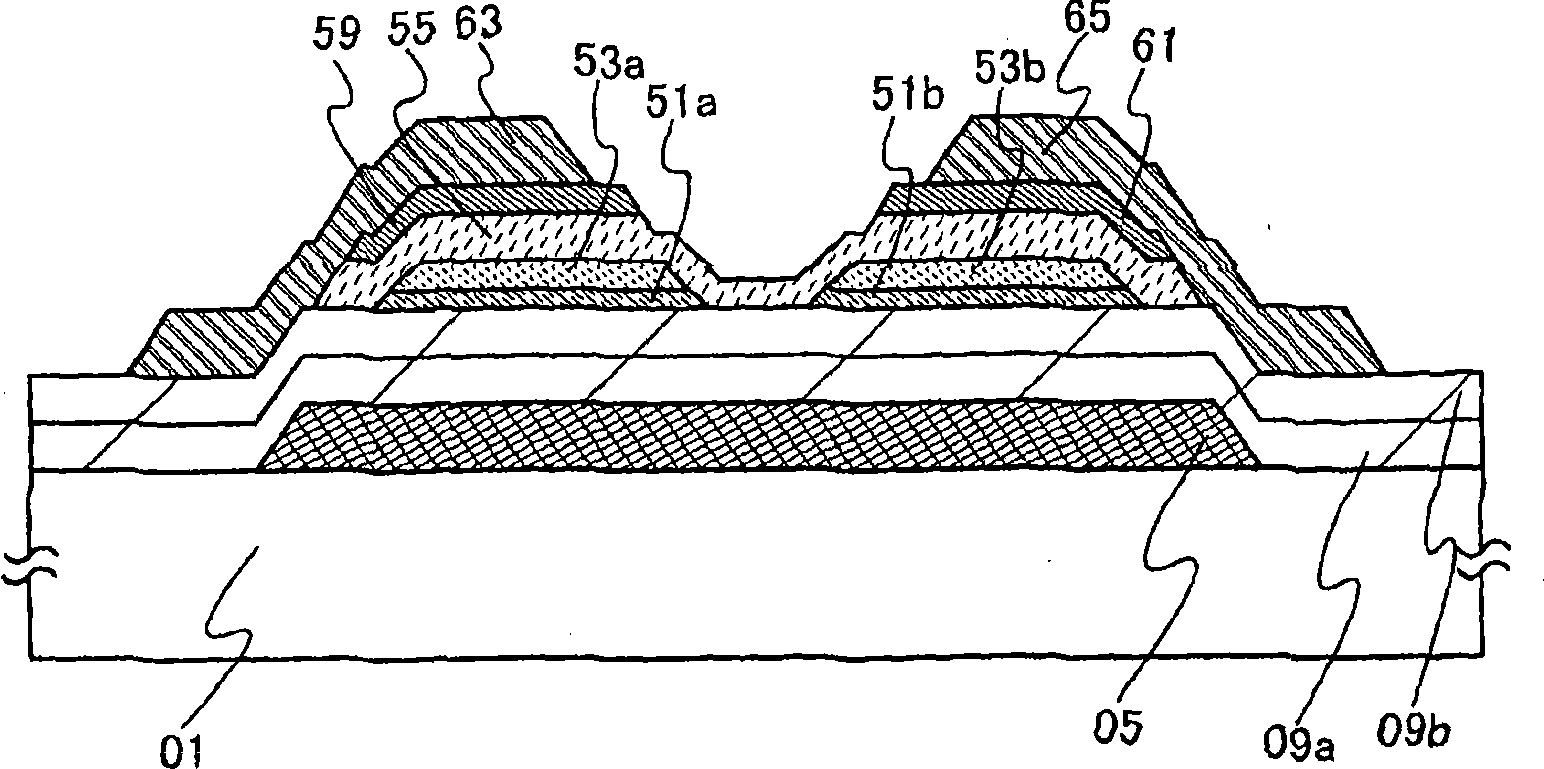

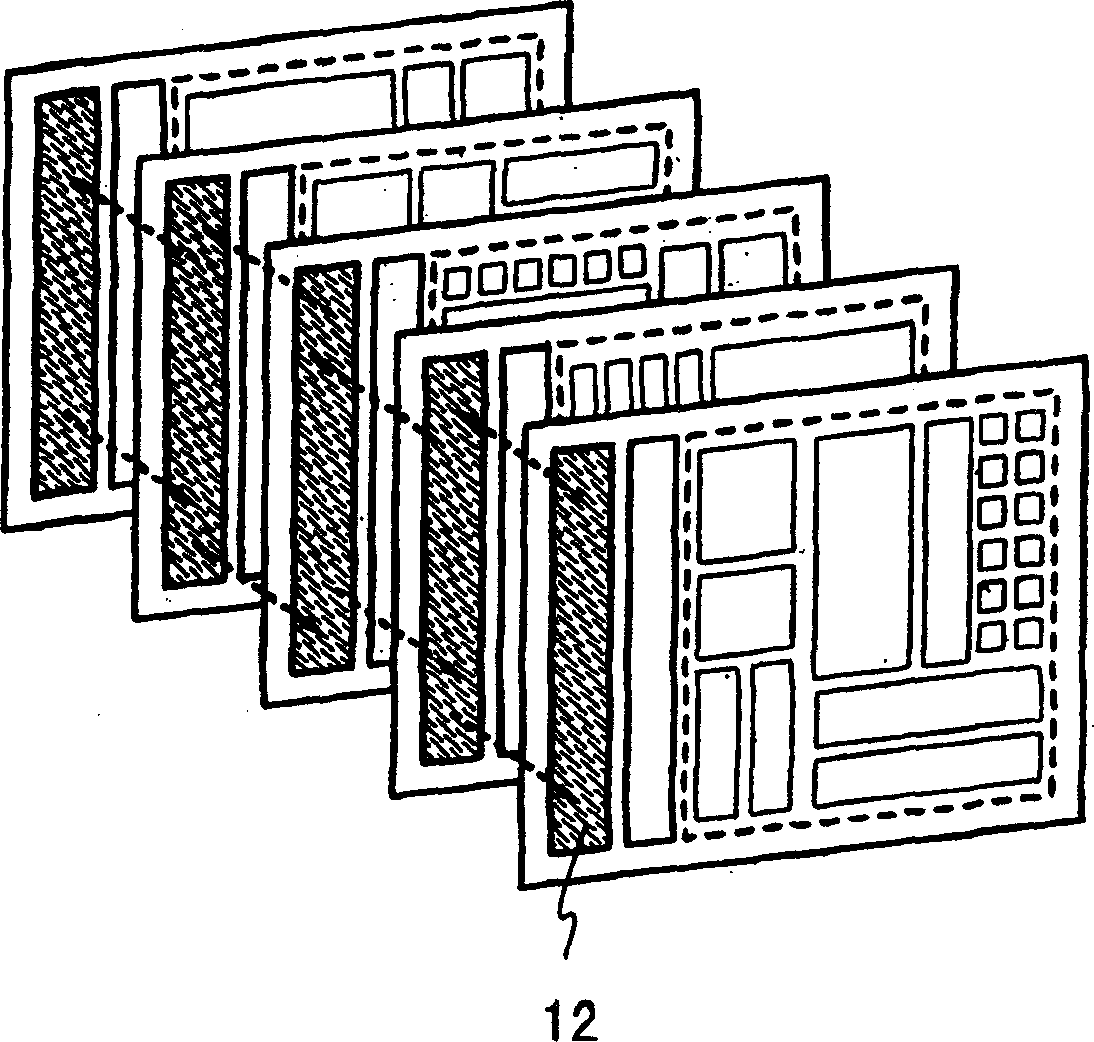

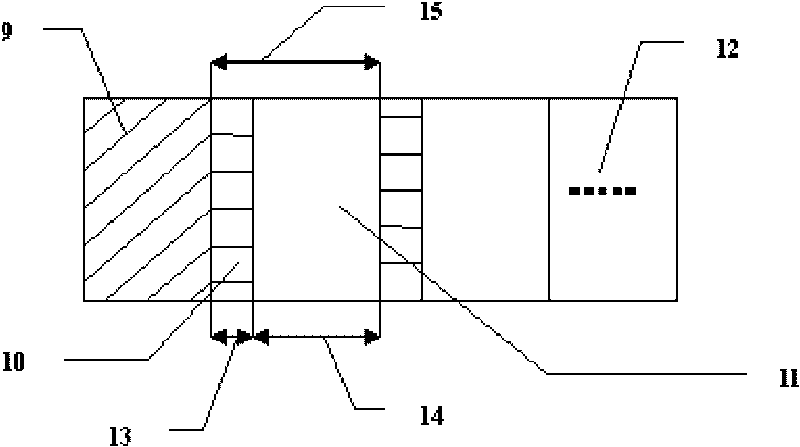

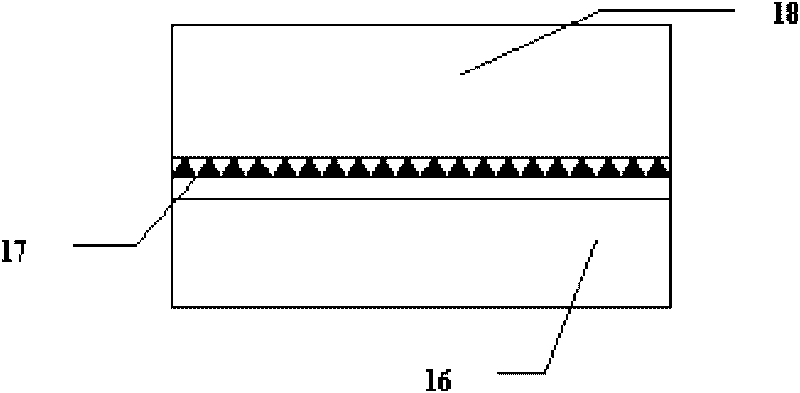

Semiconductor film and producing method and equipment, and method for producing single crystal film

InactiveCN1354495AWork at high speedContains changes in critical voltageTransistorPolycrystalline material growthRegular patternSingle crystal

A method of fabricating a single crystal thin film includes forming a non-single crystal thin film on an insulating base; subjecting the non-single crystal thin film to a first heat-treatment, thereby forming a polycrystalline thin film in which polycrystalline grains are aligned in an approximately regular pattern; and subjecting the polycrystalline thin film to a second heat-treatment, thereby forming a single crystal thin film in which the polycrystalline grains are bonded to each other. In this method, either the first heat-treatment or the second heat-treatment may be performed by irradiation of laser beams, preferably, emitted from an excimer laser. A single crystal thin film formed by this fabrication method has a performance higher than a related art polycrystalline thin film and is suitable for fabricating a device having stable characteristics. The single crystal thin film can be fabricated for a short-time by using laser irradiation as the heat-treatments.

Owner:SONY CORP

Method for manufacturing semiconductor device

InactiveCN101447412AImprove responsivenessWork at high speedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringChemical vapor deposition

In order to improve the quality of a microcrystalline semiconductor film which is formed at an early stage of deposition, a microcrystalline semiconductor film near an interface with a base insulating film is formed under a deposition condition in which a deposition rate is low but the quality of a film to be formed is high; then, a microcrystalline semiconductor film is further deposited at a deposition rate which is increased stepwise or gradually. The microcrystalline semiconductor film is formed in a reaction chamber which is provided in a deposition chamber with space around the reaction chamber, by a chemical vapor deposition method. Further, a scaling gas is supplied into the space to help place the reaction chamber in an ultrahigh vacuum, whereby the concentration of an impurity in the microcrystalline semiconductor film near the interface with the base insulating film is reduced.

Owner:SEMICON ENERGY LAB CO LTD

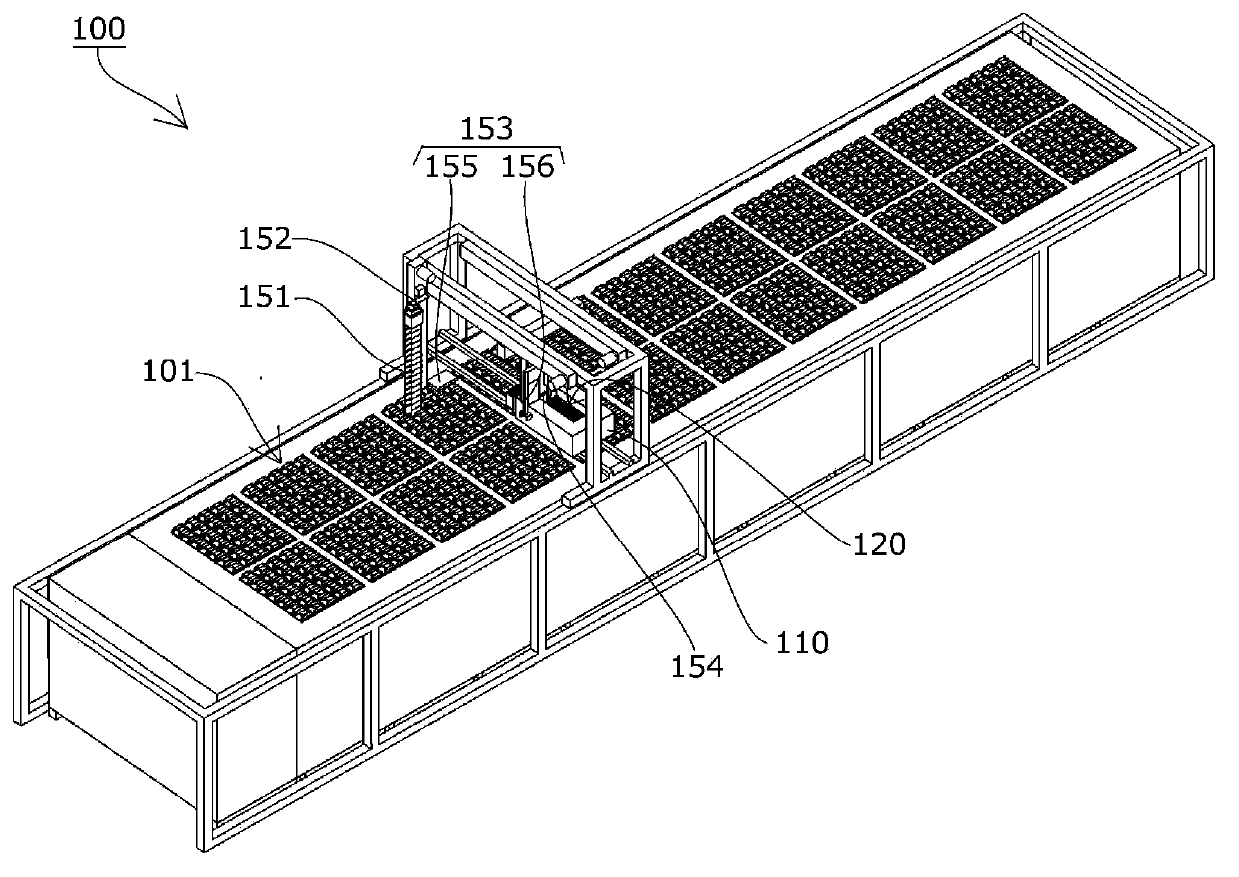

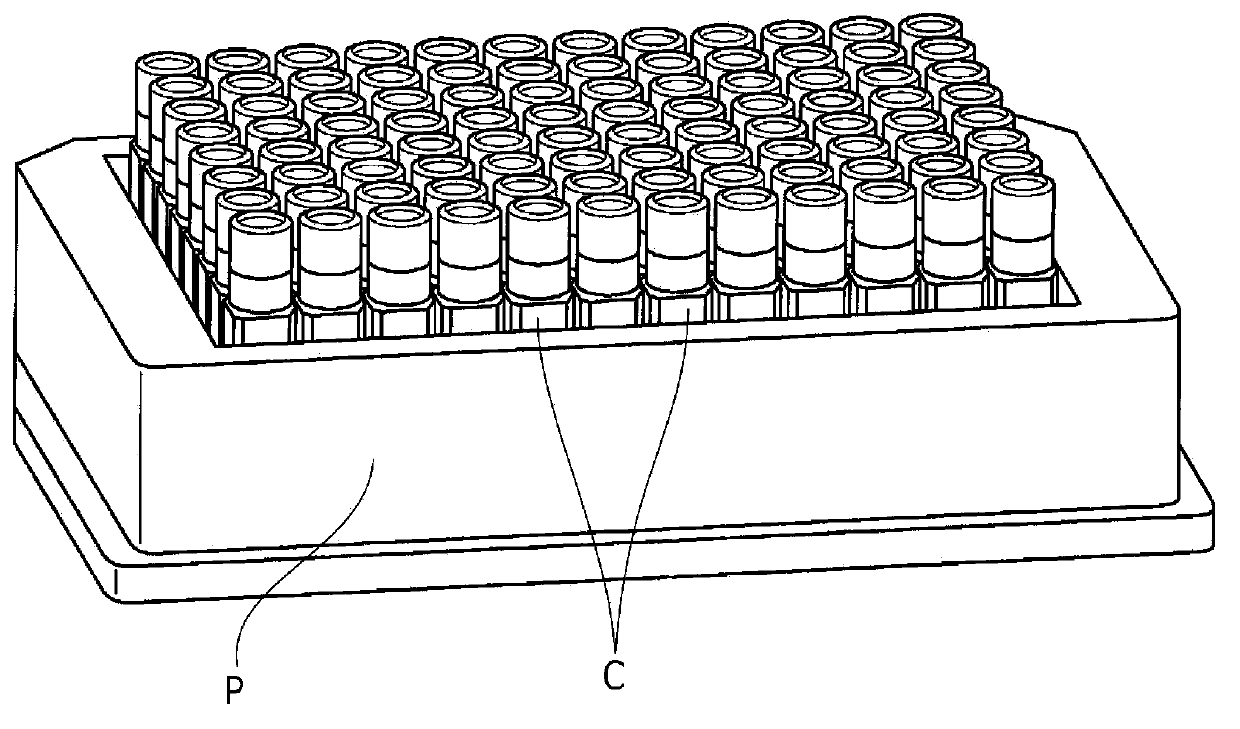

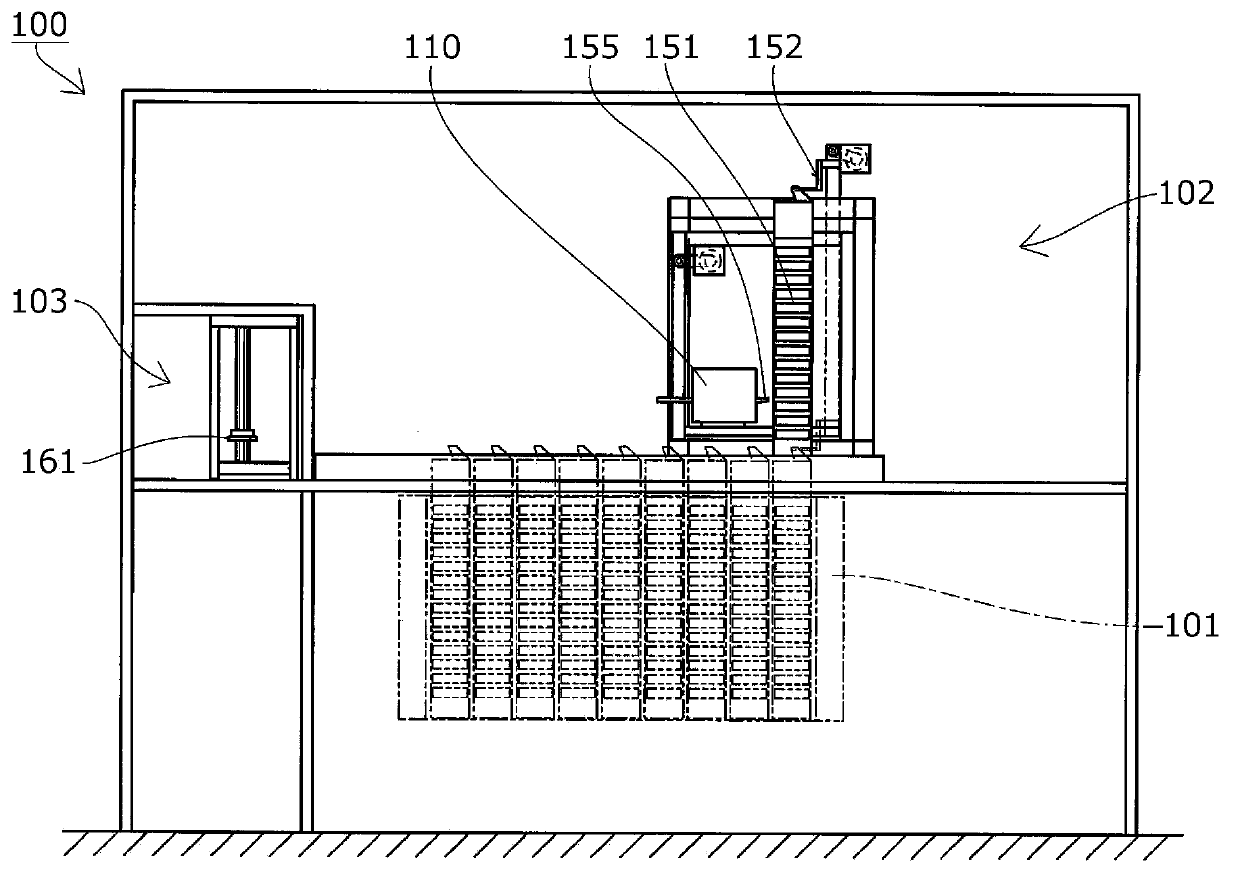

Low-temperature storage system

InactiveCN103964110AWork at high speedLow costPreparing sample for investigationStorage devicesMoisture condensationCoolant

The invention provides a low-temperature storage system, which does not cause a temperature rise of a container in extraction action, prevents deterioration of a sample in the container and moisture condensation on the container, does not require a special machine, and can work at high speed, and costs required by manufacture and use are reduced and the system is easy to use. Specifically, a low-temperature storage system (100) has a container housing unit (110) which formed in a manner of being movable in a space at an upper side of a lower-temperature storage chamber (101) where a plurality of containers (C) housing samples are stored, and the container housing unit (110) has a low-temperature housing groove (120), an upper opening, and housing containers (C), and a coolant tube (121) which cools the inside of the low-temperature housing groove (120).

Owner:TSUBAKIMOTO CHAIN CO +1

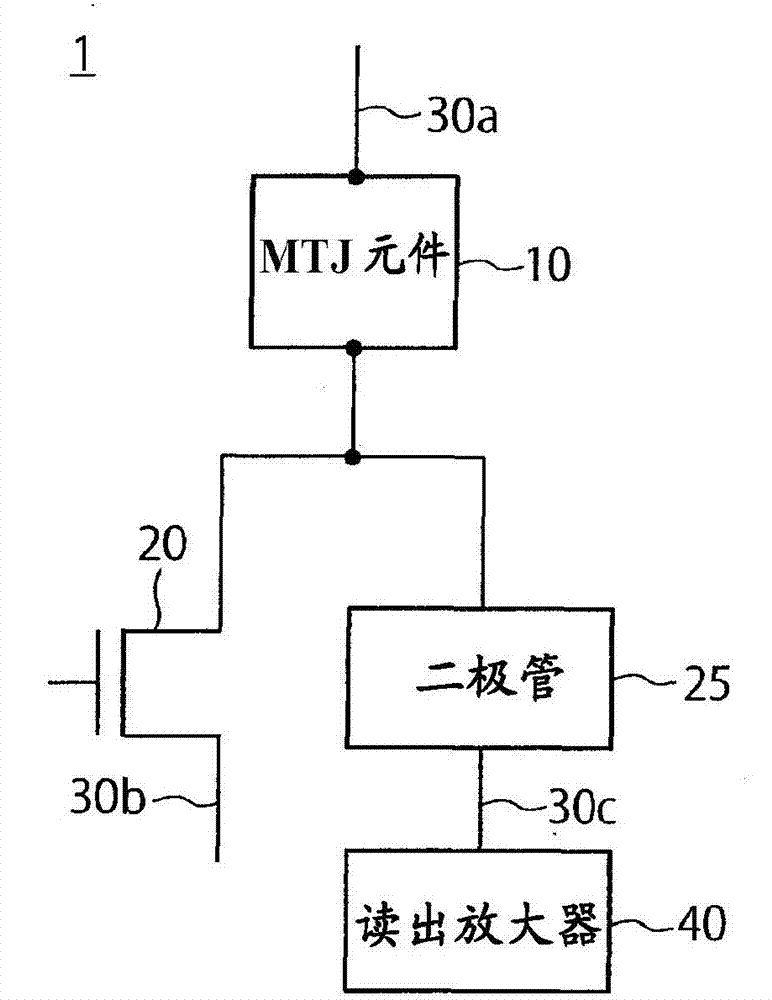

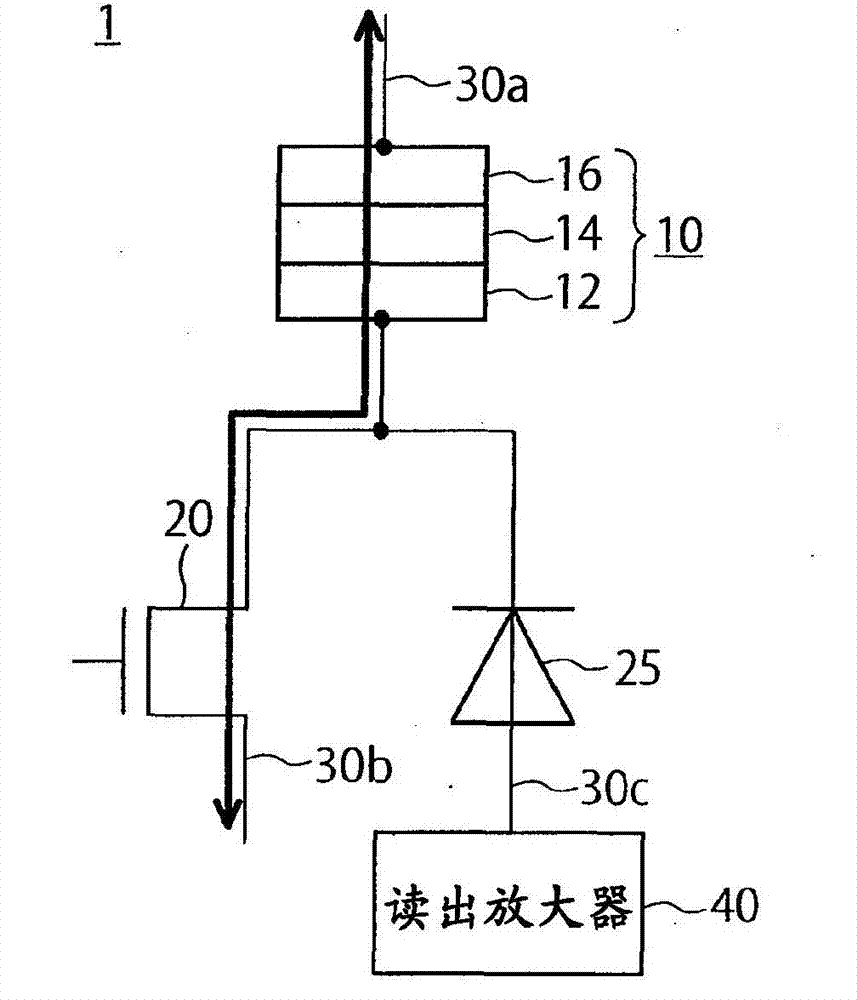

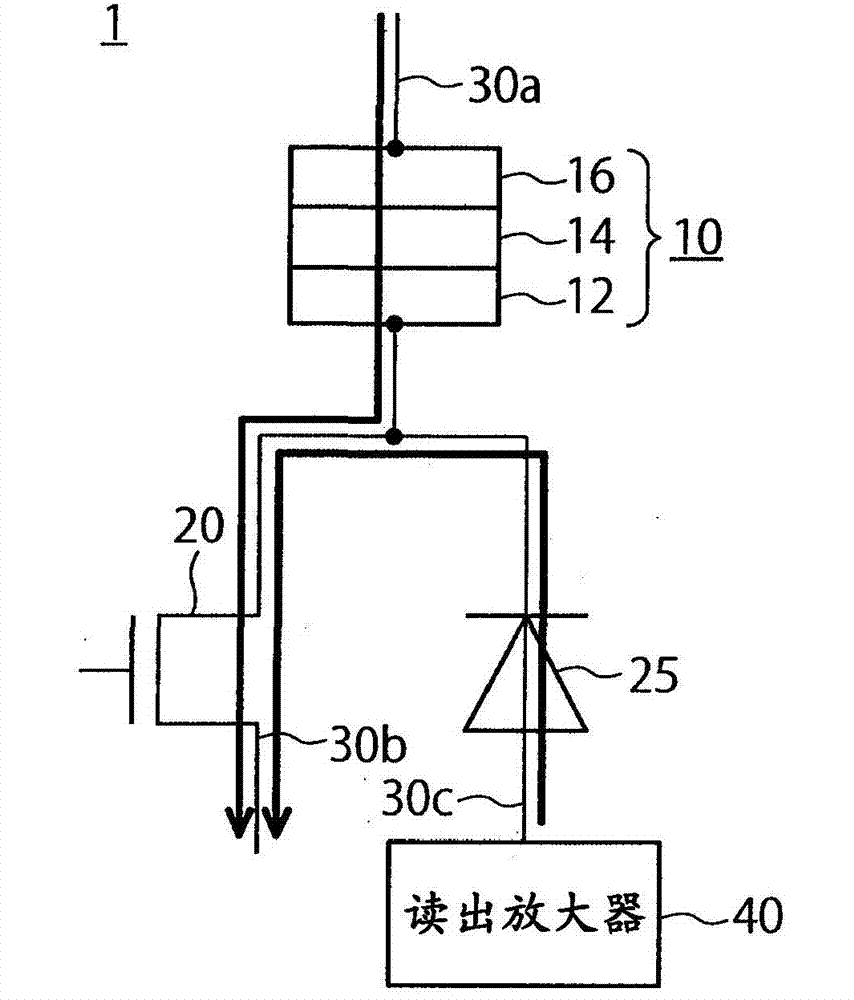

Magnetic random access memory

InactiveCN103021449AWork at high speedSolid-state devicesDigital storageStatic random-access memoryMagnetic memory

The invention provides a magnetic memory to realize high-speed operations. A magnetic memory according to an embodiment includes: a magnetoresistive element including a first magnetic layer having a magnetization direction not to be changed by spin-injection writing, a second magnetic layer having a magnetization direction to be changeable by the spin-injection writing, and a tunnel barrier layer provided between the first and second magnetic layers; a first interconnect electrically connected to one of the first and second magnetic layers; a select transistor, with one of a source and drain thereof being electrically connected to the other one of the first and second magnetic layers; a second interconnect electrically connected to the other one of the source and drain; a diode having one terminal electrically connected to the other one of the first and second magnetic layers; a third interconnect electrically connected to the other terminal of the diode; and a sense amplifier electrically connected to the third interconnect.

Owner:KK TOSHIBA

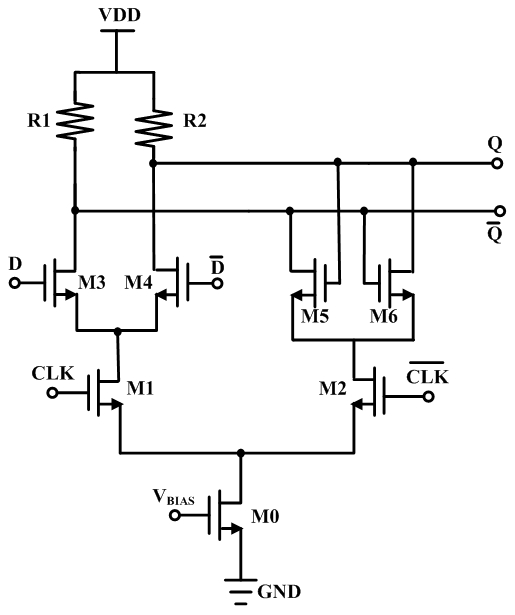

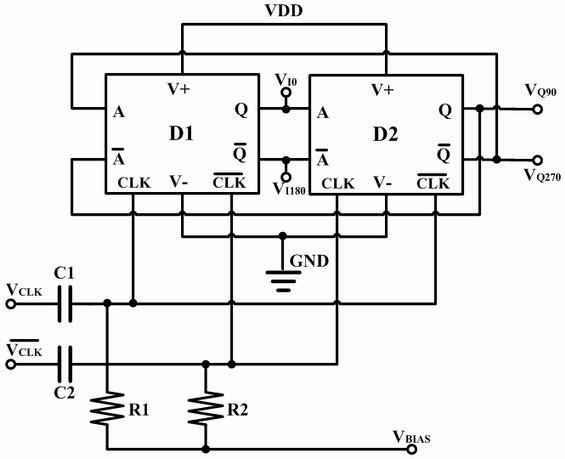

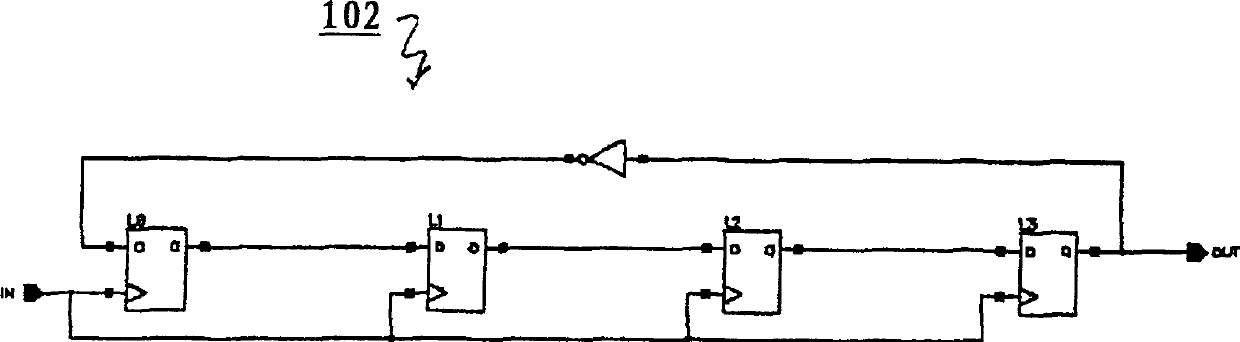

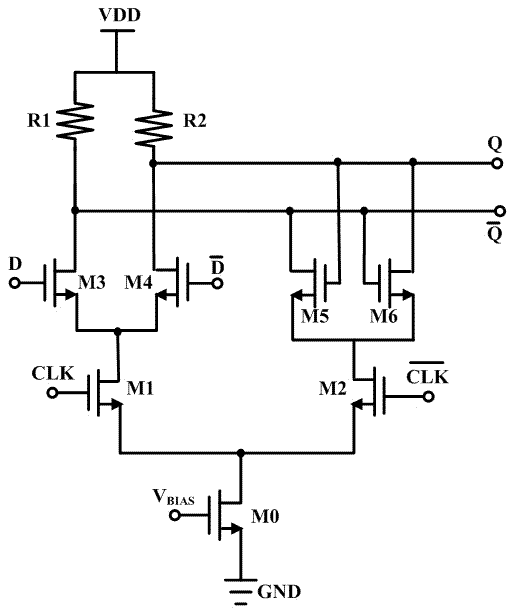

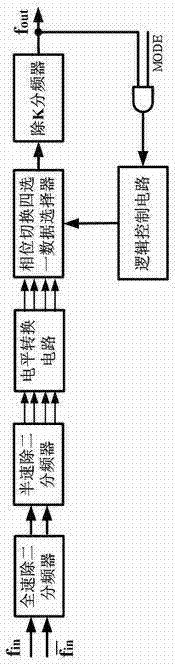

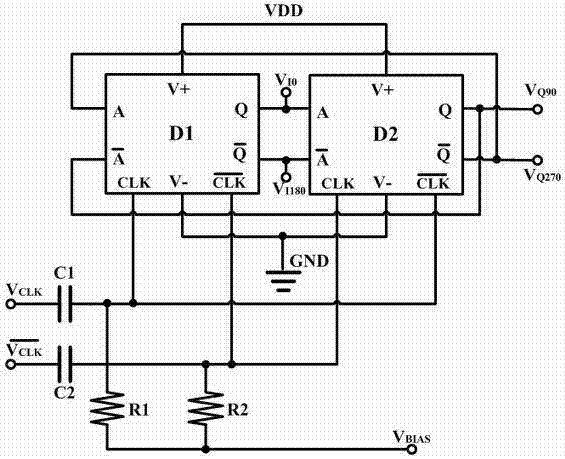

A high-speed large-swing divide-by-two frequency divider circuit based on current-mode logic

InactiveCN102291132AImprove anti-interference abilityReduce noisePulse automatic controlDual modeP channel

The invention discloses a high speed high-oscillation amplitude divide-by-two frequency divider circuit, which belongs to the technical fields of integrated circuit designing and signal processing. Specifically, the circuit mainly comprises two high speed high-oscillation amplitude D triggers which are cascaded. The D trigger of each stage eliminates the bias of a tail current source based on theconventional D trigger having a current-mode logic (CML) structure, and adopts a P-channel metal oxide semiconductor (PMOS) transistor as a load; and simultaneously, a PMOS and N-channel metal oxide semiconductor (NMOS) complementary cross coupling pair structure and the like are adopted by the output stage of the circuit to finally achieve the aims of increasing the oscillation amplitude of an output signal and making the oscillation amplitude of the output signal approximate to full oscillation amplitude under the condition of ensuring the high speed working of the circuit. The circuit not only can directly drive a post circuit, reduces system power consumption to a certain extent, compensates for the shortcomings of a conventional divide-by-two frequency divider, and is suitable for a high speed frequency divider part in a low-power consumption preposed dual-mode prescaler front-end without any additional level conversion amplification circuit.

Owner:EAST CHINA NORMAL UNIV

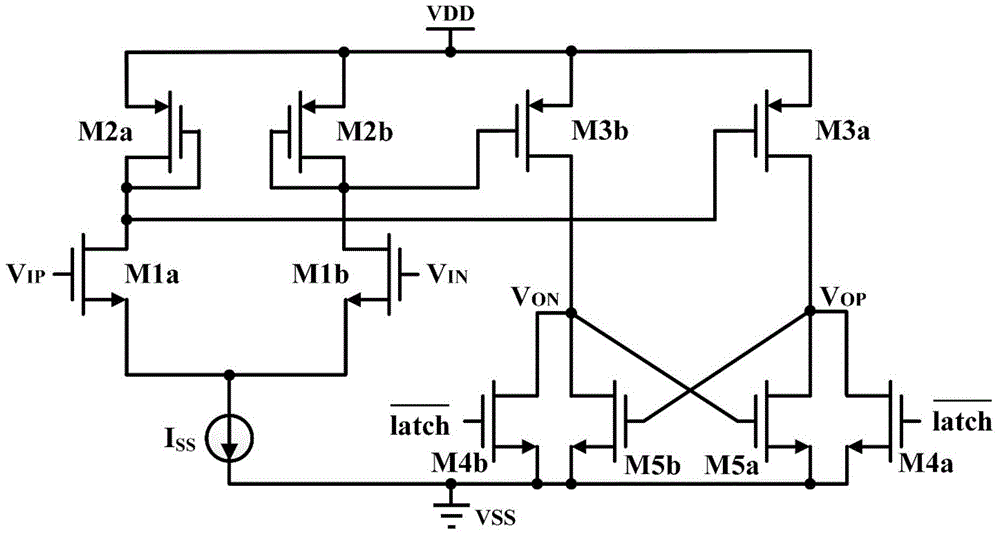

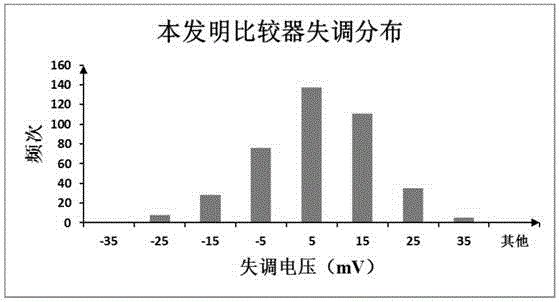

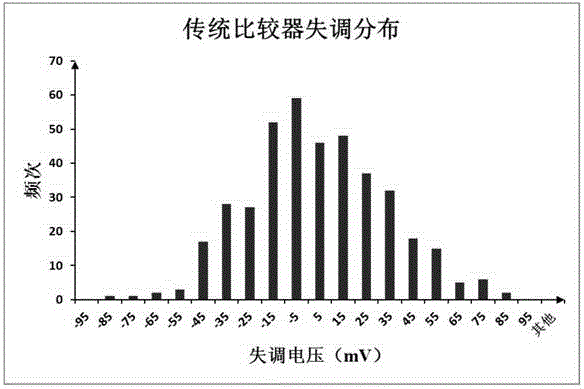

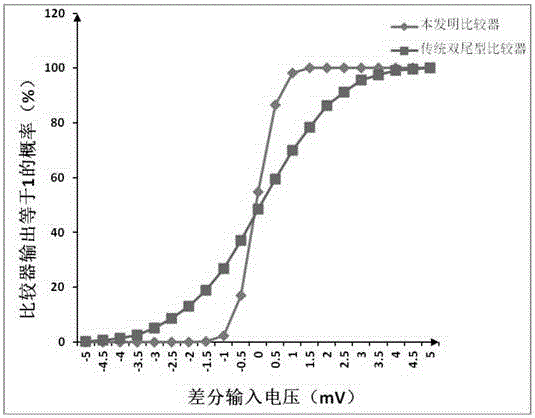

Two-level comparator

InactiveCN106209035AReduce noiseReduce offsetMultiple input and output pulse circuitsCouplingComparators circuits

The present invention relates to a two-level comparator circuit, belonging to the technical field of analog integrated circuits. The two-level comparator circuit comprises an input level and a latch level. The input level comprises a first N-channel metal oxide semiconductor (NMOS) transistor (MN1), a second NMOS transistor (MN2), a third NMOS transistor (MN3), a first p-channel metal oxide semiconductor (PMOS) transistor (MP1), a second PMOS transistor (MP2), a third PMOS transistor (MP3) and a fourth PMOS transistor (MP4). The latch level comprises a fourth NMOS transistor (MN4), a fifth NMOS transistor (MN5), a sixth NMOS transistor (MN6), a seventh NMOS transistor (MN7), an eighth NMOS transistor (MN8), a ninth NMOS transistor (MN9), a fifth PMOS transistor (MP5), a sixth PMOS transistor (MP6), a seventh PMOS transistor (MP7) and an eighth PMOS transistor (MP8). Due to reset of a node X+ and a node X- in a latch level circuit, circuit maladjustment and noise are lowered. A pair of cross-coupling transistors MP1 and MP2 is added in the input level circuit, so that the comparator has the characteristic of working at a high-speed. The two-level comparator is applicable to system circuits of high accuracy.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

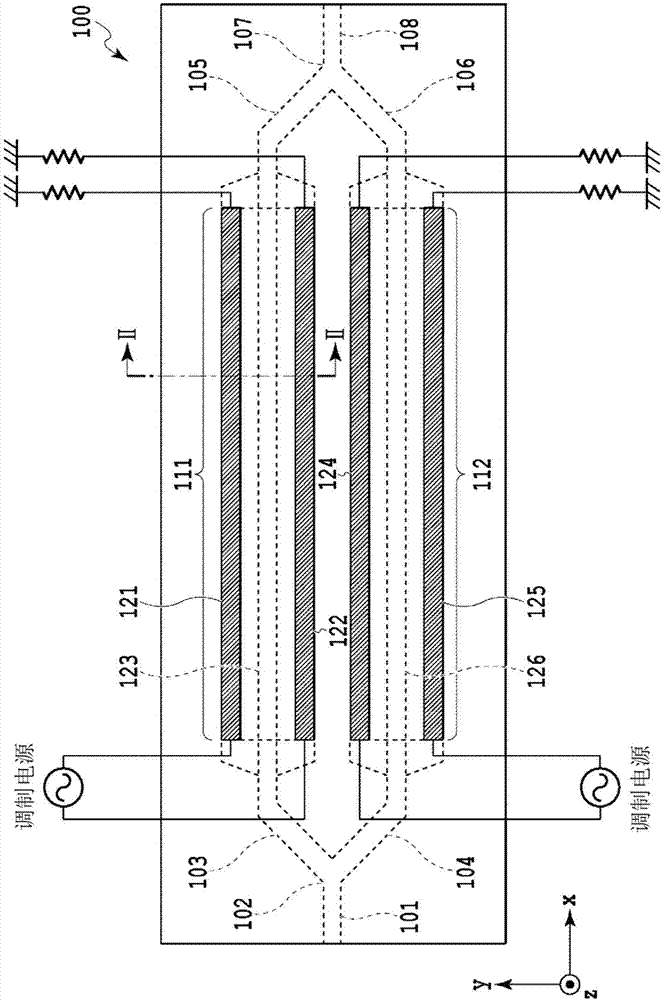

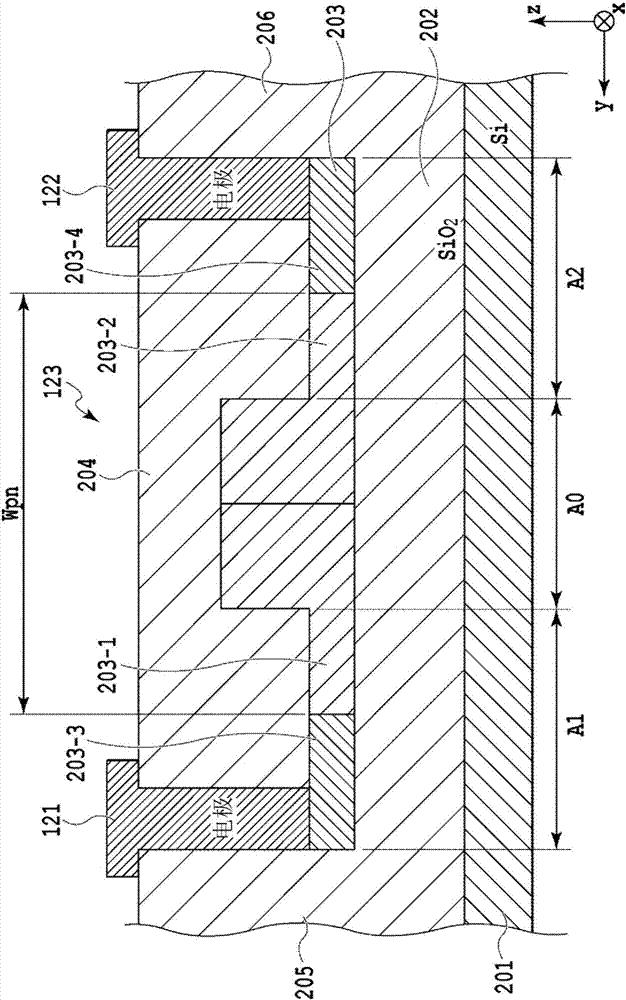

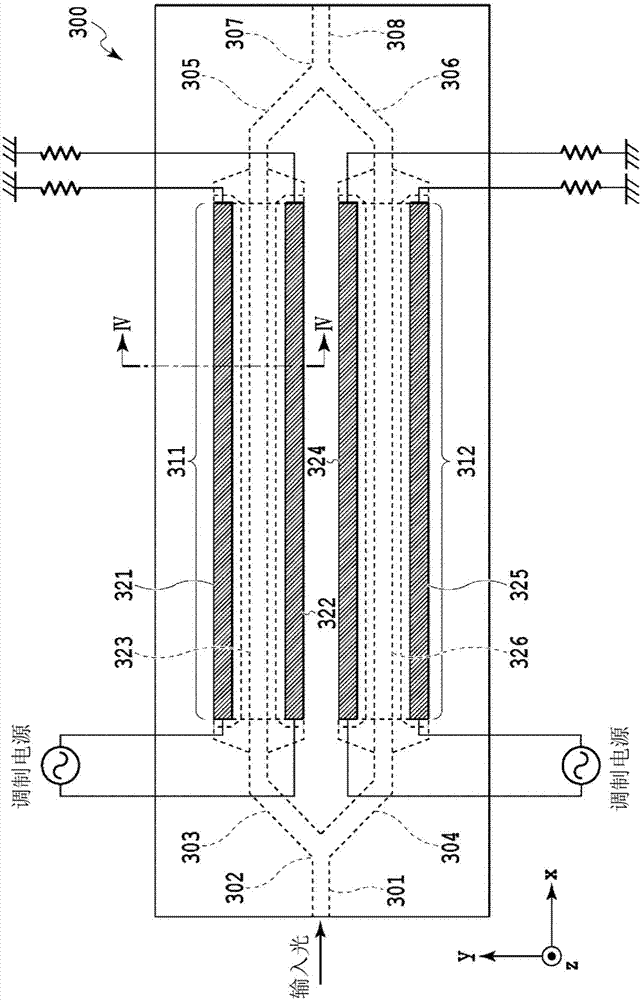

Optical modulator

This optical modulator includes a substrate and a phase modulation unit on the substrate, said phase modulation unit including: a first traveling-wave electrode, a second traveling-wave electrode, and an optical waveguide configured from a first cladding layer, a semiconductor layer, which is laminated on the first cladding layer, and has a refractive index that is higher than that of the first cladding layer, and a second cladding layer, which is laminated on the semiconductor layer, and has a refractive index that is lower than that of the semiconductor layer. The semiconductor layer is provided with: a rib section, which is formed in the optical axis direction of the optical waveguide, and is to be the core of the optical waveguide; a first slab section formed in the optical axis direction on one side of the rib section; a second slab section formed in the optical axis direction on the other side of the rib section; a third slab section formed in the optical axis direction on the first slab section side opposite to the rib section; and a fourth slab section formed in the optical axis direction on the second slab section side opposite to the rib section. The first slab section is formed thinner than the rib section and the third slab section, and the second slab section is formed thinner than the rib section and the fourth slab section.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

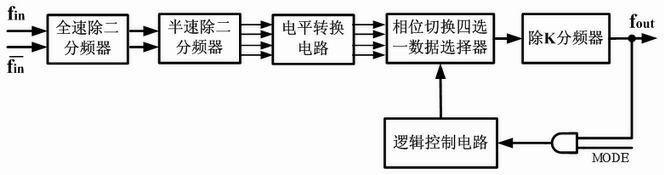

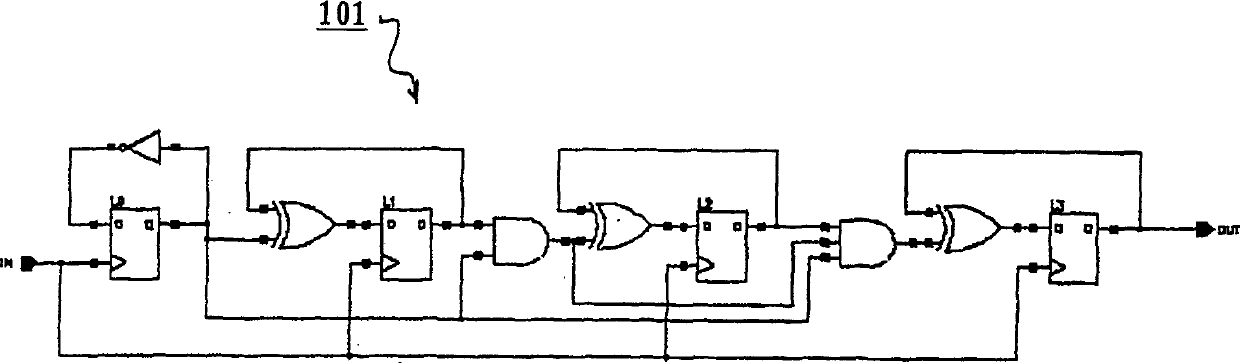

Programmable frequency divider with symmetrical output

InactiveCN1702958AOvercome inherent limitationsWork at high speedPulse automatic controlCounting chain pulse countersLogic networkLinear feedback shift register

A programmable frequency divider circuit with symmetrical output is disclosed. The frequency divider includes a non-symmetrical LFSR based component operated in series with a symmetrical divider component. Both the LFSR and the symmetrical divider may be programmed to provide flexibility. The frequency divider can dynamically adjust the divisor of the LFSR component to overcome limitations in the divide resolution due to the series combination of dividers, providing even and odd divisor values. The divider architecture can also provide higher level functions, including synchronization of multiple divider outputs, dynamic switching of divisor values and generation of multi-phased and spaced outputs. The linear feedback shift register (LFSR) component includes a feedback logic network decomposed into multiple stages to realize a maximum latch-to-latch operational latency of one gate delay regardless of the size of the LFSR.

Owner:GLOBALFOUNDRIES INC

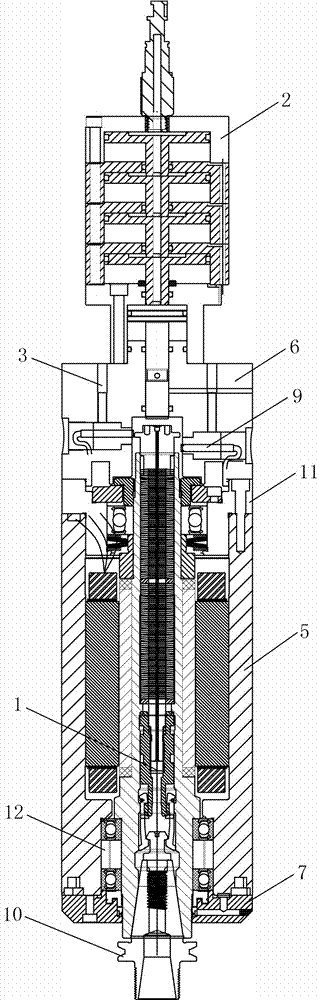

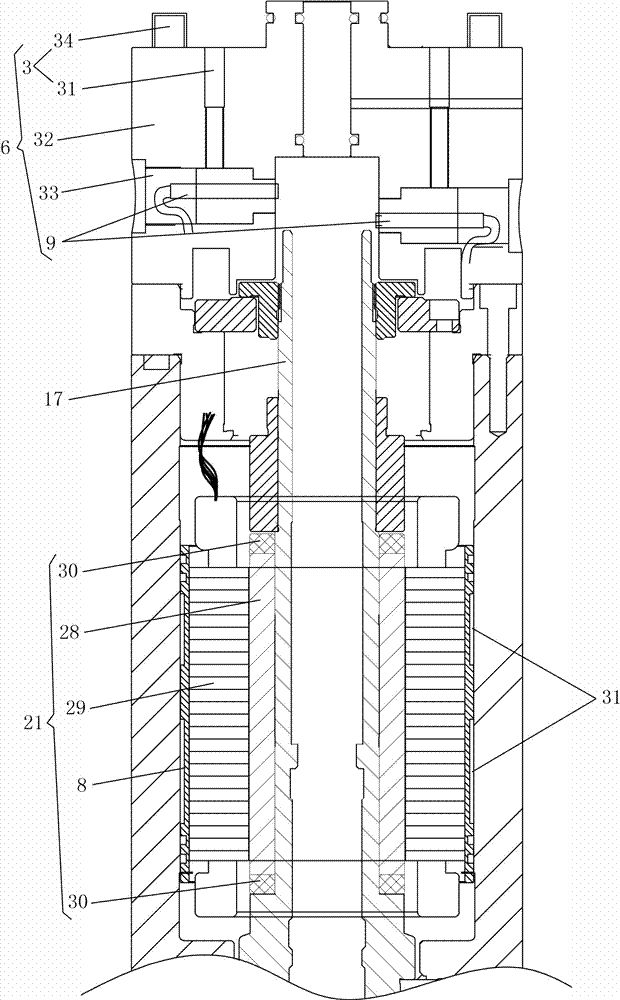

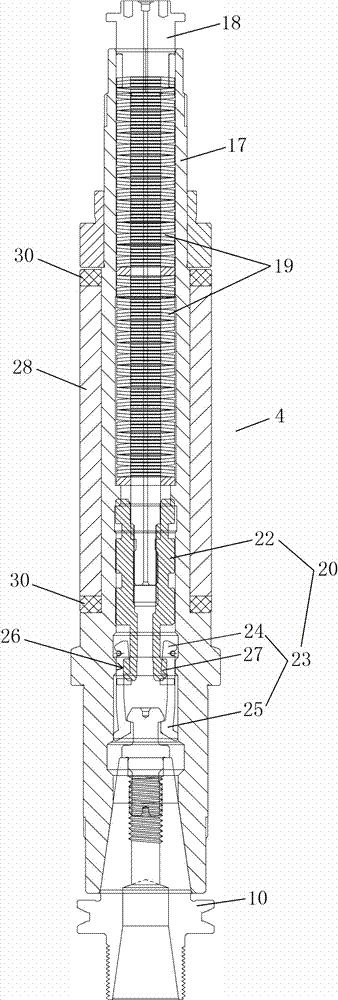

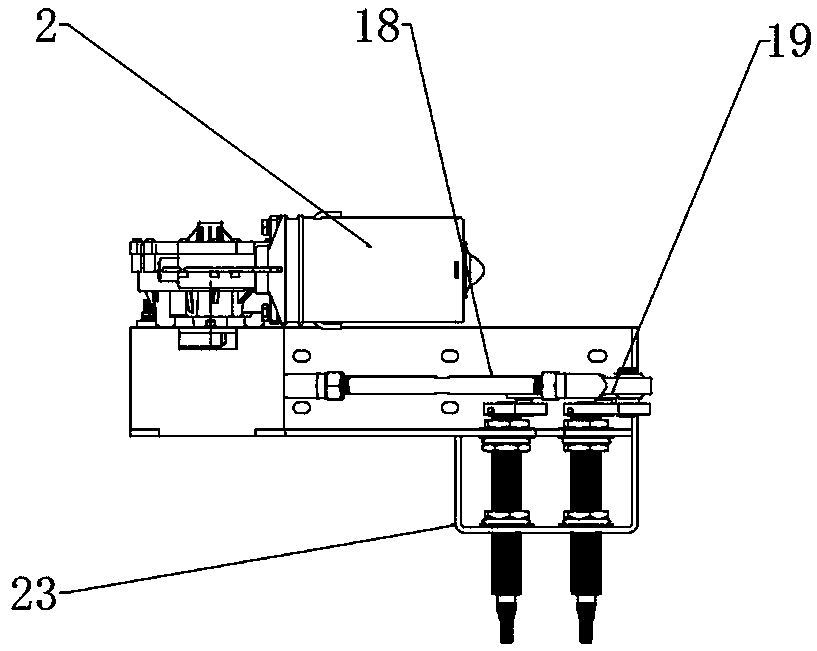

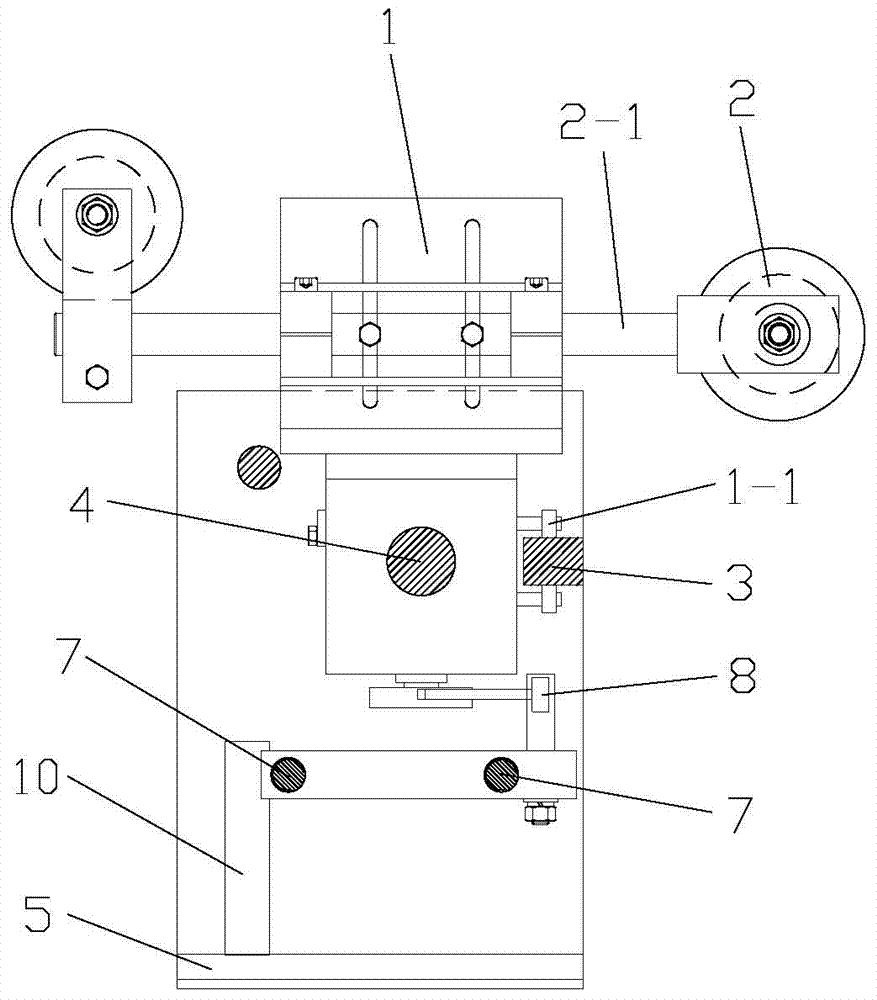

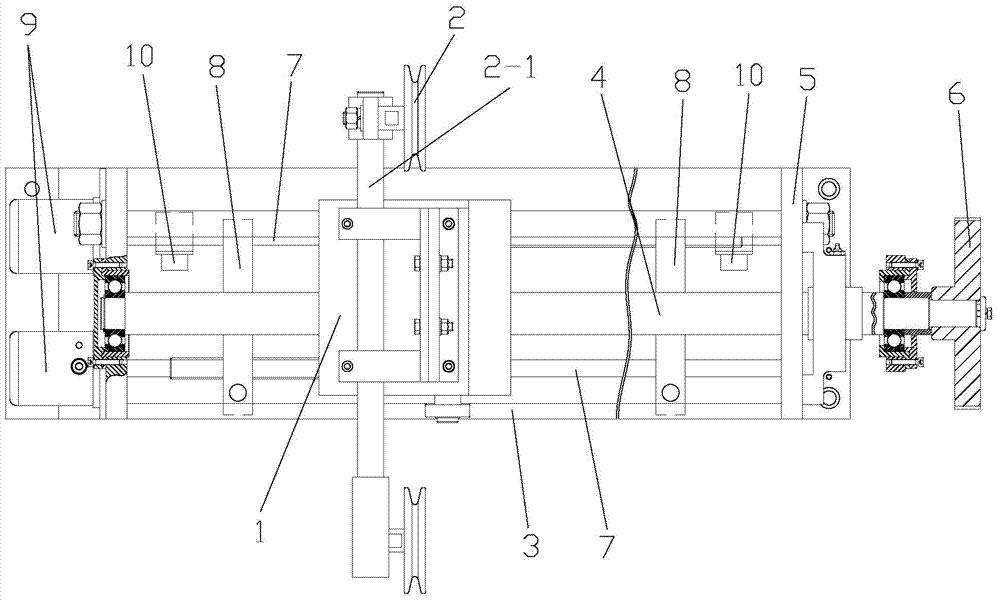

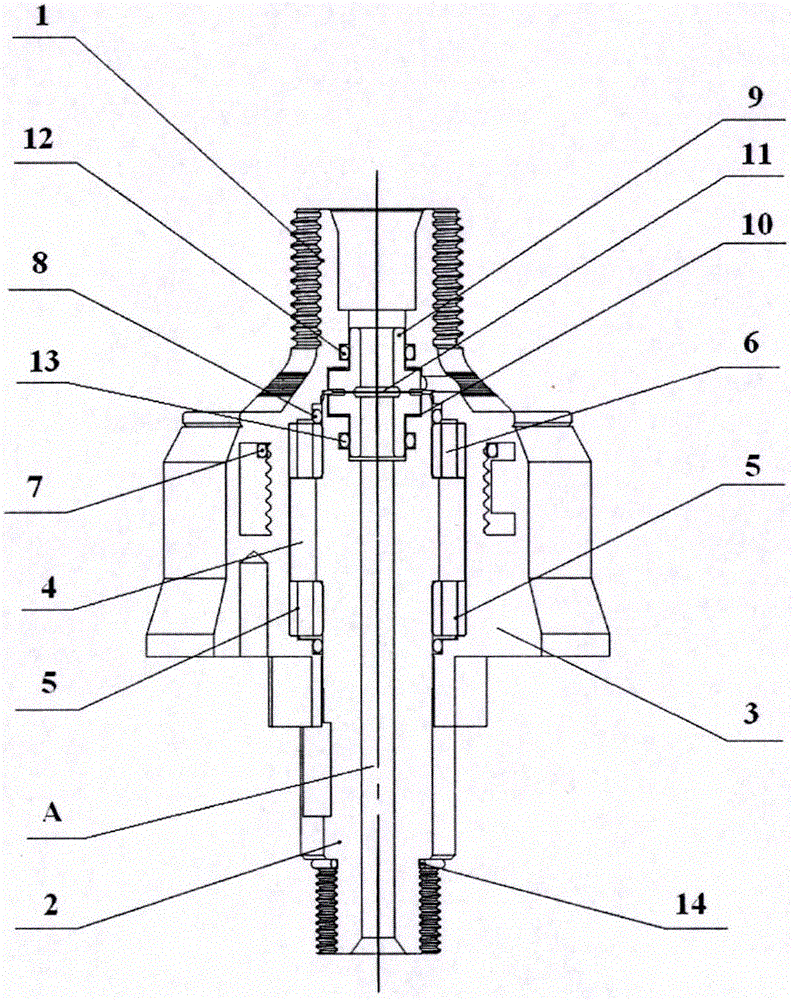

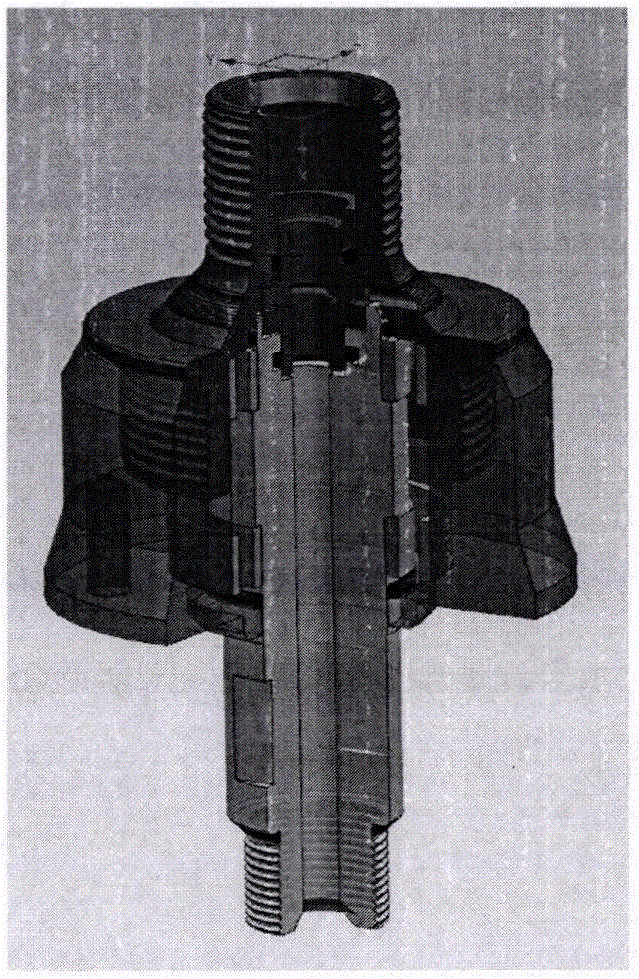

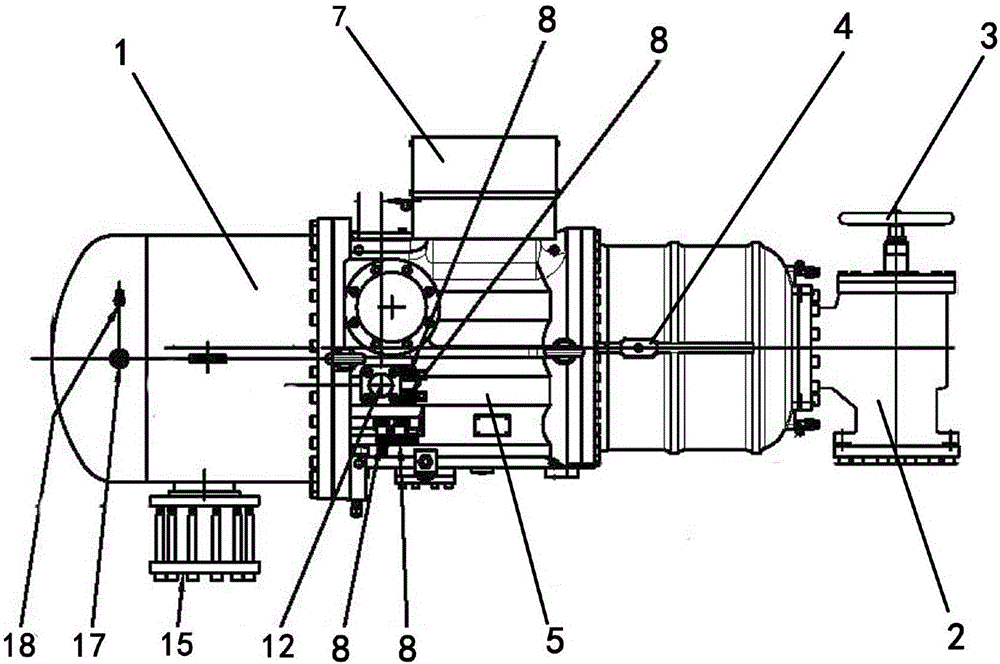

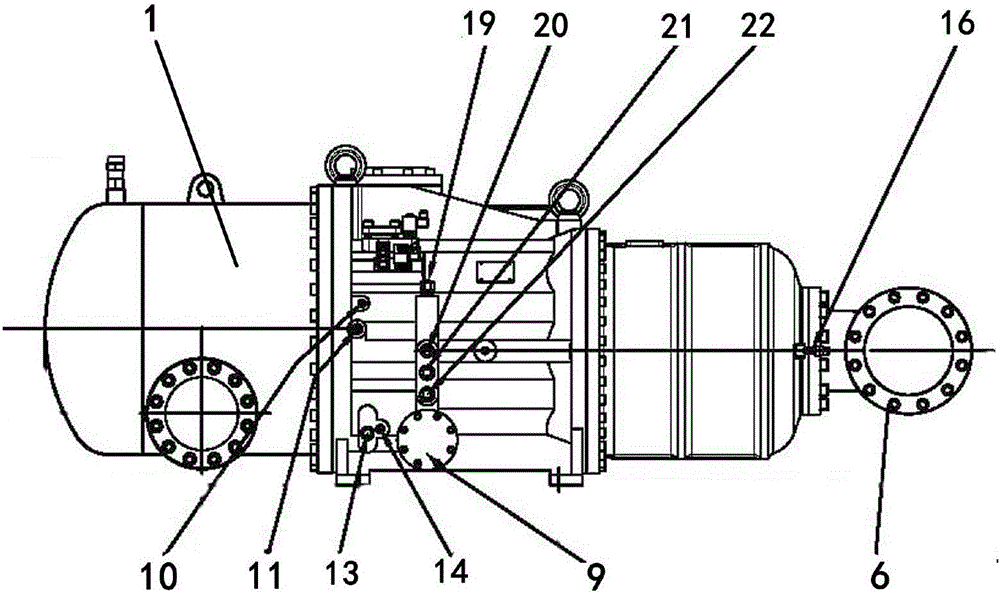

Electric spindle capable of realizing automatic tool changing and provided with build-in shank

PendingCN107042420AImprove structural strengthRealize automatic tool changeFeeding apparatusMaintainance and safety accessoriesBall bearingStator coil

The invention relates to an electric spindle capable of realizing automatic tool changing and provided with a build-in shank. A spindle body is provided with a cooling mechanism and comprises a spindle box, a back seat and a dust cover; spindle assemblies are press-fitted in the spindle box; the back seat and the dust cover are arranged at two ends of the spindle box; the spindle assemblies are fixedly mounted in the spindle box through cooling copper sleeves; a detection device and a control device are arranged on the back seat; one end of each spindle assembly is in transmission connection with a driving device; and the other end of each spindle assembly is detachably connected with an external device. The electric spindle has the beneficial effects as follows: a stator coil outer sleeve is changed from a steel piece into a brass casting, a circulating water-cooling channel is added in the casting outer sleeve, the temperature is prevented from increasing too fast, the operation precision of the spindle is kept, a clamping jaw and the shank are organically combined, meanwhile, a built-in encoder connected with a control center is configured, functions of automatic tool changing, instant accurate stop and the like are realized, a rotor magnetic piece is in short-circuited connection through an end copper ring, the consumption is reduced, a steel angular contact ball bearing is replaced with a ceramic ball bearing, the friction and the heat are reduced, and the life is prolonged.

Owner:岳阳市显隆电机有限公司

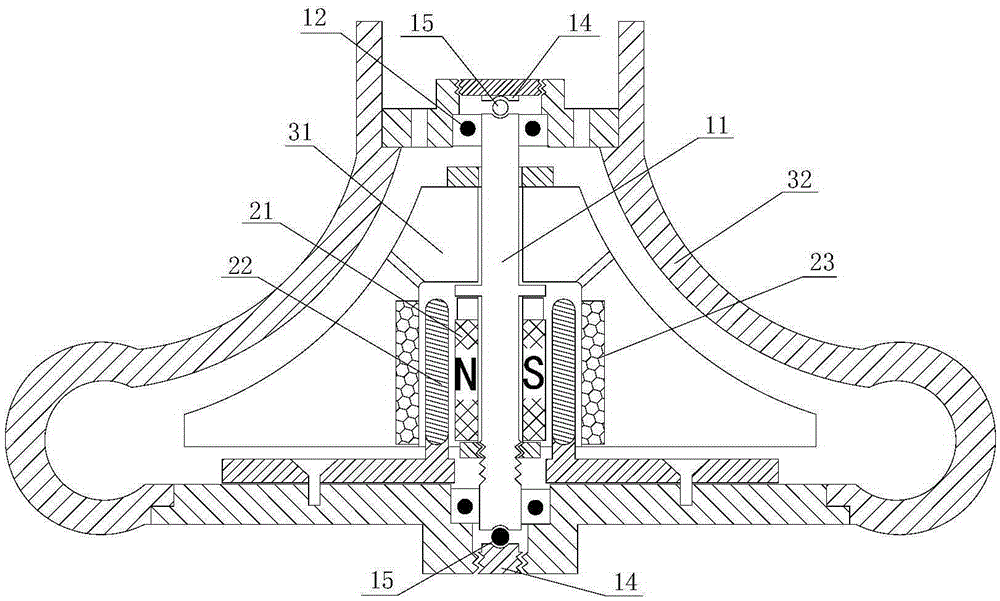

Vertical type direct connection draught fan

InactiveCN106640693AExtend your lifeSmall starting currentPump componentsMechanical energy handlingImpellerMotor efficiency

The invention discloses a vertical type direct connection draught fan. The vertical type direct connection draught fan mainly comprises a shaft, a bearing, a three-dimensional curved surface impeller, a permanent magnet rotor, a stator coil without an iron core and an impeller shell. The shaft is installed on the impeller shell through the bearing. The permanent magnet rotor, the impeller and the shaft are fixedly connected. The stator coil and the impeller shell are fixedly connected. The impeller is arranged in the impeller shell. The stator coil is coupled to the permanent magnet rotor. A magnetizer is further installed on the other side, symmetrical to the permanent magnet rotor, of the stator coil. A brushless direct current motor and the impeller are integrally and vertically installed, so that the gravity of the impeller and the rotor is balanced to the lifting force produced by the three-dimensional impeller during working, and the axial force on the bearing is reduced to the greatest extent. The vertical type direct connection draught fan is used in cooperation with a brushless motor driver, the starting current is small, the power factor is high, and the motor efficiency is improved. The coil directly drives the rotor, a high-speed coupler is omitted through the rotor and the impeller, the cost is reduced, the system efficiency is improved, and the weight is reduced. The vertical type direct connection draught fan has the advantages of having a few components and being small in size and is simple and compact in structure.

Owner:BEIJING LIANGMING TONGCHUANG WATER TREATMENT EQUIP DEV CENT +2

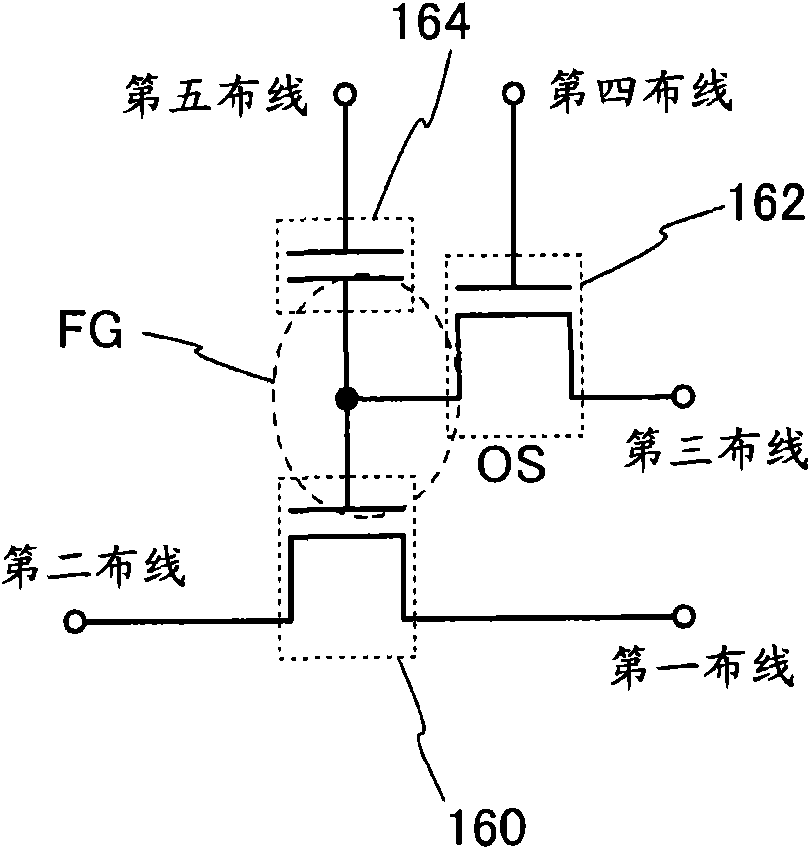

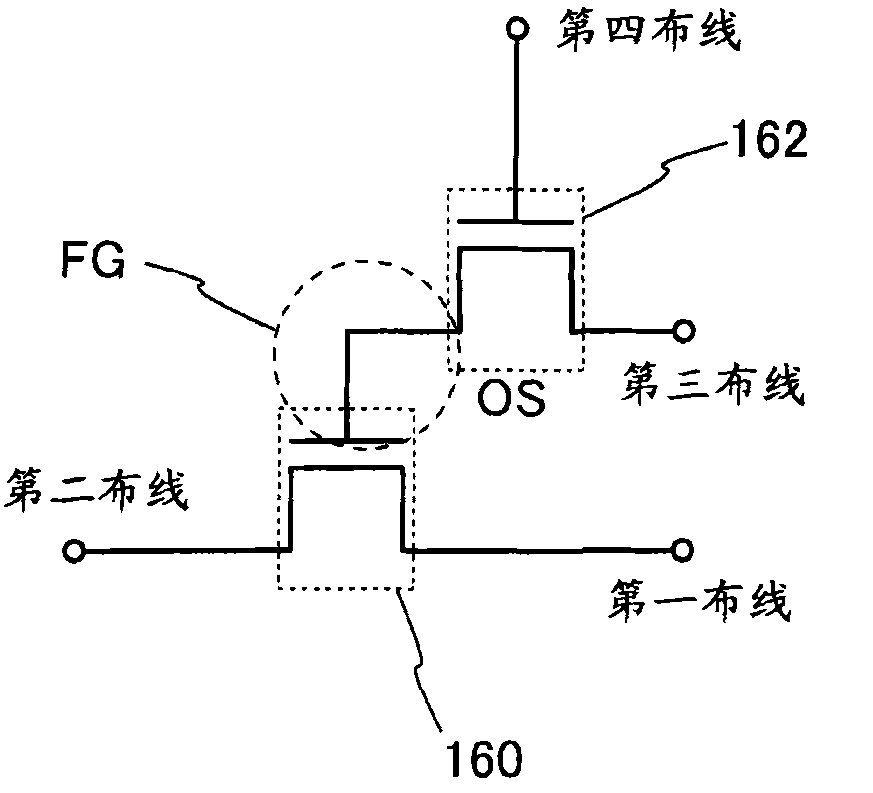

Semiconductor device and method for driving semiconductor device

InactiveCN102376713AReduce cut-off currentReduce frequencySolid-state devicesRead-only memoriesSemiconductor materialsCapacitor

The present invention relates to a semiconductor device and a method for driving the semiconductor device. It is an object to provide a semiconductor device with a novel structure in which stored data can be held even when power is not supplied, and does not have a limitation on the number of writing operations. The semiconductor device includes a plurality of memory cells each including a transistor including a first semiconductor material, a transistor including a second semiconductor material that is different from the first semiconductor material, and a capacitor, and a potential switching circuit having a function of supplying a power supply potential to a source line in a writing period. Thus, power consumption of the semiconductor device can be sufficiently suppressed.

Owner:SEMICON ENERGY LAB CO LTD

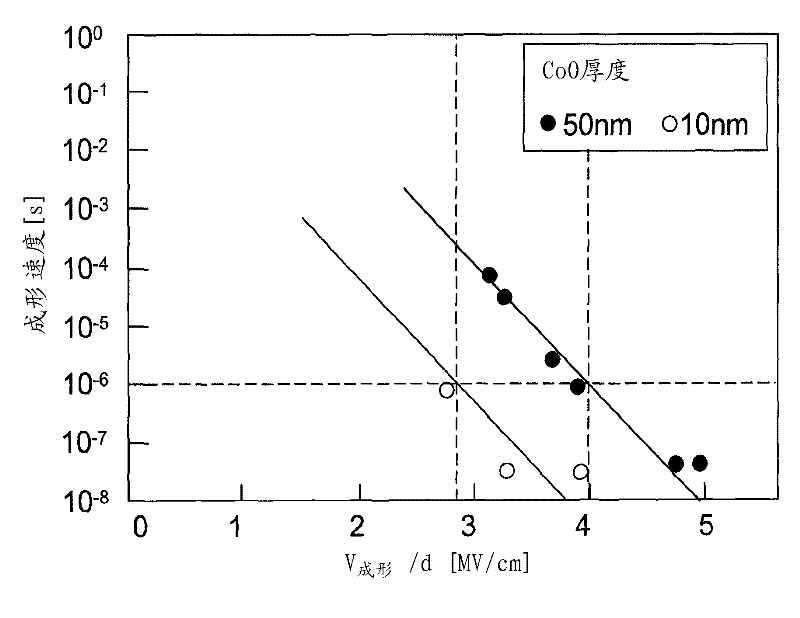

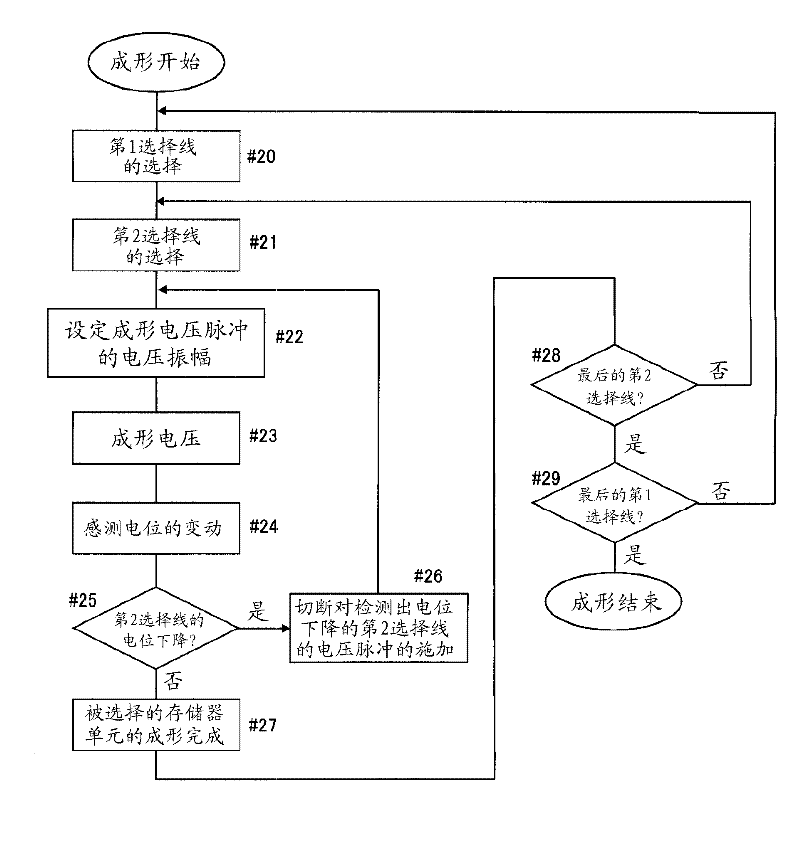

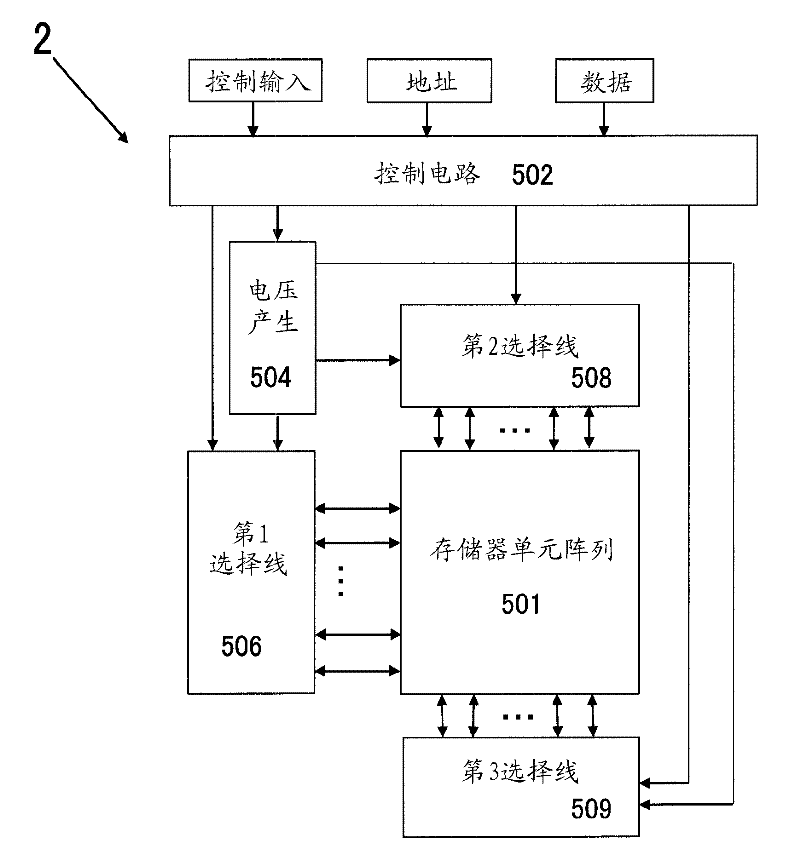

Resistance control method for nonvolatile variable resistive element

InactiveCN102347073AShorten forming timeShorten the timeRead-only memoriesDigital storageBit lineForm processing

A resistance control method for a nonvolatile variable resistive element is provided. The method realizes synchronous progress of writing, wiping and forming processing of a plurality of memory cells. The device includes a memory cell array in which the unit memory cells having nonvolatile variable resistive elements and transistors are arranged in a matrix. The memory cells that are targets of a memory operation are selected by first selection lines (word lines), second selection lines (bit lines) and third selection lines (source lines). The method includes steps of selecting one or more first selection lines, selecting a plurality of second selection lines, and applying a compensated voltage in which a change in potential of the third selection lines caused by current flowing into the third selection lines through the second selection lines is compensated in a voltage that is necessary for the memory operation, such that the voltage necessary for the memory operation is applied to all of the selected memory cells.

Owner:SHARP KK

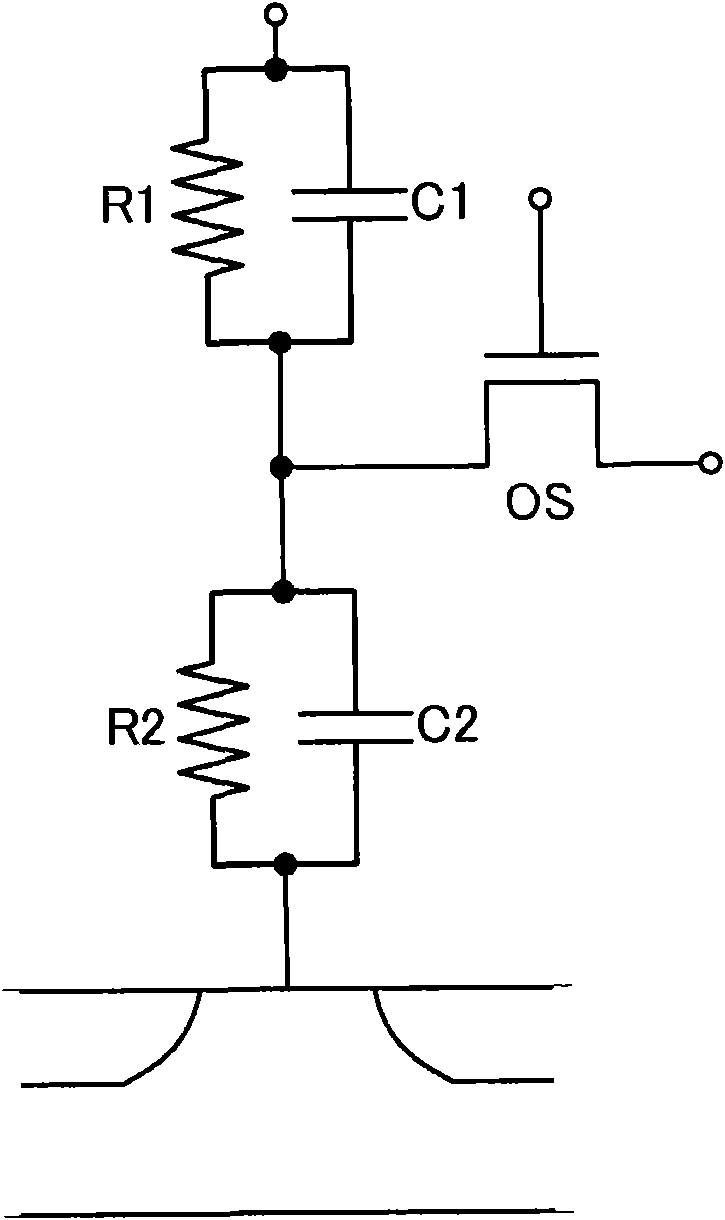

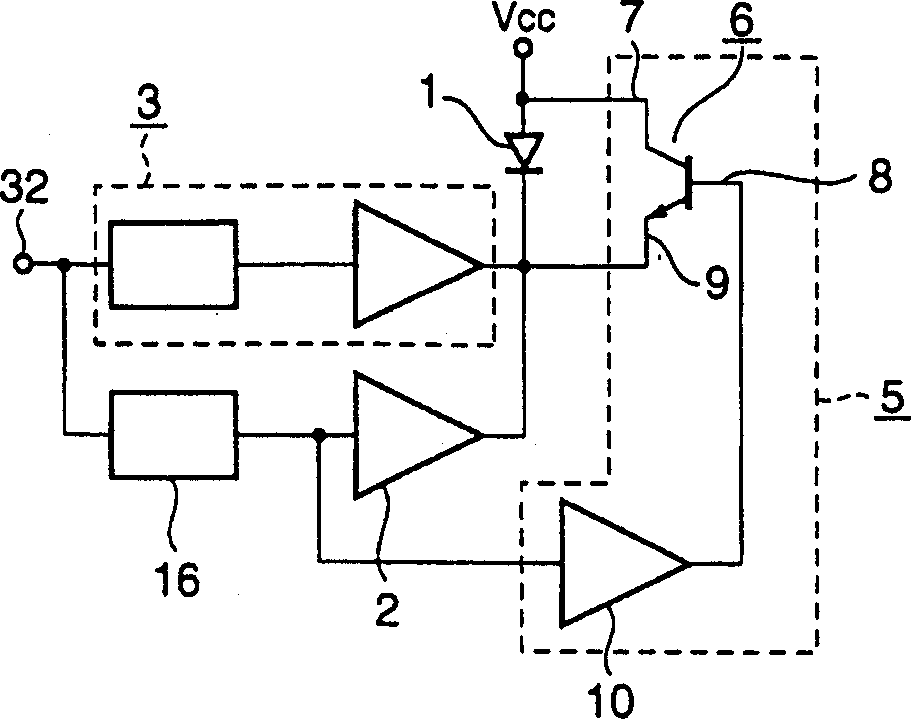

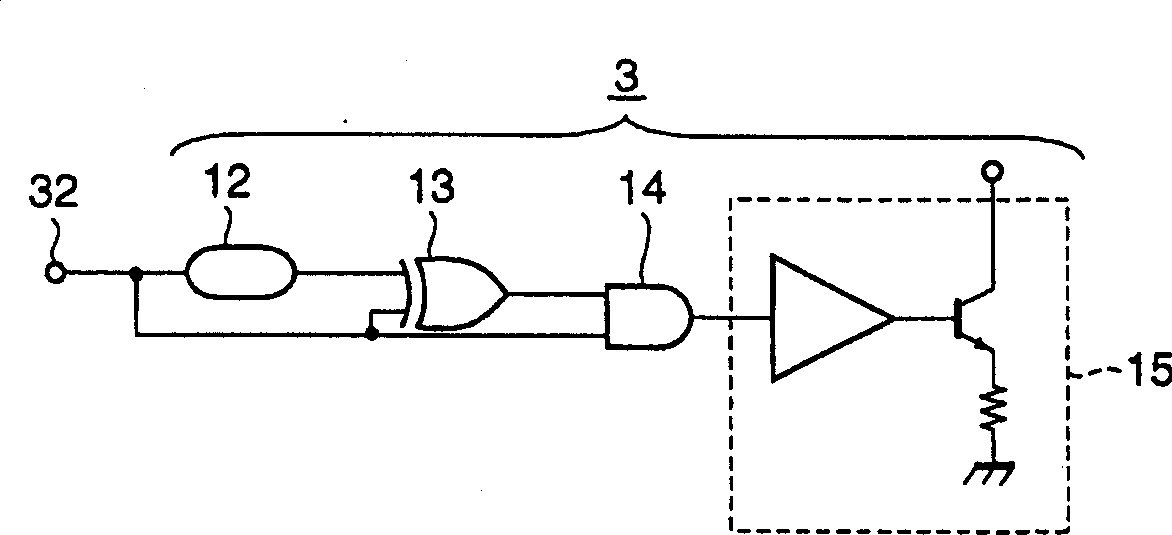

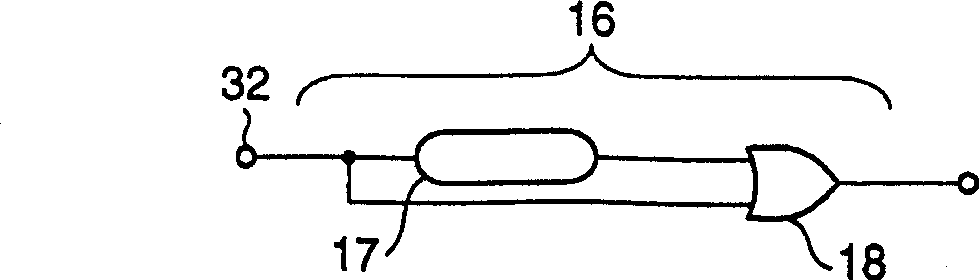

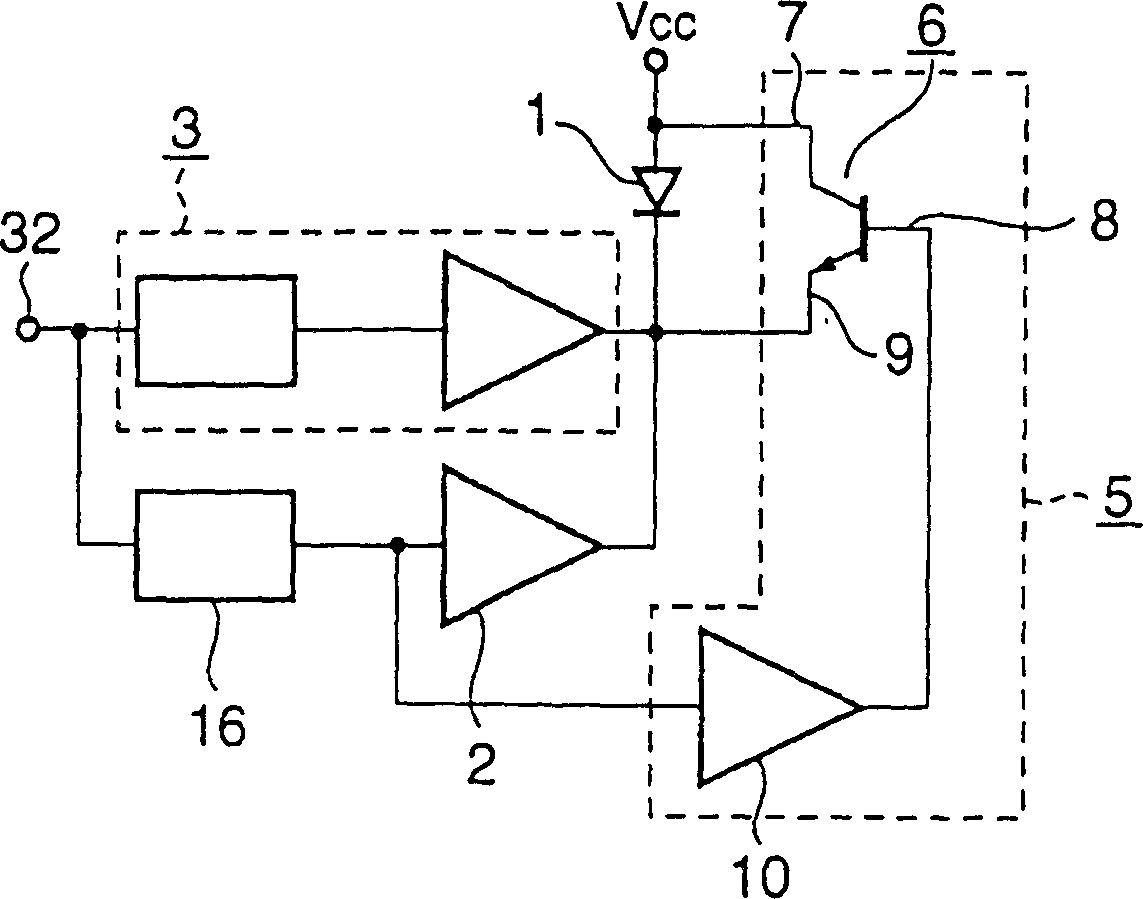

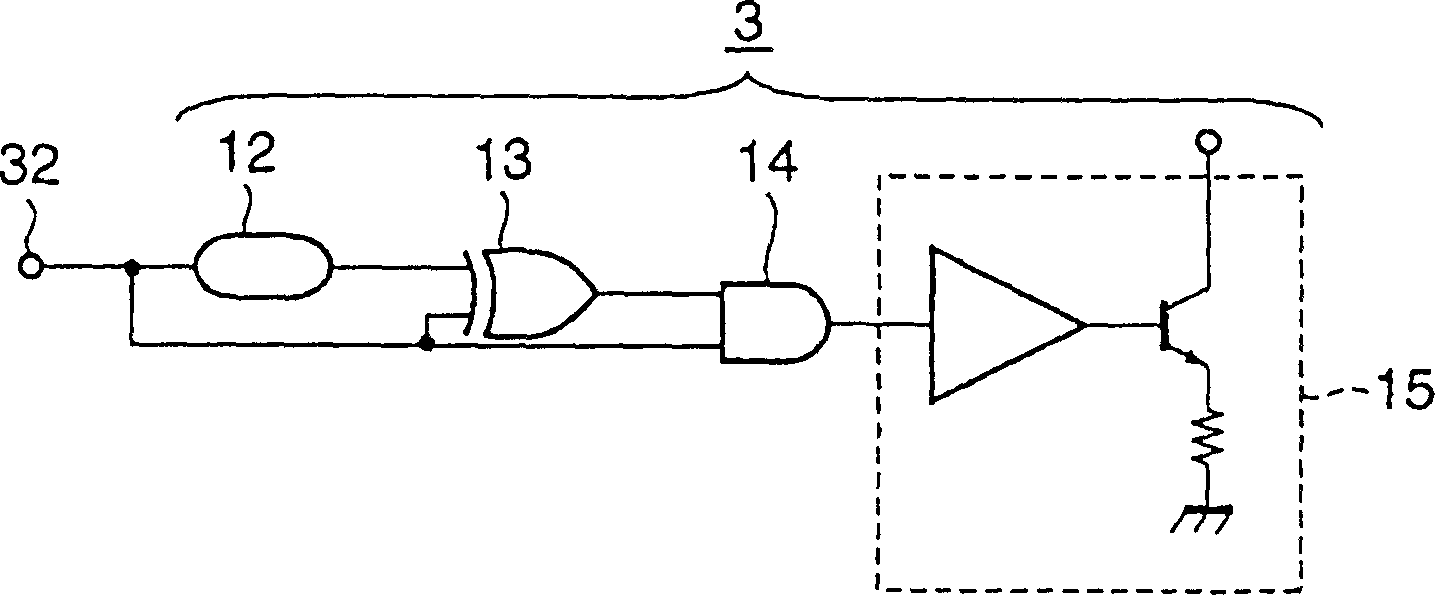

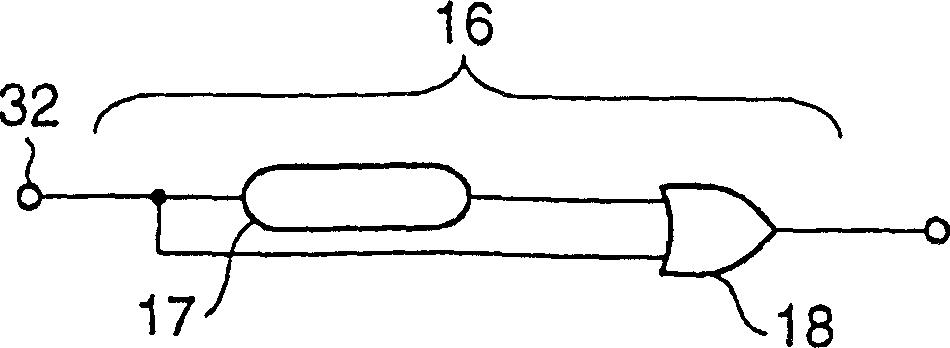

LED drive circuit and light transmission module therewith

InactiveCN1347161AWork at high speedShorten frontier timeBaseband system detailsDistortion/dispersion eliminationLeading edgeCurrent switch

A light-emitting diode driving circuit according to an embodiment of this invention includes a light-emitting diode (1), a first current switch circuit (2) connected in series with the light-emitting diode (1), the first current switch circuit (2) turning on / off a current in accordance with an external input signal input from an input terminal (32), a pulse current generating circuit (3) connected in parallel with the first current switch circuit (2), the pulse current generating circuit (3) supplying a pulse current including a pulse width smaller than the pulse width of the external input signal and shaping a leading edge portion of an optical waveform output from the light-emitting diode (1) into a desired optical waveform, and a discharge circuit (5) connected in parallel with the light-emitting diode (1), the discharge circuit (5) quickly discharging charge stored in the light-emitting diode (1) when the current to the first current switch circuit (2) is turned off.

Owner:KK TOSHIBA

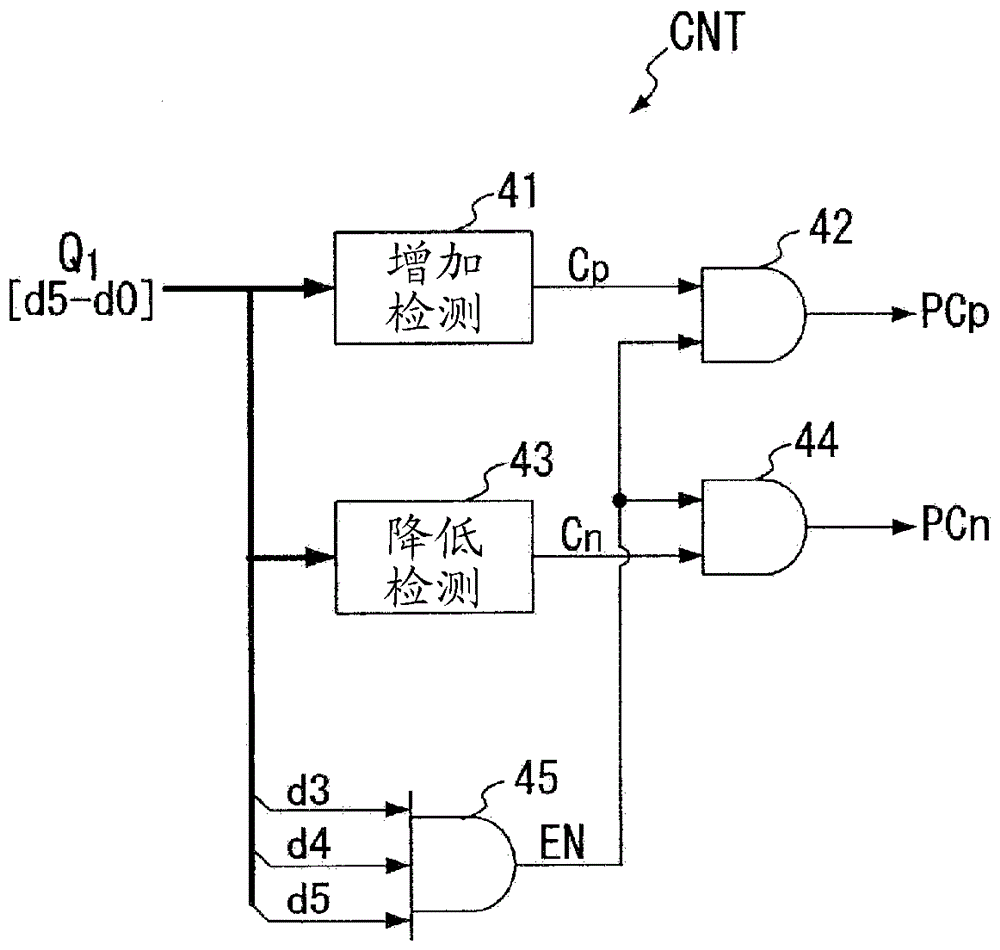

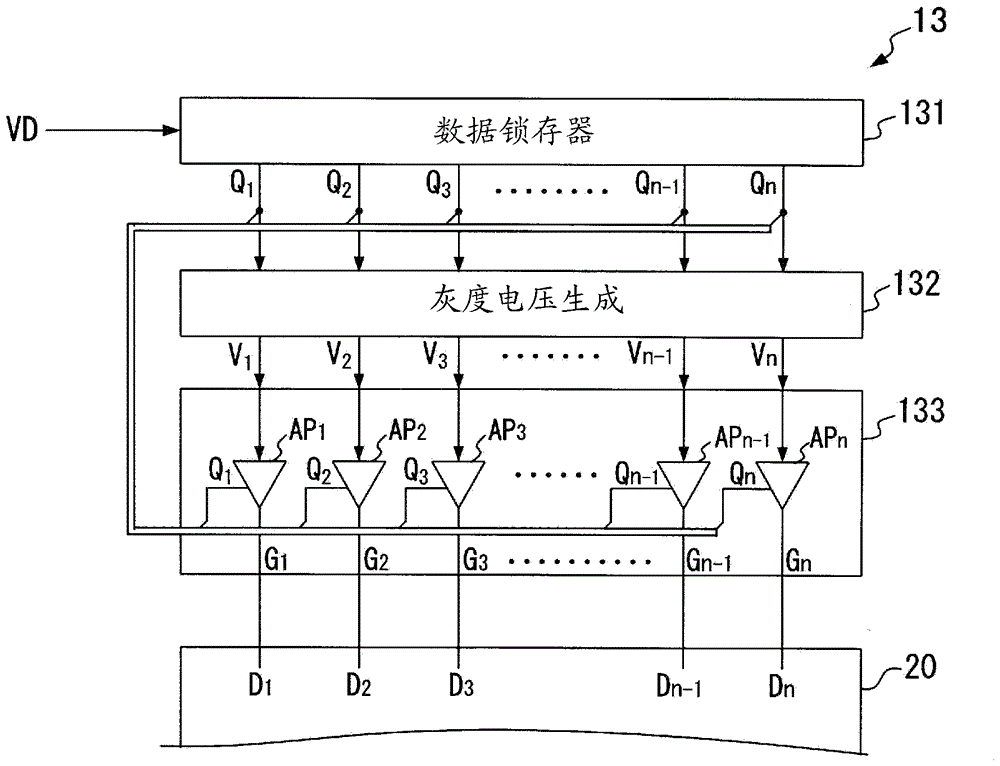

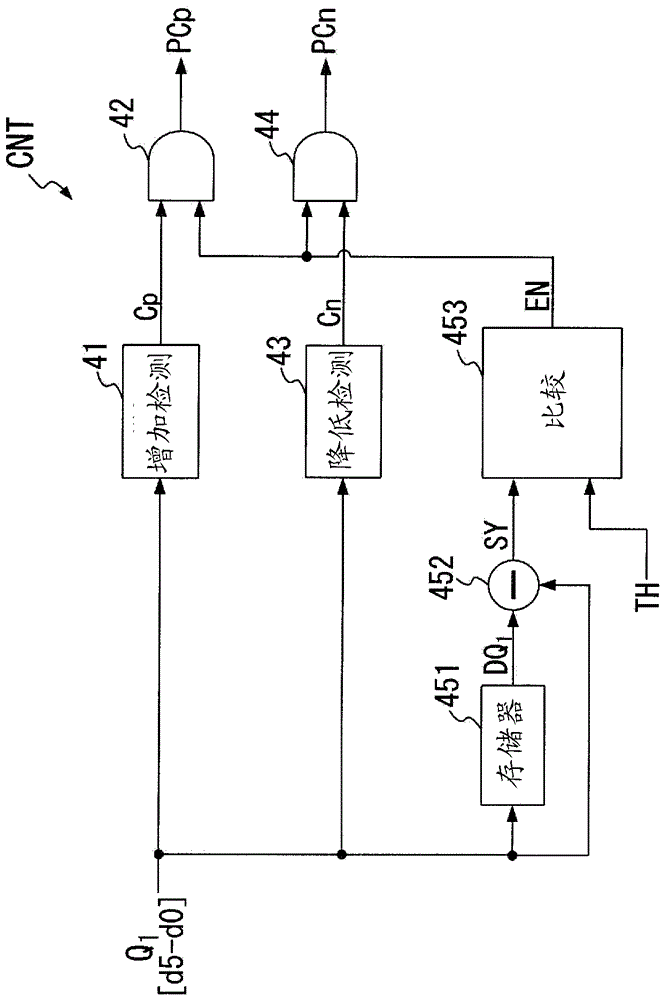

Amplifier and display driver including amplifier

ActiveCN105469753AHigh-speed processingReduce power consumptionStatic indicating devicesAudio power amplifierData value

The invention relates to an amplifier and a display driver including an amplifier, aiming to suppress power dissipation and work in high speed. When an amplifier supplies to a drive line a driving signal based on an input voltage corresponding to a data value indicated by input data, and feeds to an output line a current corresponding to a voltage value on the drive line, the amplifier precharges the drive line at start of increase or decrease of the input voltage. Furthermore, the amplifier stops the precharge when the data value indicated by the input data is smaller than a reference value, or when a difference between a data value at present and a data value immediately therebefore in a series of data values indicated by the input data is smaller than a reference difference value.

Owner:LAPIS SEMICON CO LTD

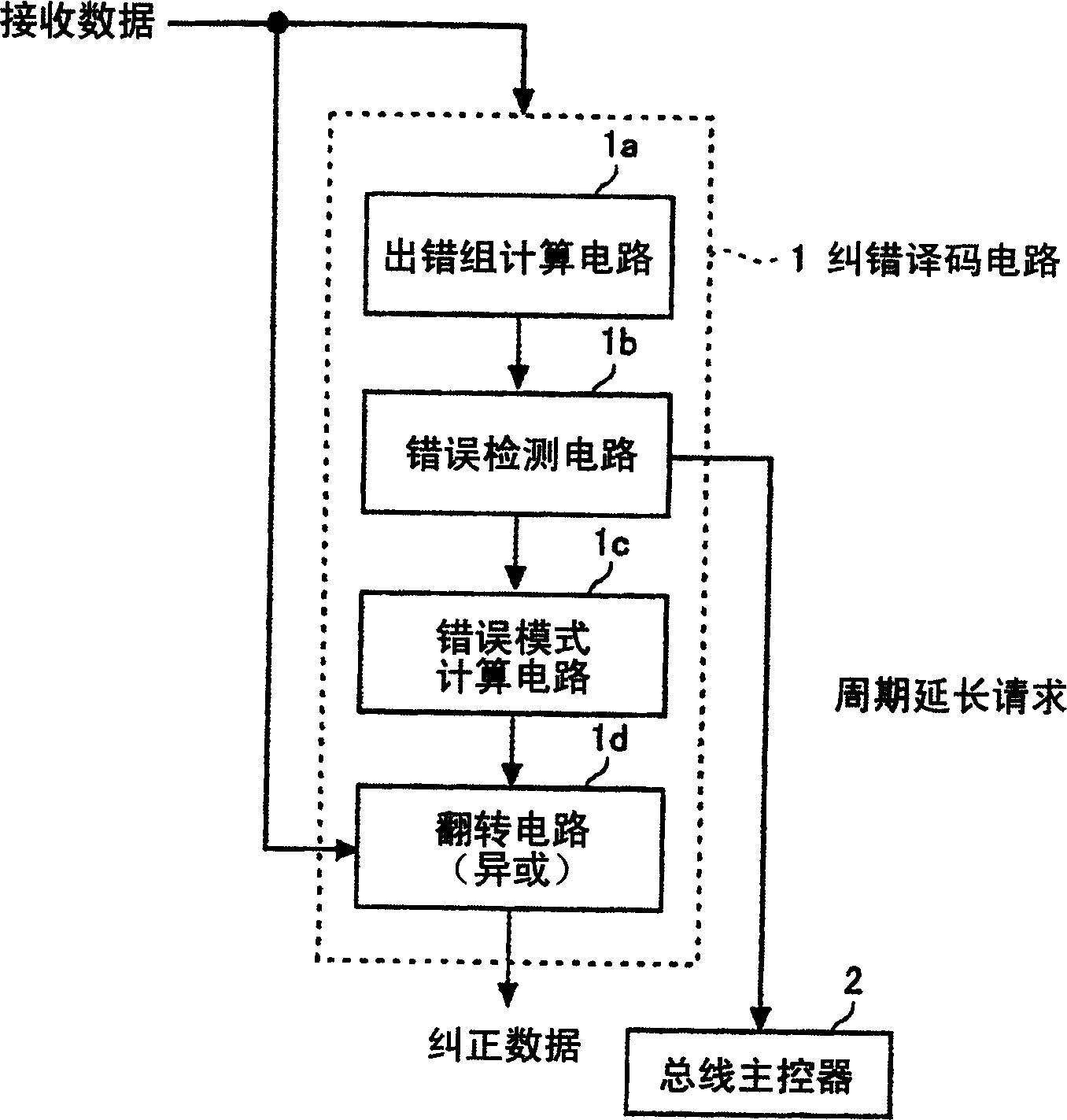

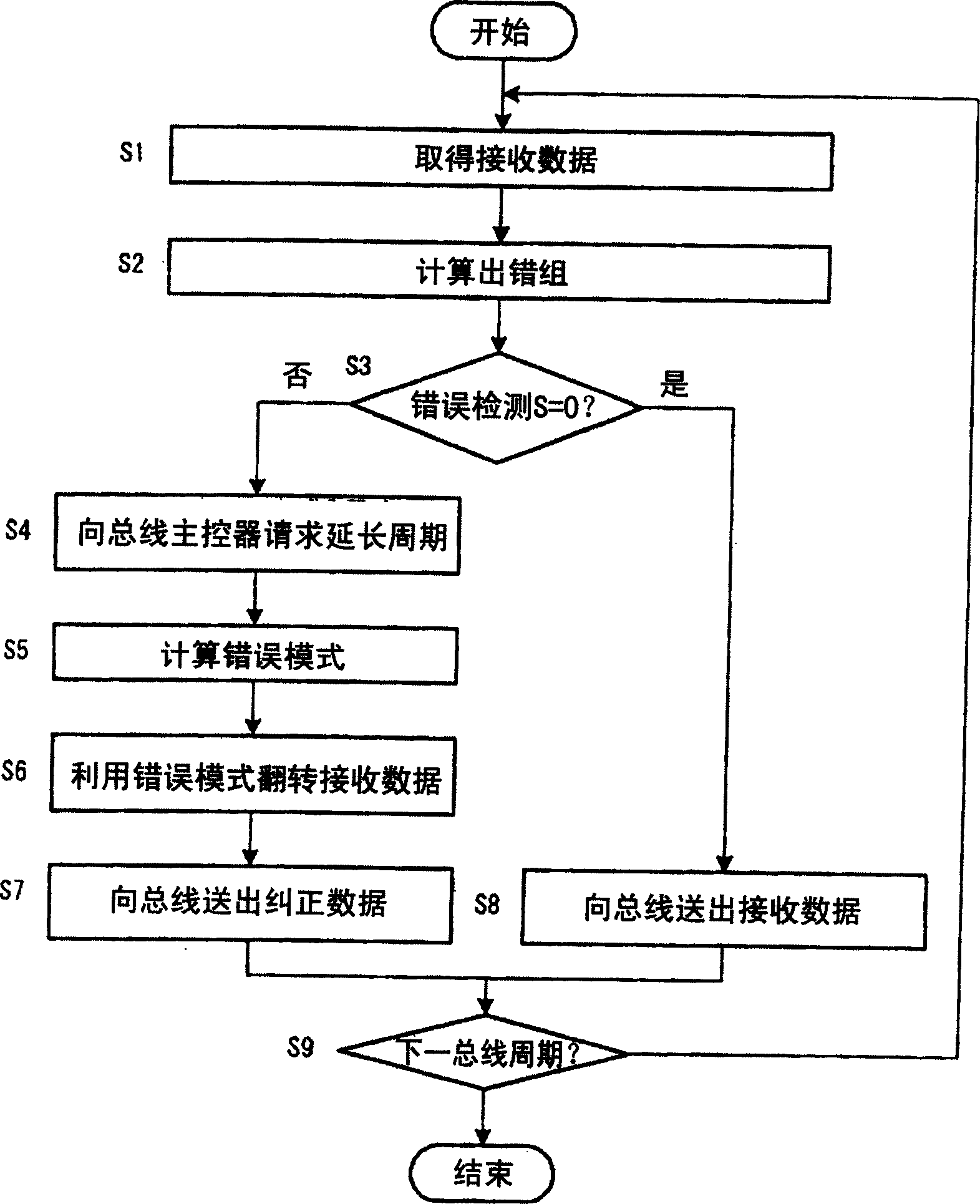

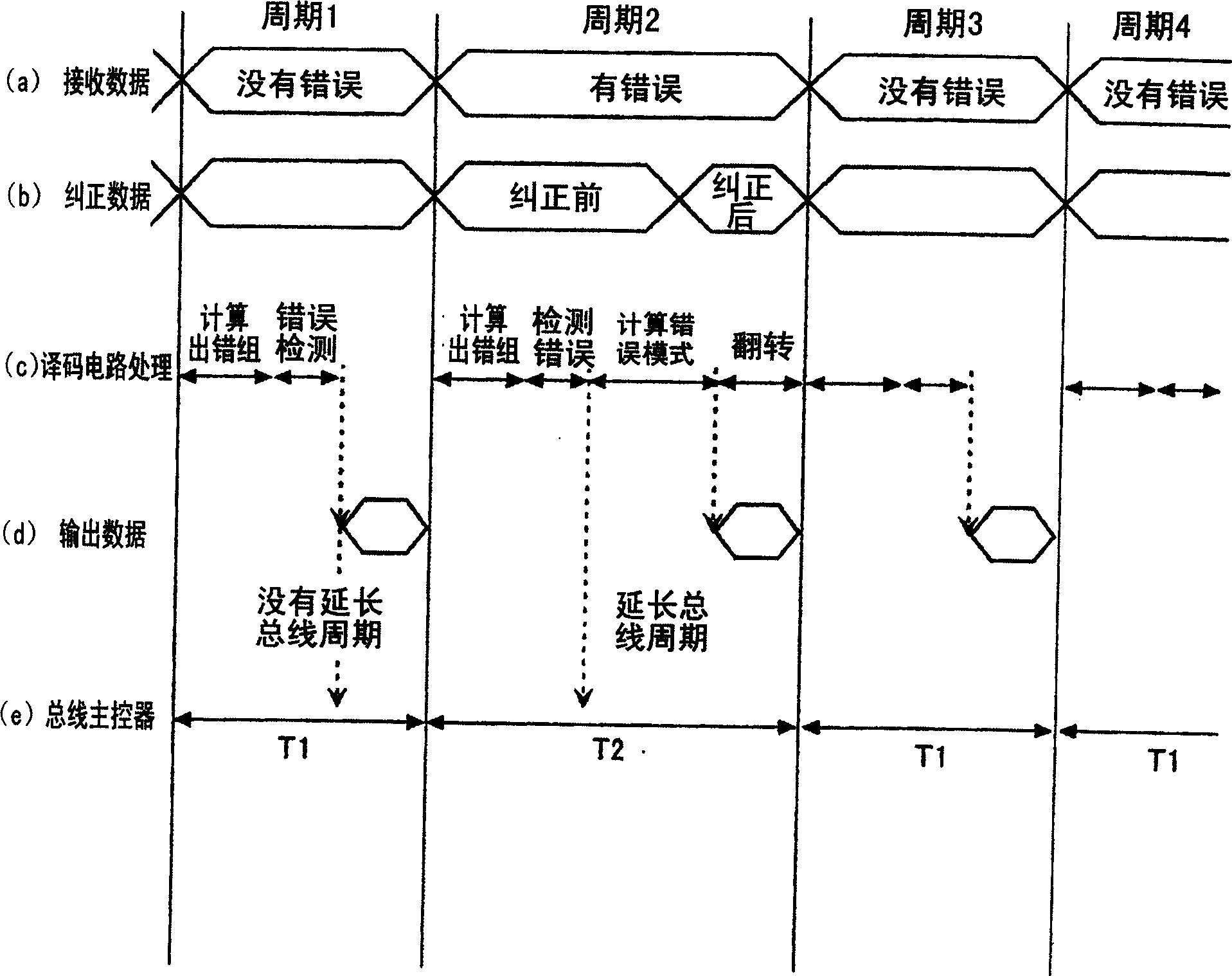

Error decoding circuit, data bus control method and data bus system

InactiveCN1595812AWork at high speedExtended bus cycleError preventionCode conversionComputer hardwareBus mastering

An error decoding circuit comprises a syndrome computing circuit for computing a syndrome on a receive data, an error detecting circuit for detecting an error based on the syndrome, an error pattern computing circuit for computing an error pattern based on the syndrome, and an inverting circuit for performing an error correction of a receive data based on the computed error pattern. Only when there is an error in the receive data, based on the detection result of the error detecting circuit, a request signal for extension of a bus cycle is outputted to a bus master. On the other hand, if there is no error in the receive data, an inputted data is outputted to a data bus without correction. By so doing, the high speed operation of the data bus is executed.

Owner:FANUC LTD

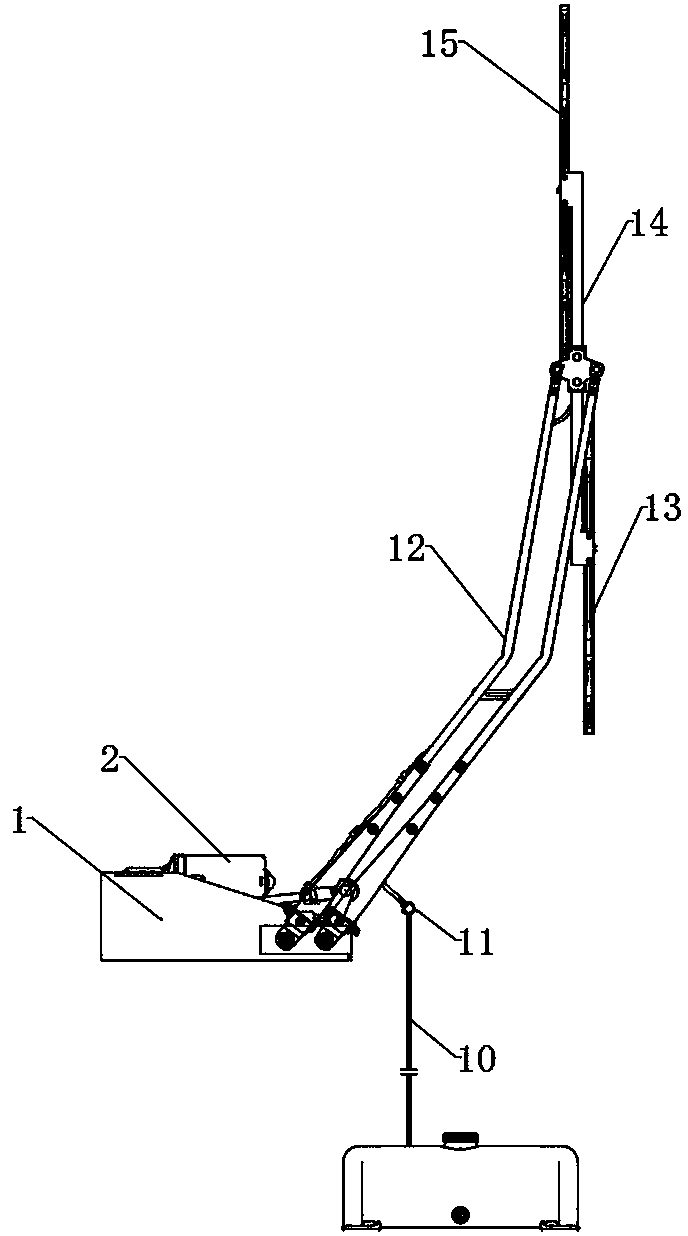

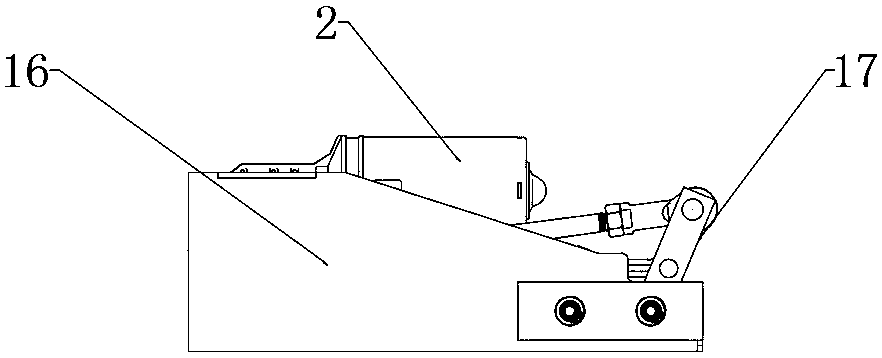

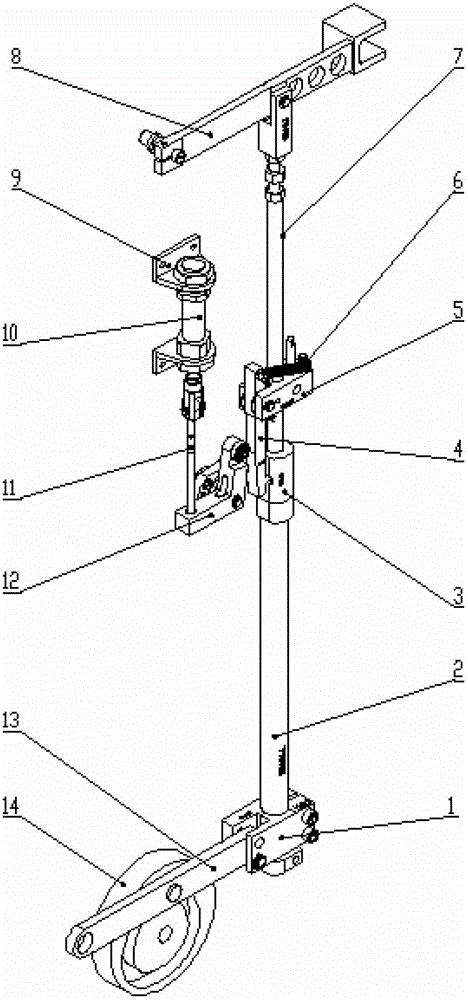

High-speed railway wiper system

PendingCN108583514AWork at low speedWork at high speedVehicle cleaningAgricultural engineeringControl switch

The invention discloses a high-speed railway wiper system. The high-speed railway wiper system comprises a driving assembly part, a wiper motor interface, a control switch, a wiper control box, a washing motor interface, a water-deficient sensor interface, a wall-penetrating joint, a scraping arm, a first scraping blade, a scraping blade connecting rod, a second scraping blade, an anti-floating block, a copper scraping arm joint, a scraping arm triangle, and a connecting arm, a scraping blade seat, an anti-loosening nut, a spring fixed rod, a fixed nut, a spring and a nozzle. The scraping blade connecting rod is fixed to one side of the scraping blade seat through a screw, the first scraping blade is fixed to one end of the scraping blade connecting rod through a screw, and the second scraping blade is fixed to the other end of the scraping blade connecting rod through a screw. According to the high-speed railway wiper system, two large load scraping blades are adopted in the first scraping blade and the second scraping blade, the two scraping blade are connected with the scraping blade connecting rod in a bolt mode, the total length of the scraping blades are increased, and the scraping area is increased, the connection mode is safe and reliable, the high-speed railway wiper system is durable and easy to repair and replace, and the high-speed railway wiper system can completely replace imported parts.

Owner:瑞安市亚星汽车配件有限公司

Current-mode-logic-based high speed high-oscillation amplitude divide-by-two frequency divider circuit

InactiveCN102291132BImprove anti-interference abilityReduce noisePulse automatic controlDual modeP channel

The invention discloses a high speed high-oscillation amplitude divide-by-two frequency divider circuit, which belongs to the technical fields of integrated circuit designing and signal processing. Specifically, the circuit mainly comprises two high speed high-oscillation amplitude D triggers which are cascaded. The D trigger of each stage eliminates the bias of a tail current source based on theconventional D trigger having a current-mode logic (CML) structure, and adopts a P-channel metal oxide semiconductor (PMOS) transistor as a load; and simultaneously, a PMOS and N-channel metal oxide semiconductor (NMOS) complementary cross coupling pair structure and the like are adopted by the output stage of the circuit to finally achieve the aims of increasing the oscillation amplitude of an output signal and making the oscillation amplitude of the output signal approximate to full oscillation amplitude under the condition of ensuring the high speed working of the circuit. The circuit not only can directly drive a post circuit, reduces system power consumption to a certain extent, compensates for the shortcomings of a conventional divide-by-two frequency divider, and is suitable for a high speed frequency divider part in a low-power consumption preposed dual-mode prescaler front-end without any additional level conversion amplification circuit.

Owner:EAST CHINA NORMAL UNIV

Thin-film transistor and display device

InactiveCN101521231ARaise donor concentrationHigh Field Effect MobilityTransistorSolid-state devicesDisplay deviceImpurity

A thin-film transistor includes a pair of impurity semiconductor layers in which an impurity element imparting one conductivity type is added to form a source and drain regions so as to be overlapped at least partly with a gate electrode with a gate insulating layer interposed between the gate electrode and the impurity semiconductor layers; a pair of conductive layers which is overlapped over thegate insulating layers at least partly with the gate electrode and the impurity semiconductor layers, and is disposed with a space therebetween in a channel length direction; and an amorphous semiconductor layer which is in contact with the gate insulating layer and the pair of conductive layers and is extended between the pair of conductive layers.

Owner:SEMICON ENERGY LAB CO LTD

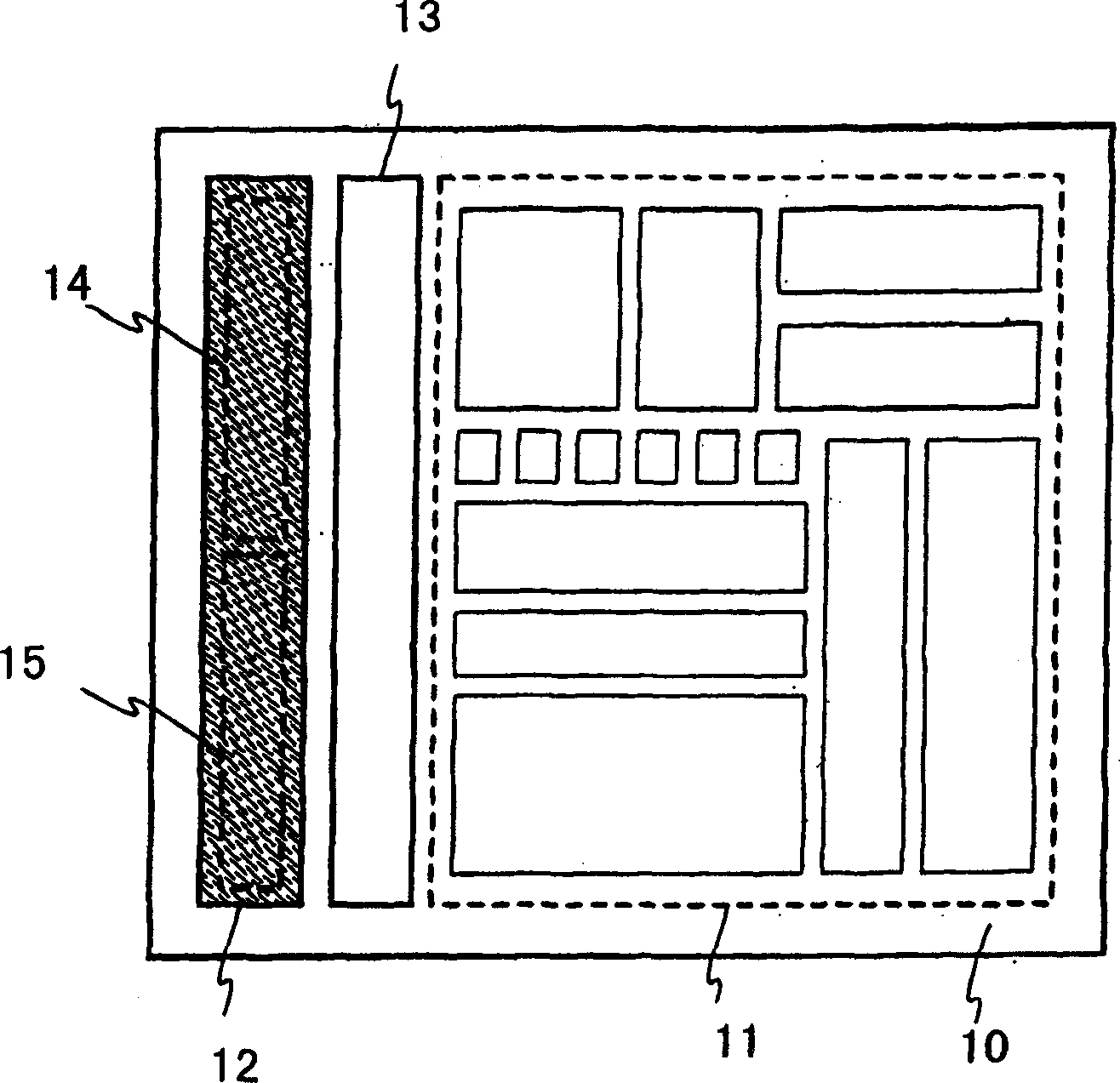

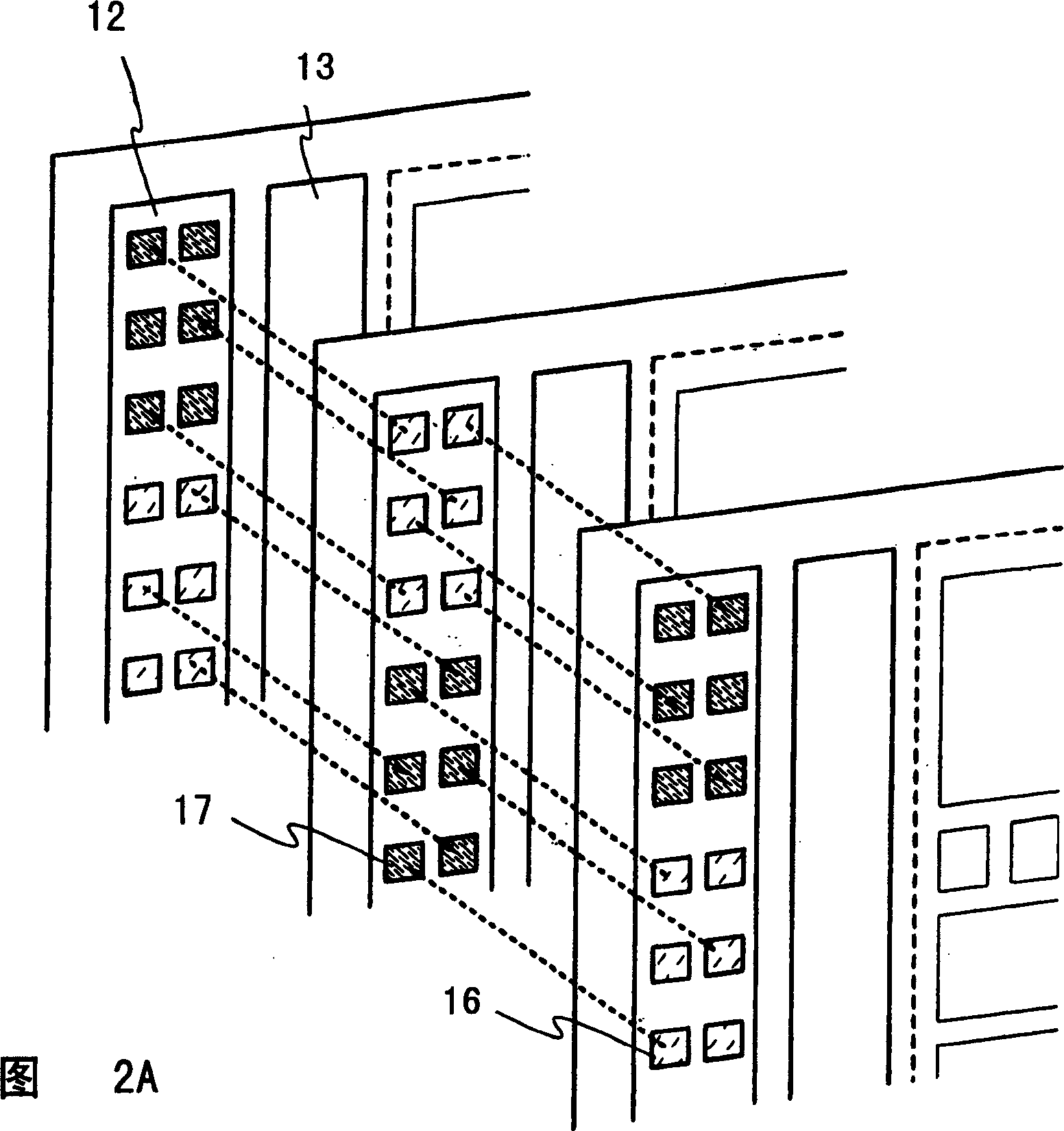

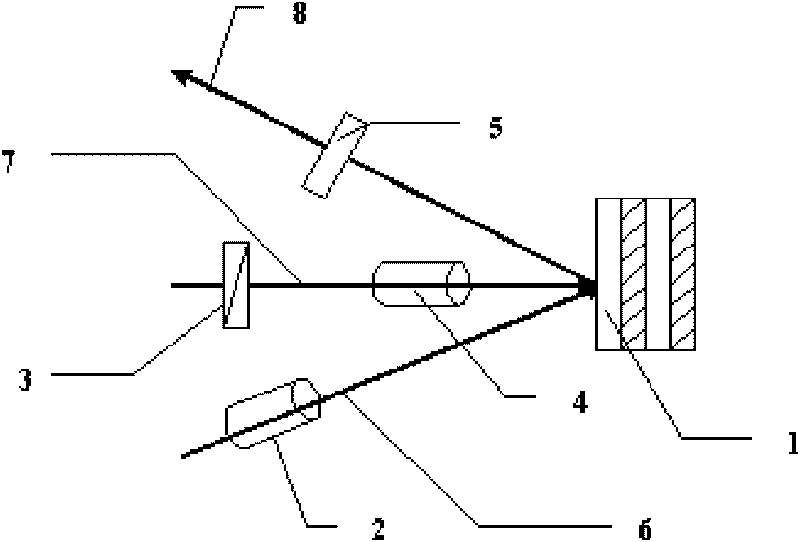

Semiconductor device and microprocessor

InactiveCN1458695ASuppression of increase in the number of process stepsInhibition increase timeStatic indicating devicesSemiconductor/solid-state device detailsHigh rateEngineering

An object of the present invention is to provide a semiconductor device using a cheap glass substrate, capable of corresponding to the increase of the amount of information and further, having a high performance and an integrated circuit capable of operating at a high rate. A variety of circuits configuring an integrated circuit are formed on a plurality of glass substrates, the transmission of a signal between the respective glass substrates is performed by what is called an optical interconnect using an optical signal. Concretely, alight emitting element is provided on the output side of a circuit disposed on the upper stage formed on one glass substrate, and a photo-detecting element is formed so as to oppose to the relevant light emitting element on the input side of a circuit disposed on the rear stage formed on another glass substrate. Then, an optical signal converted from an electrical signal outputted from a circuit disposed on the upper stage is outputted from the light emitting element, the relevant optical signal is converted into an electrical signal by a photo-detecting element and inputted into a circuit disposed on the rear stage.

Owner:SEMICON ENERGY LAB CO LTD

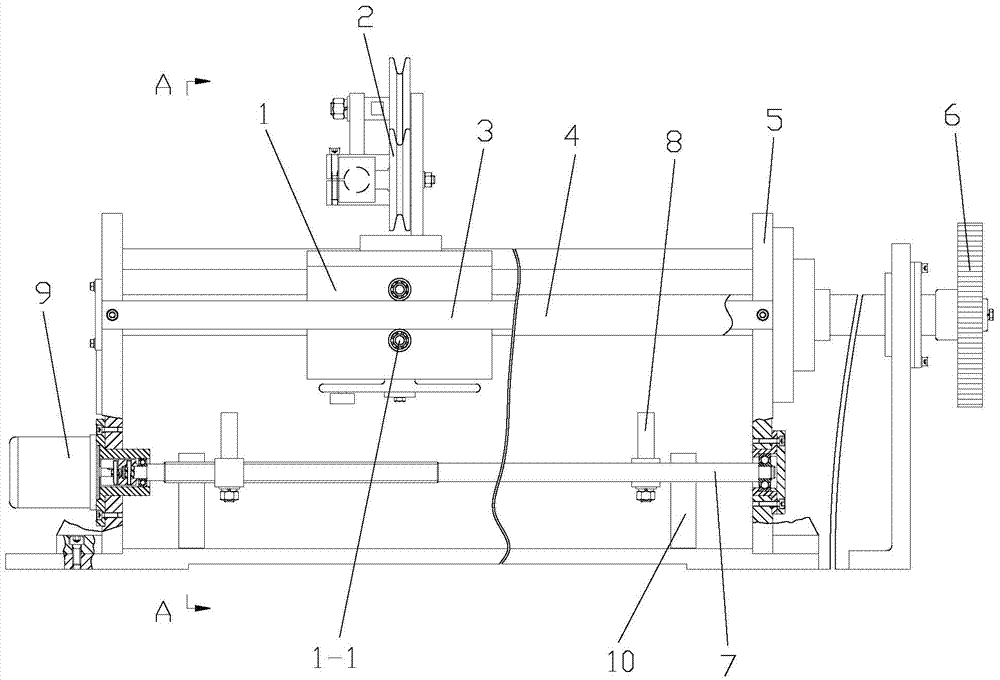

Wire-arranging mechanism of intermediate drawing take-up machine

The invention discloses a wire-arranging mechanism of an intermediate drawing take-up machine. The wire-arranging mechanism of the intermediate drawing take-up machine comprises a supporting seat, two screw rods, two collision rods and a smooth bar wire-arranging device, two ends of the screw rods are connected with left and right sides of the lower portion of the supporting seat respectively, the two screw rods are arranged in a front-back mode, a synchronous motor is arranged at one end of each screw rod, the left end of one screw rod located on the front side is provided with a screw thread, the right end of one screw rod located on the rear side is provided with a screw thread, the two collision rods are arranged in a left-right mode, the front end of one collision rod located on the left side is in threaded connection with the left end of the screw rod located on the front side and the rear end of the collision rod is in sliding joint with the left end of the screw rod located on the rear side, the rear end of one collision rod located on the right side is in threaded connection with the right end of the screw rod located on the rear side and the front end of the collision rod is in sliding joint with the right end of the screw rod located on the front side, two ends of a smooth rod shaft of the smooth bar wire-arranging device are connected with two sides of the supporting seat respectively, guide wheels are installed on front and rear sides of the upper portion of the smooth bar wire-arranging device, a synchronous belt wheel is fixed at one end of the smooth rod shaft, and guide rods are installed between left and right sides of the upper portion of the supporting seat. By means of the wire-arranging mechanism of the intermediate drawing take-up machine, problems of complicated structure, difficult adjustment and high costs in terms of existing wire-arranging mechanisms can be solved.

Owner:THE NORTHWEST MACHINE

Filling reversing structure

ActiveCN102976255AGuaranteed synchronicityMotor execution coordinationLiquid bottlingElectric machineRotary valve

The invention discloses a filling reversing structure. The filling reversing structure is characterized by comprising a cam power device, a reversing control structure and an executing mechanism, wherein the cam power device is used for providing transmission power to the device, and comprises a cam; the middle part of the cam is provided with a through hole for connecting a motor output shaft, and connected with a swinging arm by a cam slot formed in the cam; the end part of the swinging arm is connected with the reversing control structure by a hoop; the reversing control structure comprises an air cylinder and an air cylinder tension rod, wherein the air cylinder tension rod is connected with the air cylinder; the air cylinder drives a control rod to move; the control rod is connected with a hanger control rod mechanism to drive the hanger control rod mechanism to move; the executing mechanism comprises a movable rod which is connected with the reversing control structure, wherein the end part of the movable rod is connected with a rotary valve swinging arm; and the rotary valve swinging arm rotates up and down along with the motion of the movable rod, so that reversing motion is achieved. The filling reversely structure not only achieves transmission integration, but also well achieves transmission automation, so that the operation of the product is stable, the cost is low, a way of controlling a large part with a small part is delicately achieved, and the cost performance is relatively high.

Owner:SHANGHAI KINGSUN PACKING MACHINERY

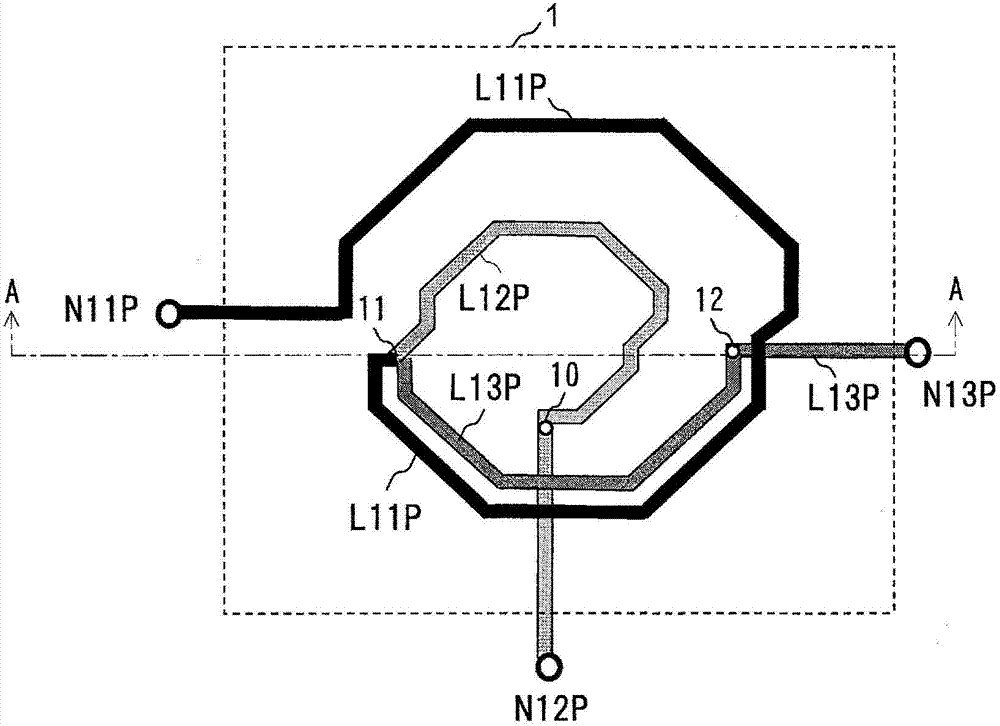

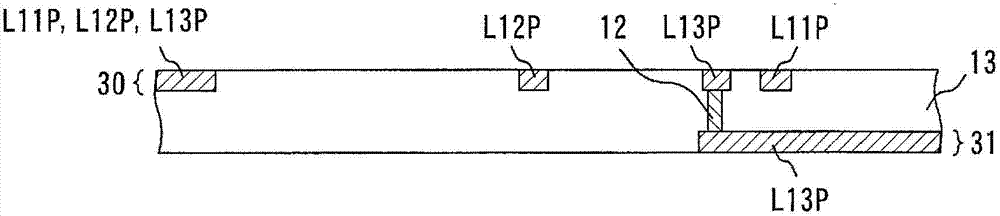

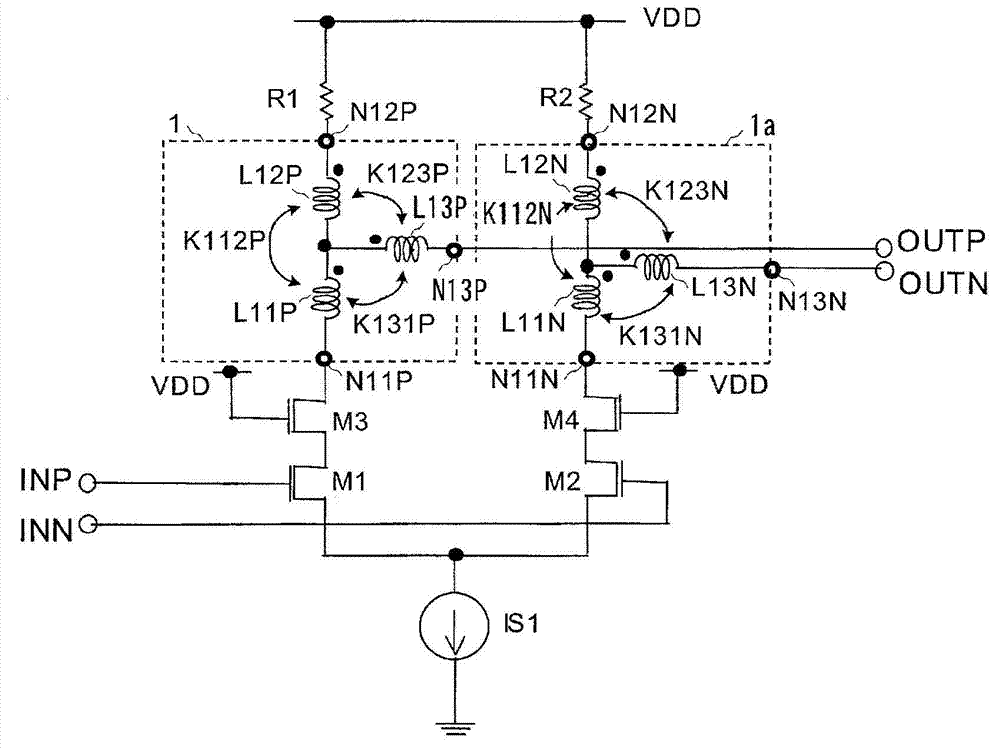

Inductor

InactiveCN103168354ALarge frequency band extension effectEnhanced frequency band extension effectMultiple-port active networksSemiconductor/solid-state device detailsEngineeringInductor

An inductor (1) is provided with: inductor (L11P), the start point of which is connected to terminal (N11P), and which is formed in the shape of a spiral on the outer circumference of an inductor region; inductor (L12P), the end point of which is connected to terminal (N12P), and which is formed in the shape of a spiral on the inner circumference of the inductor region with the end point of inductor (L11P) functioning as the start point of inductor (L12P); and inductor (L13P), the end point of which is connected to terminal (N13P), and which is formed in the shape of a spiral in a region sandwiched by inductor (L11P) and inductor (L12P) with the connecting point of inductor (L11P) and inductor (L12P) functioning as the start point of inductor (L13P).

Owner:NIPPON TELEGRAPH & TELEPHONE CORP +1

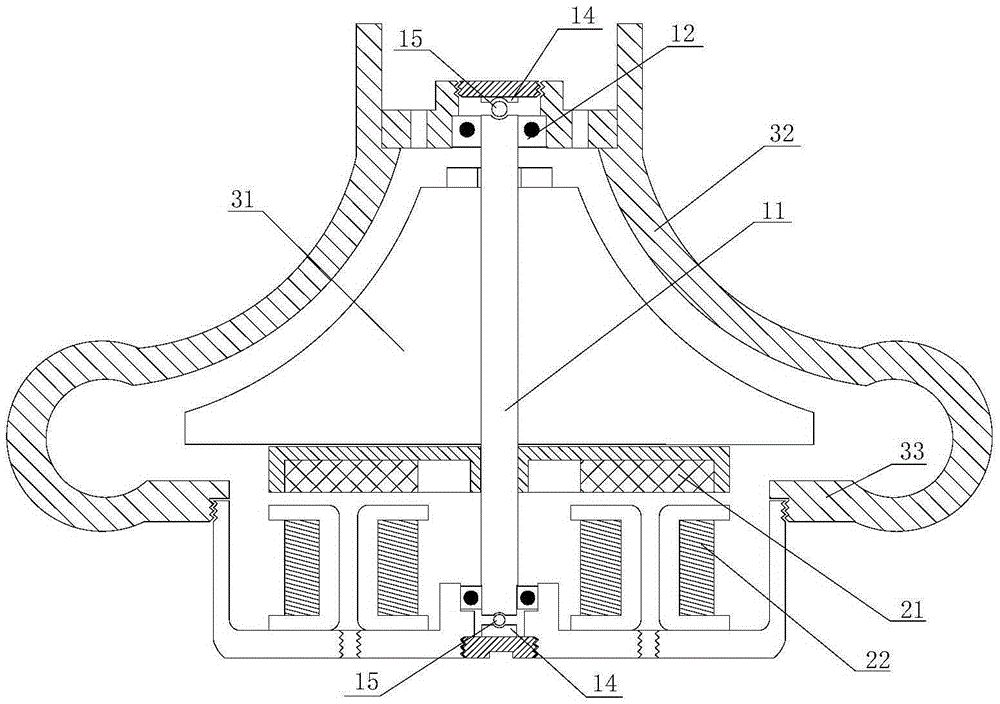

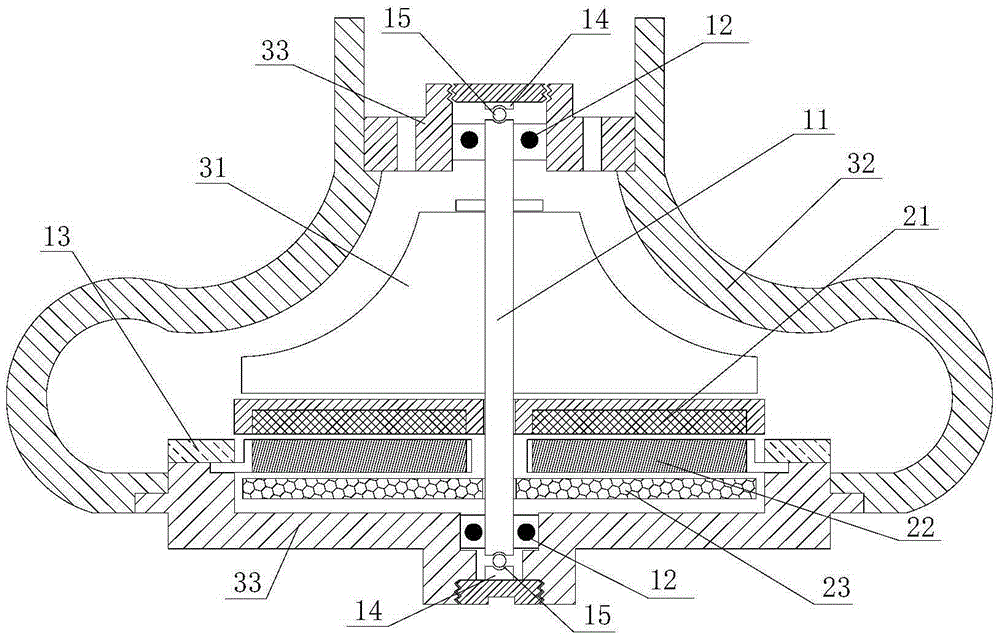

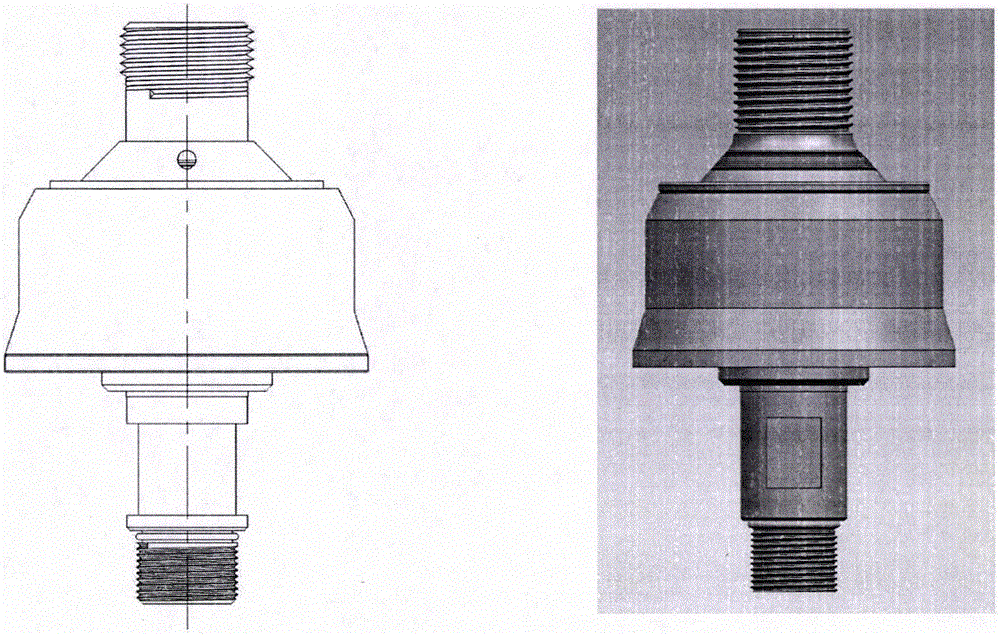

Rotator for high-pressure cleaning equipment

The invention provides a rotator for high-pressure cleaning equipment. The rotator for the high-pressure cleaning equipment comprises a fixing piece, a rotating shaft and a shell, wherein the fixing piece is detachably connected with the shell in a fastening mode, the rotating shaft is supported in an inner cavity of the fixing piece and the shell through a bearing and can rotate relative to the fixing piece and the shell, and axial movement, relative to the fixing piece and the shell, of the rotating shaft is limited by the bearing. High-pressure water used for cleaning can penetrate through a through flow channel penetrating through the fixing piece, the shell and the rotating shaft to flow out. The fixing piece is in dynamic seal connection with the rotating shaft through two sealing bushes. The sealing bushes are partially pressed oppositely in the axial direction, so that dynamic seal is formed on a contact end face. The rotator for the high-pressure cleaning equipment has the advantages that in the high-pressure cleaning process, the rotator can stably and reliably operate for a long time, the structure is simple, the strength is reliable, and the rotating limit is high. Rotation of the rotator is controlled through a high-pressure water gun, rotation for cleaning is stopped when water supply is stopped, a braking function is achieved through damping of a connecting block of the rotator, and thus the speed is decreased instantly and rotation is stopped.

Owner:常州航天岳达精密机械有限公司 +3

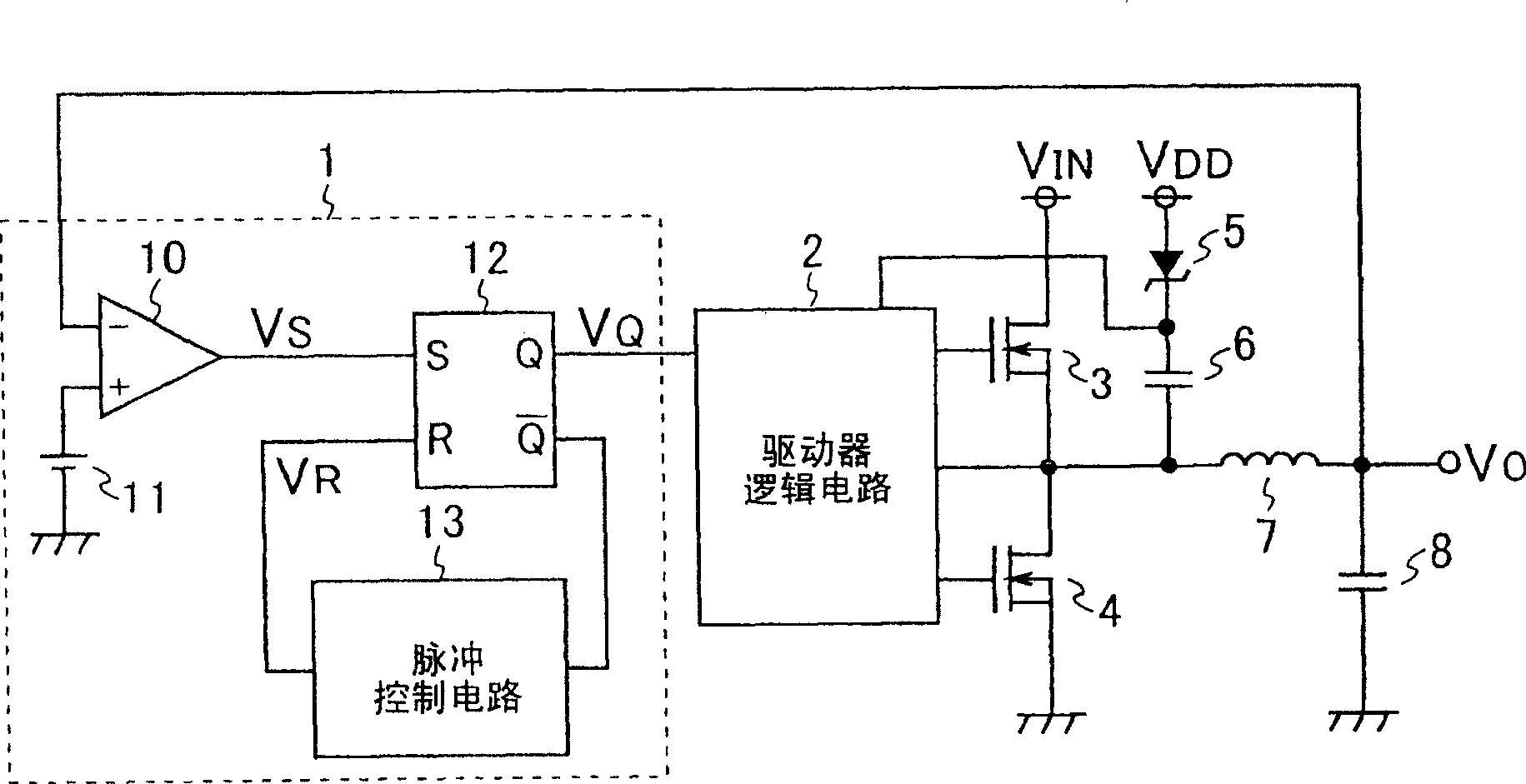

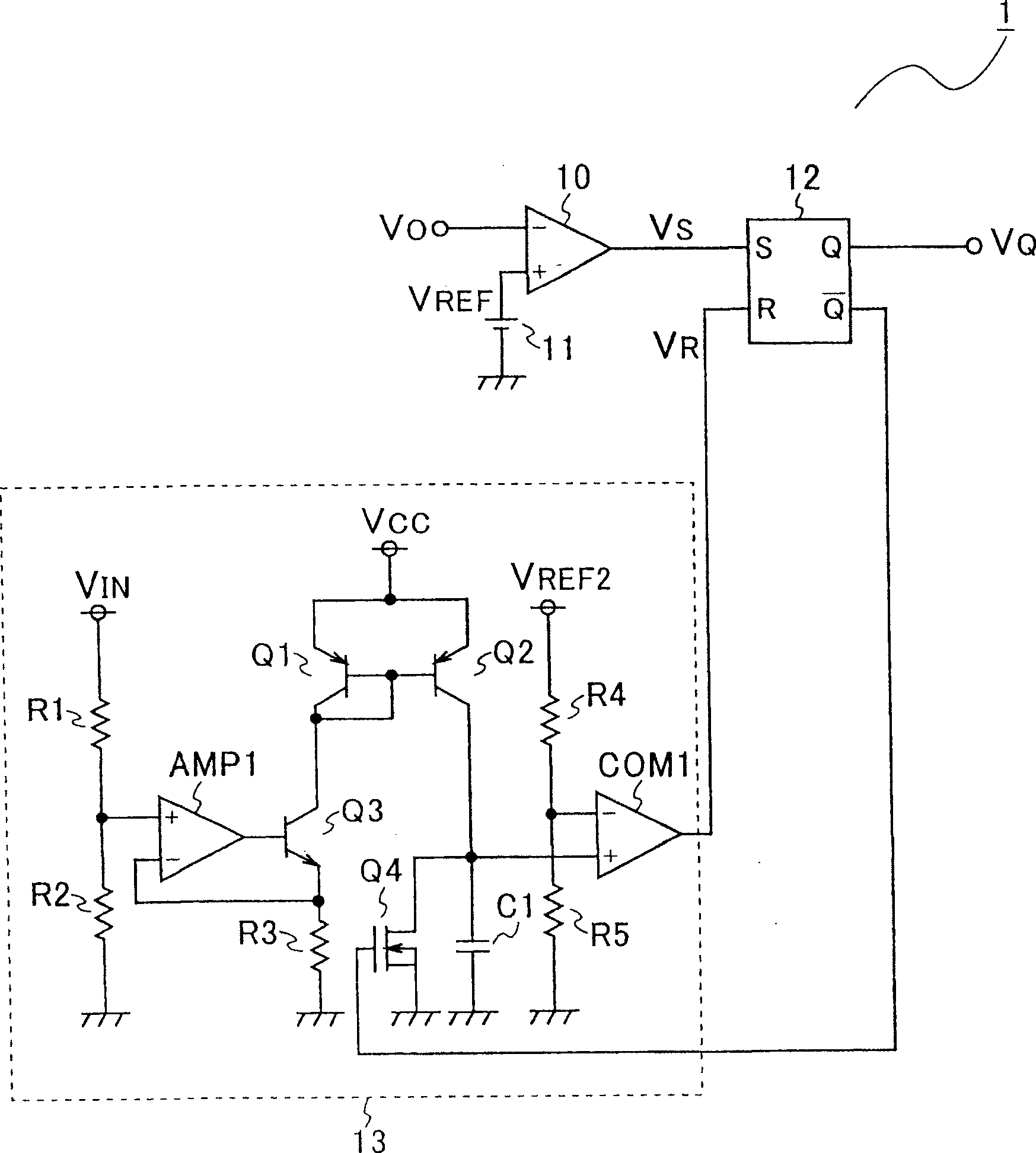

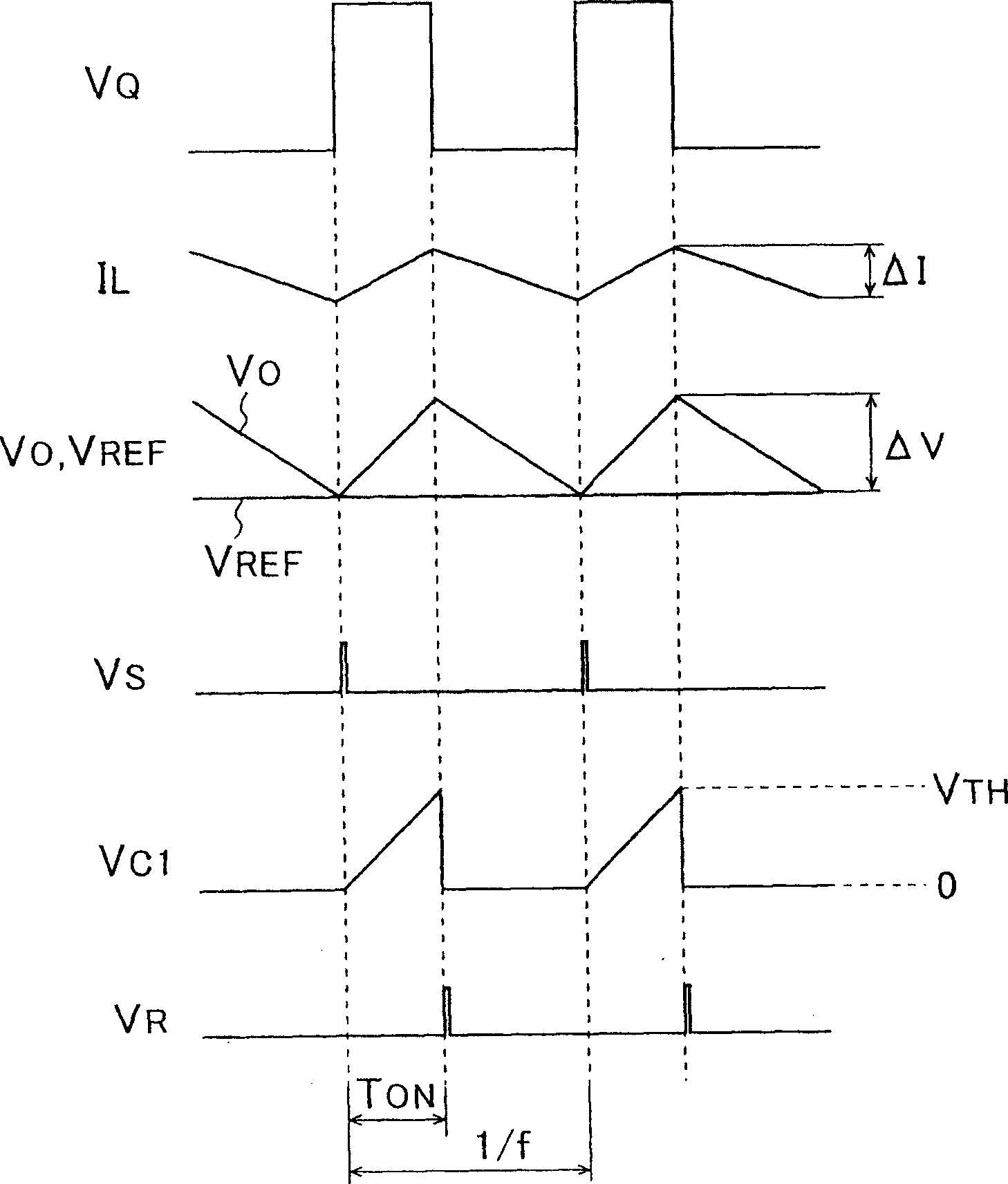

Switching regulator

ActiveCN100492837CGeneration of controlWork at high speedDc-dc conversionElectric variable regulationPulse controlControl signal

A control signal generating circuit (1) comprises a comparator (10) for comparing an output voltage VO with a reference voltage outputted from a reference voltage source (11), a flip-flop (12) set by the output of the comparator (10), and a pulse control circuit (13) which receives an input voltage VIN, a reference voltage VREF2, and the inverted output of the flip-flop (12), sets the on time in accordance with the ratio between the input voltage VIN and the reference voltage VREF2, and resets the flip-flop (12) when the on time elapses after the output pulse of the flip-flop (12) rises. The output pulse of the flip-flop (12) is outputted as a control signal into a driver logic circuit (2). The driver logic circuit (2) performs on / off control of NMOSs (3, 4) according to the control signal. Thus, a switching regulator capable of operating at high speed can be realized.

Owner:ROHM CO LTD

All-optical switch

The invention relates to an all-optical switch of a photoelectric device, which is used for solving the problem that an optical passive device has slow response in an optical add-drop multiplexing system and an optical cross connection system of an all-optical high-speed network or cannot work normally at the room temperature. The all-optical switch comprises a multi-quantum dot layer semiconductor optical element of a Bragg structure positioned on a base platform, a control light fiber collimator, a polarizer, a signal light fiber collimator and an analyzer, wherein the multi-quantum dot layer optical element consists of N Bragg-structural composite layers extended and grown from a substrate; and each composite layer consists of a quantum dot layer and a barrier layer. The all-optical switch has the advantages of capability of realizing ultra-fast switching actions, relatively greater switching contrast, relatively lower insertion loss, low saturated pumping efficiency, switching response wavelength in an optical communication waveband, room temperature response characteristic, reliable performance and long service life, can be applied to the optical add-drop multiplexing system and the optical cross connection system and also can directly realize the transmission and routing of heavy traffic of signals in an optical layer.

Owner:HUAZHONG UNIV OF SCI & TECH

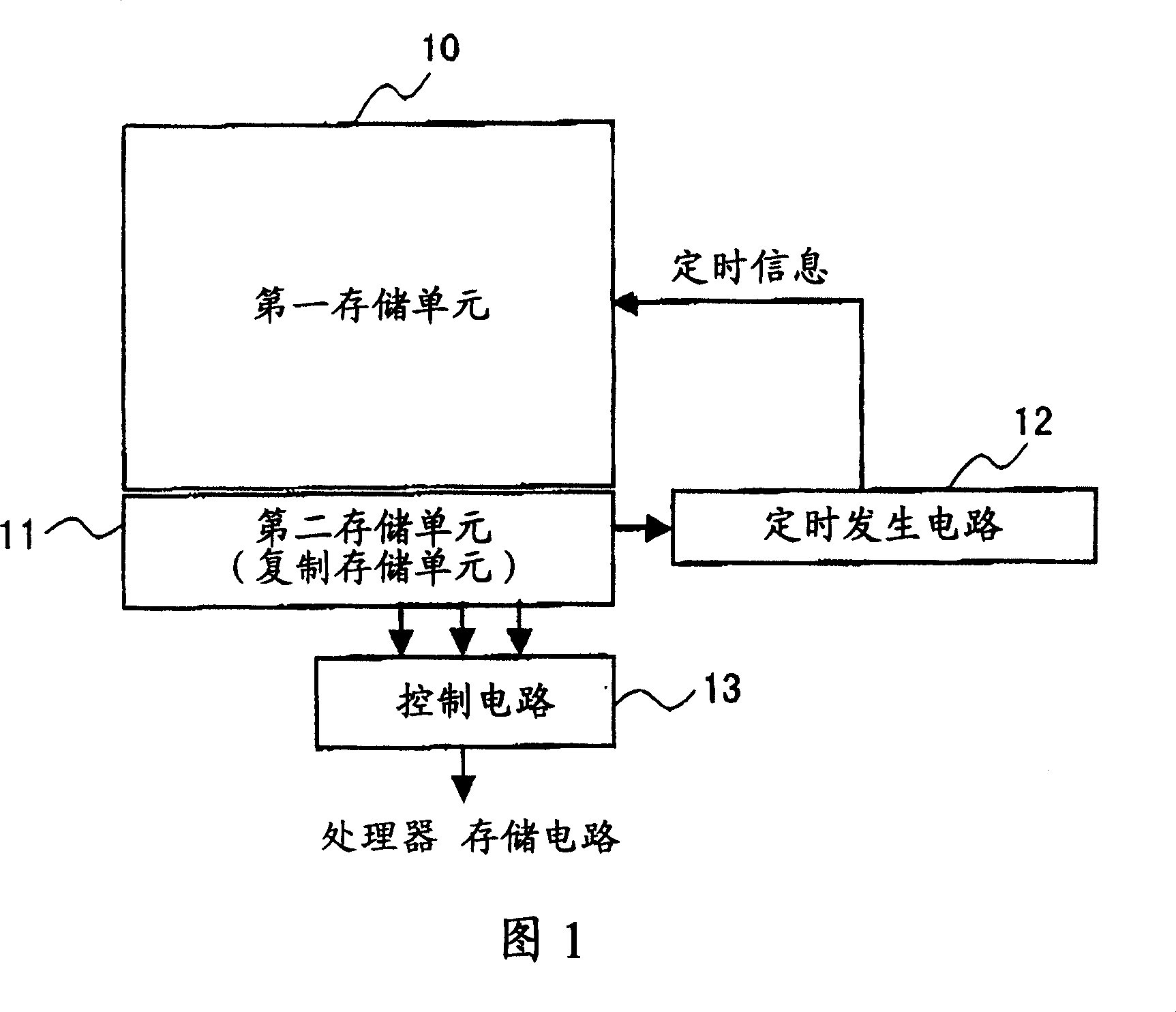

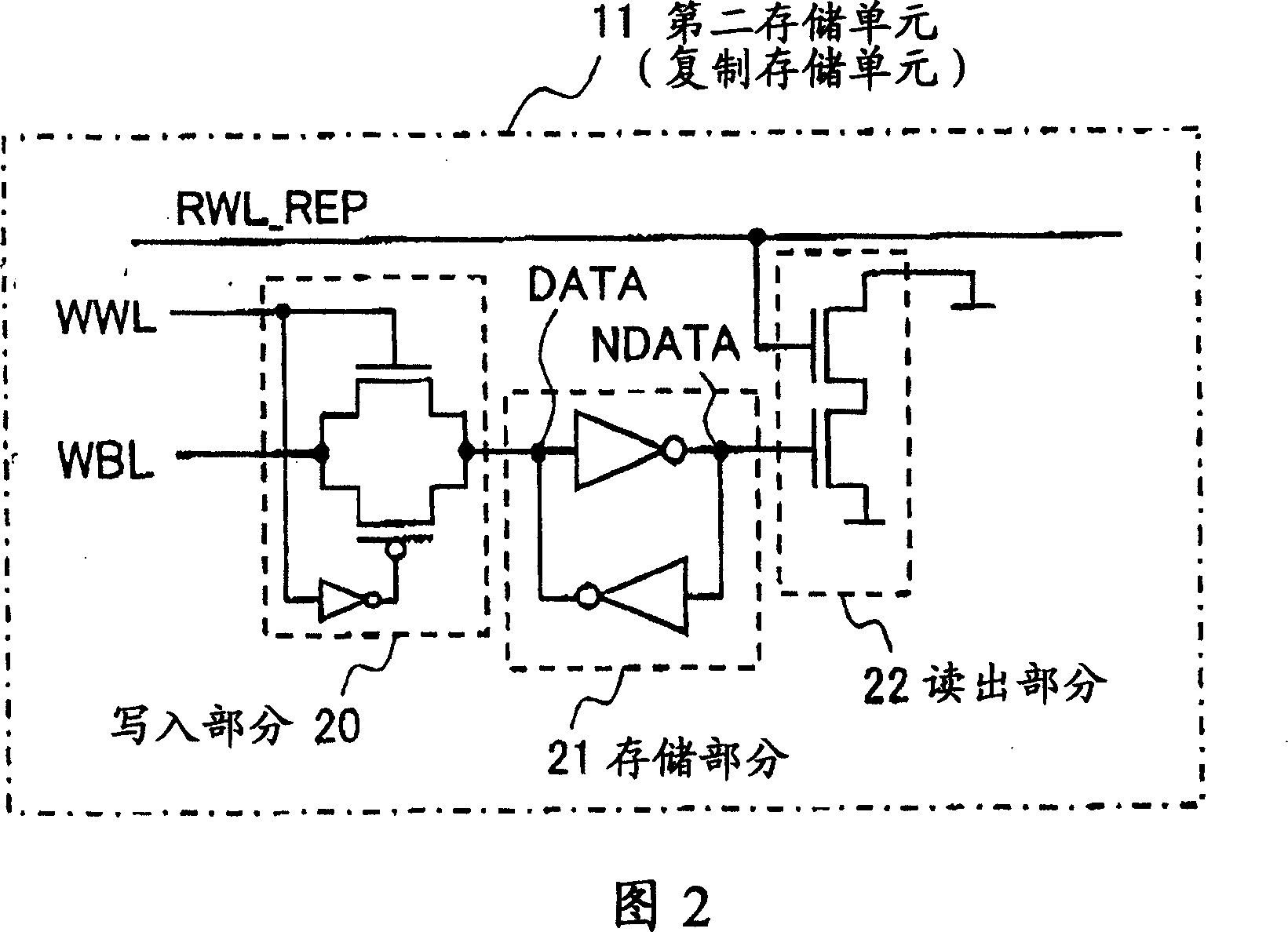

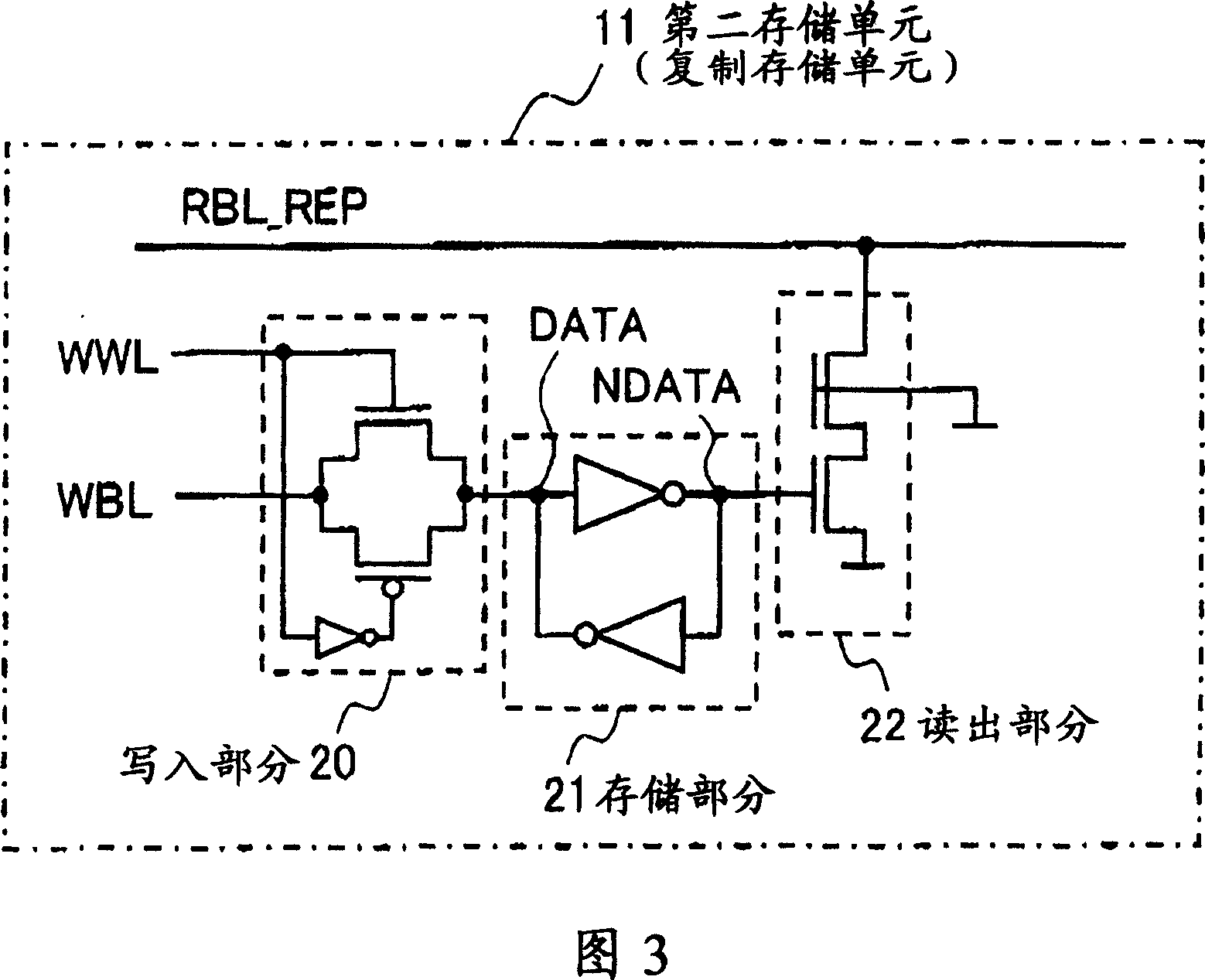

Memory circuit

InactiveCN1959841AReduce power consumptionWork fasterDigital storageMemory systemsParallel computingMemory circuits

There is provided a memory circuit including a first memory cell mapped on an address space accessible from a processor, and a second memory cell not mapped on the address space and having the same constitution as that of the first memory cell, wherein a control circuit for executing a control function relating to the memory circuit is included, and an output signal line of the second memory cell is connected to the control circuit.

Owner:PANASONIC CORP

LED Drive circuit and light transmission module therewith

InactiveCN1190855CWork at high speedShorten frontier timeBaseband system detailsDistortion/dispersion eliminationHemt circuitsLight-emitting diode

A light-emitting diode driving circuit according to an embodiment of this invention includes a light-emitting diode (1), a first current switch circuit (2) connected in series with the light-emitting diode (1), the first current switch circuit (2) turning on / off a current in accordance with an external input signal input from an input terminal (32), a pulse current generating circuit (3) connected in parallel with the first current switch circuit (2), the pulse current generating circuit (3) supplying a pulse current including a pulse width smaller than the pulse width of the external input signal and shaping a leading edge portion of an optical waveform output from the light-emitting diode (1) into a desired optical waveform, and a discharge circuit (5) connected in parallel with the light-emitting diode (1), the discharge circuit (5) quickly discharging charge stored in the light-emitting diode (1) when the current to the first current switch circuit (2) is turned off.

Owner:KK TOSHIBA

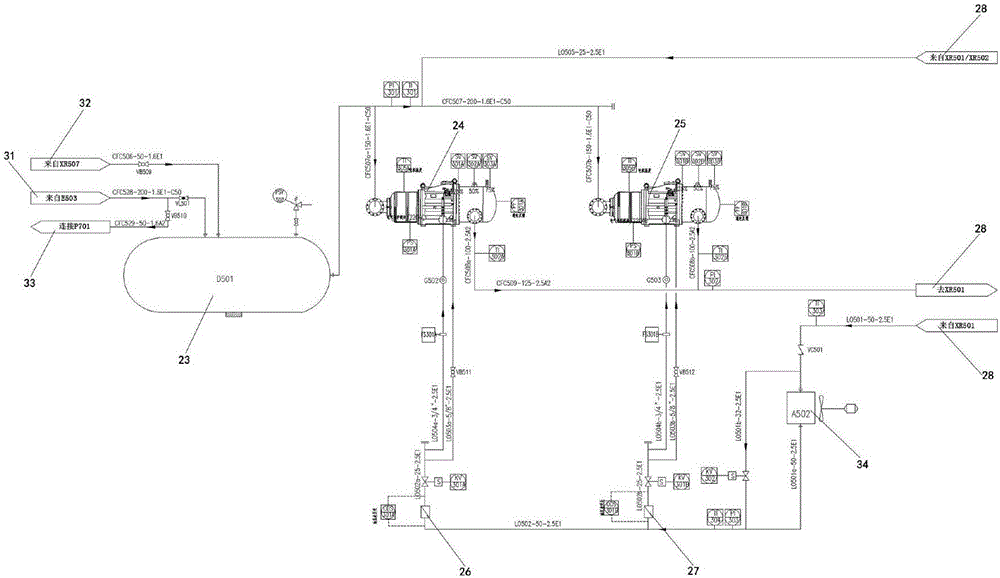

Screw compressor for mixed refrigeration field and application method thereof

InactiveCN106567830AStable jobWork smoothly and at high speedCompression machines with non-reversible cycleRotary piston pumpsControl systemEngineering

The invention discloses a screw compressor for a mixed refrigeration field and an application method thereof. The screw compressor comprises a machine body; a cylinder, a piston, a connecting rod and a machine body compression chamber are mounted on the machine body; the connecting rod and the piston are tightly connected to the machine body; a volume adjusting electromagnetic valve, a machine oil filter, a position indicator, a mechanical compression chamber spraying port, a cleaning hole cover flange and an oil release valve are mounted in the machine body compression chamber; and a safety valve and a high-pressure side angle valve are mounted at the bottom end of the outer wall of the machine body. The application method is to firstly adjust the ratio of R22 mixed refrigerant and to control a control system and an oil return system of the screw compressor to achieve the effect of deep cooling. The screw compressor with high reliability, convenience to operate and maintain, good power balance and high adaptability is applied to a compression process of the R22 compression mixed refrigerant, so that the energy consumption is reduced, and the equipment investment cost is reduced.

Owner:宁夏凯添燃气发展股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com