Filling reversing structure

A control structure and power device technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of inability to guarantee the accuracy of reversing transmission, unfavorable high-speed filling automation, complex reversing structure, etc., and achieve compact structure , high cost performance, and the effect of increasing the speed of commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

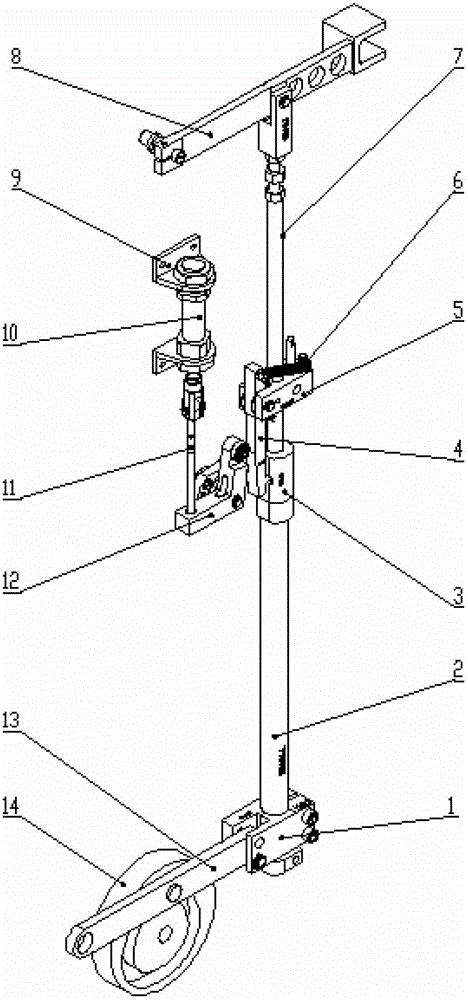

[0022] refer to figure 1 A filling reversing structure is composed of a cam power structure, a filling reversing control structure and a filling reversing execution structure.

[0023] The cam 14 is directly connected to the output shaft of the active motor to provide power for the swing arm 13. One end of the swing arm 13 is fixed on the box, and the middle is connected with the cam groove and swings up and down with the cam 14. The other end of the swing arm 13 is connected to the movable The sleeves 2 are connected, so that the movable sleeve 2 can reciprocate up and down.

[0024] Working principle of the present invention:

[0025] When there is a workpiece signal, the cylinder 10 will move upwards, and the control rod 12 will rotate cloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com