Constant volume combustion device for observing mutual effect of flame and pressure wave

A technology of constant volume combustion and pressure wave, which is applied in the direction of internal combustion engine testing, etc., can solve the problems of insufficient optimization of the inner cavity structure of constant volume incendiary bombs, interference with flame propagation, instability of flame combustion pressure waves and wall reflection waves, etc. The effect of maintaining or forming, ensuring the safety of the test, and not easy to leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

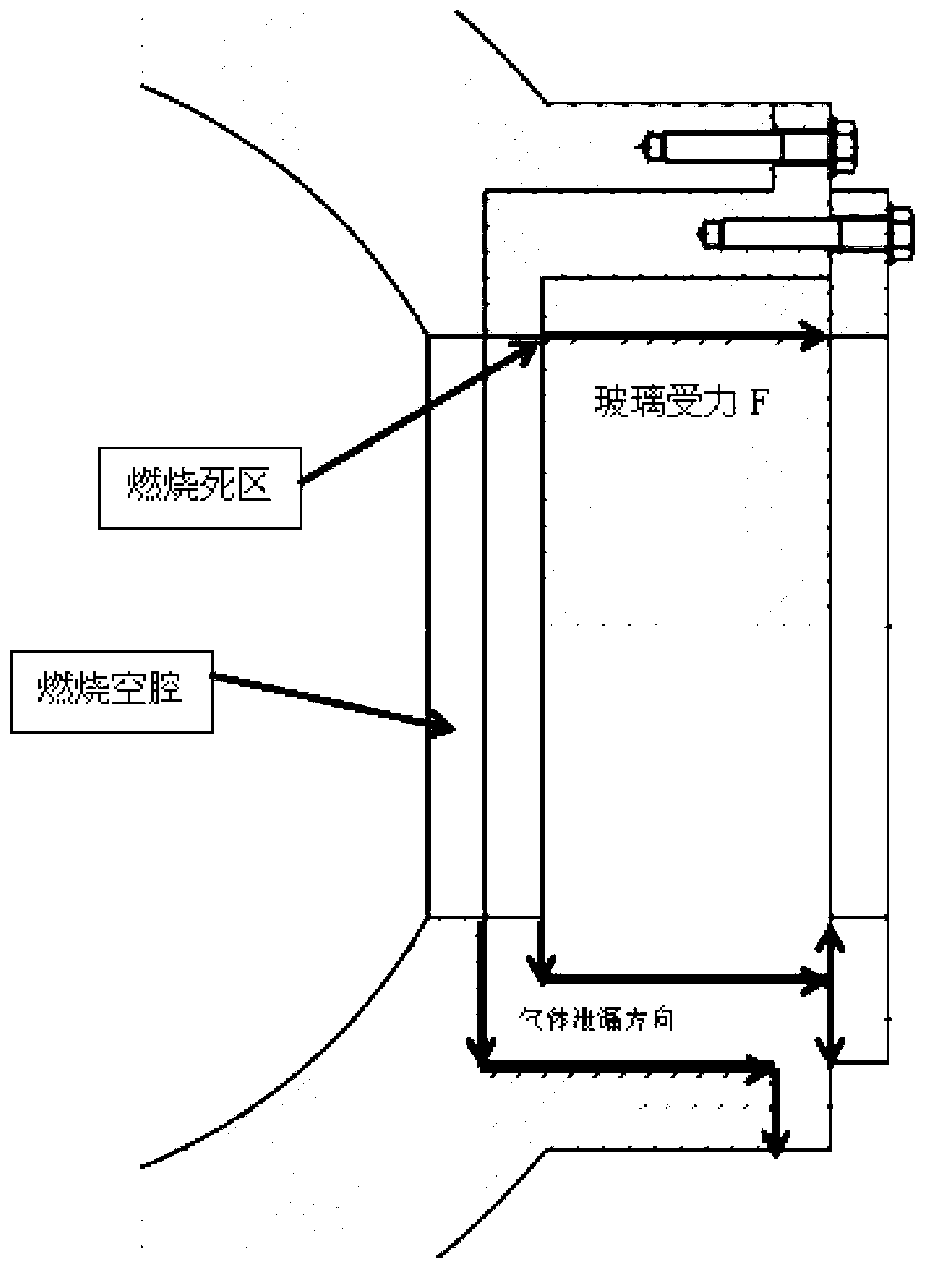

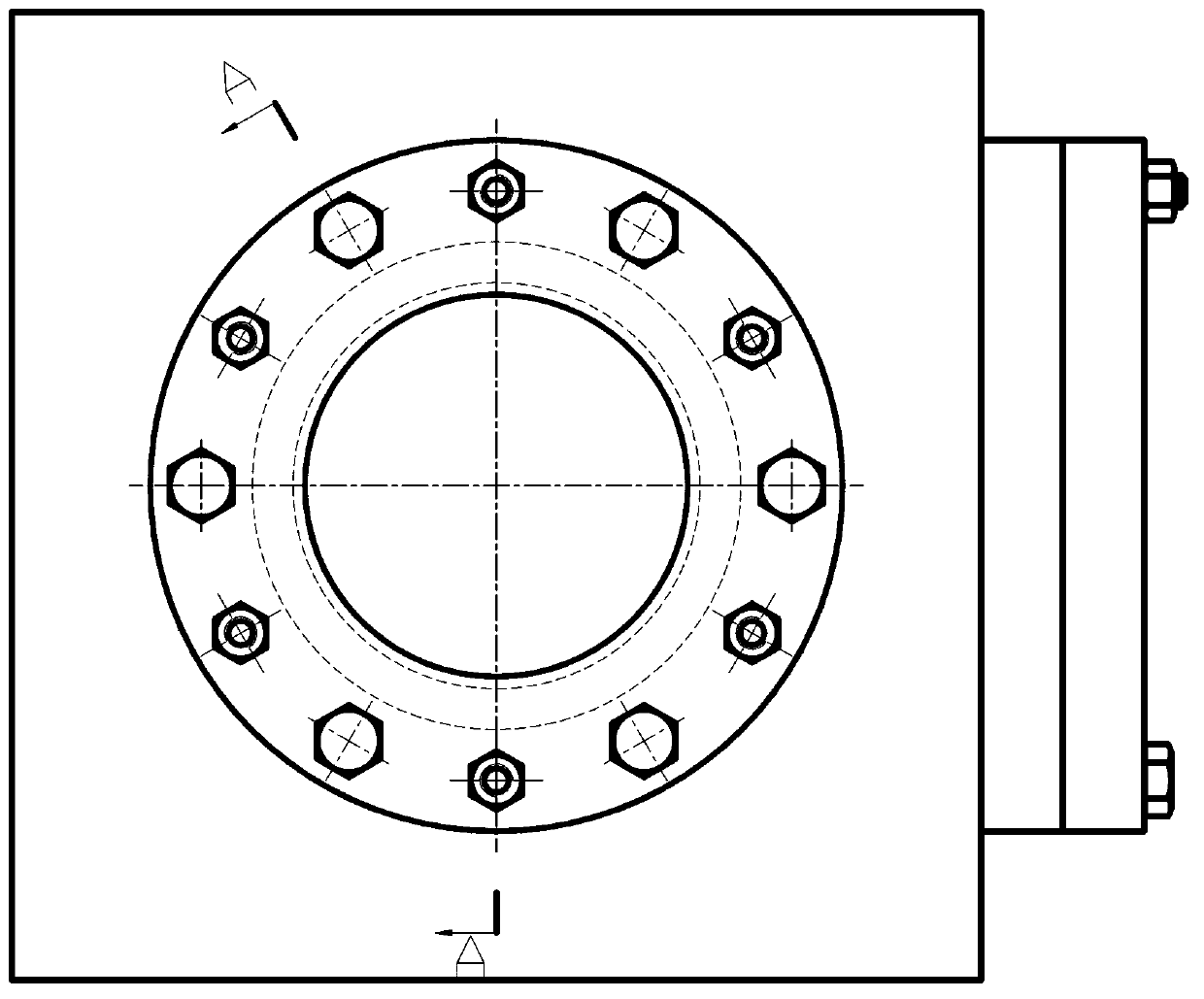

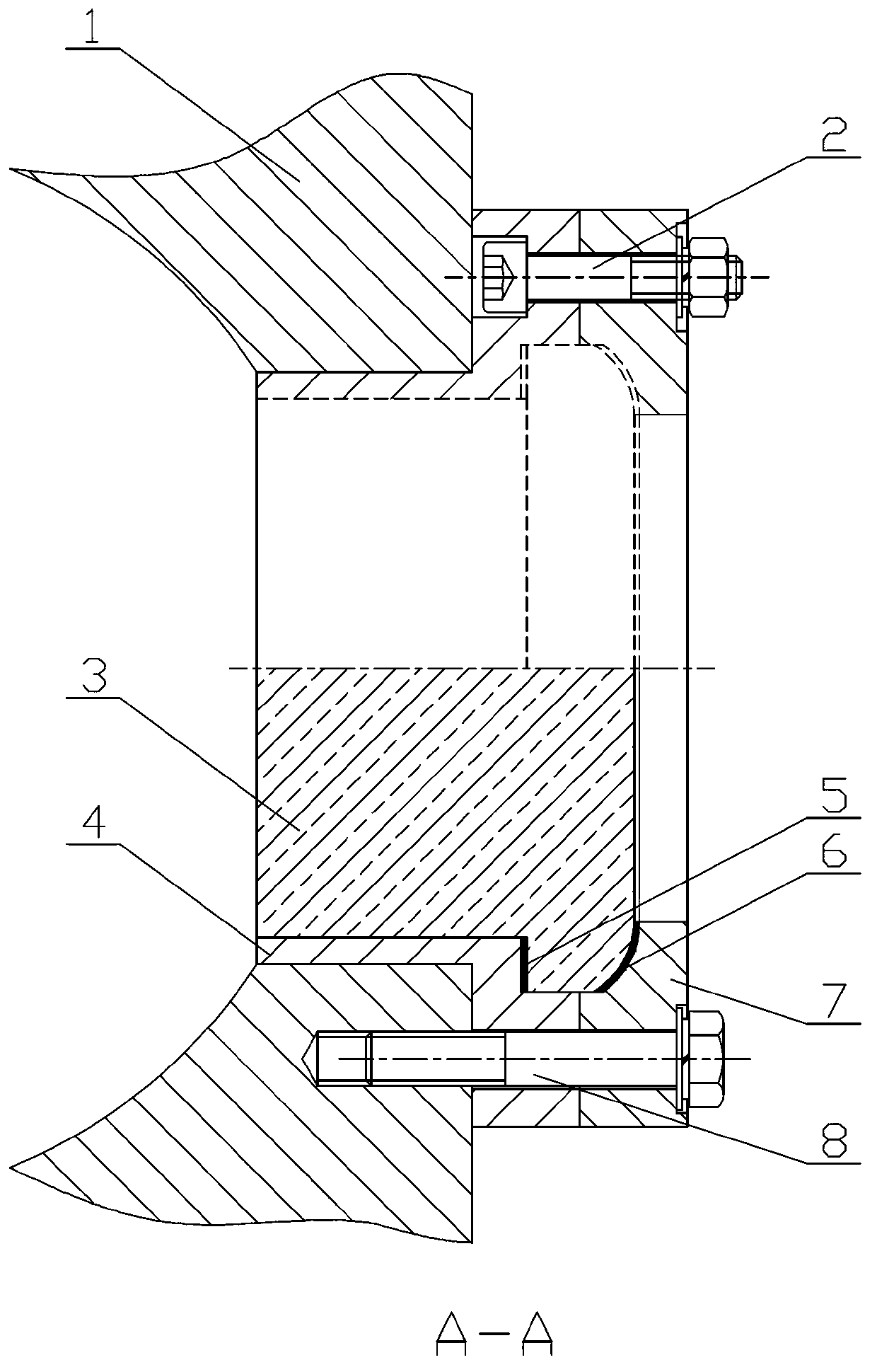

[0027] like figure 2 and image 3 As shown, this embodiment discloses a constant volume combustion device, the inner cavity of the combustion bomb body 1 adopts a spherical structure, and three observation holes in the shape of through holes are arranged on the combustion bomb body 1, and the observation holes are used for installing optical observation window. The optical observation window is mainly composed of an optical glass 3, an embedded end cover 4 and a compression end cover 7. The embedded end cover 4 and the compression end cover 7 are installed on the optical glass 3 and connected to each other through the M6 inner hexagonal bolt 2, and then through The M8 outer hexagonal bolt 8 is integrally inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com