Sound barrier structure for high speed railways

A high-speed railway and sound barrier technology, applied in construction, noise absorption devices, etc., can solve the problems of unsatisfactory structural safety performance, high cost of sound barrier installation, and complicated construction process, so as to shorten the assembly time and improve the resistance to external shocks. The ability to destroy by vibration force and the effect of good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

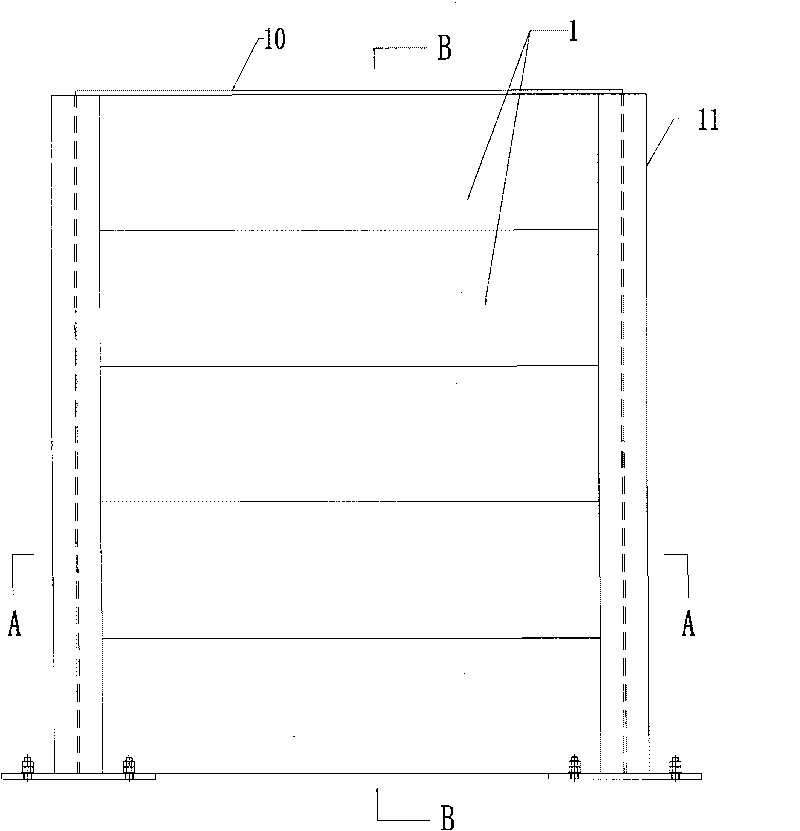

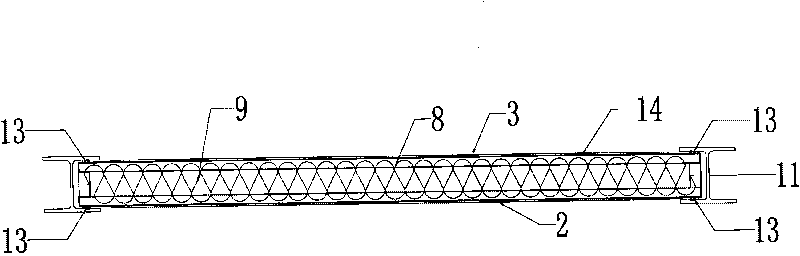

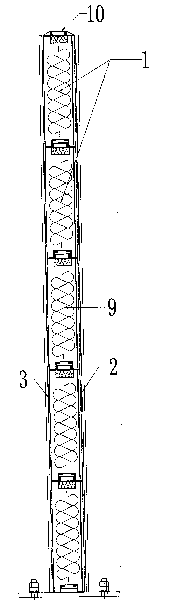

[0020] Attached below figure 1 to attach Figure 8 To further illustrate the present invention, the preferred embodiment of the present invention is: a high-speed railway sound barrier structure mainly made of aluminum and steel, which includes a steel column 11, and the lower part of the steel column 11 is embedded in the Concrete base steel structure connection; In actual engineering, the I-shaped steel column can also be poured into the concrete foundation or the lower part of the steel column 11 can be connected to the steel structure embedded in the concrete base by welding, and the middle of the steel column 11 can be inserted into the The sound barrier absorption / sound insulation unit plate 1 filled with sound absorption material 9, the installation process of the steel column 11 and the sound barrier absorption / sound insulation unit 1 is that the concrete base is poured first, and the steel screw is pre-embedded in the concrete base. The steel column 11 of the seat is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com