Post insulator and insulation post

A technology of pillar insulators and insulating tubes, applied in the field of pillar insulators and insulating pillars, can solve problems such as gas leakage, achieve the effects of no maintenance and monitoring, large micro-water control margin, and reducing the difficulty of micro-water control and production and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

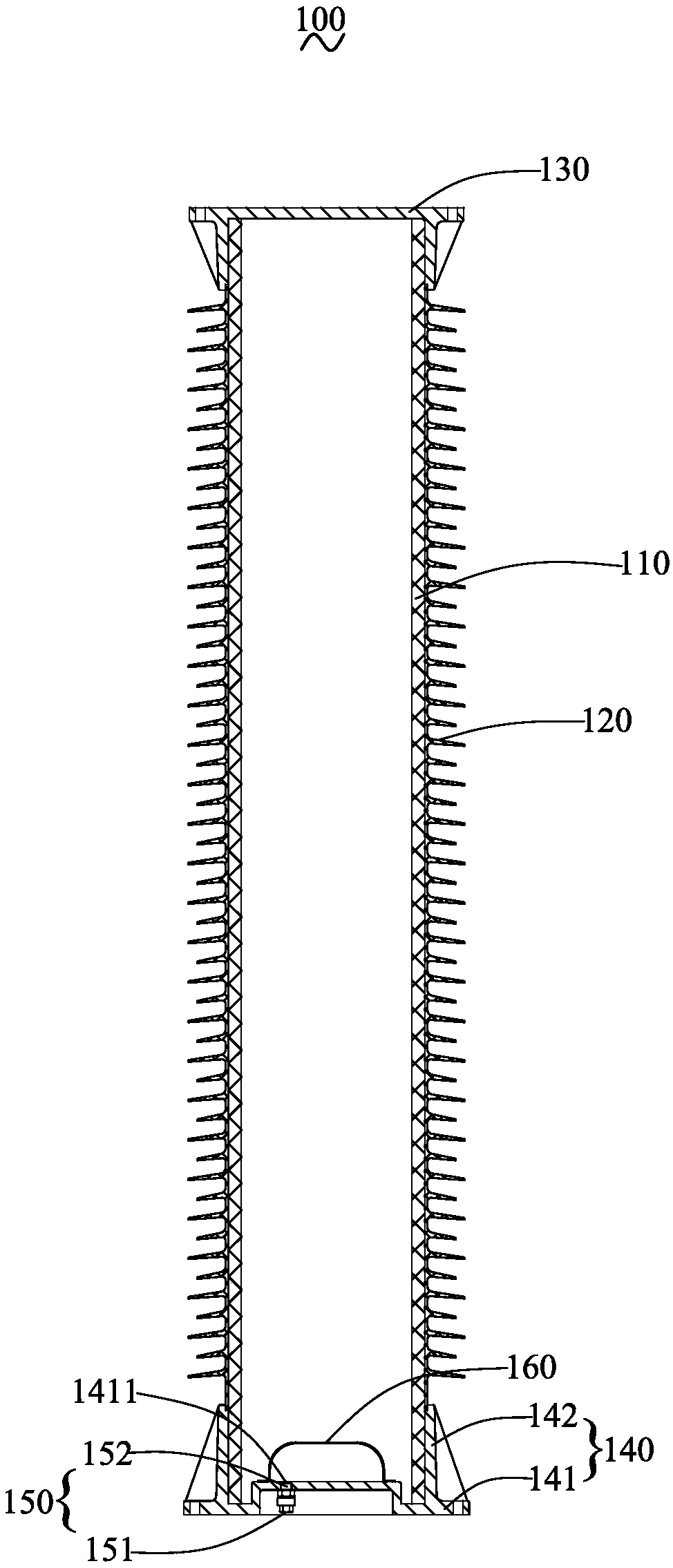

[0041] like figure 1 As shown, the post insulator 100 of this embodiment includes a hollow insulating tube 110, an umbrella skirt 120 located on the periphery of the hollow insulating tube 110, and an upper flange 130 and a lower flange 140 arranged at both ends of the hollow insulating tube 110. The hollow insulating tube Gas is sealed inside 110, and the absolute pressure of the gas is 0.1-0.15Mpa.

[0042] The absolute pressure of the gas inside the post insulator 100 is set to be 0.1-0.15Mpa. The gas in the hollow insulating tube 110 is in a state of normal pressure, which is not easy to leak from the hollow insulating tube 110 , and avoids routine maintenance and monitoring of the post insulator 100 . Setting the gas inside the hollow insulating tube 100 at normal pressure can also meet the pressure differences between different regions and altitudes, so as to ensure that the gas inside the hollow insulating tube 110 is in a non-negative pressure state when used in diffe...

Embodiment 2

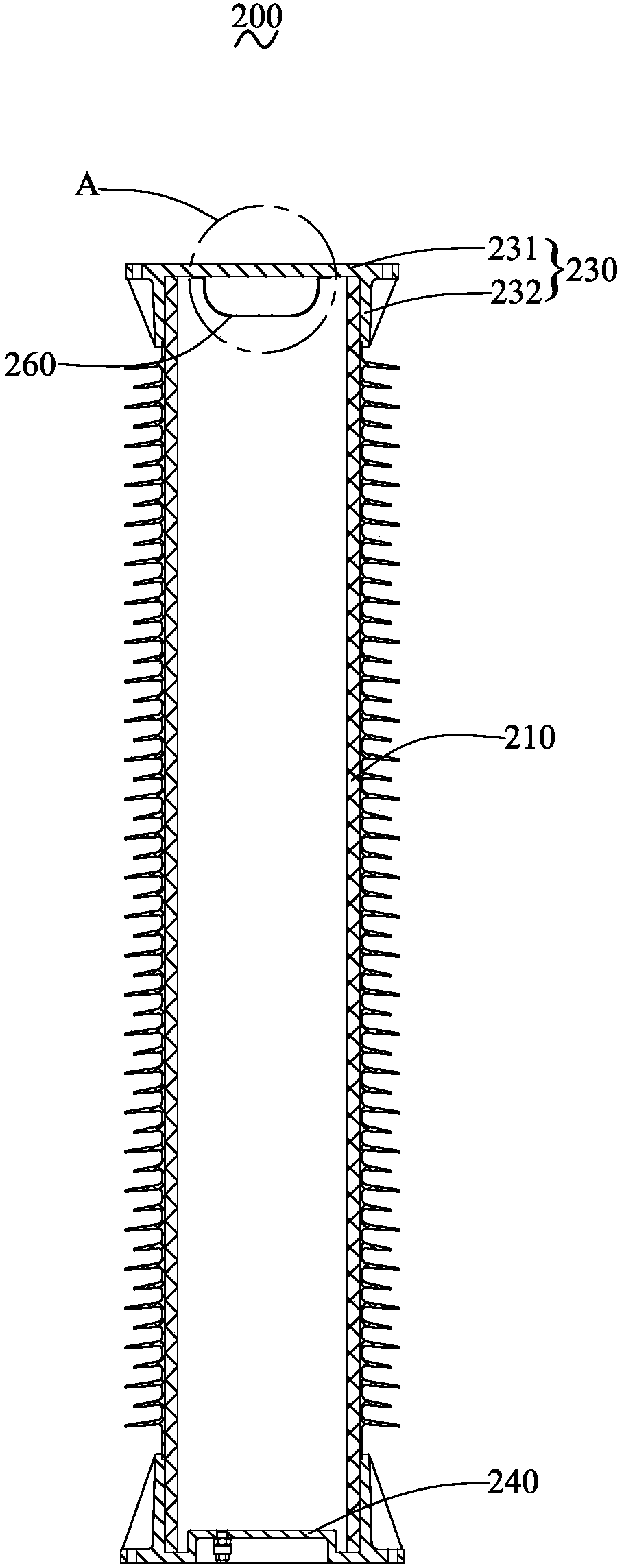

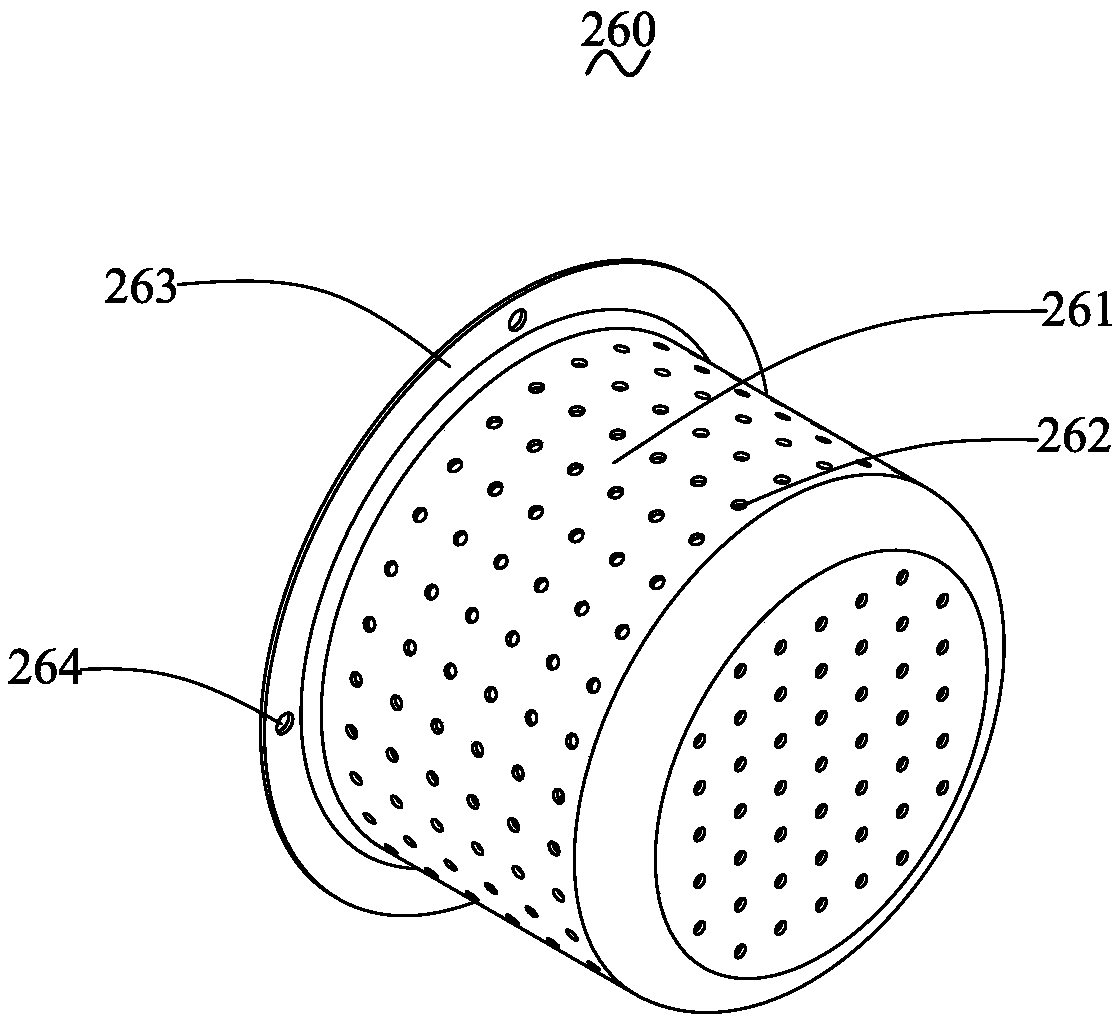

[0066] like figure 2 As shown, the post insulator 200 of this embodiment is similar in structure to the post insulator 100 in the first embodiment of the inventive post insulator. Here, the same structure will not be repeated here. The difference is that the gas and absolute pressure filled inside the post insulator 200 in this embodiment are different from those of the post insulator 100 . The drying device 260 is disposed on the upper flange 230 .

[0067] Wherein, the gas is dried high-purity nitrogen, air or sulfur hexafluoride gas.

[0068] In this embodiment, the gas is dried air. The absolute pressure of the air in the hollow insulating tube 210 is controlled to be 0.15Mpa.

[0069] Good air stability, economical and practical, filled in the hollow insulating tube 210, the absolute air pressure is controlled to 0.15 atmospheres, effectively avoiding gas leakage. Moreover, the slightly positive pressure gas can also adapt to the air pressure difference existing in ...

Embodiment 3

[0085] like Figure 5 As shown, the post insulator 300 of this embodiment is similar in structure to the post insulator 100 in the first embodiment of the inventive post insulator. The specific structure of the drying device 360 in this embodiment is the same as that of the drying device 260 in the second embodiment. Here, the same structure will not be repeated here. The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, the hollow insulating tube 310 is filled with 0.13Mpa sulfur hexafluoride gas. Both the self-sealing valve 350 and the drying device 360 are arranged on the upper flange 330 .

[0086] Wherein, the gas is dried high-purity nitrogen, air or sulfur hexafluoride gas.

[0087] In this embodiment, the gas is dried sulfur hexafluoride gas. The absolute air pressure of the air inside the hollow insulating tube 310 is controlled to be 0.13Mpa.

[0088] Wherein, a self-sealing valve 350 is provided on the upper flange 330 and / or the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water vapor permeability | aaaaa | aaaaa |

| Water vapor permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com