Connecting pipe of automobile exhaust gas purification equipment

A technology for purifying equipment and automobile exhaust, applied in the direction of flange connections, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve the problems of corrugated pipe or hose damage, inconvenient installation, etc., to achieve convenient installation and connection, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

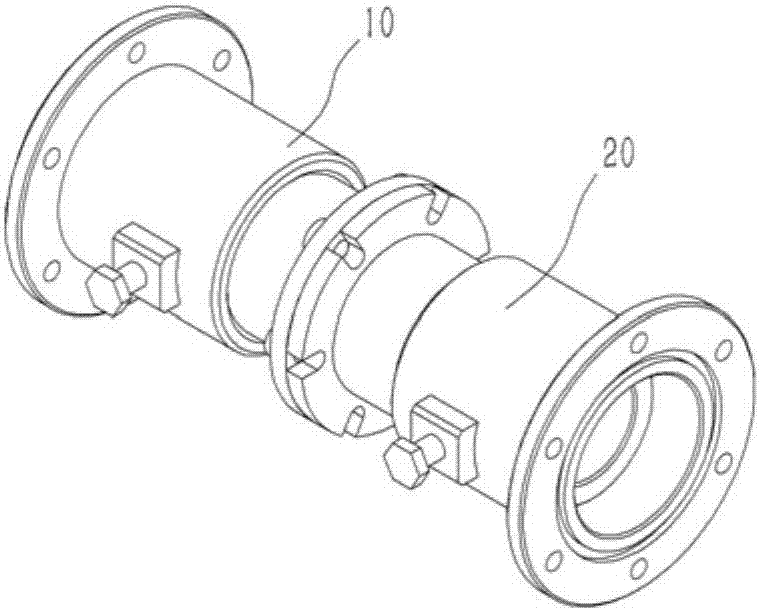

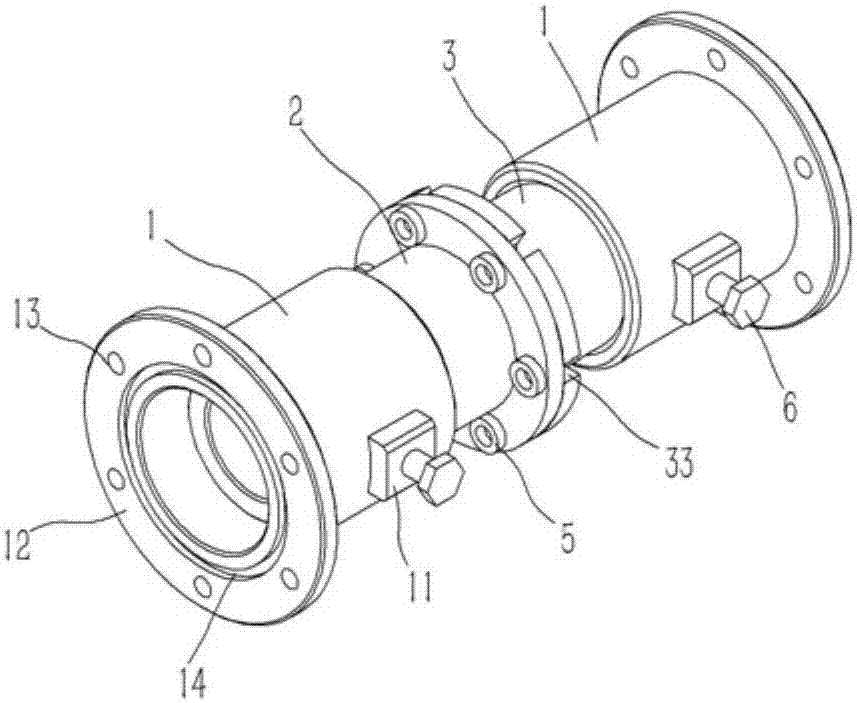

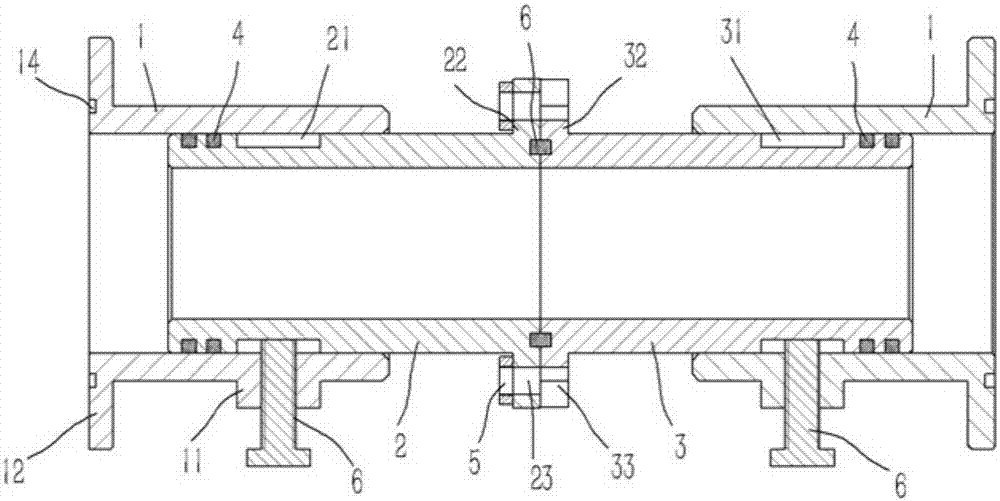

[0016] Example: see figure 1 , 2 As shown in , 3, a connecting pipe on the automobile exhaust gas purification equipment includes a first connecting pipe group 10 and a second connecting pipe group 20, the first connecting pipe group 10 is composed of an outer sleeve 1 and a first inner pipe 2, and the second connecting pipe The connecting pipe group 20 is composed of an outer sleeve 1 and a second inner tube 3. The outer end of the outer sleeve 1 is formed with a first flange 12. The first flange 12 is formed with a number of mounting holes 13. The outer wall of the outer sleeve 1 is formed with Rectangular boss 11, the first inner tube 2 and the second inner tube 3 are respectively inserted into the outer sleeve 1 of the first connecting group 10 and the outer sleeve 1 of the second connecting group 20, the first inner tube 2 One end of the second inner tube 3 and the second inner tube 3 are plugged and fixed with a plurality of seal rings 4, the seal rings 4 are pressed ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com