Rotator for high-pressure cleaning equipment

A high-pressure cleaning and spinner technology, applied in the field of spinners, can solve problems that affect cleaning efficiency and cost maintenance, spinner stuck, excess stuff stuck, etc., to ensure cleaning pressure and effect, ensure no loss of water flow pressure, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

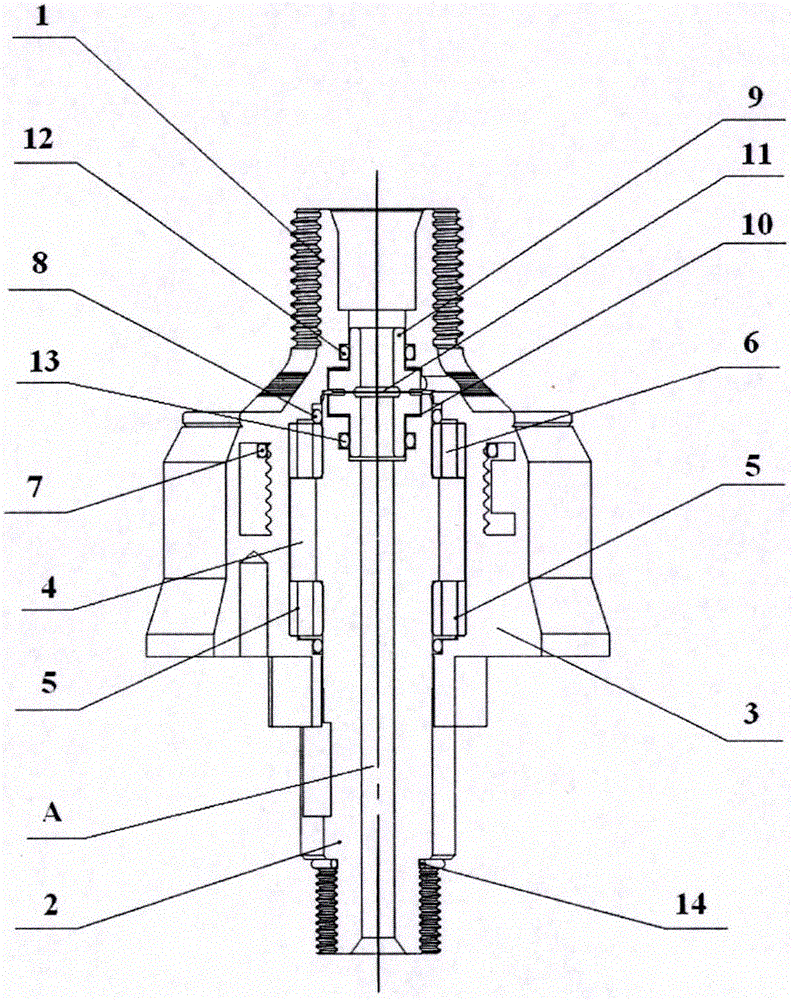

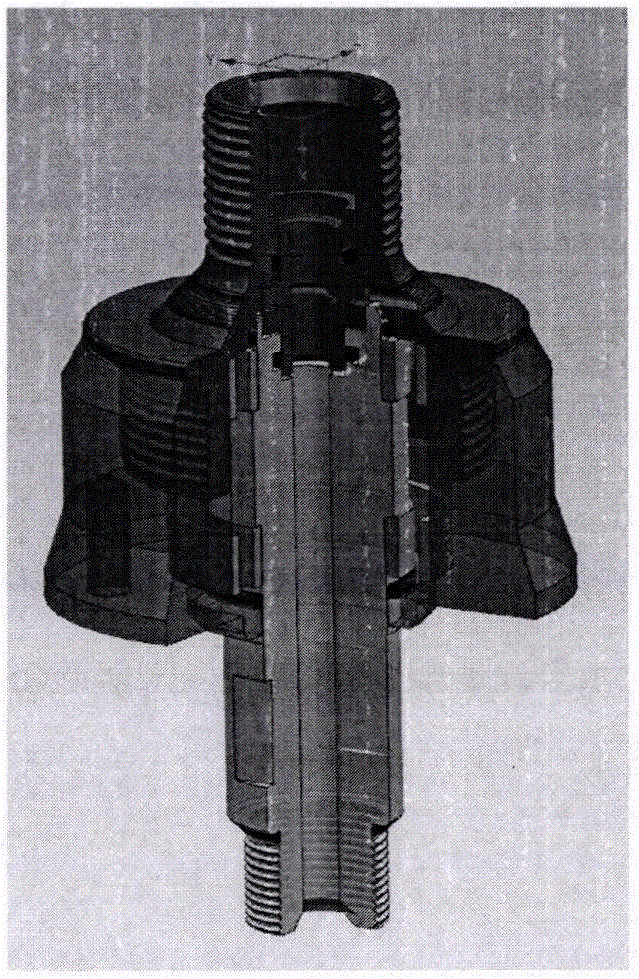

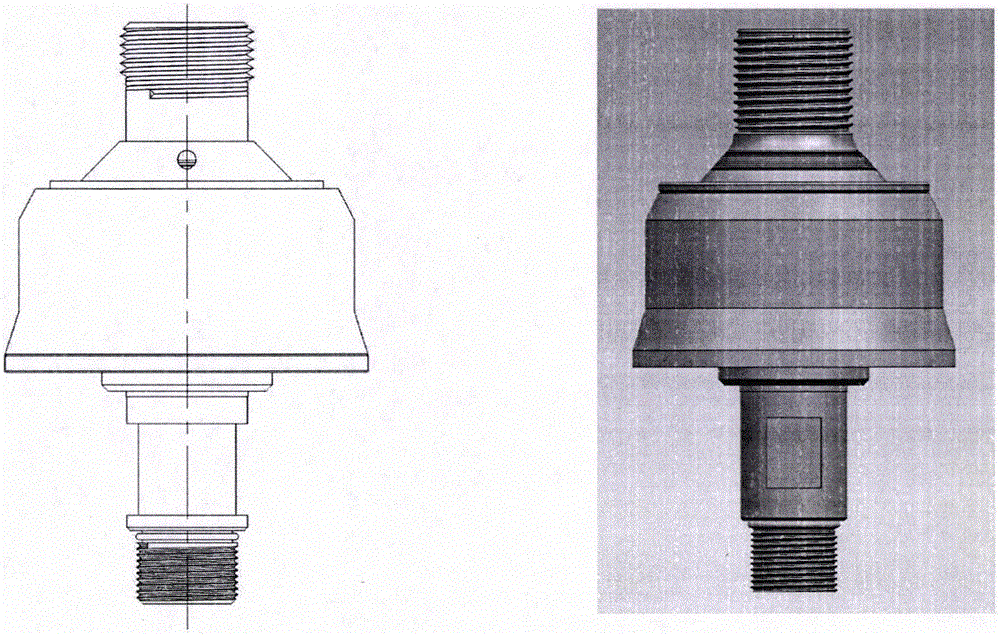

[0029] Such as figure 1 and Figure 4 As shown, the rotator of the present invention includes a fixing part 1 with a water inlet, a rotating shaft 2 with a water outlet, and a casing 3 . Both the upper part and the lower part of the fixing part 1 are provided with external threads. The shell 3 is tightly connected with the fixing member 1 through threads. The rotating shaft 2 is supported on the casing and the fixing piece through bearings and can rotate relative to the casing and the fixing piece. At the same time, by setting a boss or a shoulder on the rotating shaft to cooperate with the bearing, the axis relative to the casing and the fixing piece is limited. to move. The rotating shaft 2 is provided with a through central channel A through which the high-pressure fluid passes.

[0030] The fixture 1 is an integral hollow tubular part consisting of an upper columnar body 11, a lower columnar body 12 and a middle part 13 connecting the upper columnar body 11 and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com