Semiconductor device and microprocessor

A microprocessor and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems that it is difficult to draw fine patterns on large-size glass substrates at high speed, and it is impossible to suppress the size of TFTs. Achieve the effect of suppressing cost increase, suppressing quantity increase, and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

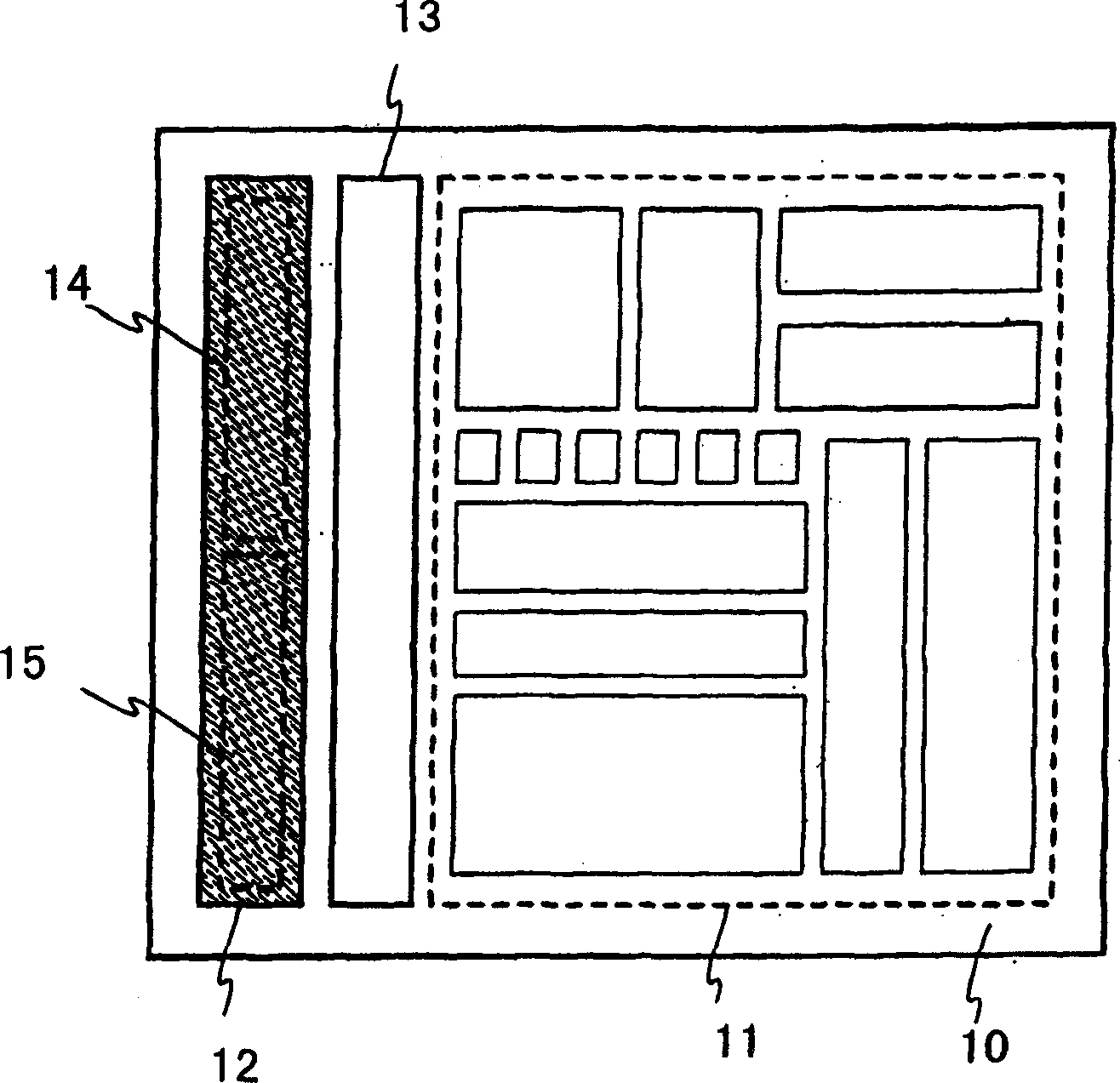

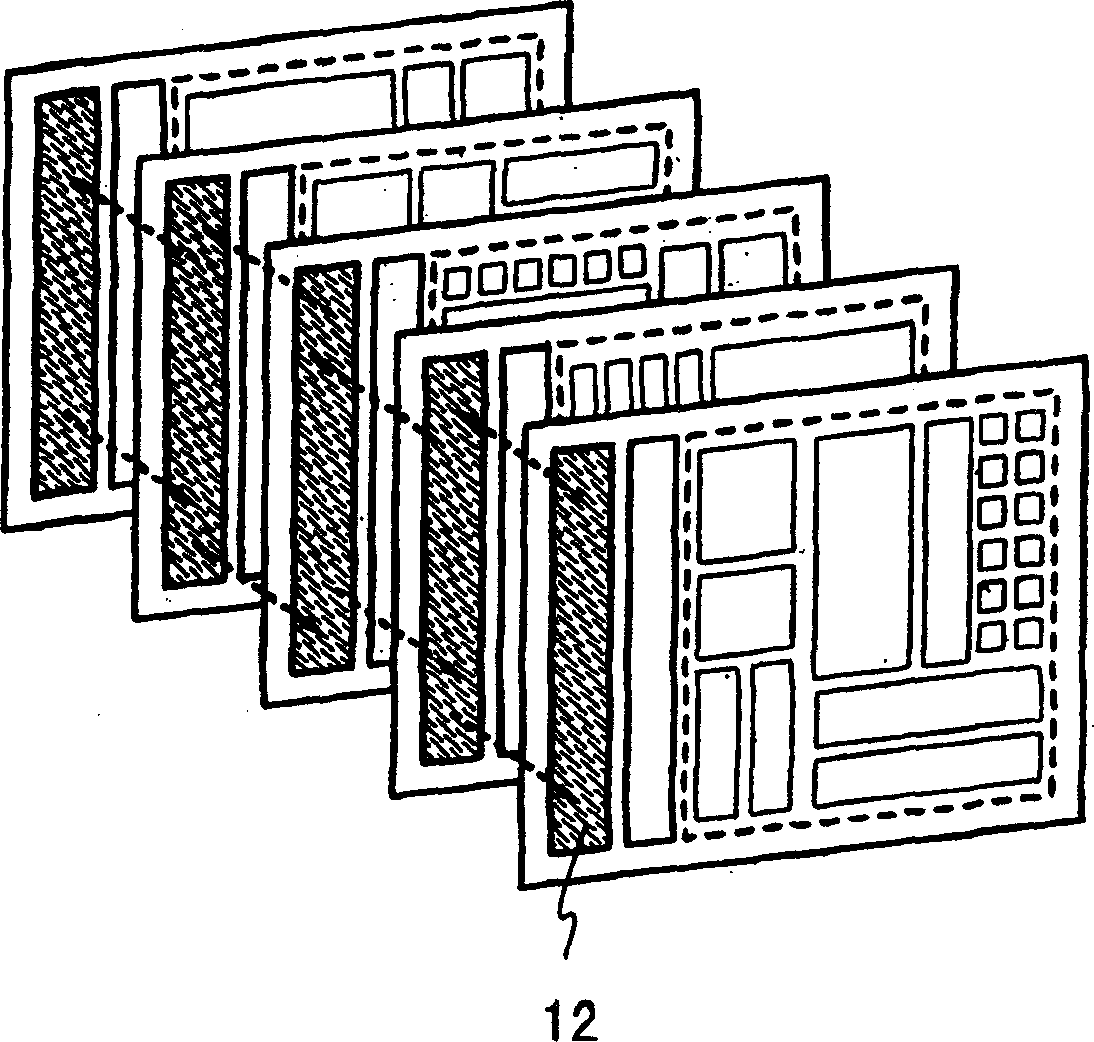

[0052] In this example, an example will be described below in which a CPU core of a CPU (Central Processing Unit) typified by a microprocessor is formed on a plurality of glass substrates and the respective substrates are connected to optical interconnections.

[0053] TFTs formed on glass substrates operate slower than single crystal transistors. Therefore, in the case where the CPU is formed on a glass substrate, when the processing content becomes complicated, it is difficult for a single CPU core to perform processing at a sufficient speed. Then, a series of processing steps of the CPU core is divided into several processing steps according to each purpose, and the CPU core formed on one substrate is allocated to each processing step. Thus, a series of processing steps can be performed, similar to the case of using a single CPU core by connecting a plurality of substrates on which each CPU core is formed by optical interconnection. A CPU core formed on each substrate can ...

example 2

[0067] In this example, an example of a semiconductor display device which is one of the semiconductor devices of the present invention will be described below.

[0068] exist Figure 5 In , the structure of the semiconductor display device of this example is represented as a block diagram. Figure 5 In this method, two glass substrates are used. On the first substrate 200, an external input terminal 225, a VRAM (Video Random Access Memory) 201, a time signal generation circuit 202, an image signal processing circuit 203, and a control signal processing circuit 203 are provided. The light output section 204 for the image signal and the light output section 205 for the image signal.

[0069] One or more light emitting elements 220 and a light emitting element driving section 221 corresponding to the one or more light emitting elements 220 are formed at the light output section 204 for control signals and the light output section 205 for image signals, respectively. It should ...

example 3

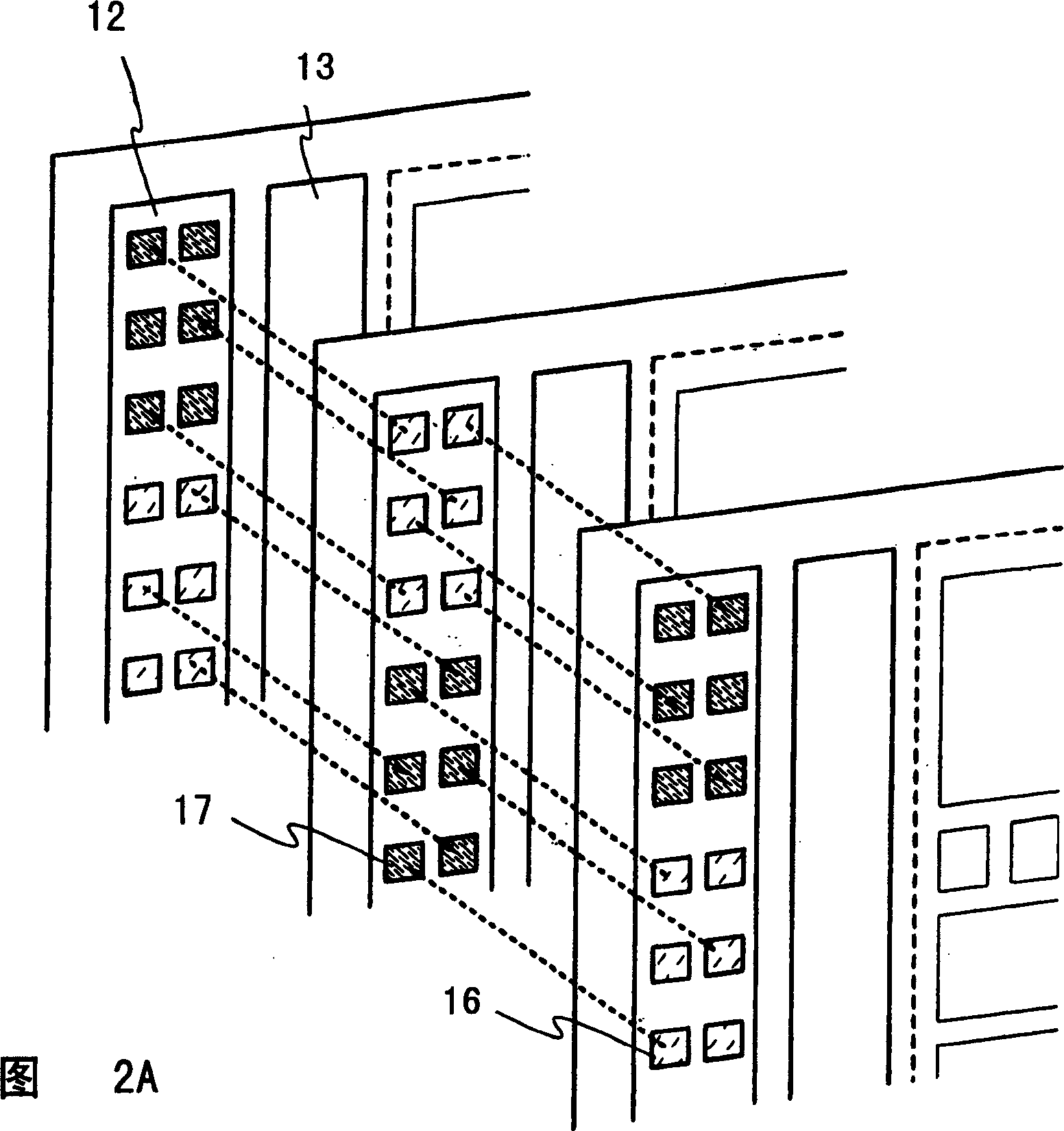

[0100] In this example, an example of how substrates on which circuits are formed are stacked layer by layer will be described below.

[0101] exist Figure 8A In , an example of a cross-sectional view of the semiconductor device of this example is shown. The light input part 301 and the light output part 302 are provided on a plurality of substrates 300 . In addition, an adhesive 304 is filled between the respective substrates, and a spacer 303 is used to fix the distance between the substrates.

[0102] It should be noted that the adhesive is not necessarily required to be filled between the substrates, and it is possible to partially use the adhesive so that air, inert gas, and other gases exist between the light input portion and the light output portion.

[0103] The light output portion 302 provided on each substrate corresponds to at least one light input portion 301 formed on another substrate 300 . Thus, in this example, the position of each substrate 300 in the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com