Patents

Literature

43results about How to "Tightly sealed connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

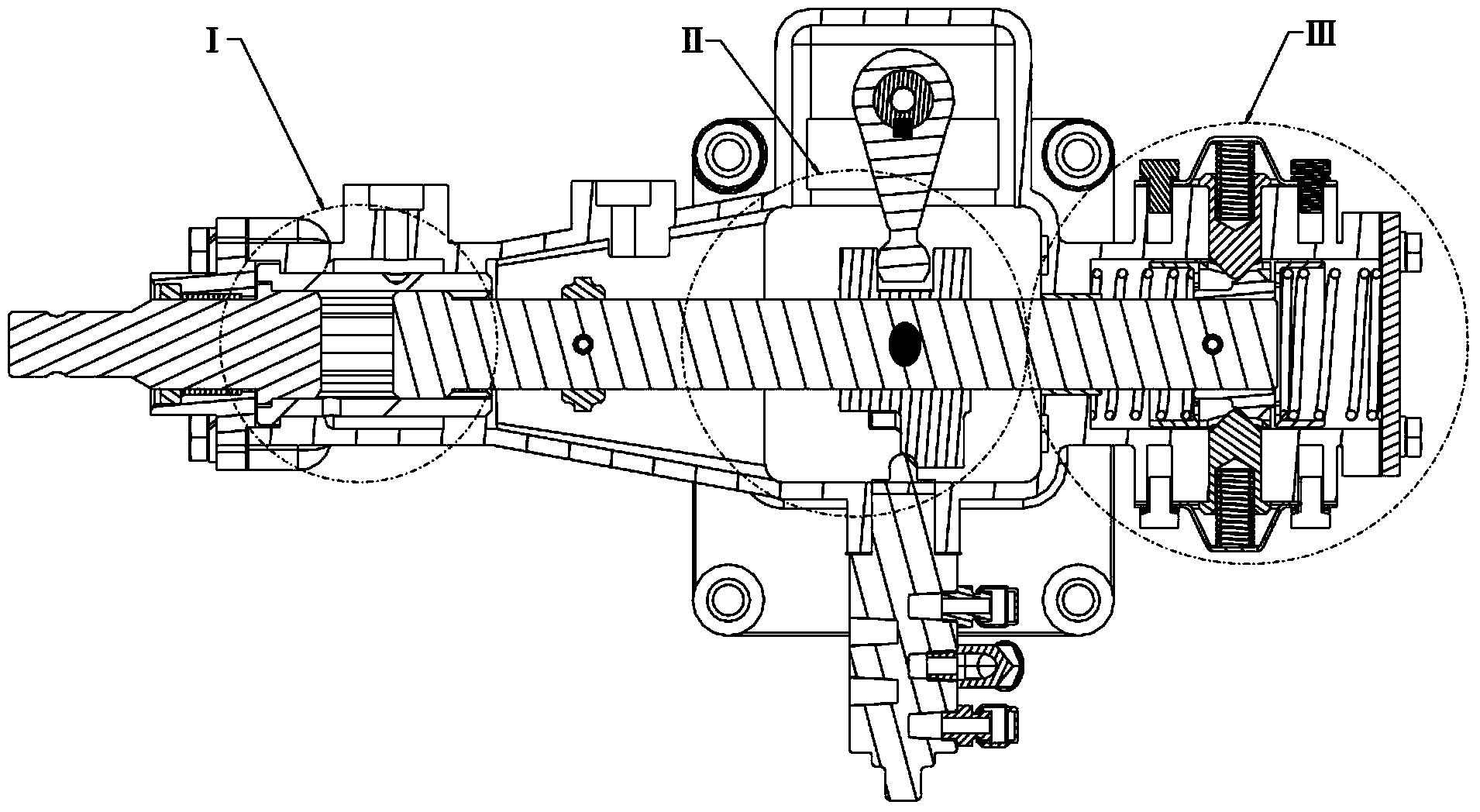

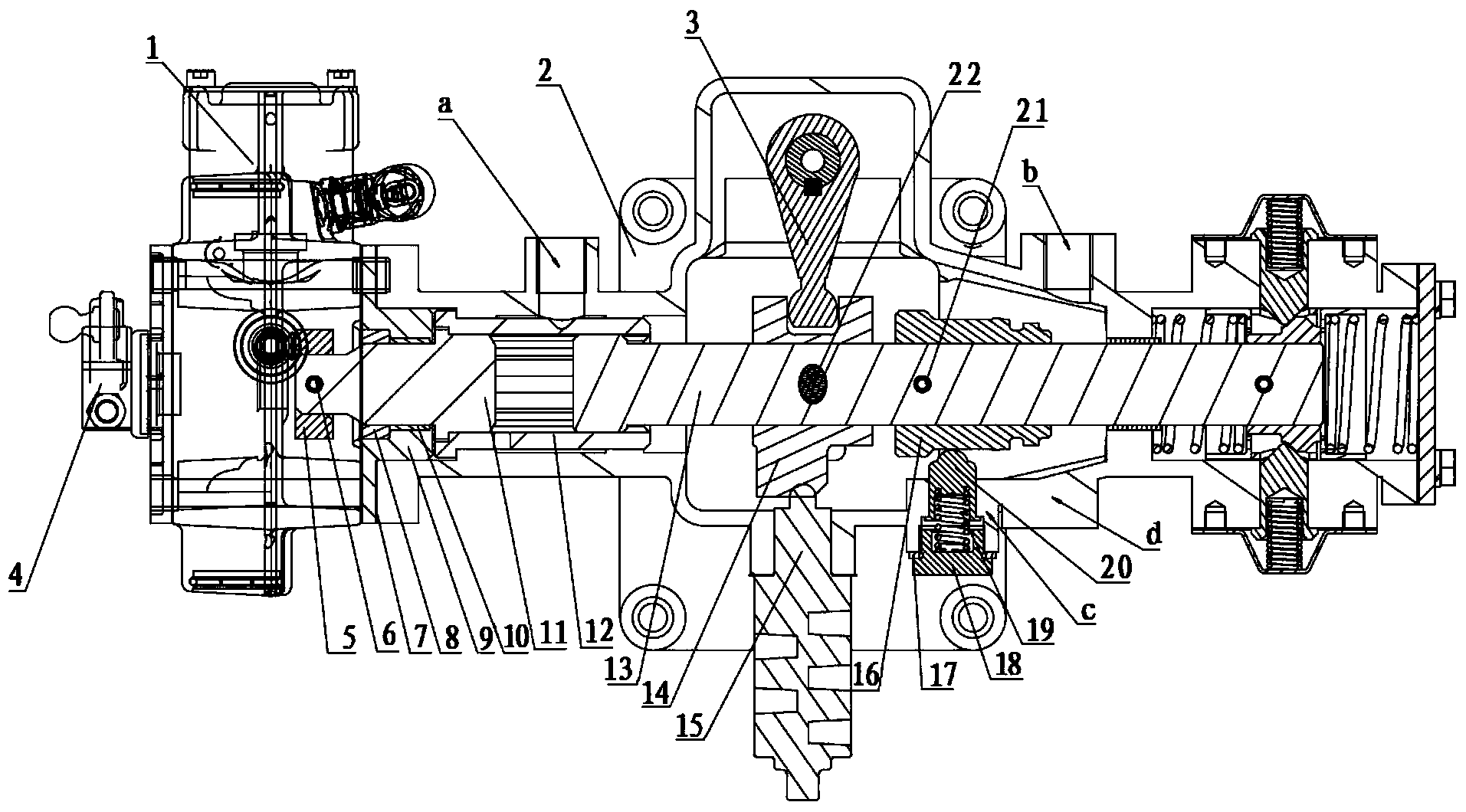

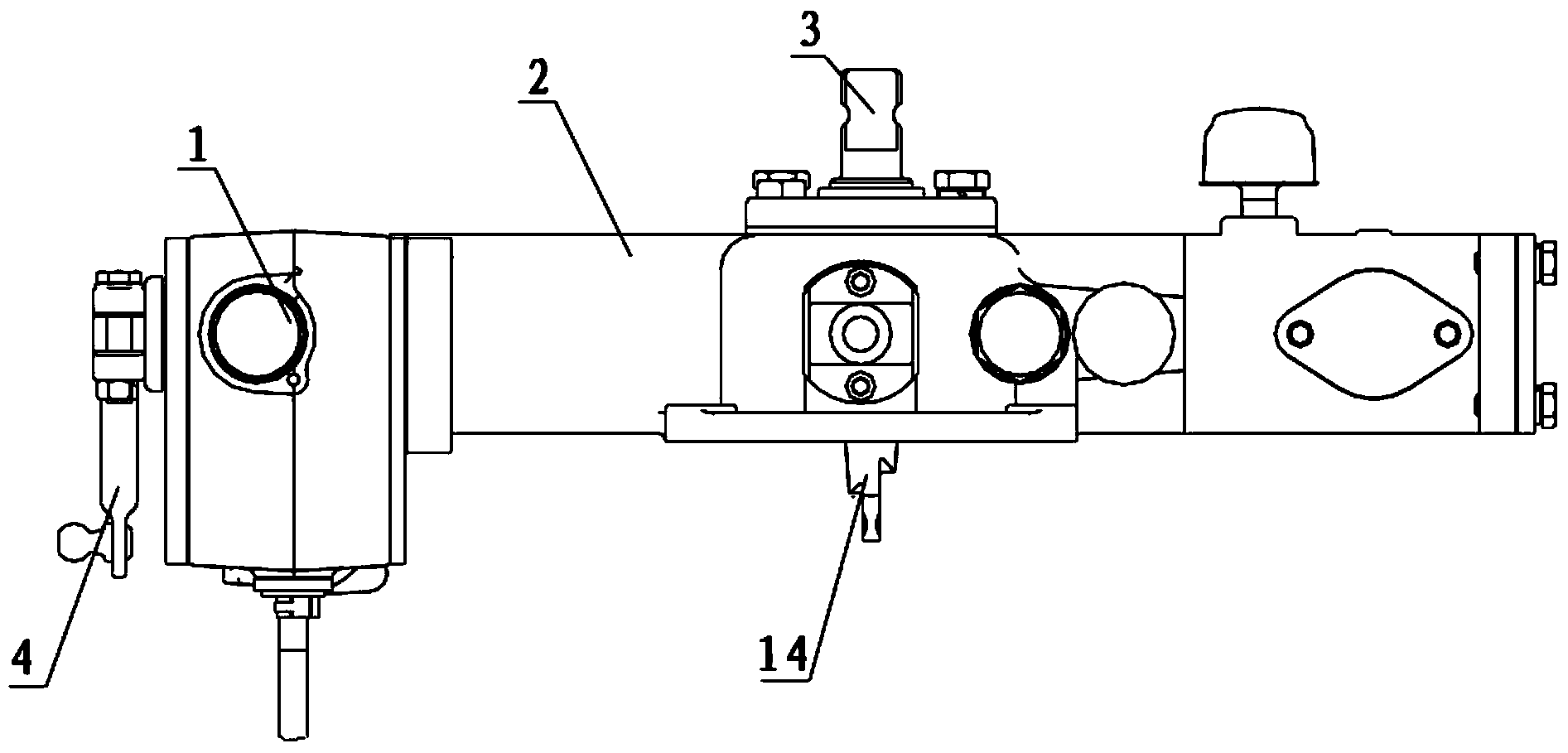

Transmission dual-H control mechanism

ActiveCN103968067AHigh strengthImprove operating experienceGearing controlH controlElectrical and Electronics engineering

Owner:SHAANXI FAST GEAR CO

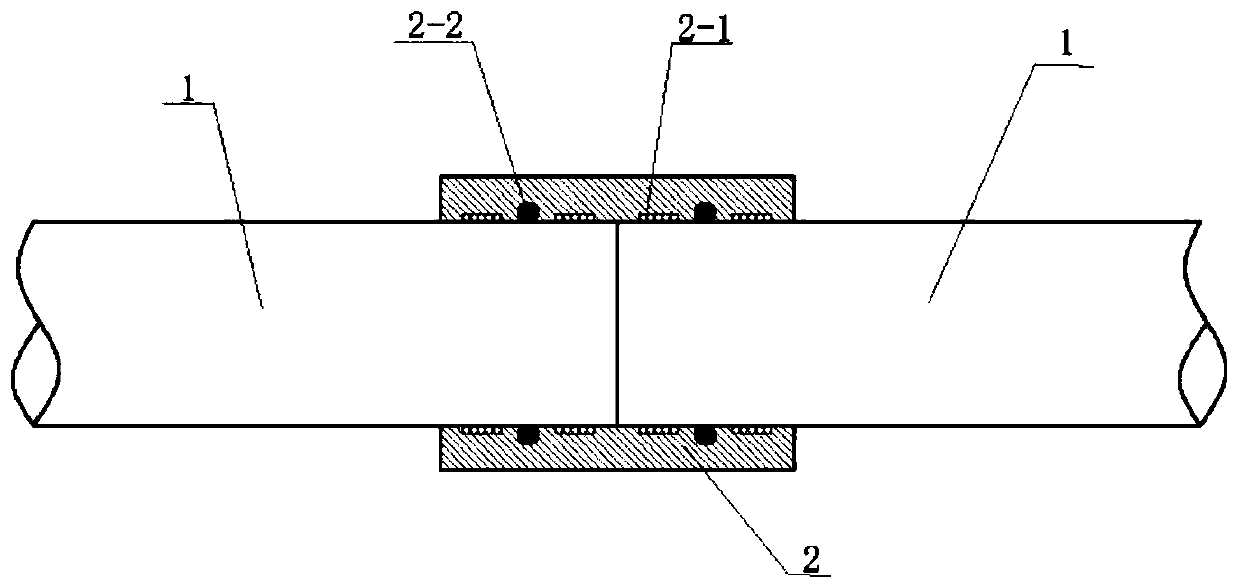

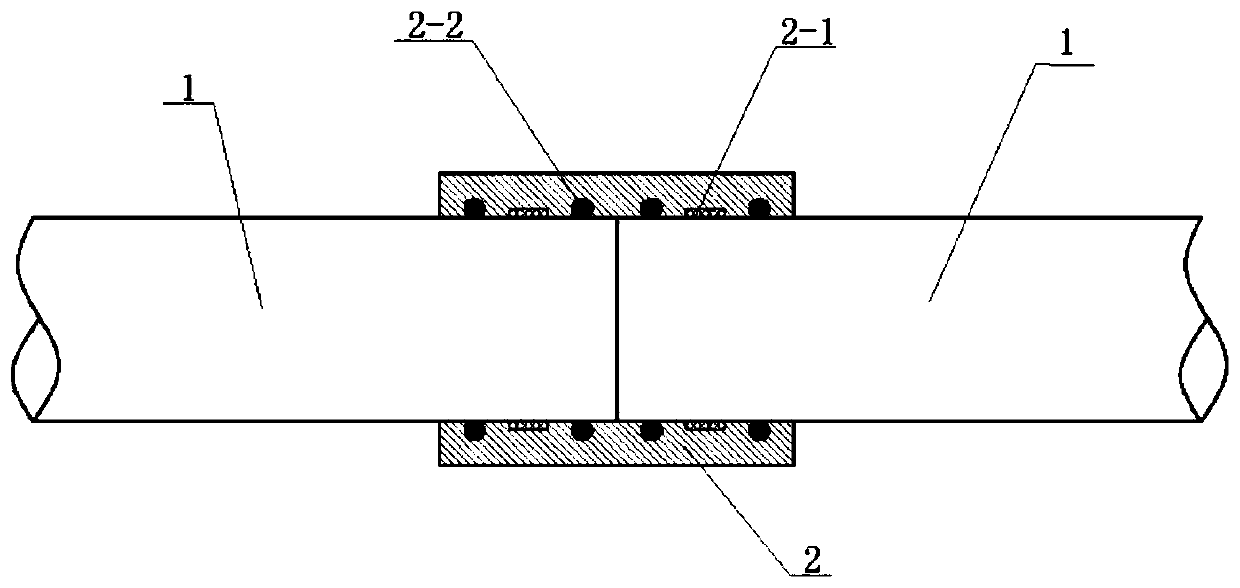

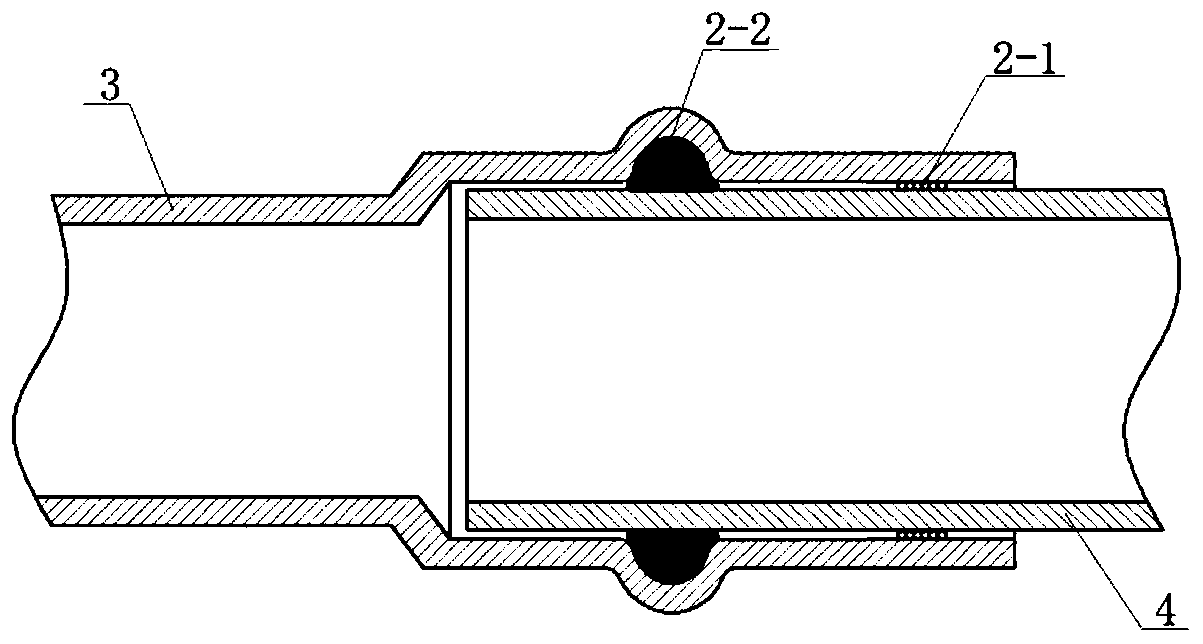

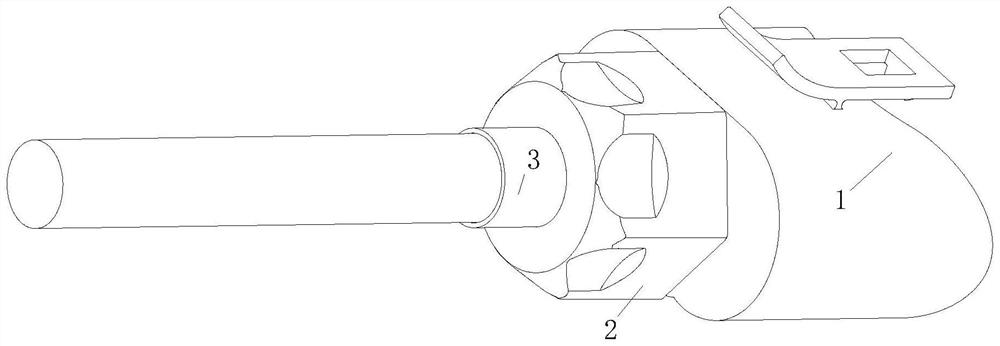

Combined sealing connecting method for plastic pipes

InactiveCN110657305AImprove sealingImprove stress resistancePipe connection arrangementsStructural engineeringMaterials science

The invention discloses a combined sealing connecting method for plastic pipes and belongs to the technical field of plastic pipes. Two plastic pipes, needing to be connected, with the same pipe diameter are horizontally placed; then the inner wall of a connecting casing pipe is provided with a sealing ring and a heating element; then the connecting casing pipe is firstly sleeved with the left plastic pipe, and then the right plastic pipe is in butt joint with the left plastic pipe; and then the heating element is electrified and melts the inner wall of the connecting casing pipe and the outerwalls of the plastic pipes in a heating manner. A rubber sealing ring and heating element melting and welding double-sealing technological means is adopted, pipeline connection is firmer, sealing isensured, and leakage is avoided; and the combined sealing and connecting method is widely applied to the fields of civic building water supply and drainage, gas and industrial pipelines and the like.

Owner:谭连平

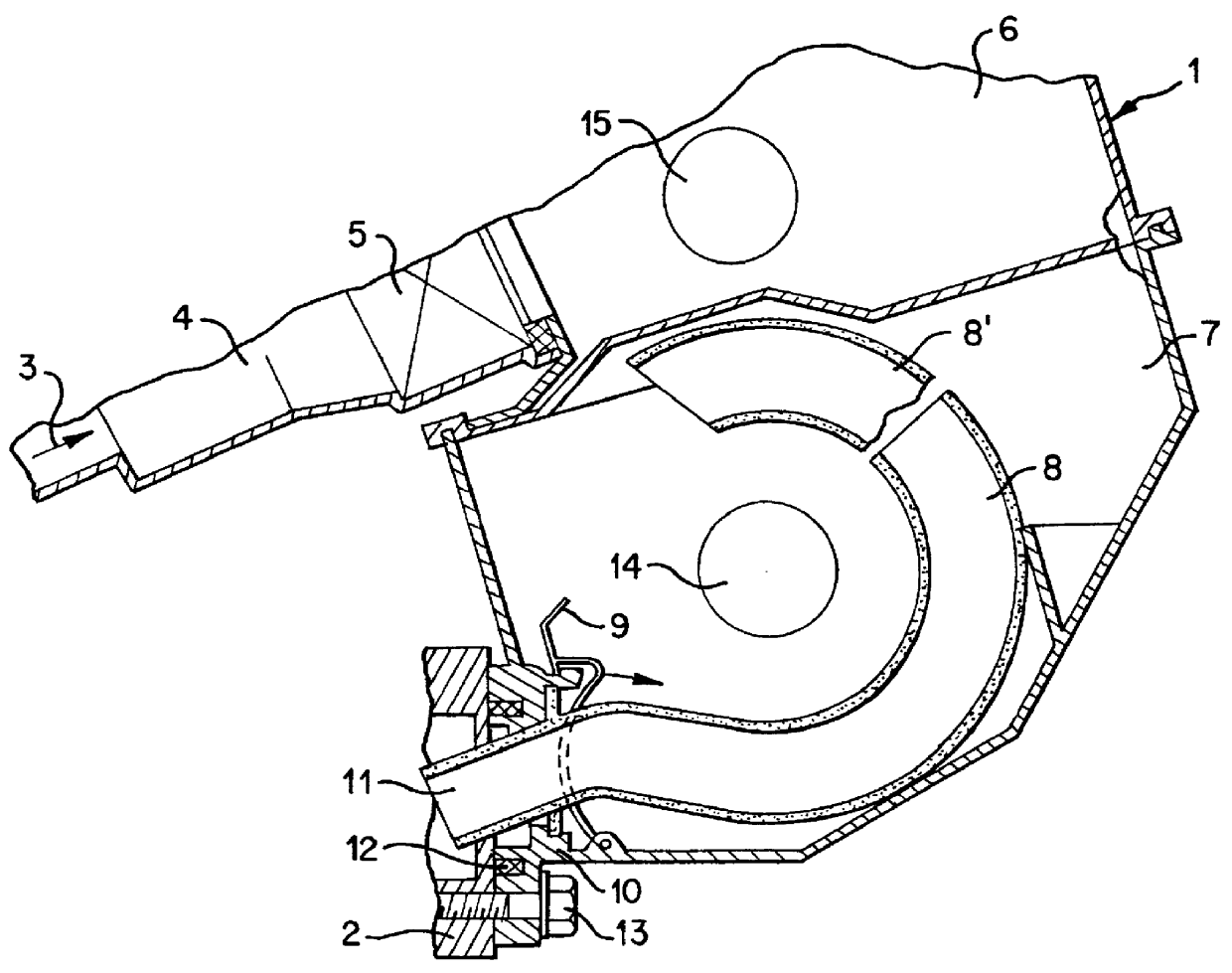

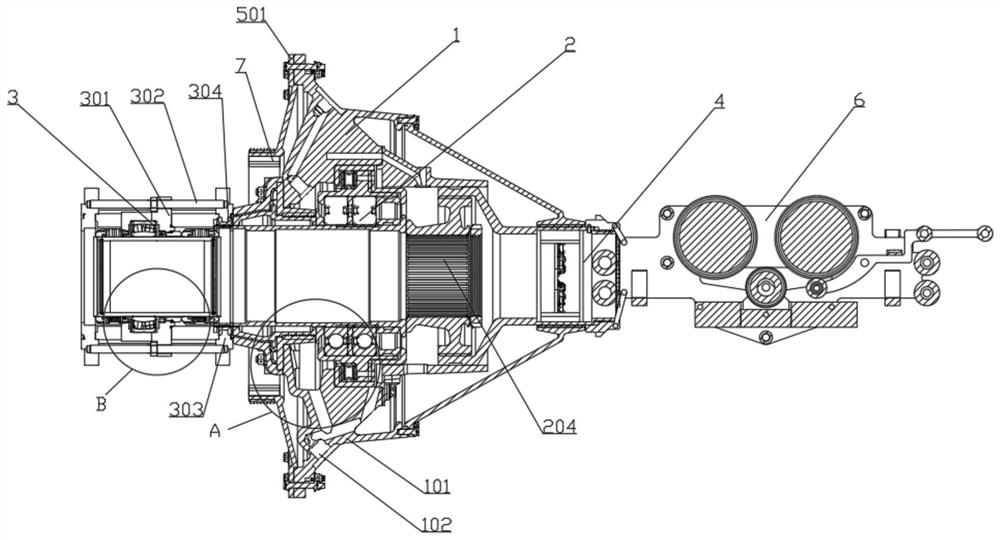

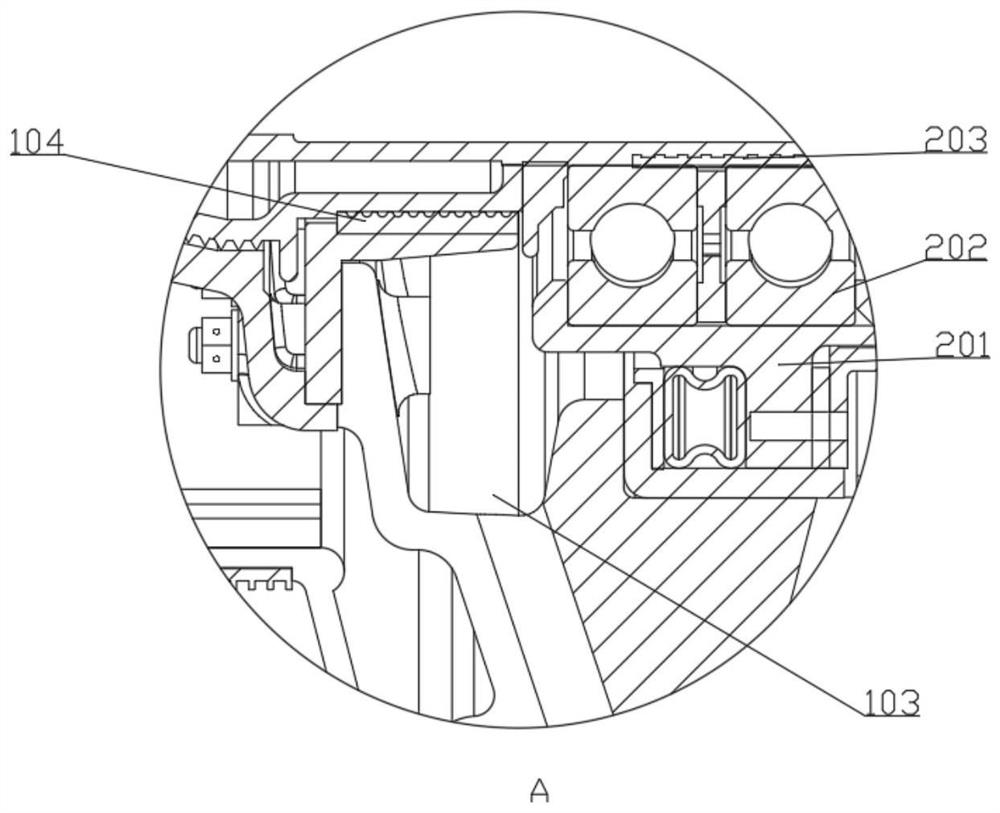

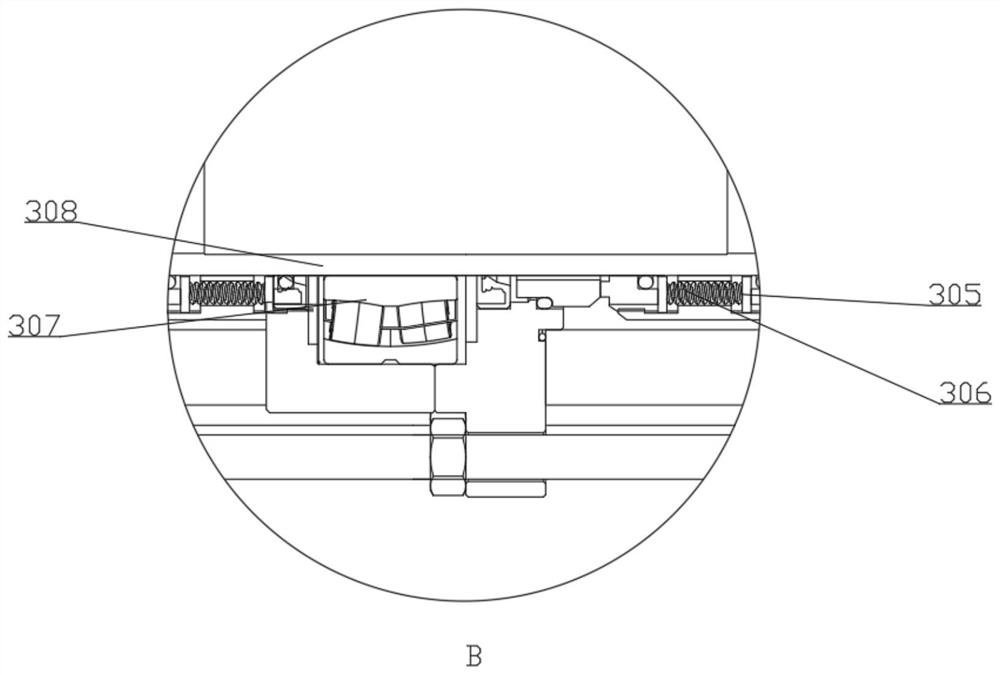

Air intake module for an internal combustion engine

InactiveUS6161514ASimple processImprove sealingMuscle operated startersMachines/enginesCylinder headEngineering

PCT No. PCT / EP97 / 06213 Sec. 371 Date Aug. 11, 1999 Sec. 102(e) Date Aug. 11, 1999 PCT Filed Nov. 8, 1997 PCT Pub. No. WO98 / 21468 PCT Pub. Date May 22, 1998A suction or air intake module for an internal combustion engine comprising an air suction pipe made of synthetic resin material and a flange joint at the air intake on the cylinder head housing of the internal combustion engine. The air suction pipe is a one-piece blown element of synthetic resin material and is disposed by a spring in a housing part of the air intake module with the air outlet end of the air suction pipe extending into the area of a connection between the housing part and the cylinder head housing. A flange is arranged in the connecting area between the housing part and the cylinder head housing, the flange forming a single piece with the housing part and enabling the housing part to be sealingly attached to the air inlet of the cylinder head housing.

Owner:MANN HUMMEL GMBH

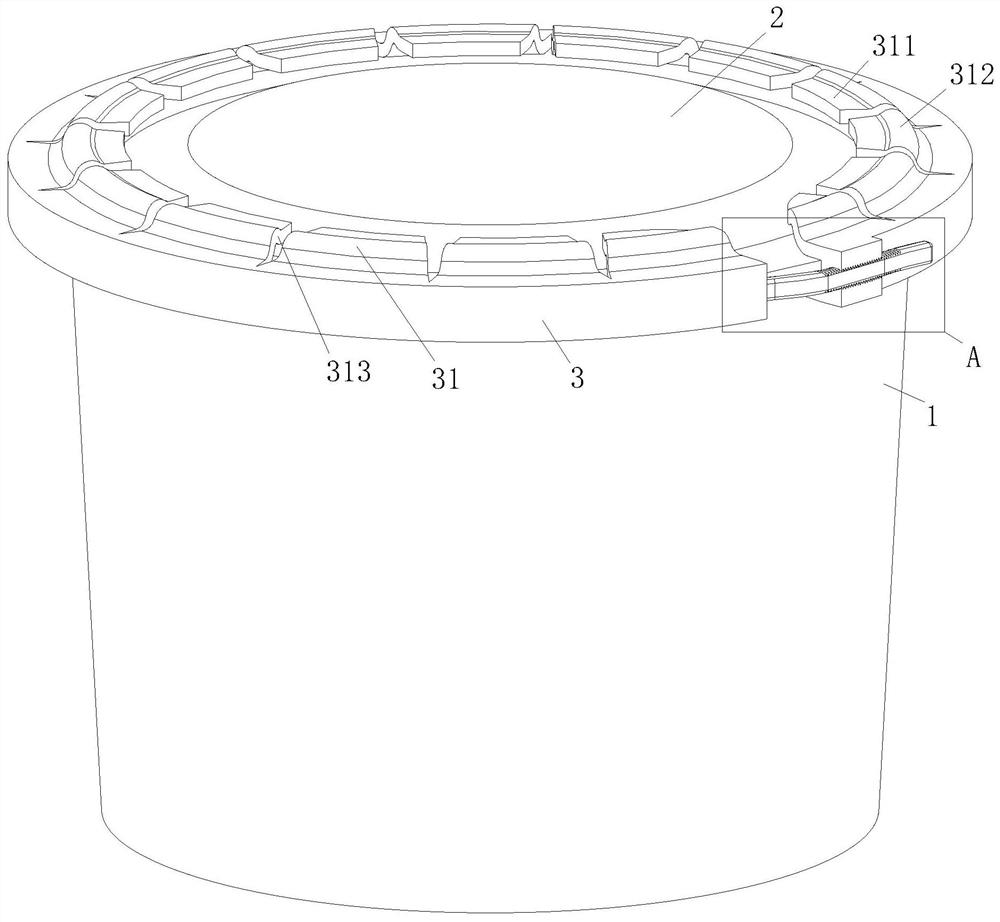

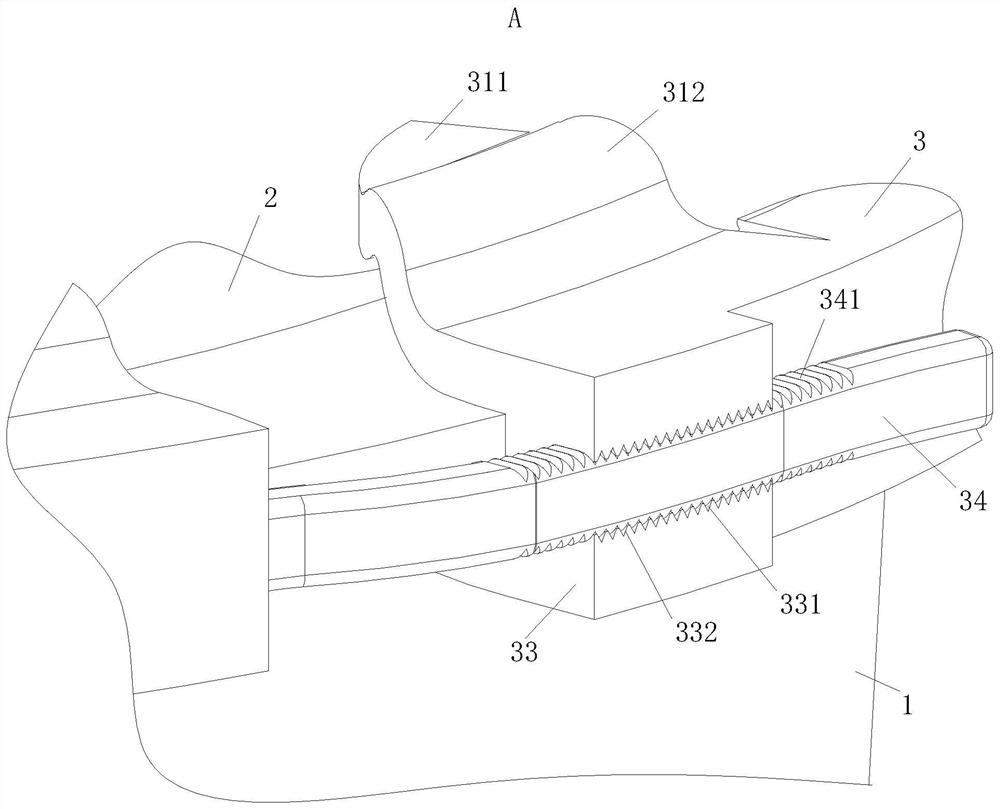

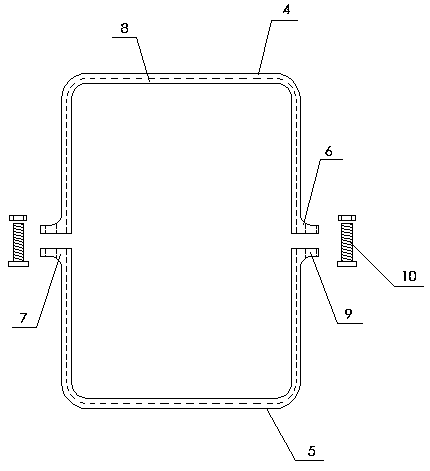

Leakage-proof disposable plastic lunch box

ActiveCN111634546AAchieve sealingEasy to useClamping mechanismStructural engineeringMechanical engineering

The invention belongs to the technical field of articles for daily use, and particularly relates to a leakage-proof disposable plastic lunch box which comprises a box body, a box cover and a sealing component. A first flange is arranged on the upper end edge of the box body, a second flange is arranged on the edge of the box cover, and the exteriors of the second flange and the first flange are surrounded by the sealing component. According to the leakage-proof disposable plastic lunch box, the cross section of the sealing component is arranged to be in the rectangular notch shape, the first flange on the box body and the second flange on the box cover are extruded and attached together through the rectangular notch shape of the sealing component, then sealing between the box body and thebox cover can be achieved, the disposable plastic lunch box can well prevent internal food from spilling and leaking, and the use requirements of users are met; when the box cover is opened, only thehead and the tail of the sealing component need to be disconnected firstly, then the box cover is opened, in the process, the box cover is not bent or deformed, the problem that food juice on the boxcover is ejected out is avoided, and therefore a user can use the box more conveniently and better.

Owner:富岭科技股份有限公司

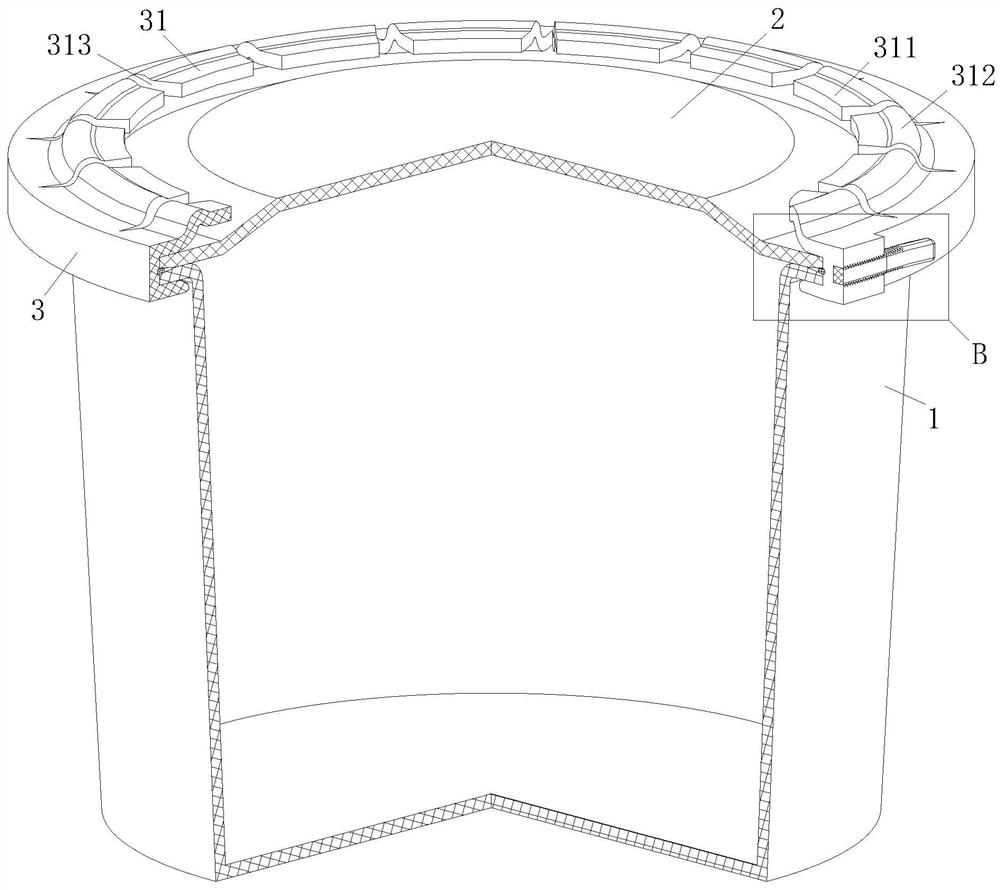

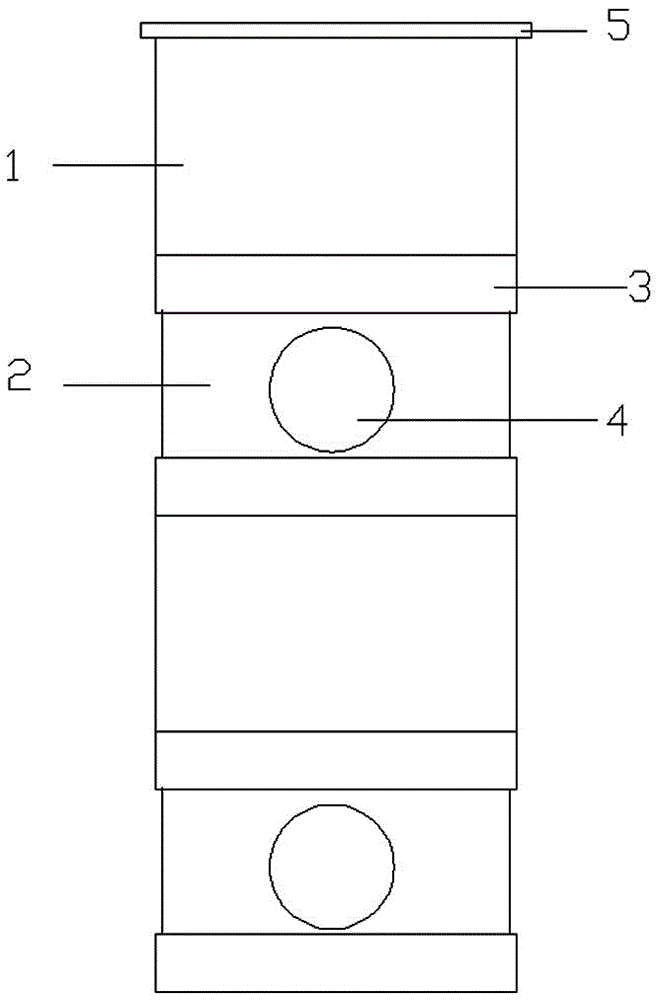

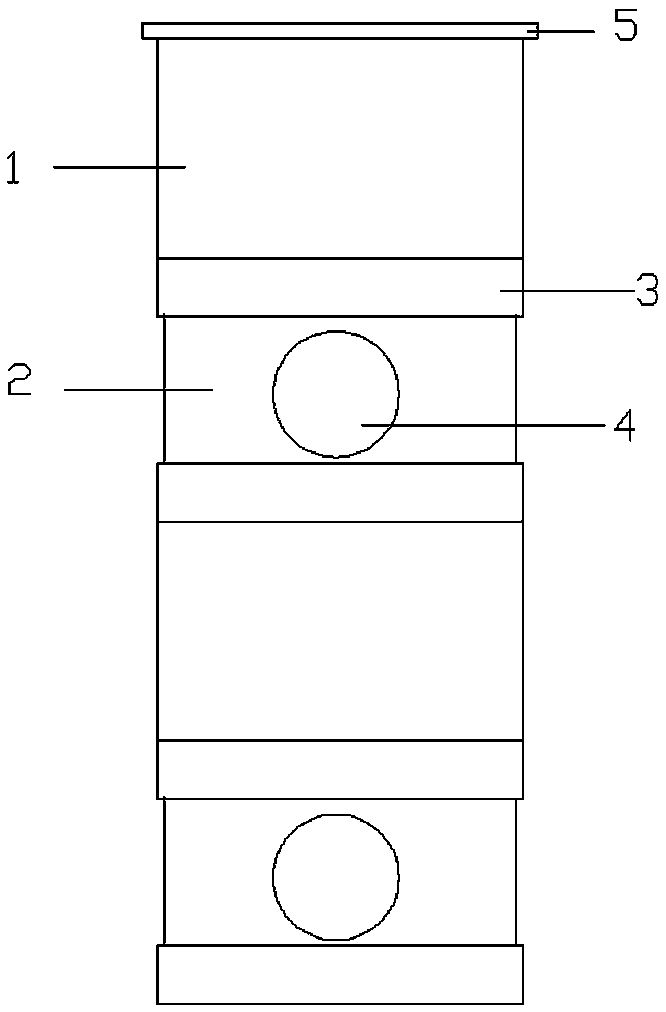

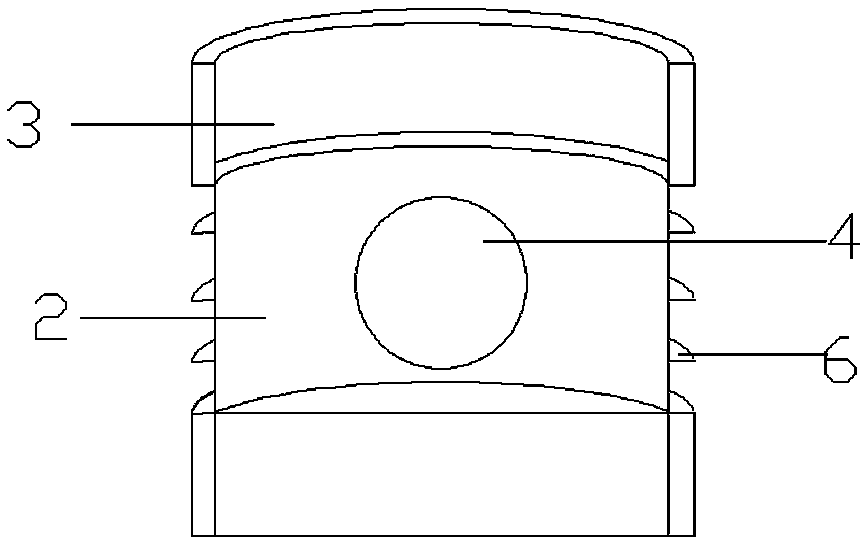

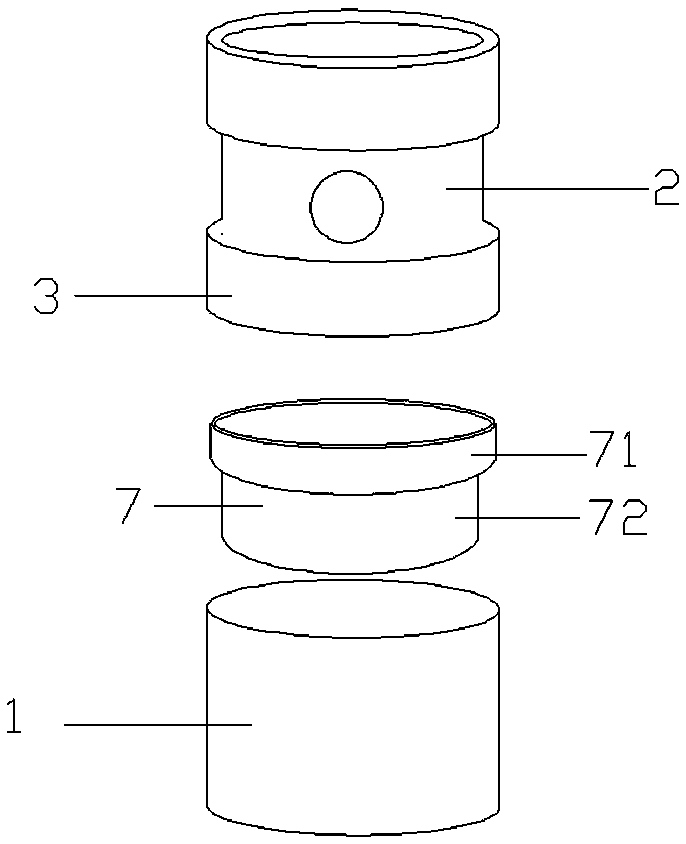

Inspection well with multilayer structure and manufacturing method thereof

InactiveCN106567411ANot easy to damageTightly sealed connectionArtificial islandsUnderwater structuresUnderground tunnelEngineering

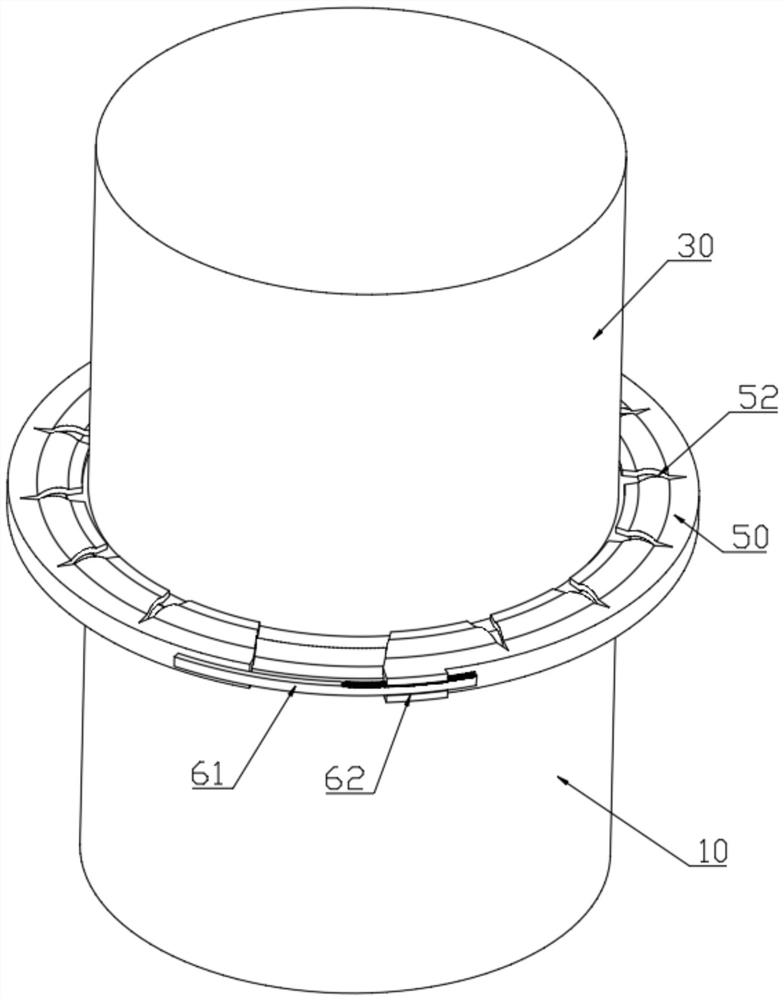

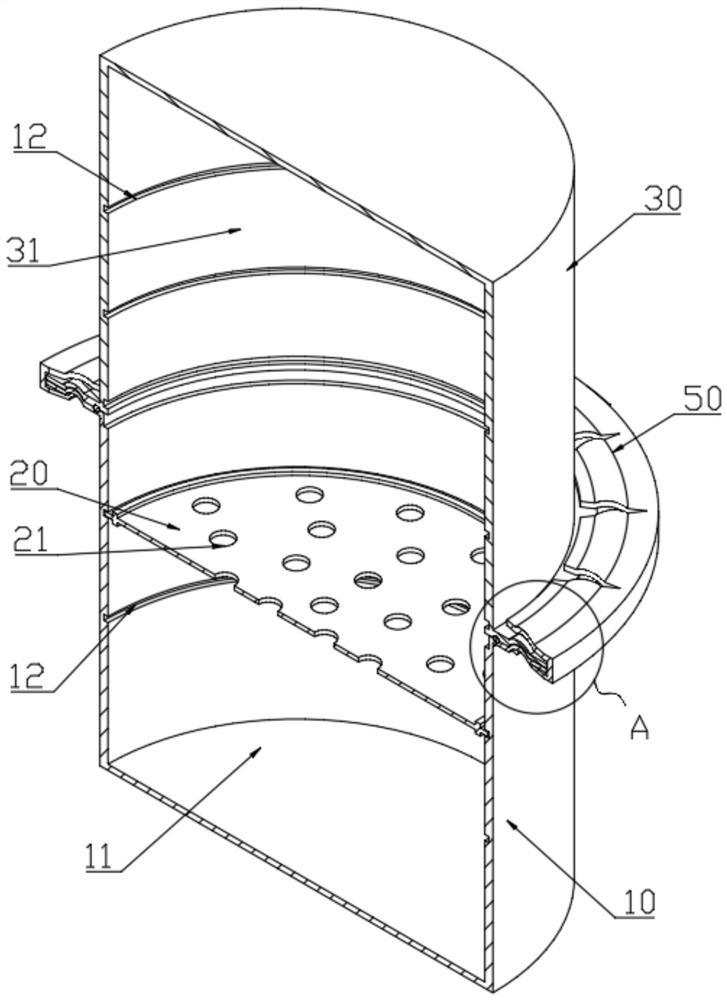

The invention discloses a multilayer inspection well and a manufacturing method thereof. The inspection well comprises multiple layers of well shafts, multiple layers of well bases, and a well lid, wherein the well base in each layer comprises a cylindrical base part, well shaft connectors which extend from the upper and lower ends of the base part, and at least one transversely formed pipeline connector; at least one ends of the well shafts are in fusion welding with the well shaft connectors in a thermoplastic manner; and the upper end of the well shaft in the topmost layer is connected with the well lid. When the multilayer inspection well is utilized, pipelines which are embedded in different underground vertical positions and have various different functions can be monitored at the same time in one inspection well; the well shafts and the well bases are in sealed connection, so that the inspection well is more stable; and when the well shafts and the well bases are connected and when the ground subsides due to overload or underground tunnels subside due to various reasons, the well shafts of the inspection well can have certain elastic deformation due to the fact that the well shafts have certain elasticity, so that connection of the pipeline connectors of the inspection well and the original pipelines remains stable, sealing performance is good, and the inspection well is not liable to damage.

Owner:HANGZHOU JINCHENG IND

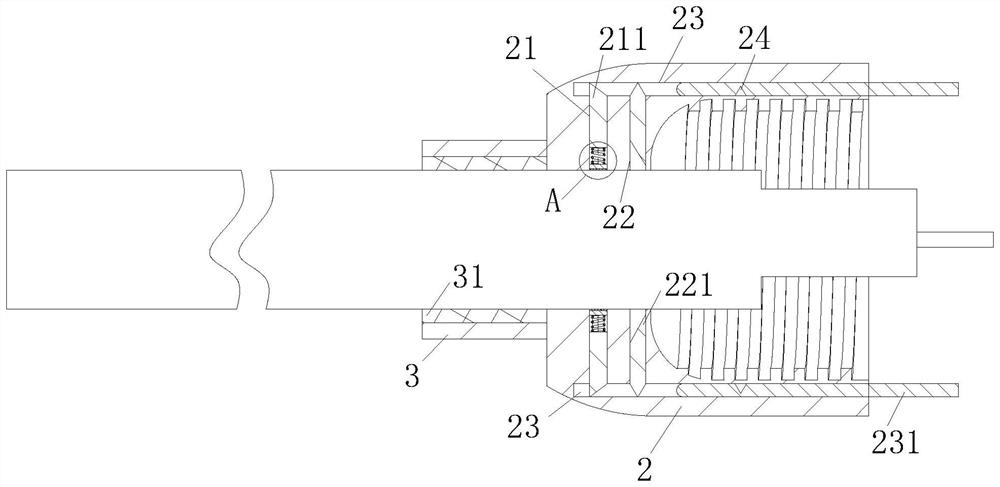

Pipe joint and use method thereof

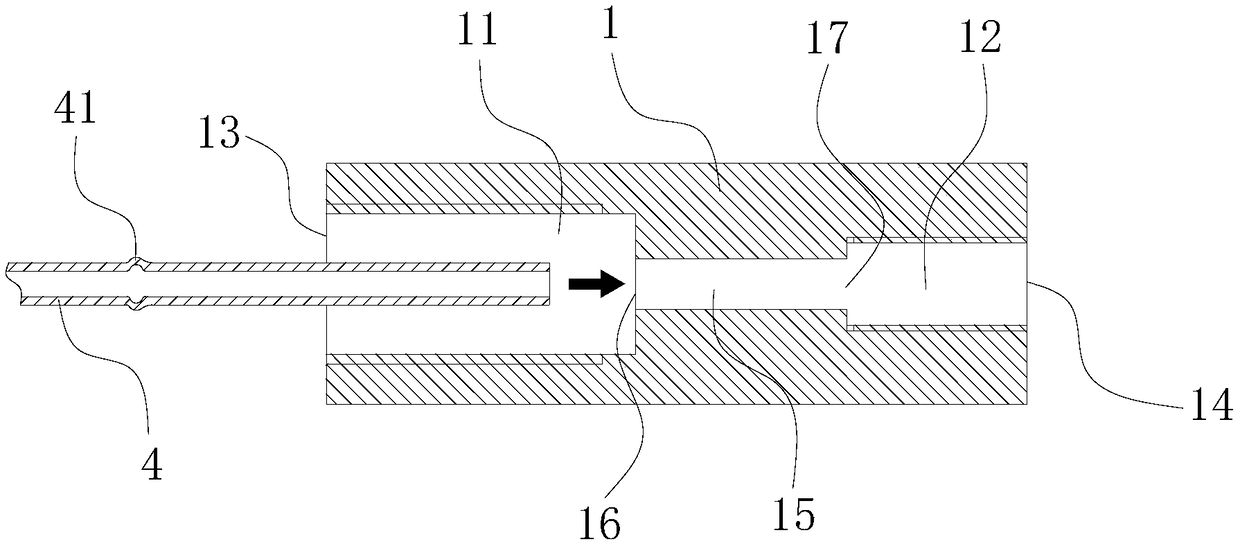

PendingCN109084107ASimple structureImproved ability to withstand ultra-high pressureHose connectionsNon-disconnectible pipe-jointsEngineering

The invention provides a pipe joint, which comprises a joint body, wherein a cavity and an outer hole are formed inside the joint body; the cavity has a first outer insertion port which is used for inserting a soft pipe to be connected and is formed in one end of the joint body; the outer hole has a second outer insertion port which is used for inserting a hard pipe to be connected and is formed in the other end of the joint body; an inner hole is further communicated between the cavity and the outer hole; the inner hole has an inner insertion port formed in the innermost end of the cavity; alining pipe is arranged in the cavity; one end of the lining pipe is inserted into the inner hole through the inner insertion port, and the other end of the lining pipe is provided with a connecting section inserted into the soft pipe; and at least one bulged part is arranged on the connecting section. Compared with the prior art, the pipe joint improves the connection stability between the soft pipe and the hard pipe, solves the problem of narrowing of an inner runner due to inward sinking of the soft pipe, and is simple in structure, low in manufacturing cost and convenient to use. The invention further provides a use method of the pipe joint. The use method has the advantages of simplicity, convenience and easiness in learning.

Owner:HUIZHOU HYDRO CARESYS MEDICAL CO LTD

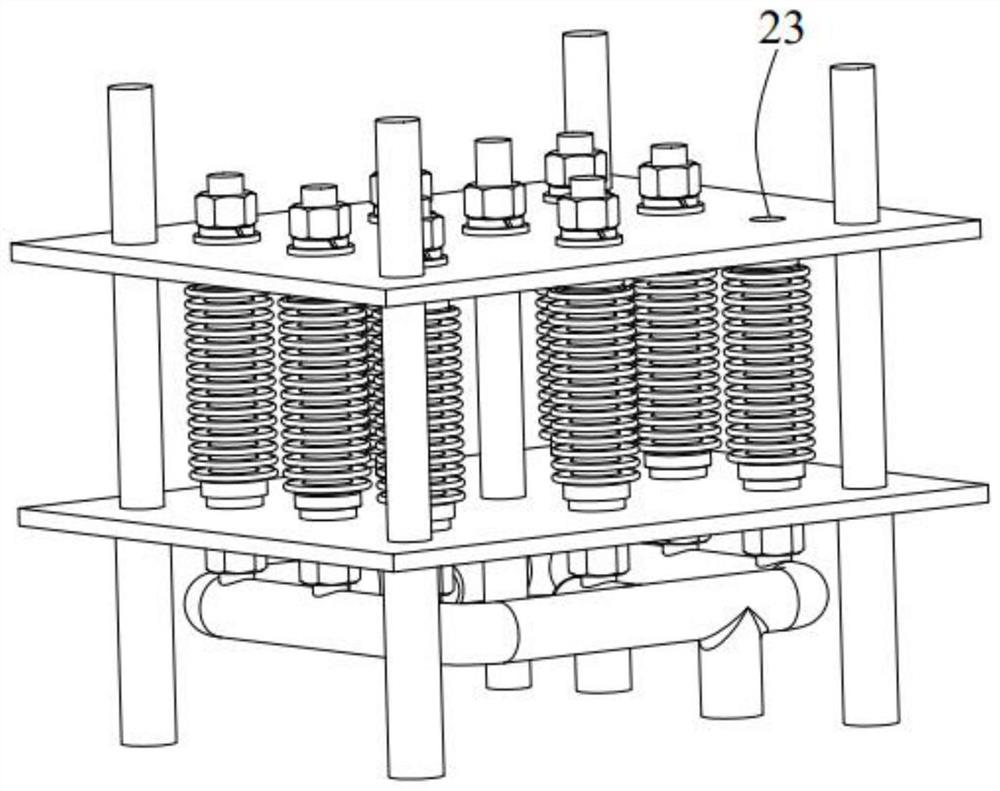

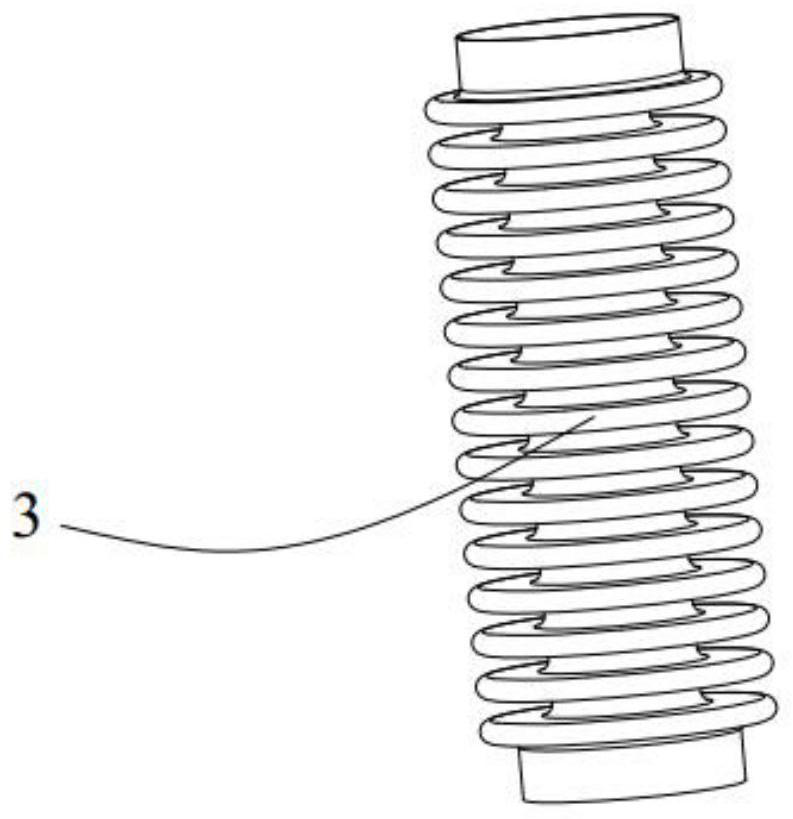

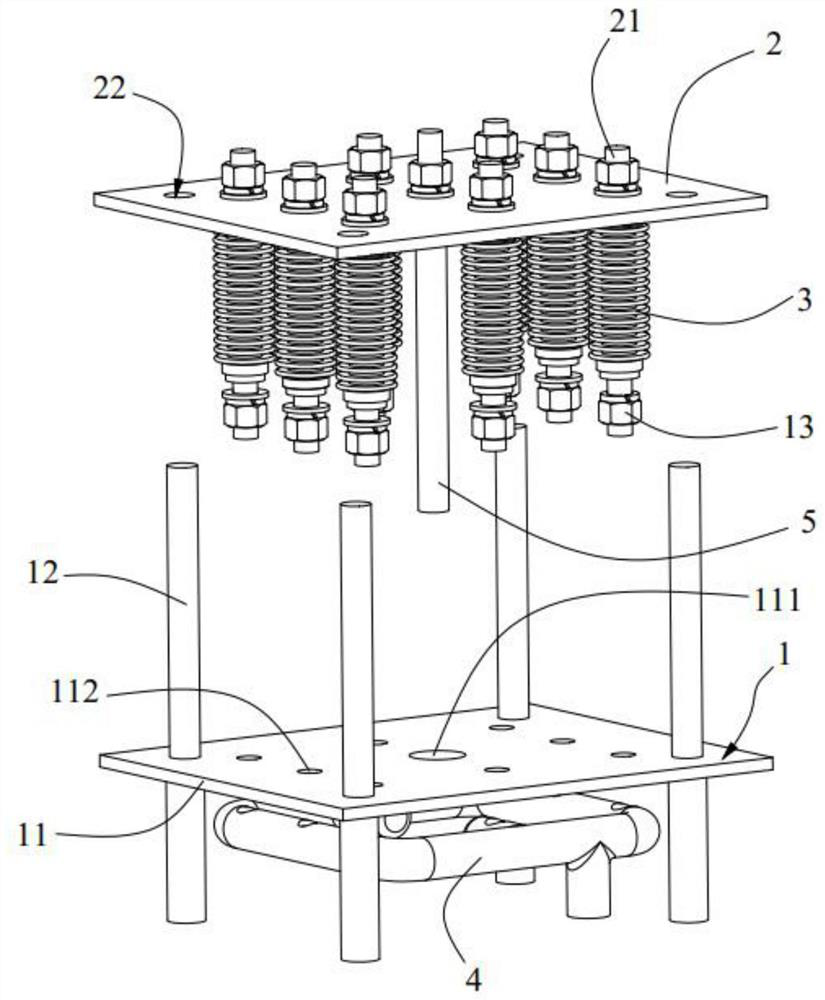

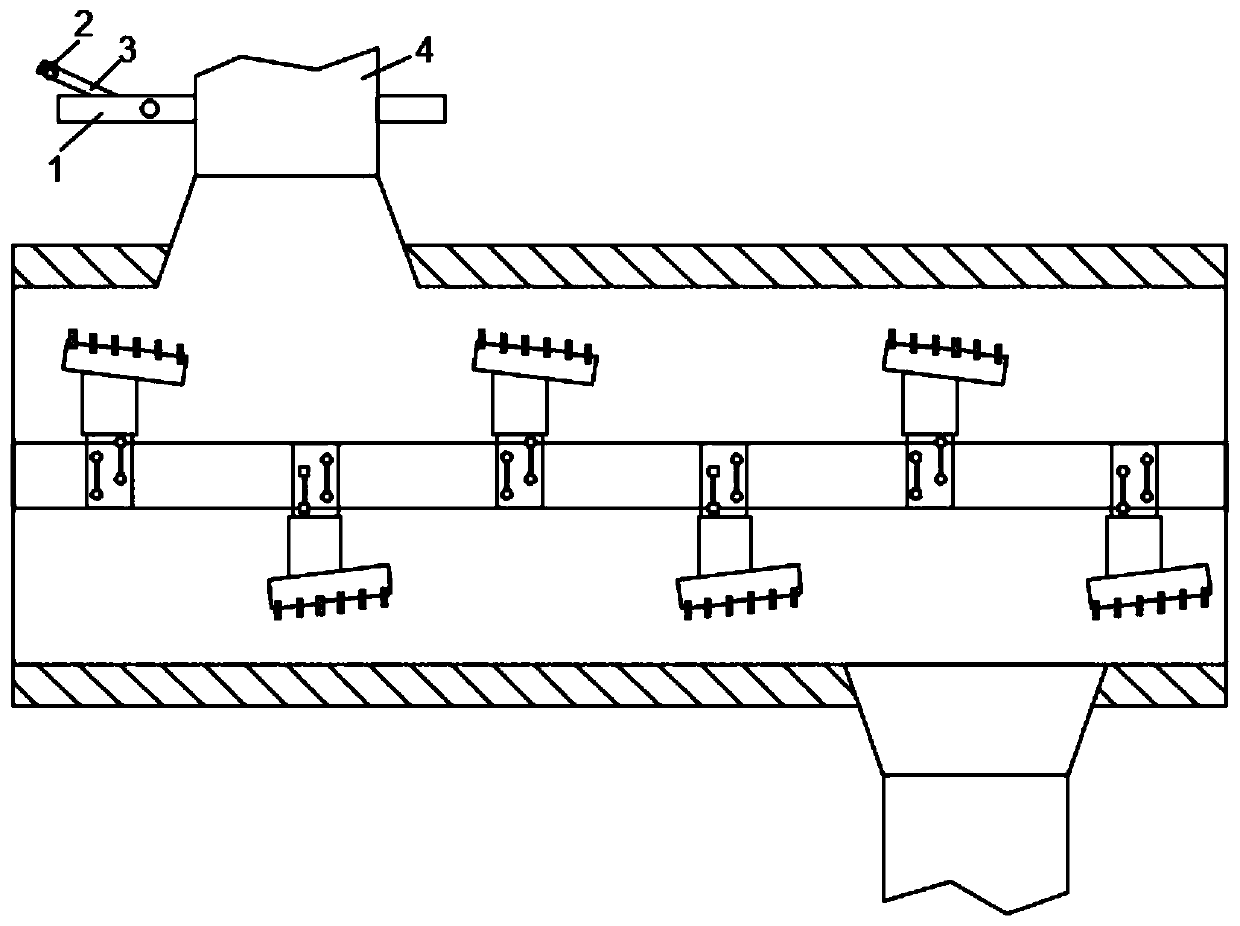

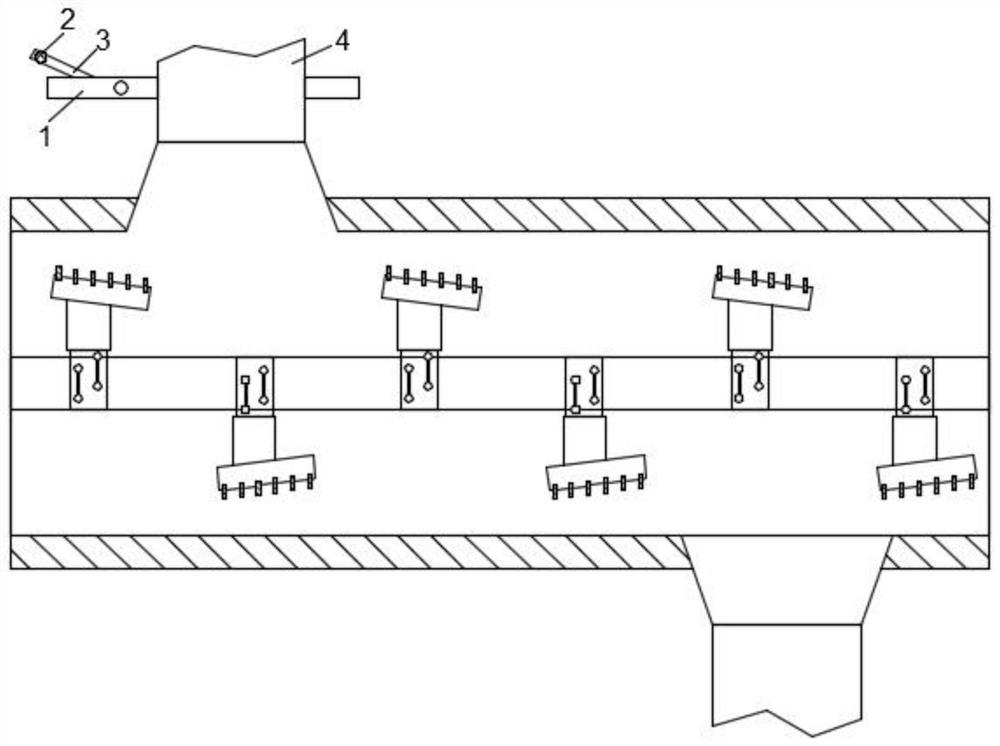

Corrugated pipe service life test device

PendingCN113008545ATightly sealed connectionGuaranteed connection tightnessMachine part testingStructural engineeringMechanical engineering

The invention discloses a corrugated pipe service life test device, and belongs to the technical field of vacuum arc extinguish chamber tests. The corrugated pipe service life test device comprises a supporting assembly and a movable part, the movable part can reciprocate in the vertical direction relative to the supporting assembly, sealing inflation assemblies on the supporting assembly and sealing fixing assemblies on the movable part are arranged in a one-to-one correspondence mode, and the sealing inflation assemblies and the sealing fixing assemblies are configured to be connected with the two ends of a corrugated pipe in a sealed mode and fill gas with the set pressure into the corrugated pipes, the real working condition is simulated, at least two corrugated pipes can be tested, and the detection efficiency is improved.

Owner:陕西宝光集团有限公司 +1

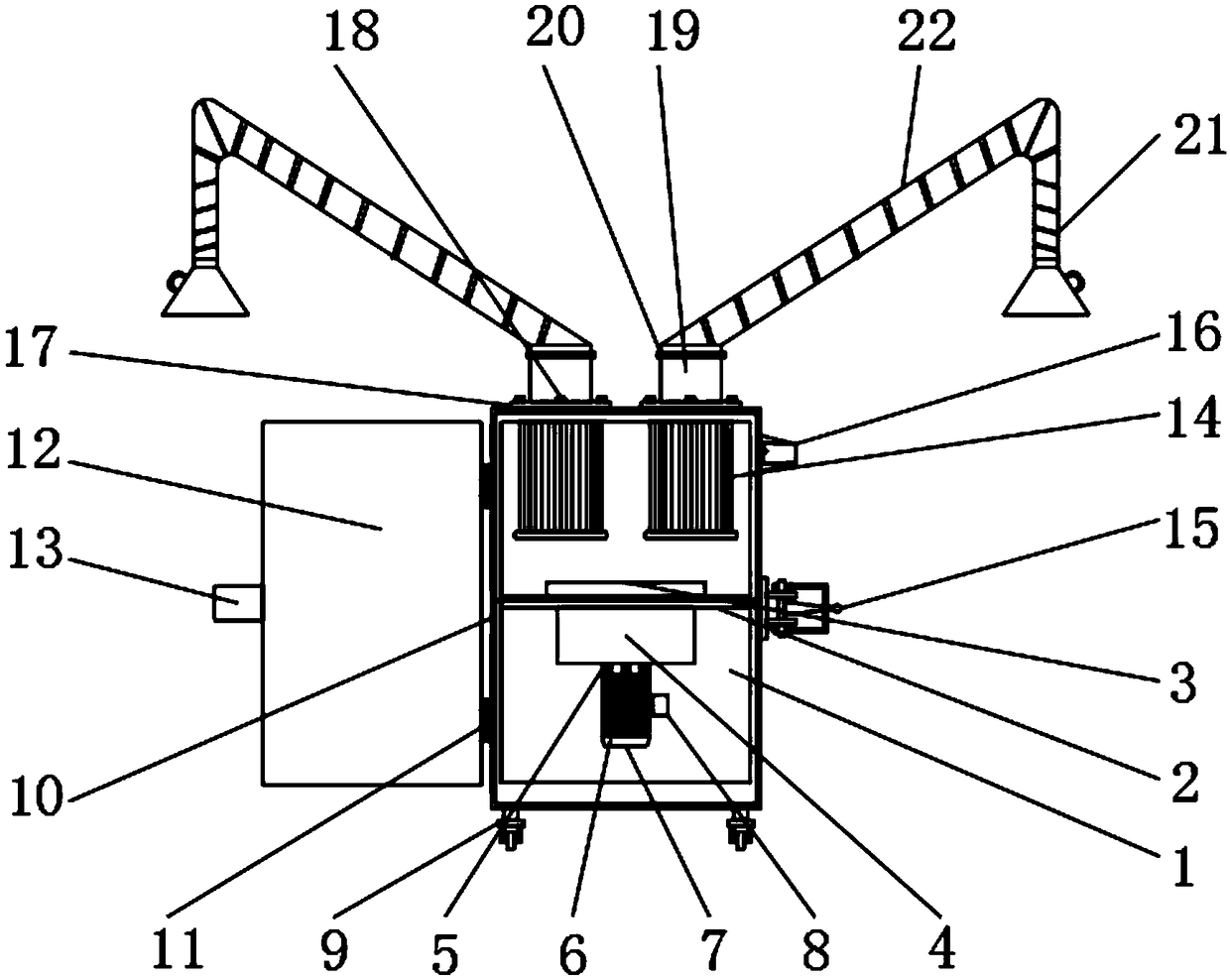

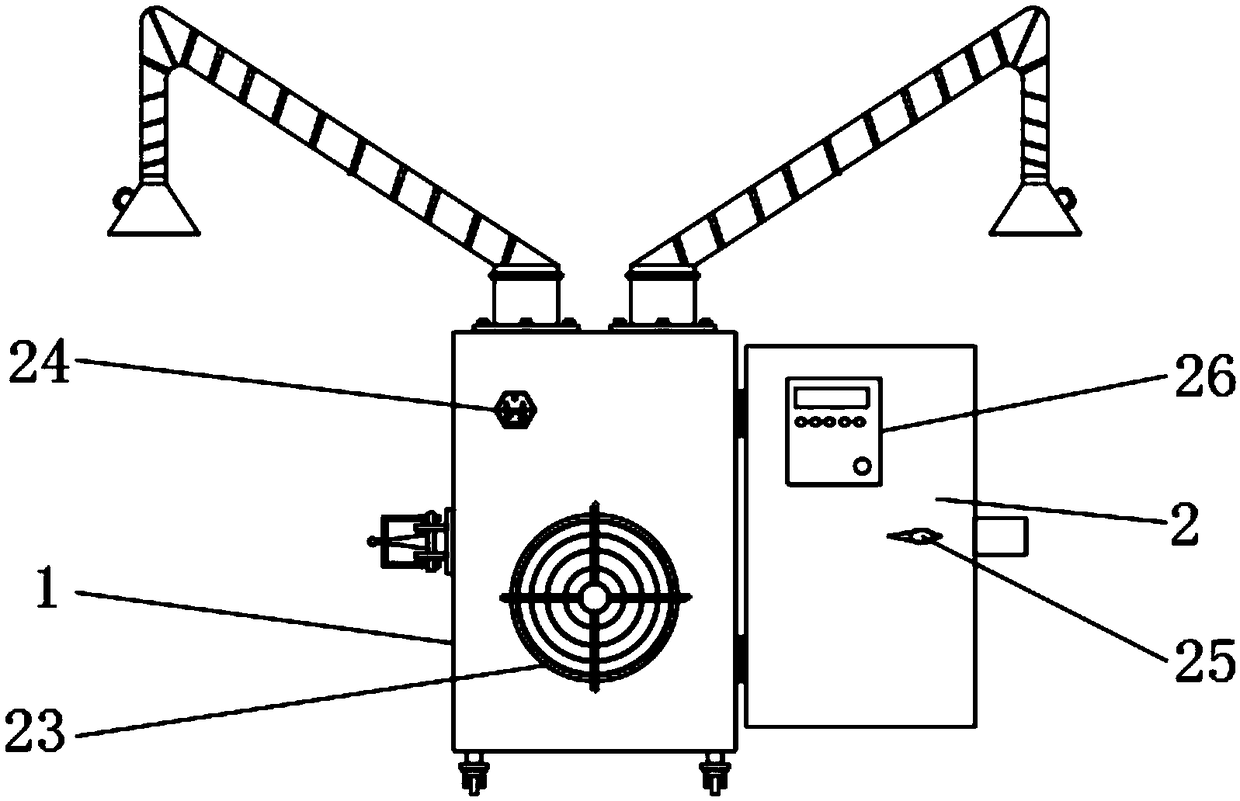

Movable welding fume purification device for environmental protection engineering

InactiveCN109260852AFlexibleStretch and rotate at willGas treatmentDispersed particle filtrationEnvironmental resistanceElectric machinery

The invention relates to the technical field of welding fume purification in environmental protection engineering, and in particular to a movable welding fume purification device for environmental protection engineering, which comprises a device body, a partition is arranged at the middle position of the external surface of the inside of the device body, the central part of the upper end of the partition is provided with a suction hole, a turbine which is close to the bottom of the partition is arranged at the lower end of the suction hole, a motor fixing plate is arranged at the lower end ofthe turbine, an electric rotary shaft which is close to the inner side of the motor fixing plate is arranged at the central position of the lower end of the turbine, and an electromotor is arranged atthe lower end of the electric rotary shaft. According to the movable welding fume purification device for environmental protection engineering, the flexibility of the device can be greatly increasedby moving rollers in moving units, a bolt unit can ensure that maintenance and cleaning are more convenient, torque wires of fume suction units ensure that the fume suction process of the device is more convenient, and an exhaust unit can ensure that the delayed treatment effect is better.

Owner:广东锐拓环境科技有限公司

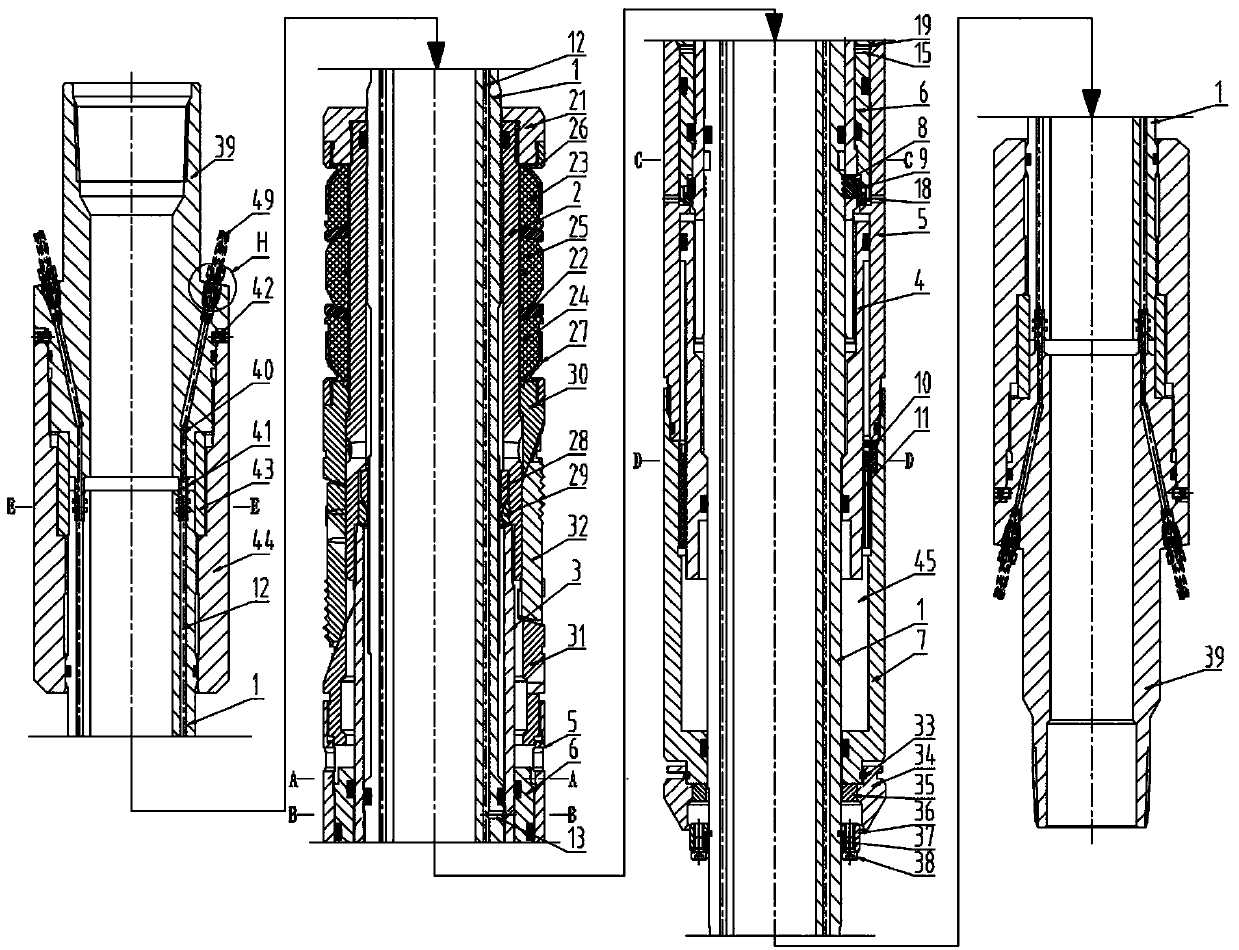

Hydraulic control static setting through pipeline packer

PendingCN109098685AAvoid high pressure frictionAvoid restrictionsSealing/packingHydro energy generationEngineeringFrictional resistance

The invention discloses a hydraulic control static setting through pipeline packer. The hydraulic control static setting through pipeline packer comprises a central pipe, a sealing barrel, a connecting barrel, a locking barrel, an outer barrel, an unlocking casing, a sealing module, a slip module, a limiting ring, an anti-rotating ring, a one-way locking ring and a shear module. The hydraulic control static setting through pipeline packer can form an internal sealed pressure transfer channel to achieve static hydraulic setting, avoid the limitations that pressurized seating via an oil casing pipe cannot be achieved inside an electric pump production well as well as that high pressurizing frictional resistance of control pipelines and low flowing speed of hydraulic oil result in slow setting. Meanwhile, the hydraulic control static setting through pipeline packer can solve the technical problem that oil jacket annulus pressurized setting and mechanical setting are inapplicable in the prior art, thereby being well applicable to multi-layer intelligent well completion and identical in function to common hydraulic setting recoverable packers.

Owner:CHUANNAN ENERGY TECH CO LTD

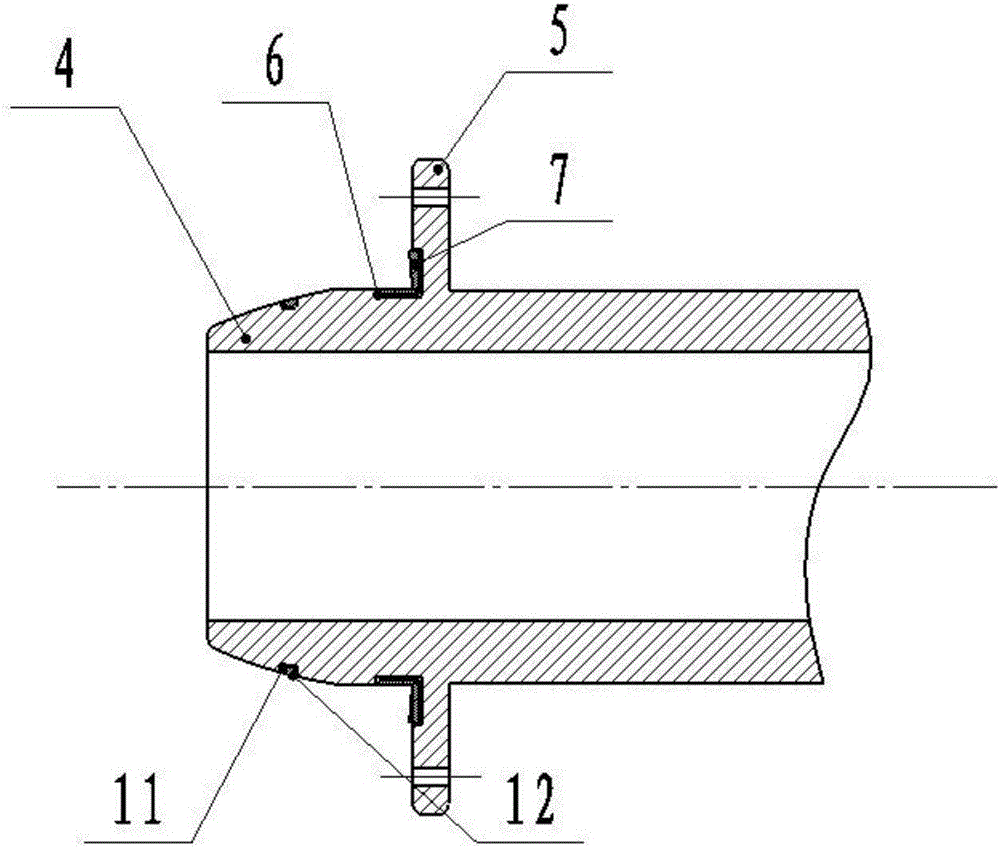

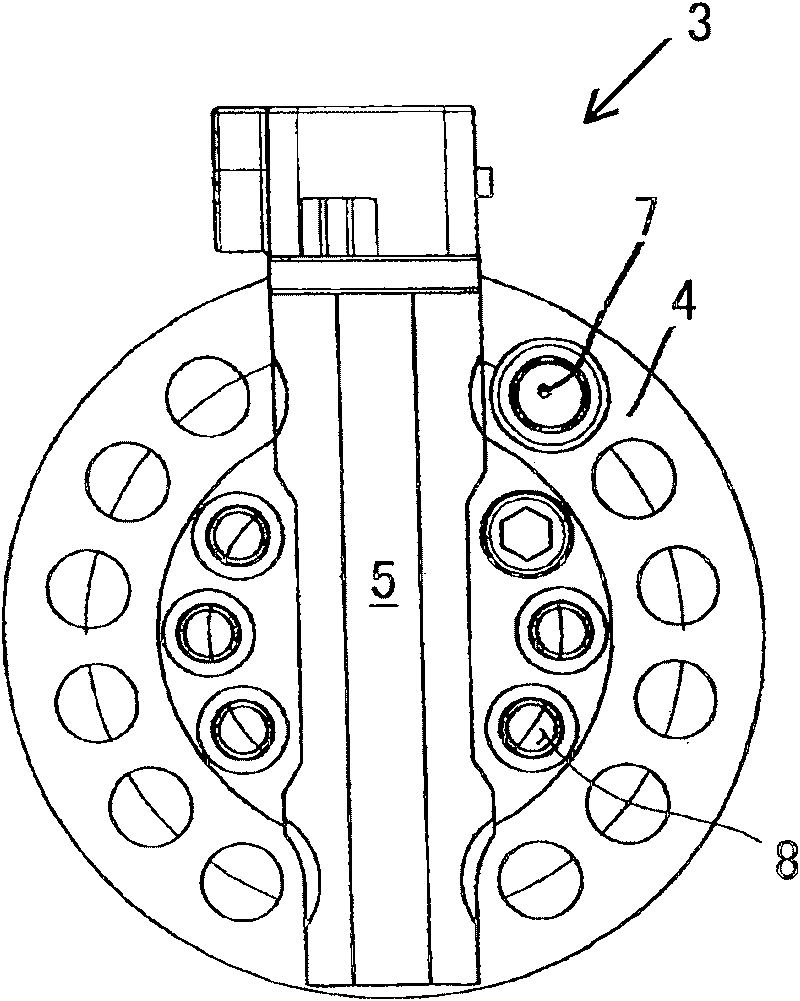

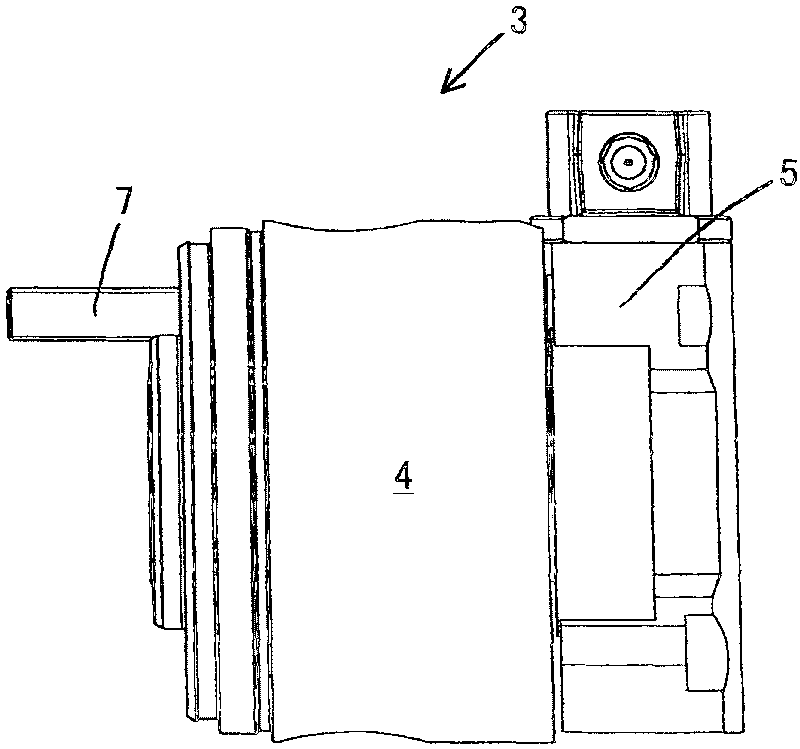

Cooling water atomizing device of powerful cooling machine

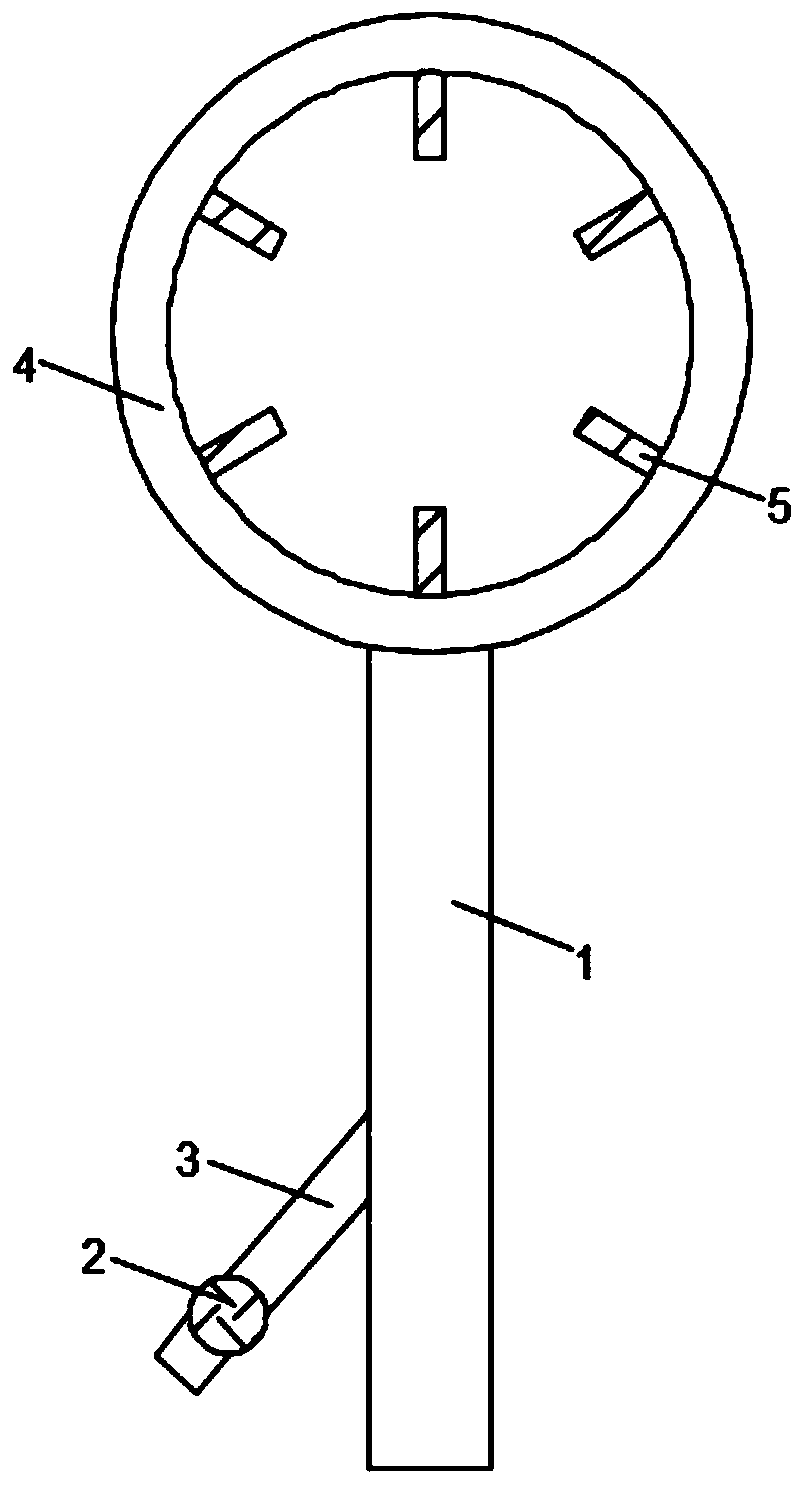

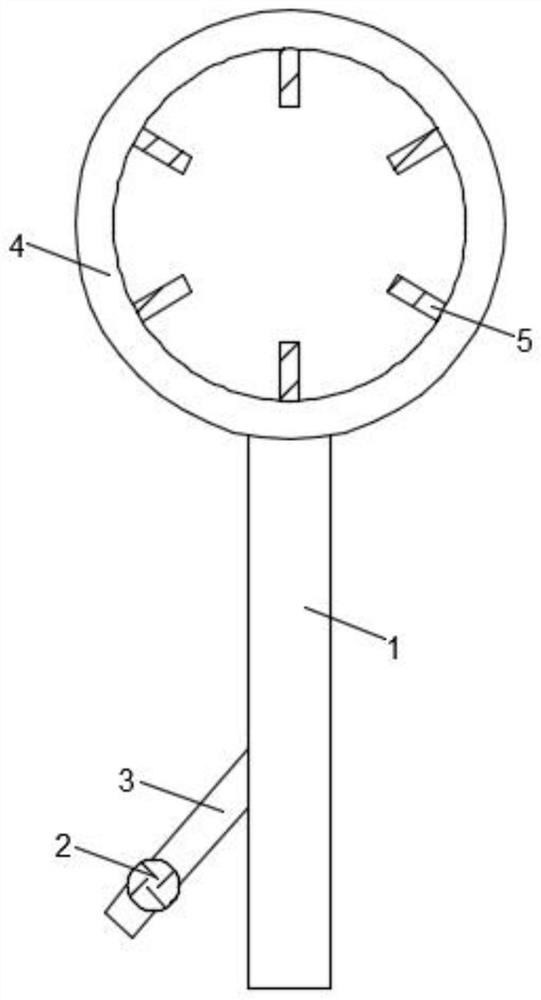

ActiveCN111473681ATightly sealed connectionMake sure to enterLiquid spraying apparatusTrickle coolersEngineeringMechanics

The invention discloses a cooling water atomizing device of a powerful cooling machine. The cooling water atomizing device of the powerful cooling machine comprises an annular pipe installed in a discharging pipe of the powerful cooling machine in a sleeving manner. By correspondingly forming inner holes and connection holes in the annular pipe and the discharging pipe of the powerful cooling machine, spray nozzles integrated and connected with the annular pipe are stably arranged in the discharging pipe of the powerful cooling machine in a sleeved manner; outer holes are correspondingly formed in the annular pipe and the cooling water pipe, so that the cooling water pipe is conveniently and fixedly connected to the annular pipe; a side hole formed in the middle of the cooling water pipe is utilized to achieve sealed connection between a compressed air pipe and the cooling water pipe, air in the compressed air pipe is controlled through a ball valve so as to pressurize water in the cooling water pipe, so that the water in the cooling water pipe is fully atomized; atomized water in the cooling water pipe and compressed air can be evenly fed into the discharging pipe of the powerfulcooling machine, so that paste materials can be evenly cooled; and the situation that due to uneven temperature of the paste materials, a carbon block generates crack is avoided, so that waste is reduced, and cost is saved.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +2

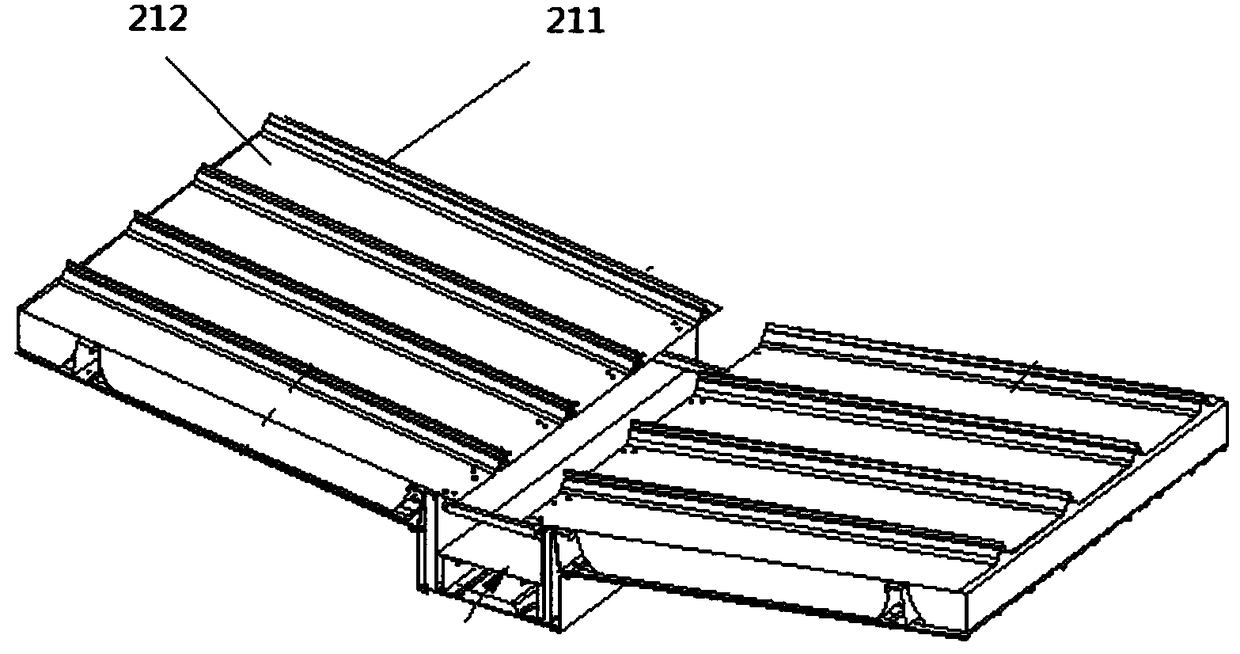

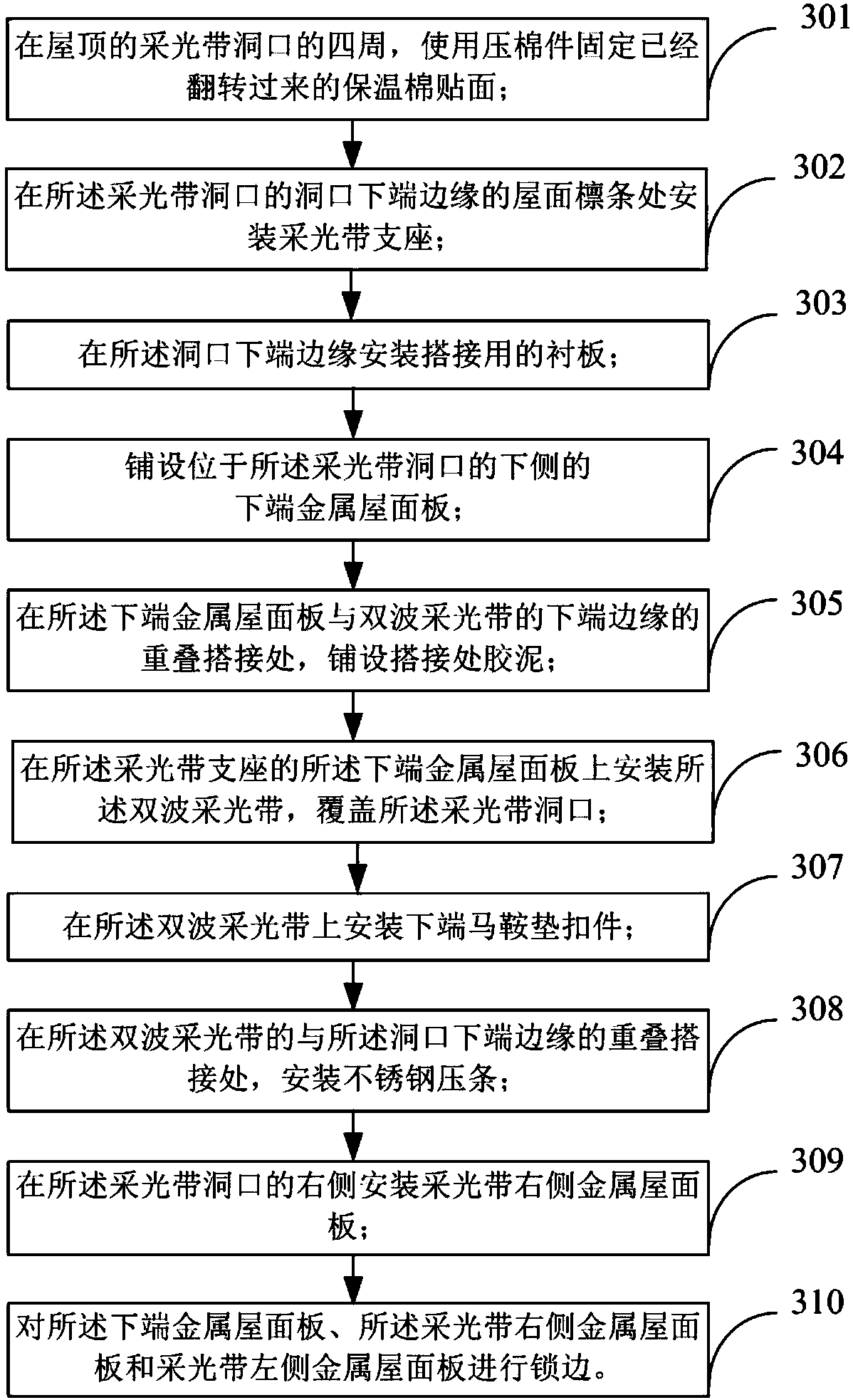

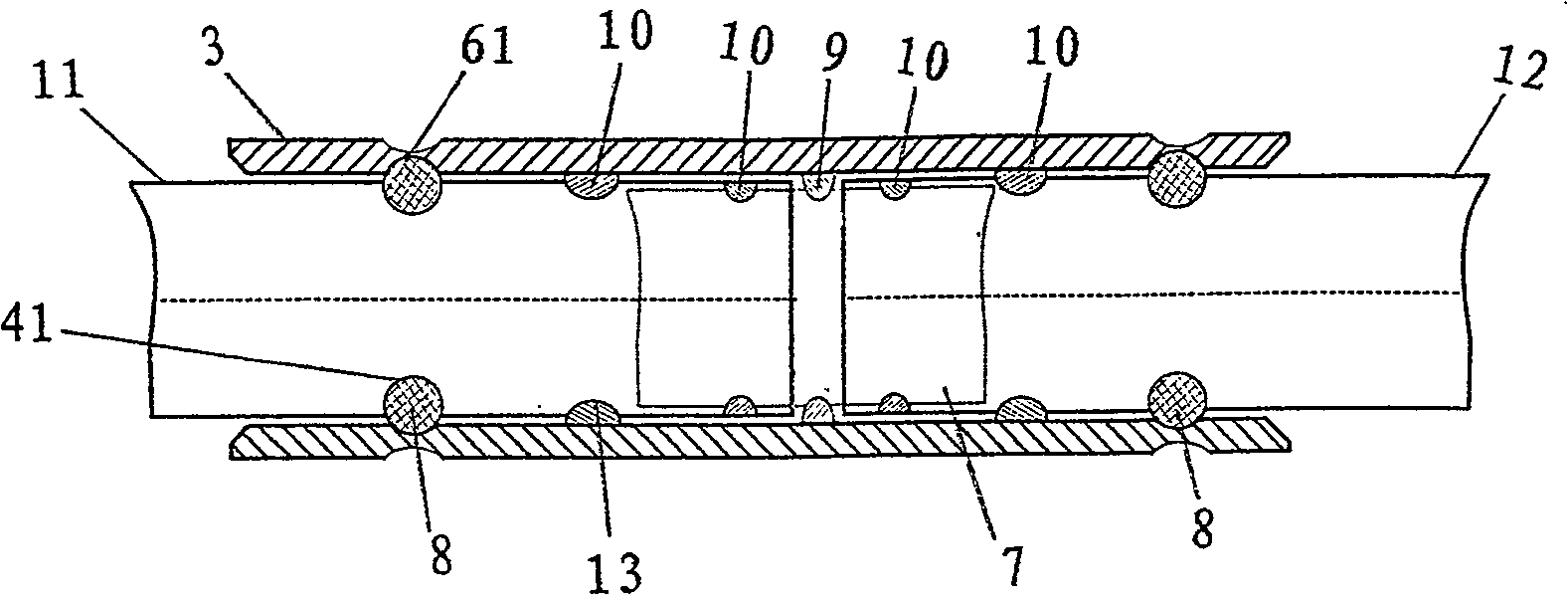

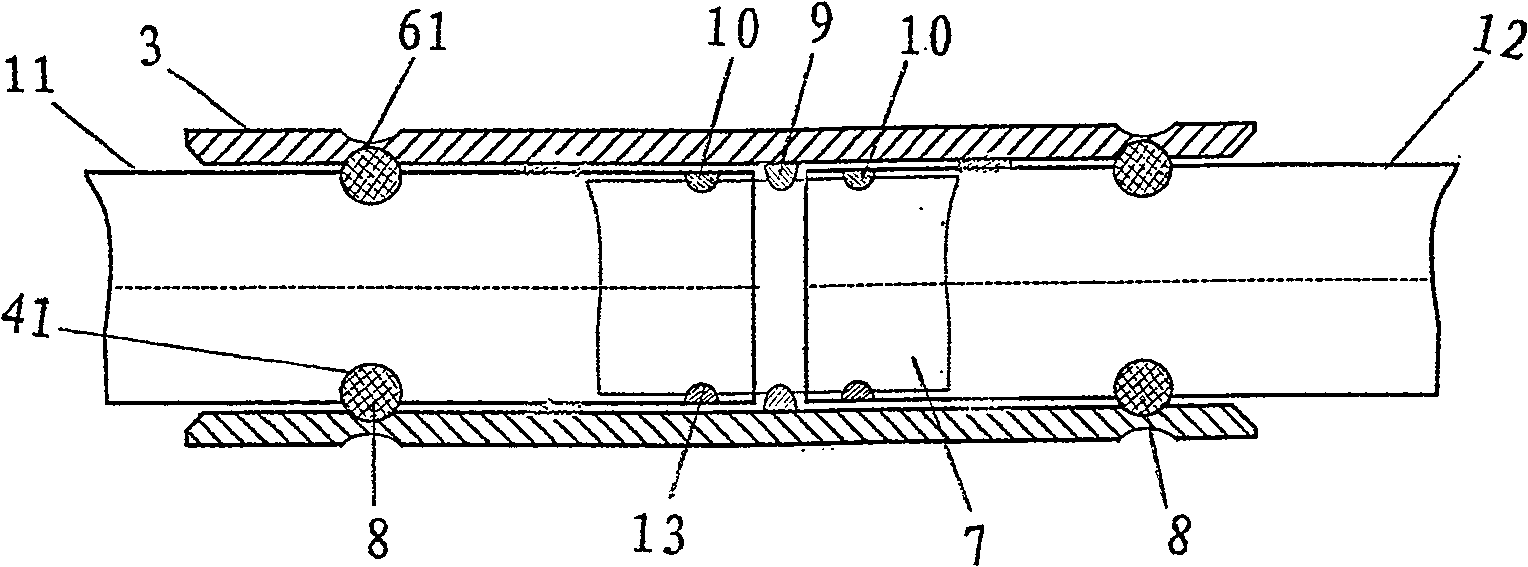

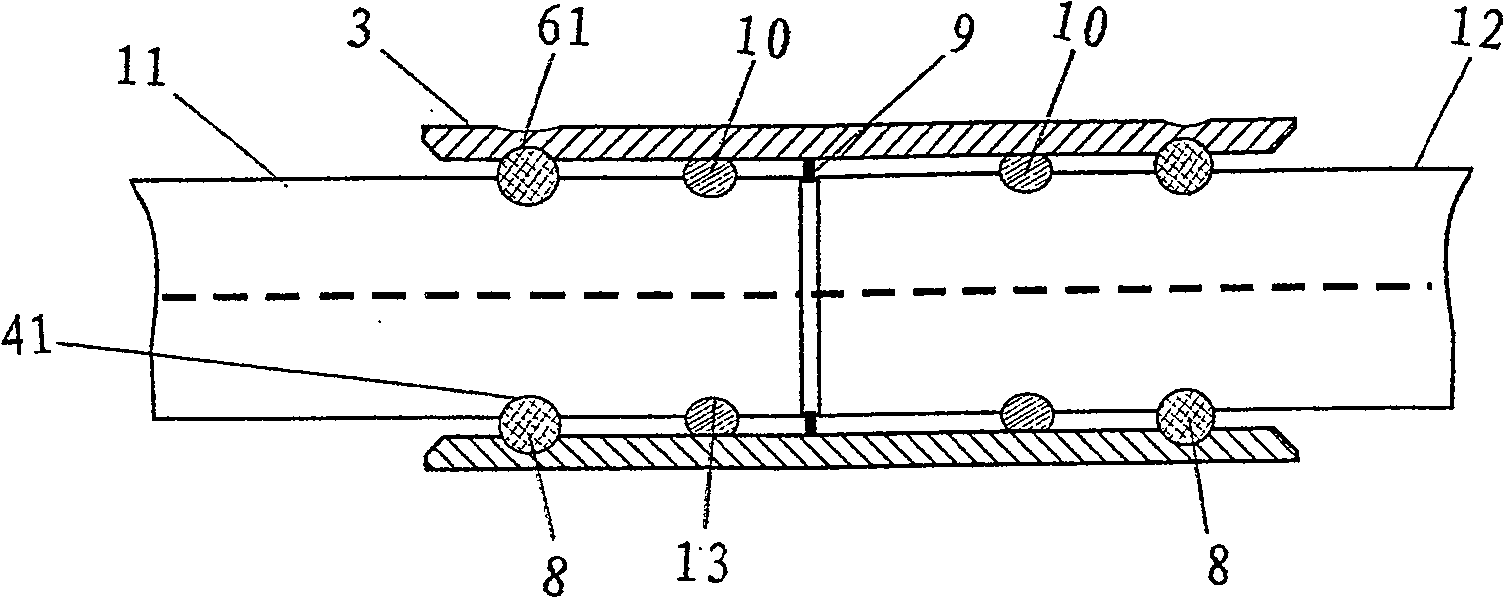

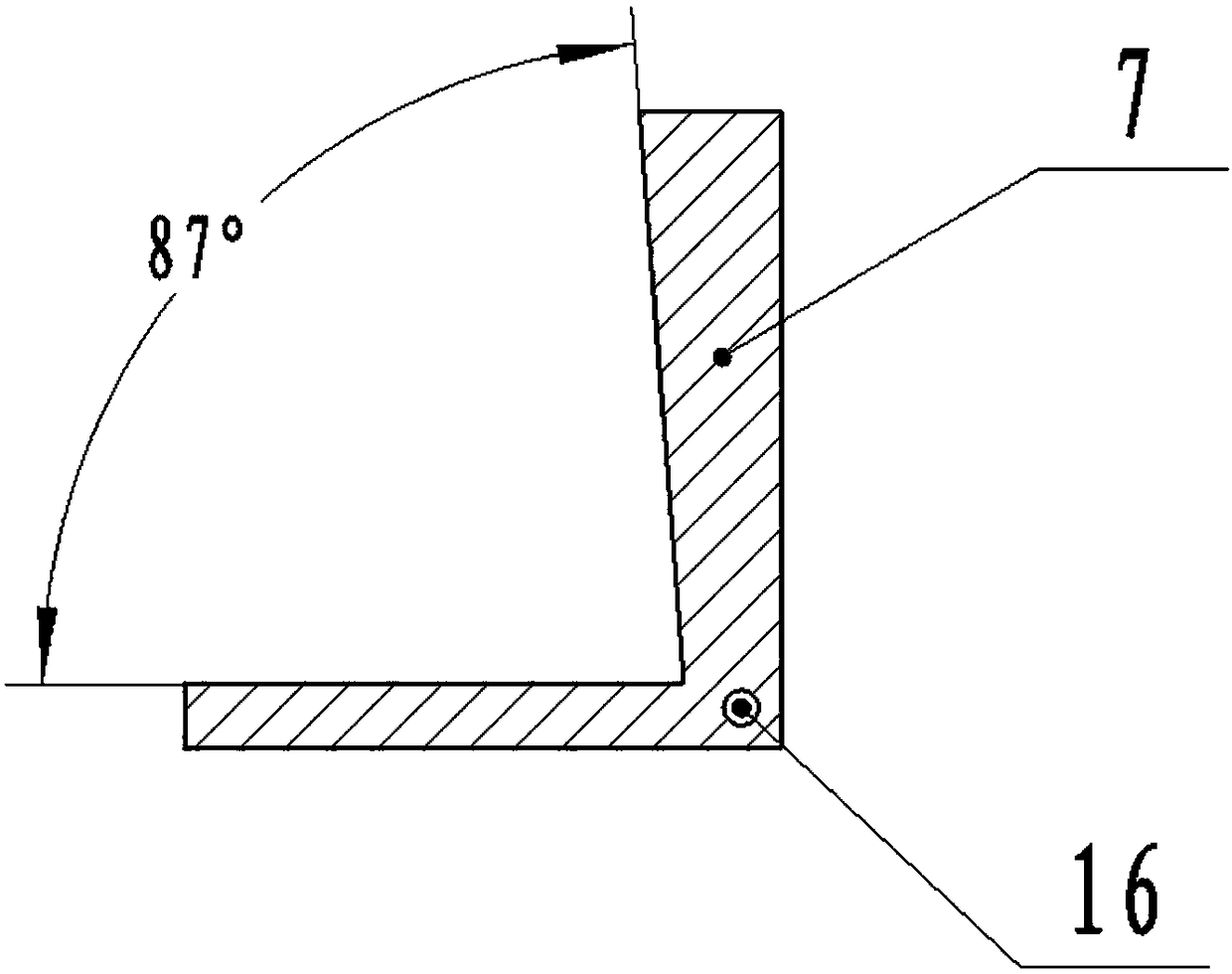

Connection structure of lower end of double-wave daylighting band joint and installation method thereof

PendingCN108149853ATightly sealed connectionImprove the protective effectRoof covering using slabs/sheetsPurlinLap joint

The invention provides a connection structure of the lower end of a double-wave daylighting band joint and an installation method thereof, stable sealing connection at the junction of the lower end ofthe double-wave daylighting band joint is realized, and the protection effect on rainwater flowing down from the top of a slope is good. The installation method includes the steps that an overturnedthermal insulation cotton veneer is fixed at the periphery of a hole of a daylighting band at a roof by using a cotton pressing piece; a daylighting band support is installed at the roof purlin position at the edge of the lower end of the hole of the daylighting band; a liner plate is installed at the edge of the lower end of the hole for lap joint; a lower end metal roofing board on the lower side of the hole of the daylighting band is laid; cement gum at the lap joint position is paved; the double-wave daylighting band is installed on the lower end metal roofing board to cover the hole of the daylighting band; a lower end saddle pad fastener is installed on the double-wave daylighting band; a stainless steel trim strip is installed at the overlapping joint of the double-wave daylightingband and the edge of the lower end of the hole; a right side metal roofing board of the daylighting band is installed; and the metal roofing boards are overlocked.

Owner:东方诚建设集团有限公司

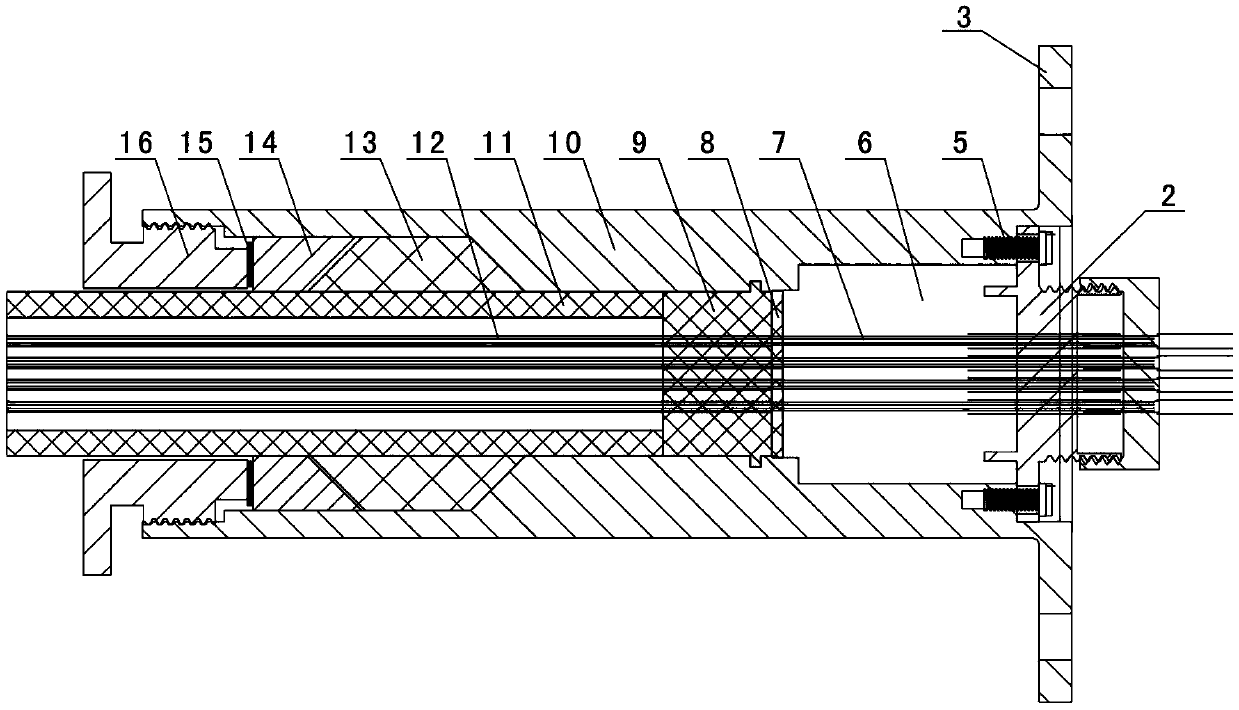

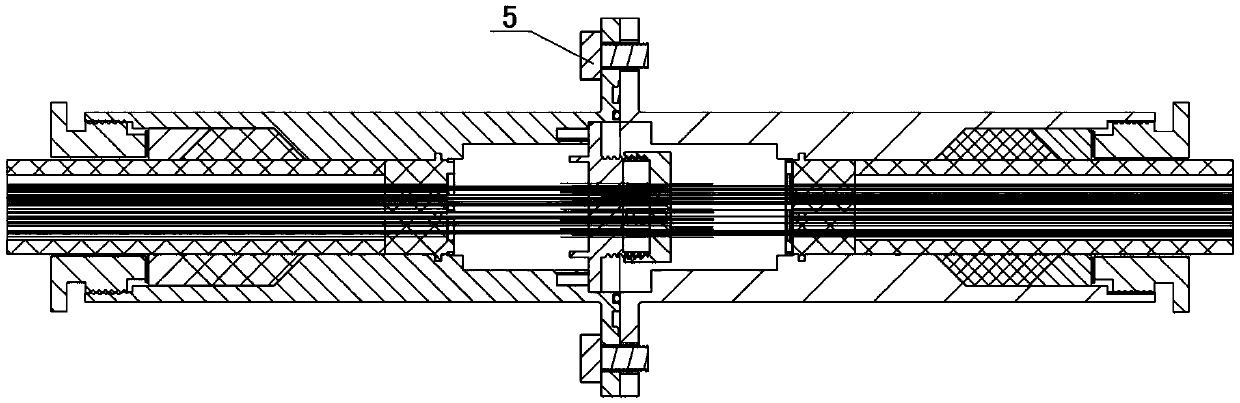

Steel wire rope cabin penetrating sealing device and method

PendingCN113803534AQuick installation and removalIncrease in sizeNon-rotating vibration suppressionPipesAerospace engineeringWire rope

The invention relates to the technical field of cabin penetrating sealing, in particular to a steel wire rope cabin penetrating sealing device and method. The steel wire rope cabin penetrating sealing device comprises a cabin penetrating part, a transfer part, a fastening guide part and a plurality of sealing parts, the fastening guide part is arranged at the front end of the cabin penetrating part, the transfer part is arranged at the rear end of the cabin penetrating part, and the sealing parts are arranged at the fixed clamping positions of the transfer part and the cabin penetrating part; and the cabin penetrating part is fixedly installed in a cabin, the sealing parts are arranged at the joint of the cabin penetrating part and the cabin, and each sealing part comprises a sealing strip which expands when encountering water. The cabin penetrating parts installed in two different cabins are connected through the transfer parts, the rapid installation, detachment and cabin penetrating effects are achieved, the cabin penetrating parts communicate with the interiors of the transfer parts, a steel wire rope penetrates through the middle, the fastening guide parts are installed in the cabin penetrating parts, and the outer wall of the steel wire rope is fixed by adjusting the sizes of fastening inner rings of the fastening guide parts. The problems that an existing steel wire rope cabin penetrating device is simple in structure and cannot provide buffering for neutralization when a steel wire rope axially shakes, and thus the steel wire rope is serious in abrasion and short in service life are solved.

Owner:上海瓯洋海洋工程集团有限公司

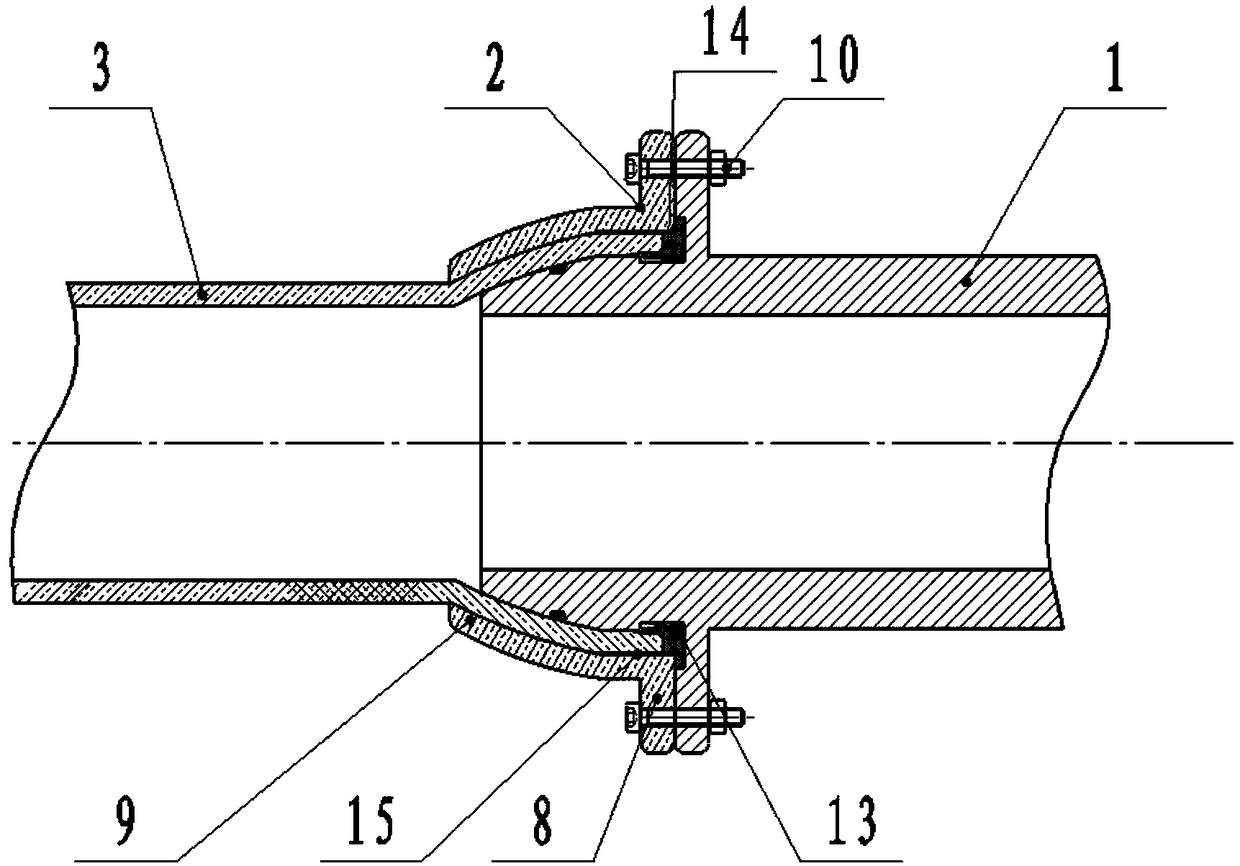

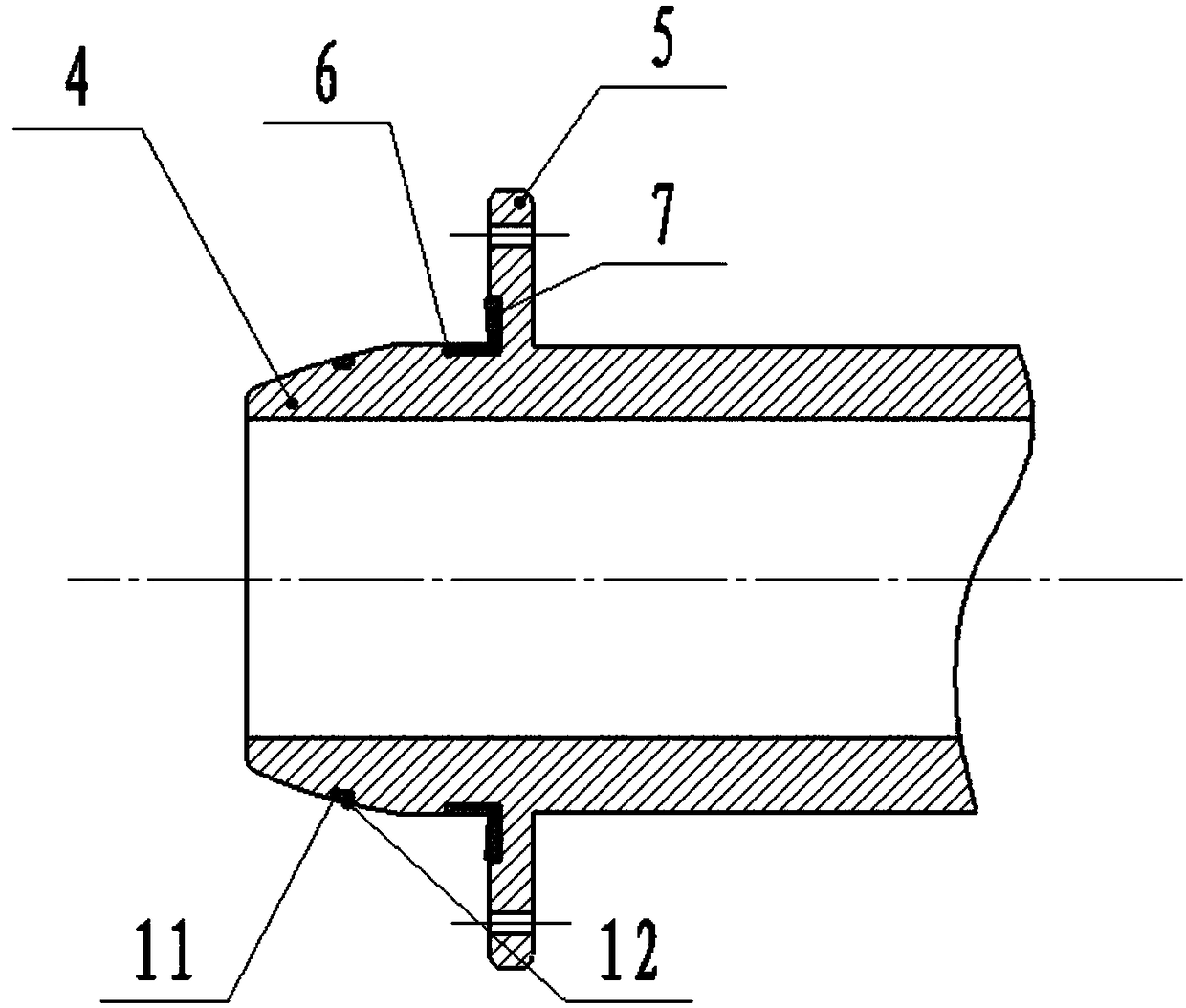

Tube jointing structure with locking bar

The invention relates to a pipe connection structure with locking strips. Two pipes are sealed by a connecting sleeve and a sealing ring. The outer circumference of the pipe to be connected is grooved, and the inner circumference of the connecting sleeve is provided with an inner ring groove corresponding to it. The outer periphery is provided with a lock hole communicating with the groove of the inner ring, and there is a lock bar between the groove of the inner ring and the groove of the outer ring. The connection structure realizes the mutual positioning between the two pipes through the cooperation of the lock hole, the lock bar, the outer ring groove and the inner ring groove, so that the two pipes can be connected firmly, the shape of the connecting sleeve is greatly reduced, and the shape is simple and beautiful, and the consumables are less. There is no need for bolts and screw holes, which greatly reduces the cost. The disassembly and assembly are simple and fast. You only need to insert or pull out the locking bar to disassemble and assemble without any tools. The structure is very simple, suitable for various pipe connections, and is not limited by the installation environment , long service life, can withstand any high pressure.

Owner:蔡海华

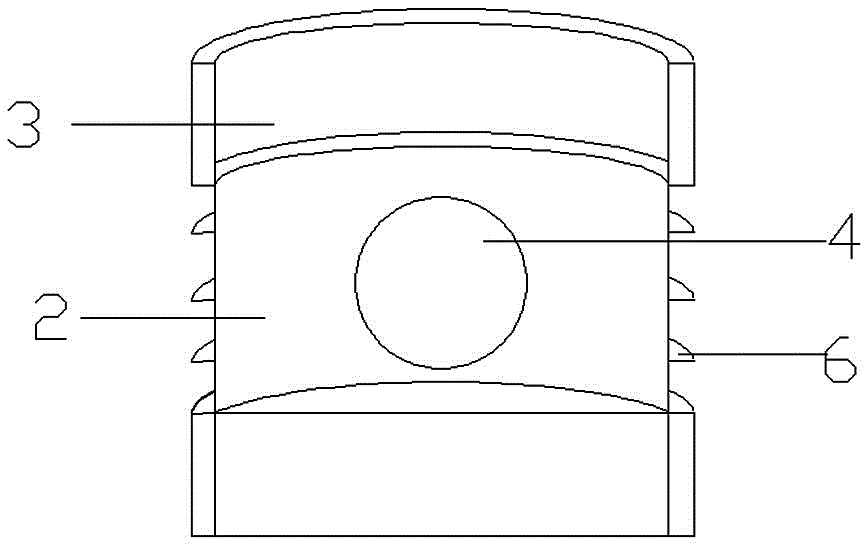

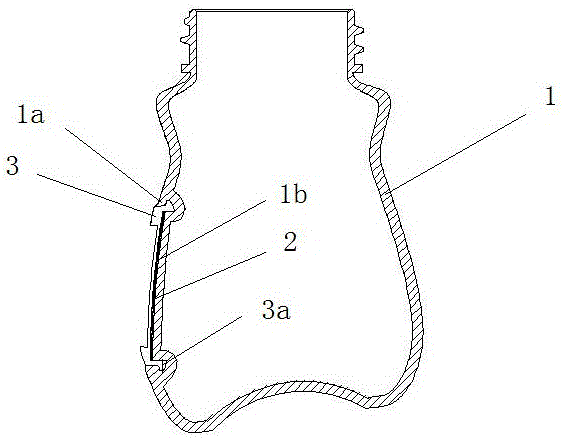

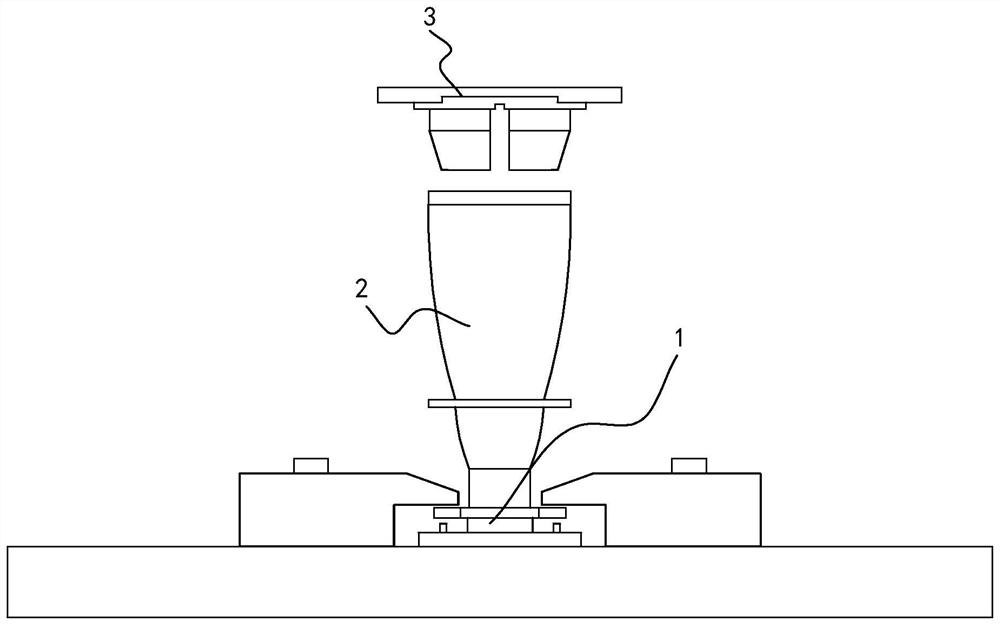

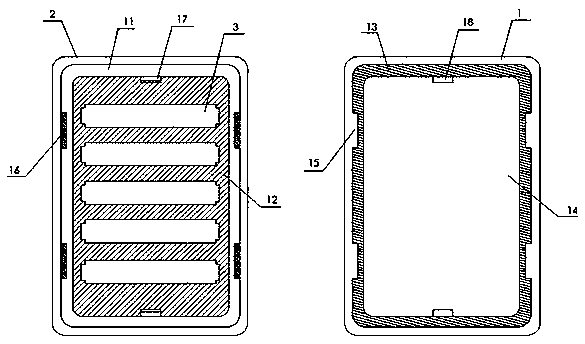

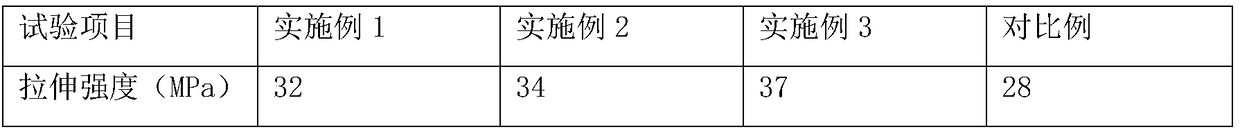

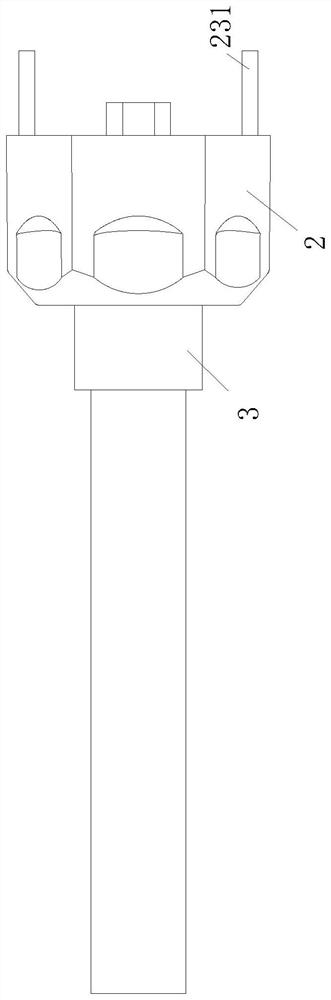

Temperature-sensitive feeding bottle with built-in lamellar temperature-sensitive display screen and manufacturing method of feeding bottle

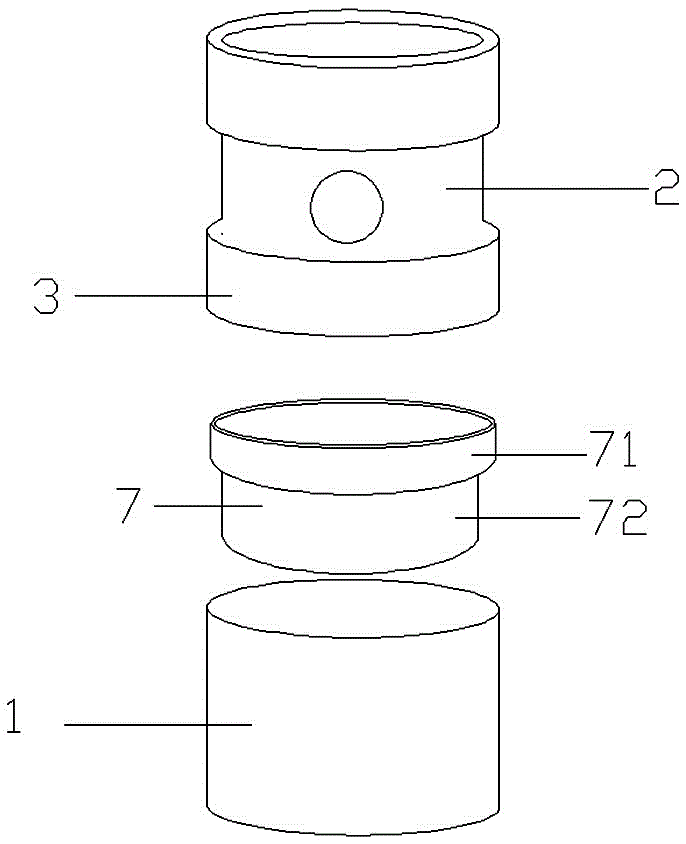

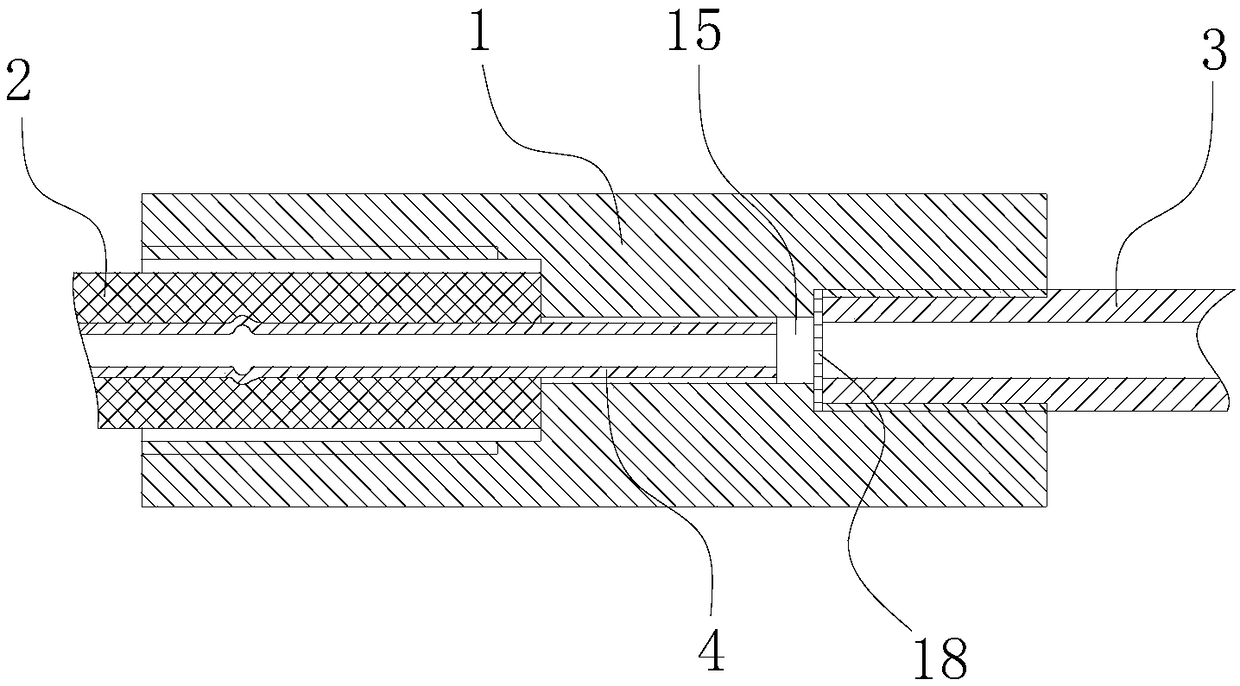

InactiveCN106038314AClose contactImprove temperature sensitivityFeeding-bottlesDomestic articlesBiochemical engineeringBottle

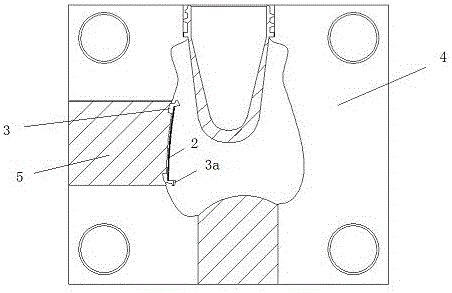

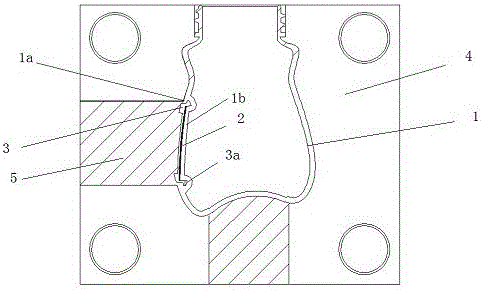

The invention discloses a temperature-sensitive feeding bottle with a built-in lamellar temperature-sensitive display screen and a manufacturing method of the feeding bottle, and realizes the purpose that the lamellar temperature-sensitive display screen does fall off and is tightly attached to the outer wall of the feeding bottle. The temperature-sensitive feeding bottle comprises a feeding bottle body (1), the lamellar temperature-sensitive display screen (2) and a fixing fastener (3) which is in a shape of a hat with a brim, wherein the feeding bottle body (1) and the fixing fastener (3) are made of plastics, the lamellar temperature-sensitive display screen (2) is placed in the hat-shaped part of the fixing fastener (3), and the brim-shaped part of the fixing fastener (3) is embedded in a corresponding preassemble position on the outer wall of the feeding bottle body (1) in a non-detachable manner. The manufacturing method includes the steps of placing a feeding bottle blank in a bottle blowing die (4), blowing the feeding bottle body (1) through a bottle blowing technology, embedding the fixing fastener (3) where the temperature-sensitive display screen (2) is assembled in the preassemble position on the outer wall of the feeding bottle body (1) in a non-detachable manner, and connecting the brim-shaped part of the fixing fastener (3) with the joint portion of the outer wall of the feeding bottle body (1) in a sealing manner.

Owner:湖南宝升塑业科技开发有限公司

Disposable meal box

The invention relates to a disposable meal box which comprises a box body, a partition plate and a cover body. The box body is provided with a containing cavity, and at least one annular groove is formed in the inner wall of the containing cavity in the circumferential direction of the containing cavity. The peripheral edge of the partition plate can be embedded in the annular groove; a plurality of through holes are formed in the partition plate; the cover body is arranged above the box body, and the cover body is connected with the box body in a sealed mode. According to the disposable meal box disclosed by the invention, by arranging the partition plate, soup can be firstly placed in the box body, then the partition plate is embedded in the annular groove, flour is further placed on the partition plate, and the cover body is covered to finish packaging; when the noodles need to be eaten, a user directly inverts the meal box, so that the noodles fall into the inner space of the cover body, soup flows into the cover body through the through holes of the partition plate, the soup and the noodles are mixed, the user can eat the noodles by opening the box body, the cover body does not need to be opened in the whole process, and the process of putting the noodles into the soup can be avoided; the situation that soup splashes out of the meal box and splashes onto a dining table is avoided, and meanwhile the situation that the soup splashes onto the hands is avoided.

Owner:台山市中尚餐厨用品有限公司

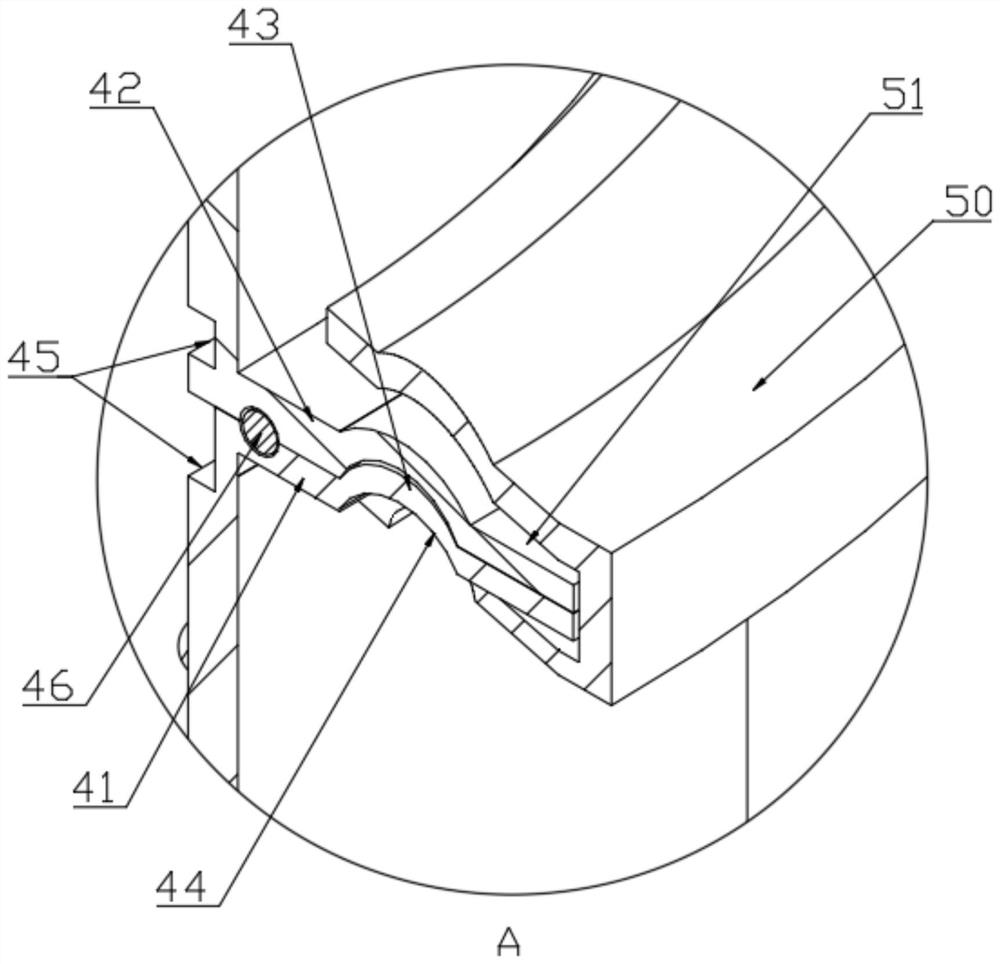

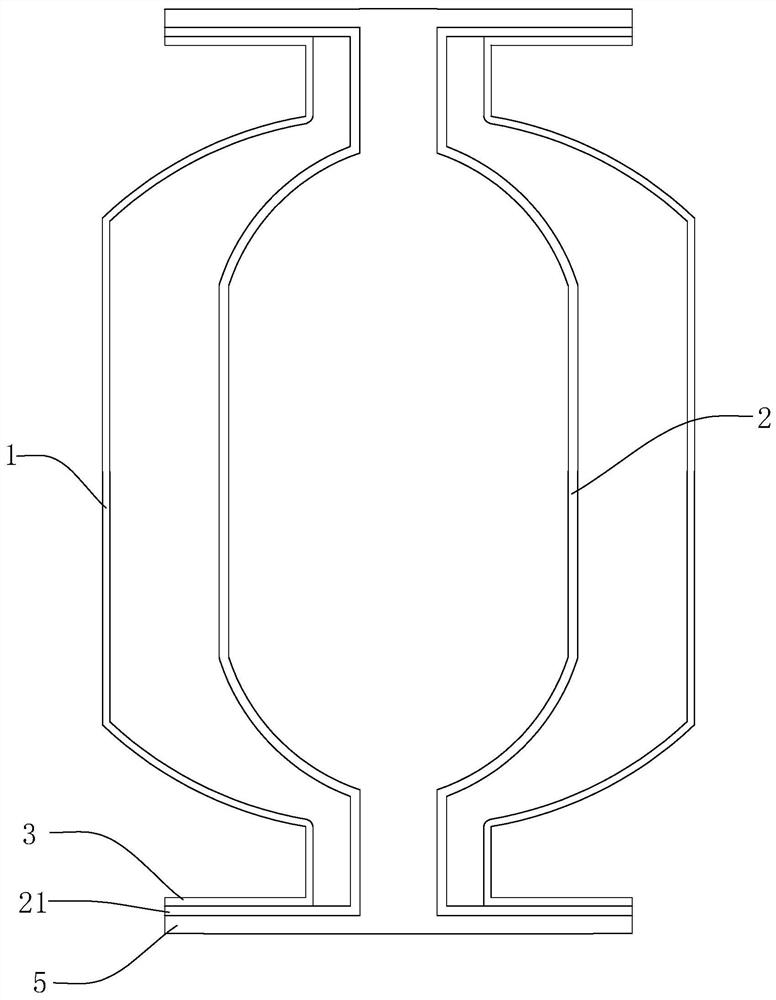

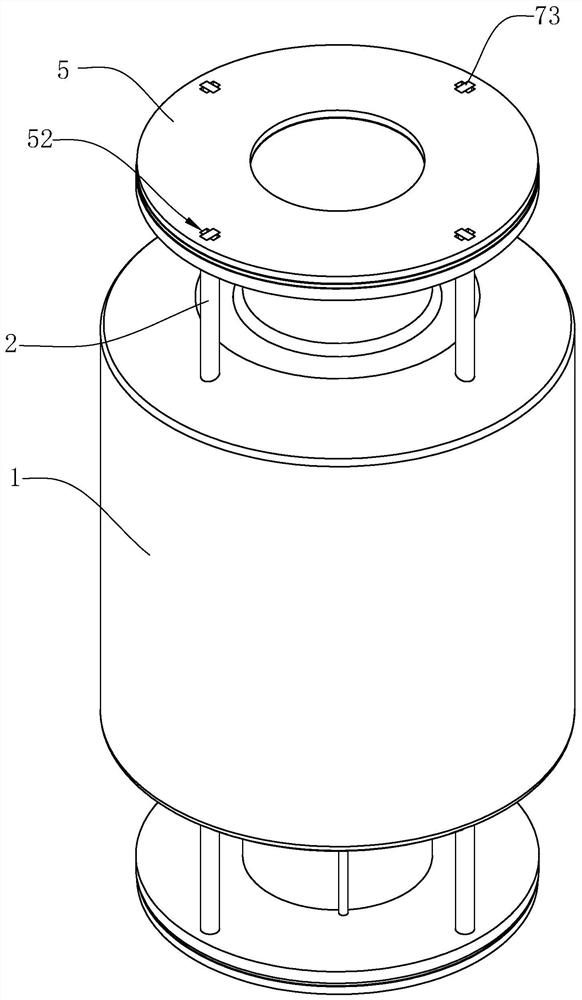

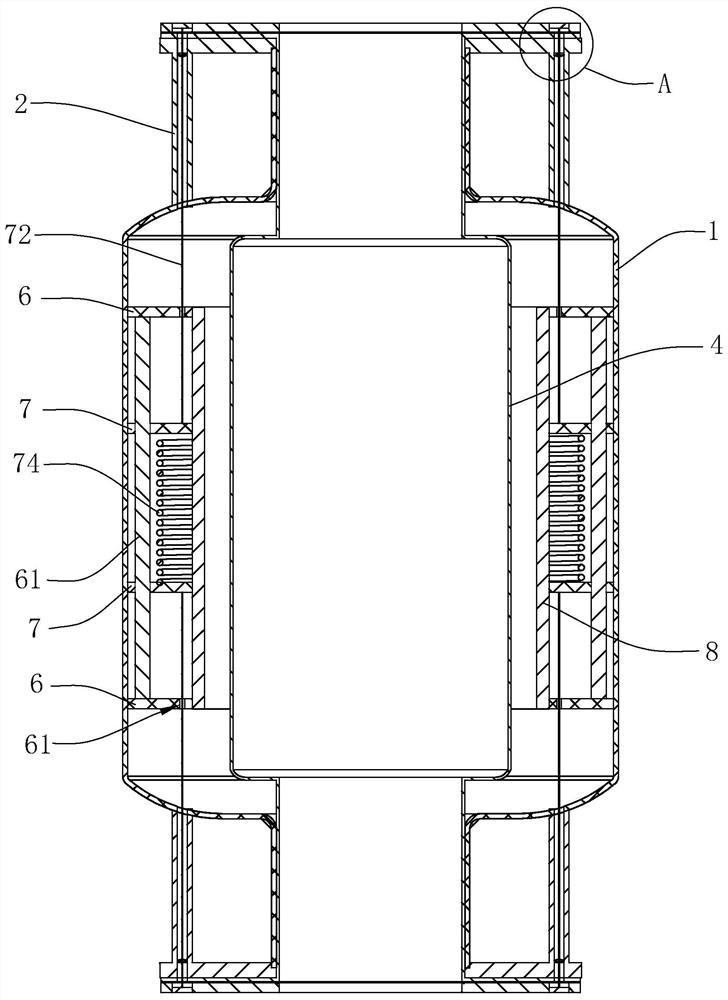

A diaphragm pressure tank with joint sealing structure

ActiveCN111535402BAchieve extrusionAchieve releaseEngine sealsWater supply tanksEngineeringMechanical engineering

The invention relates to a diaphragm air pressure tank with a joint seal structure. The diaphragm air pressure tank comprises a tank body, an inner container and annular plates, wherein flange platesare arranged at two ends of the tank body, a pair of parallel fixed rings are arranged on the inner wall of the tank body, pressure guide holes are formed in the fixed rings along the axes of the fixed rings seal rings are fixed on the inner circumferences of the fixed rings, and a pair of sliding rings moving oppositely or reversely are coaxially arranged between the fixed rings, the out circumferences and inner circumferences of the sliding rings are in sliding fit with the inner wall of the tank body and the seal rings respectively, and return springs are arranged between the sliding rings;through holes are formed in the circumference of an extension part at intervals; communication pipes are arranged in the circumference between the tank body and the flange plates at intervals; and pull wires penetrating through the communication pipes, the through holes and the pressure guide holes are arranged between the sliding rings and the annular plates. The tank has the effects that increase or decrease of air pressure in the tank body is controlled, extrusion and loosening between the annular plates and flange are achieved, and stable sealed connection of the inner container to the tank body is further achieved.

Owner:上海南汇压力容器厂有限公司

A powerful cooling machine cooling water atomization device

ActiveCN111473681BTightly sealed connectionMake sure to enterLiquid spraying apparatusTrickle coolersEngineeringMechanics

The invention discloses a cooling water atomization device for a powerful cooler, which comprises an annular pipe sheathed in a feeding pipe of the powerful cooler. In the present invention, the inner hole and the connection hole are correspondingly provided in the annular pipe and the feeding pipe of the powerful cooling machine, so that the nozzle integrally connected with the annular pipe is firmly sleeved in the feeding pipe of the powerful cooling machine; The corresponding outer hole is opened to facilitate the fixed connection of the cooling water pipe on the ring pipe; the side hole opened in the middle of the cooling water pipe is used to realize the sealed connection between the compressed air pipe and the cooling water pipe, and the air in the compressed air pipe is controlled by a ball valve to control the water in the cooling water pipe. Pressurize to make the water in the cooling water pipe fully atomized; the atomized water and compressed air in the cooling water pipe can be evenly injected into the feeding pipe of the powerful cooler, so as to cool the paste evenly and avoid Uneven temperature causes cracks in the carbon block, thereby reducing waste and realizing cost savings.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +2

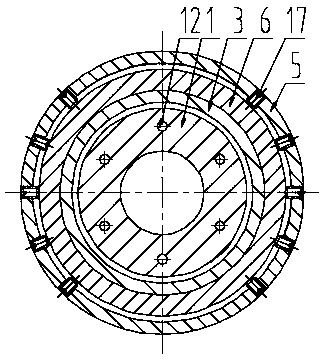

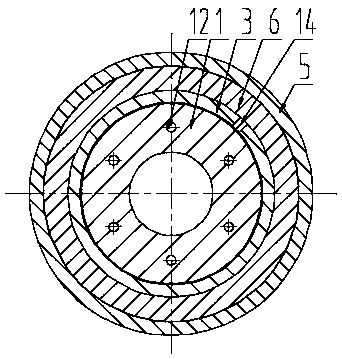

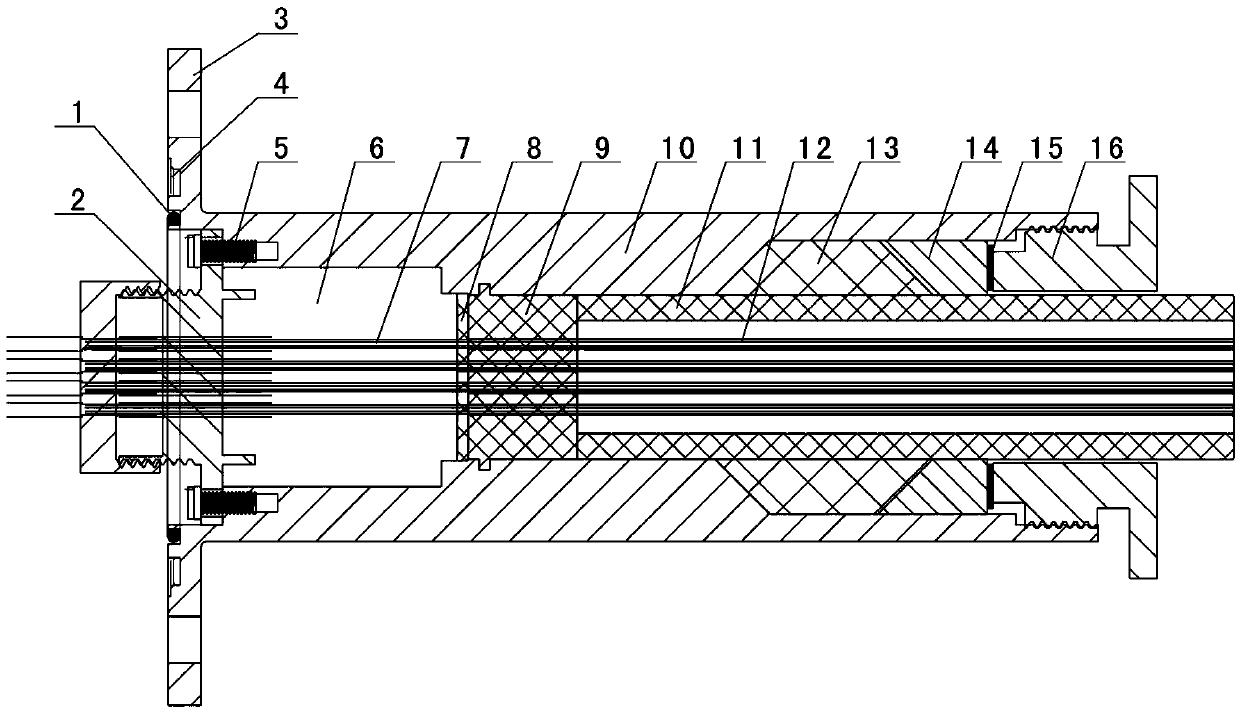

Marine cable seal connector in deep water environment

ActiveCN103840307BTightly sealed connectionFree from floodingCoupling device detailsEngineeringScrew thread

The invention discloses a cable sealing connector used for a ship in a deep water environment. The cable sealing connector comprises a sleeve, a pressing nut, a pressing ring, a sealing ring and a separating disc. The first end of the sleeve is provided with a flange used for connection, the second end of the sleeve is in threaded connection with the pressing nut, the middle section of the sleeve is a small-diameter through hole, the section, close to the first end, of the sleeve is a first large-diameter through hole, the section, close the second end, of the sleeve is a second large-diameter through hole, the pressing ring and the sealing ring are arranged in the second large-diameter through hole and are sequentially located on the inner side of the pressing nut, the separating disc is arranged in the small-diameter through hole, the diameter of the pressing nut, the diameter of the pressing ring, the diameter of the sealing ring and the diameter of the small-diameter through hole are the same and are slightly larger than the outside diameter of a cable used for the ship, and the separating disc is provided with a plurality of through holes which wires penetrate through. According to the cable sealing connector, the structure integrating the sleeve, the pressing nut, the pressing ring and the sealing ring is adopted, a connector of the cable for the ship is sealed so that the connector can bear large enough water pressure, and on the condition that the water pressure is not higher than 20 MPa, it is guaranteed that cables used for the ship and mutually connected are stably sealed and connected.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

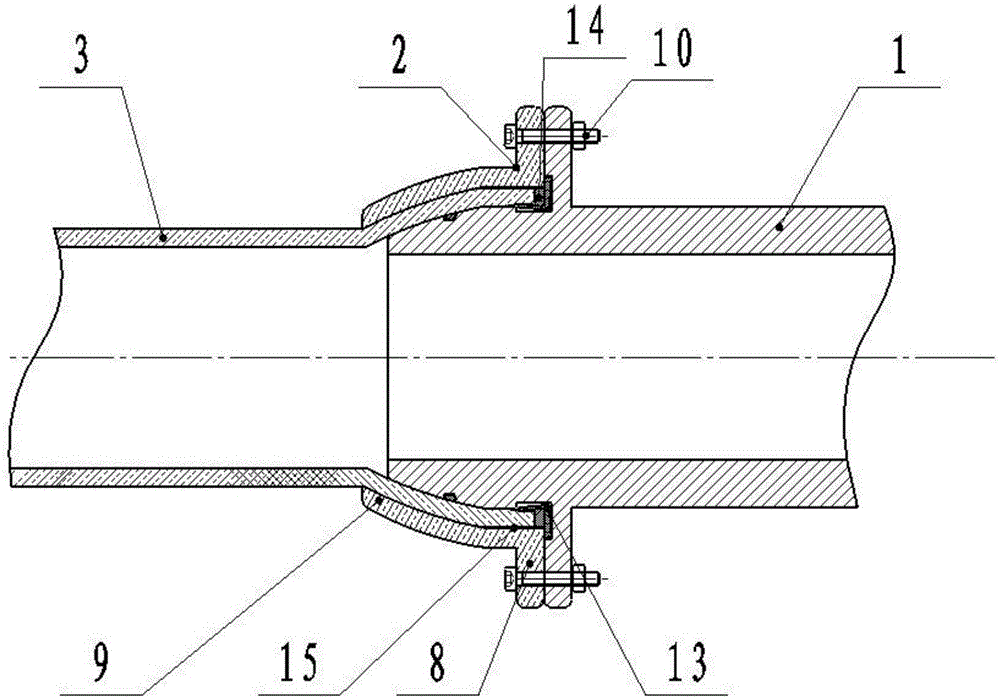

Steel-plastic composite pipe connector and method thereof

The invention discloses a steel-plastic composite pipe connector and a method thereof. The steel-plastic composite pipe connector comprises a connecting head body and a connecting pressing set. The two ends of the connecting head body are provided with conical connectors, wherein a steel-plastic composite pipe head can be sleeved with the conical connectors in an inserted manner. First connecting flanges are arranged at the positions, on the inner sides of the conical connectors, on the connecting head body. Multiple L-shaped grooves are formed in the included angle faces of the outer side faces of the first connecting flanges and the connecting head body in a surrounding manner. L-shaped tensioning blocks are arranged in the L-shaped grooves. The connecting pressing set comprises second connecting flanges and pressing sleeves. The pressing sleeves are also in a cone shape, and the second connecting flanges are arranged at the large-head ends of the pressing sleeves. The connecting pressing set can be used for clamping and sealing the steel-plastic composite pipe head by being arranged on the conical connectors in a sleeving manner, and the second connecting flanges and the first connecting flanges are matched and are firmly connected through bolts. The problems that a relatively thick steel-plastic composite pipe connector is not firm in connection, and a pipeline and the connector are likely to be disengaged or water leakage and gas leakage are likely to happen are solved.

Owner:CHINA MCC5 GROUP CORP

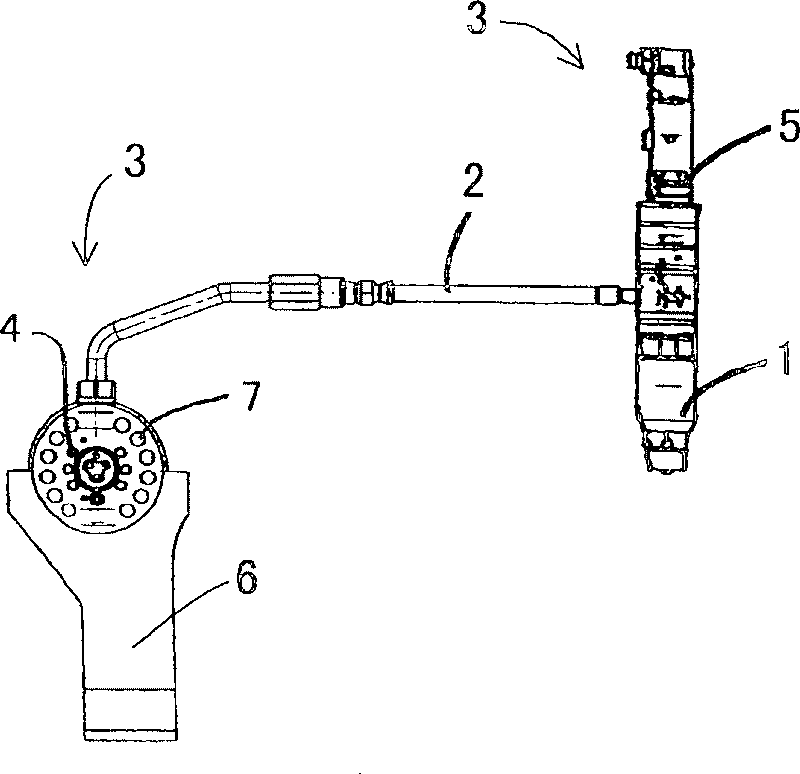

Fuel supply device with a pressure accumulator tube closed by accumulator cover

ActiveCN1818368BTightly sealed connectionPressure amplitude decayMachines/enginesFuel injection with fuel accumulatorsCommon railEngineering

The invention relates to a fuel supply device in the form of a common rail injection system, which comprises at least one accumulating chamber in an accumulator unit, which can be sealed by at least one end surface by an accumulator cover, wherein all functional units are integrated in the accumulator cover in consideration of the supply and the guide of fuel. In order to be accessible to each functional unit and keep the advantages that the attenuation of the amplitude pressure applied on the functional units of the accumulator cover, specifically a two-position three-port valve and a pressure pipe, the invention provides that the accumulator cover consists of two modules in a form of a sealing element and a control unit, so that the sealing element is hermetically connected with the accumulator unit, and the control unit can be located optionally in the pressure pipe between the sealing element and a fuel injector for supplying fuel.

Owner:MAN ENERGY SOLUTIONS SA

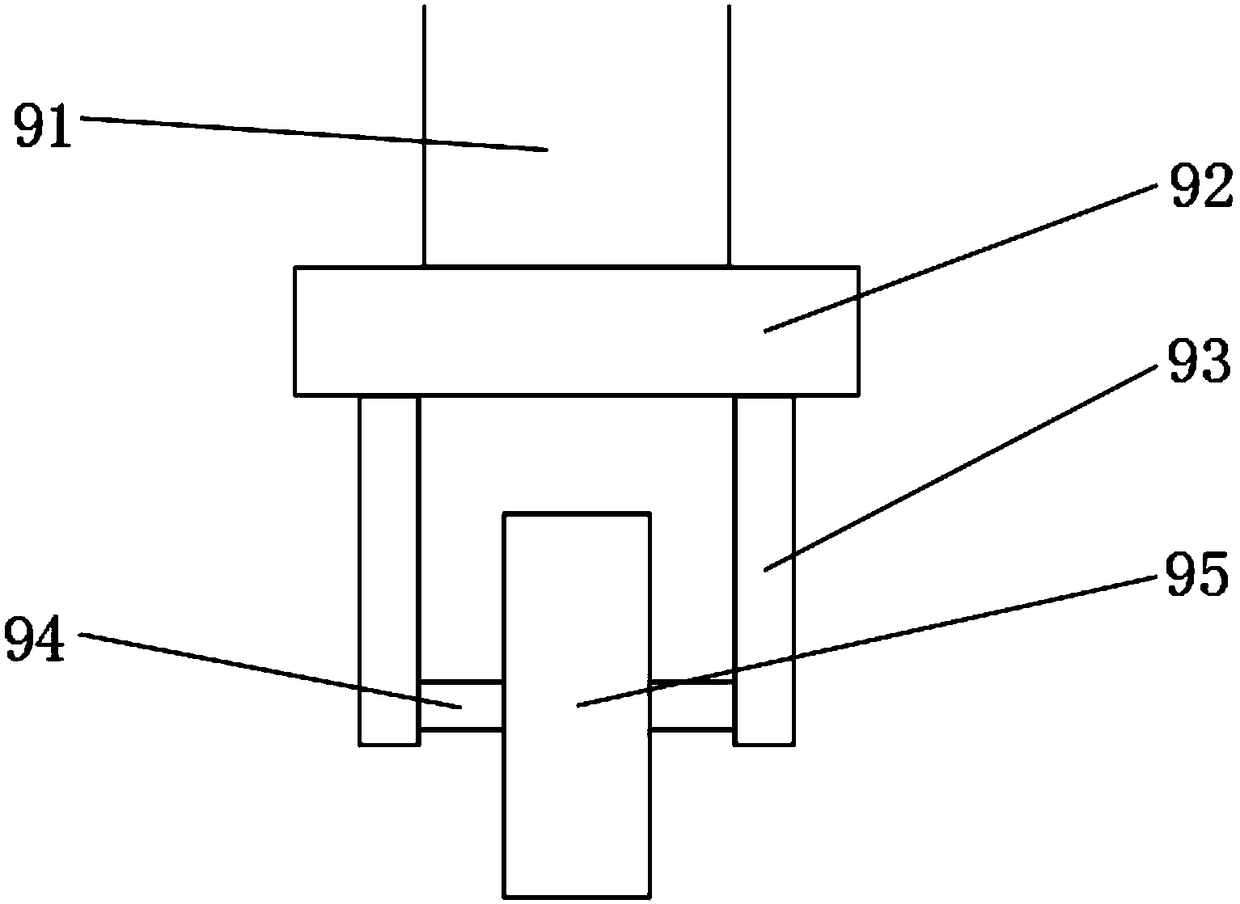

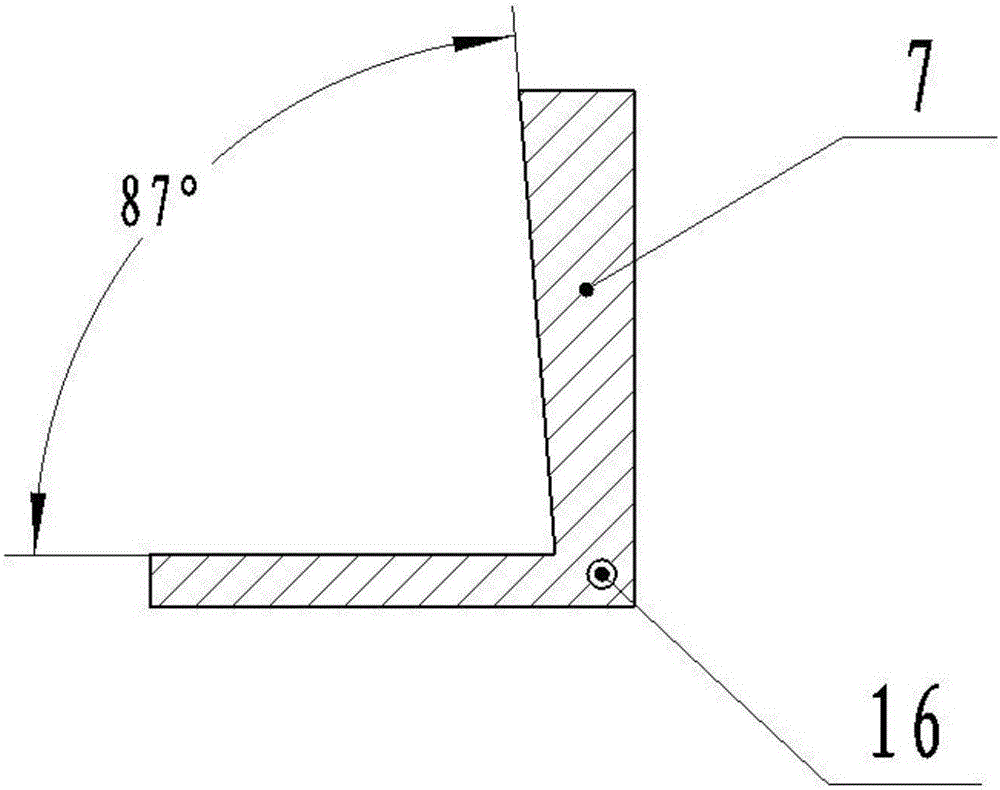

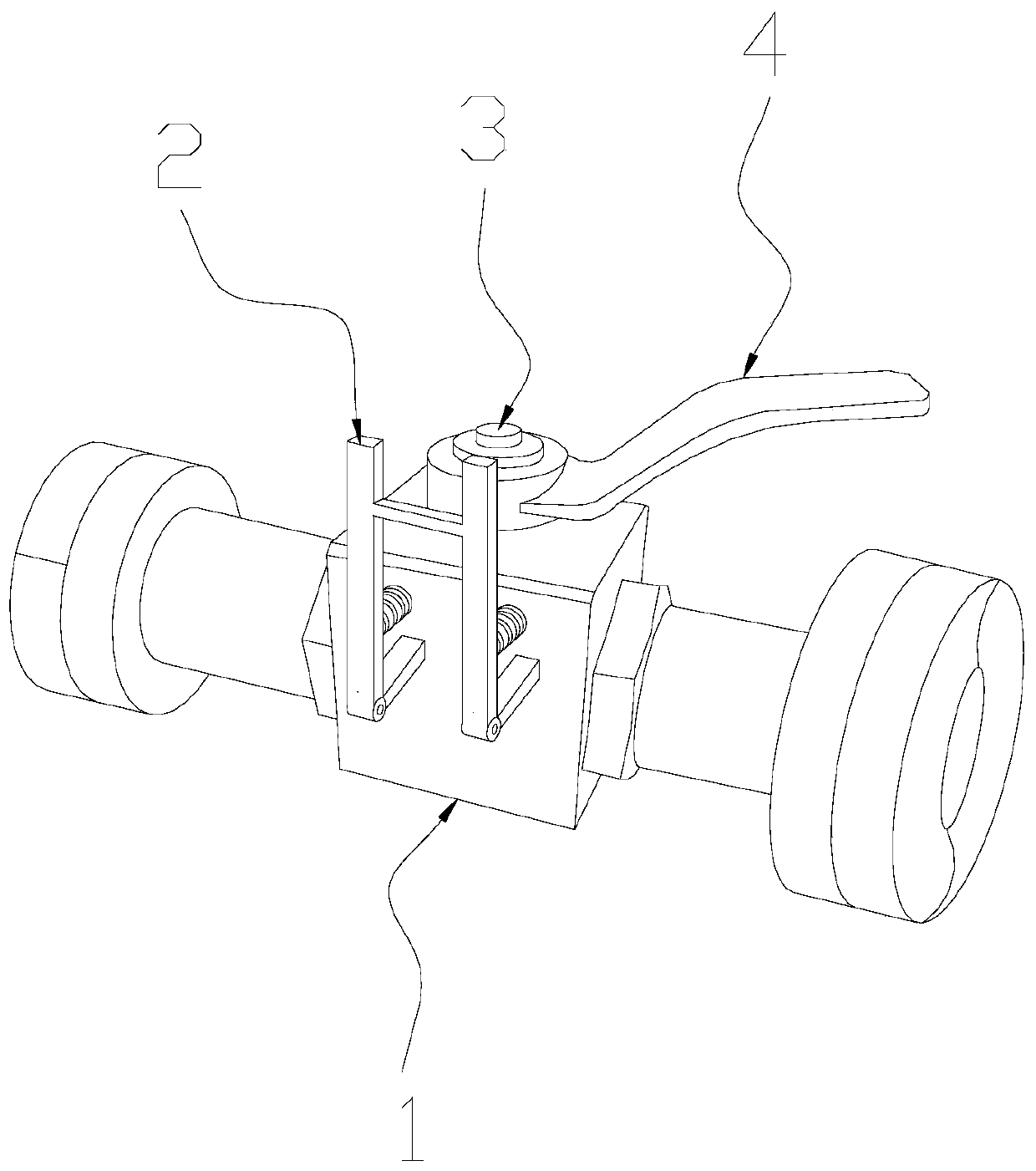

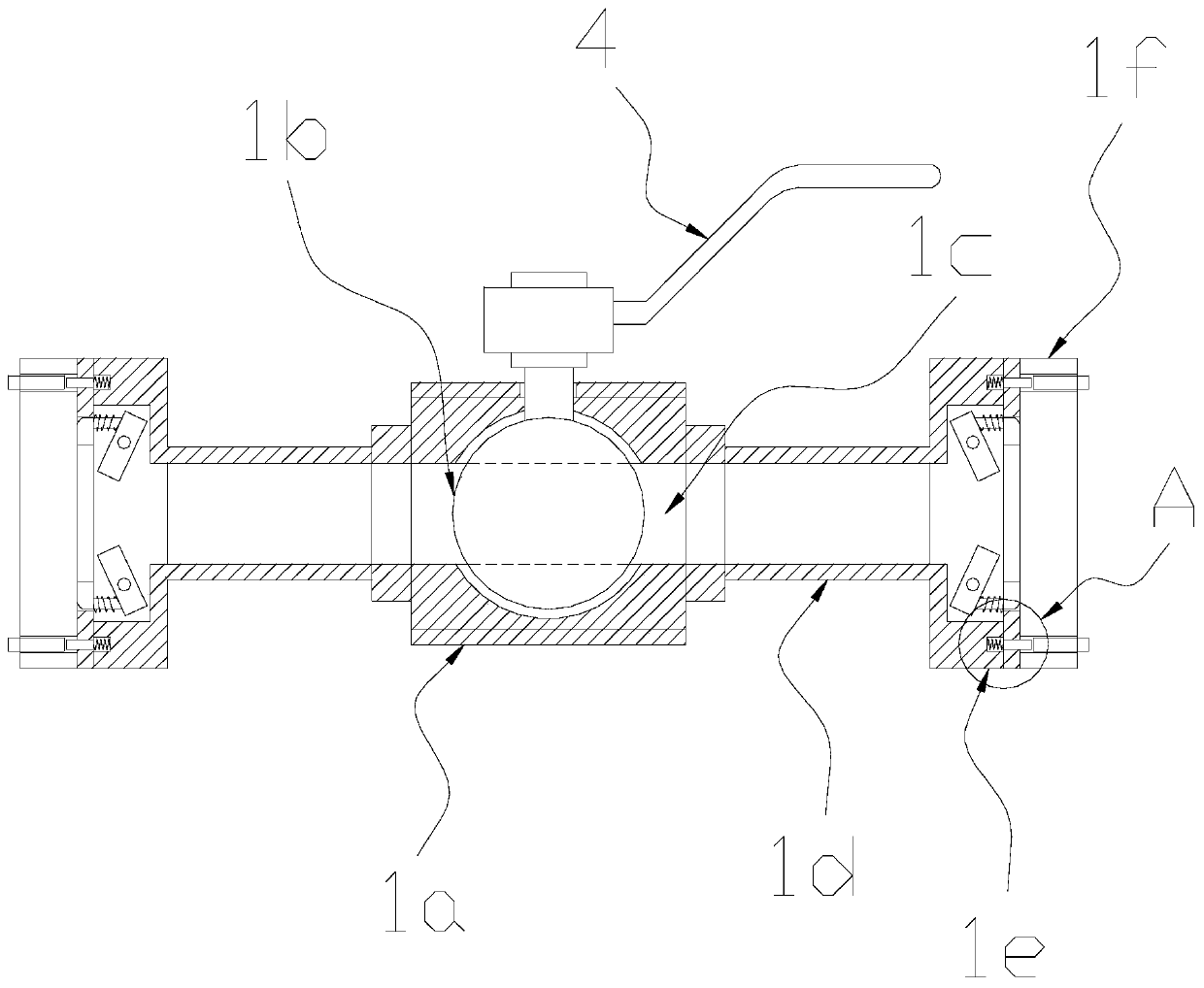

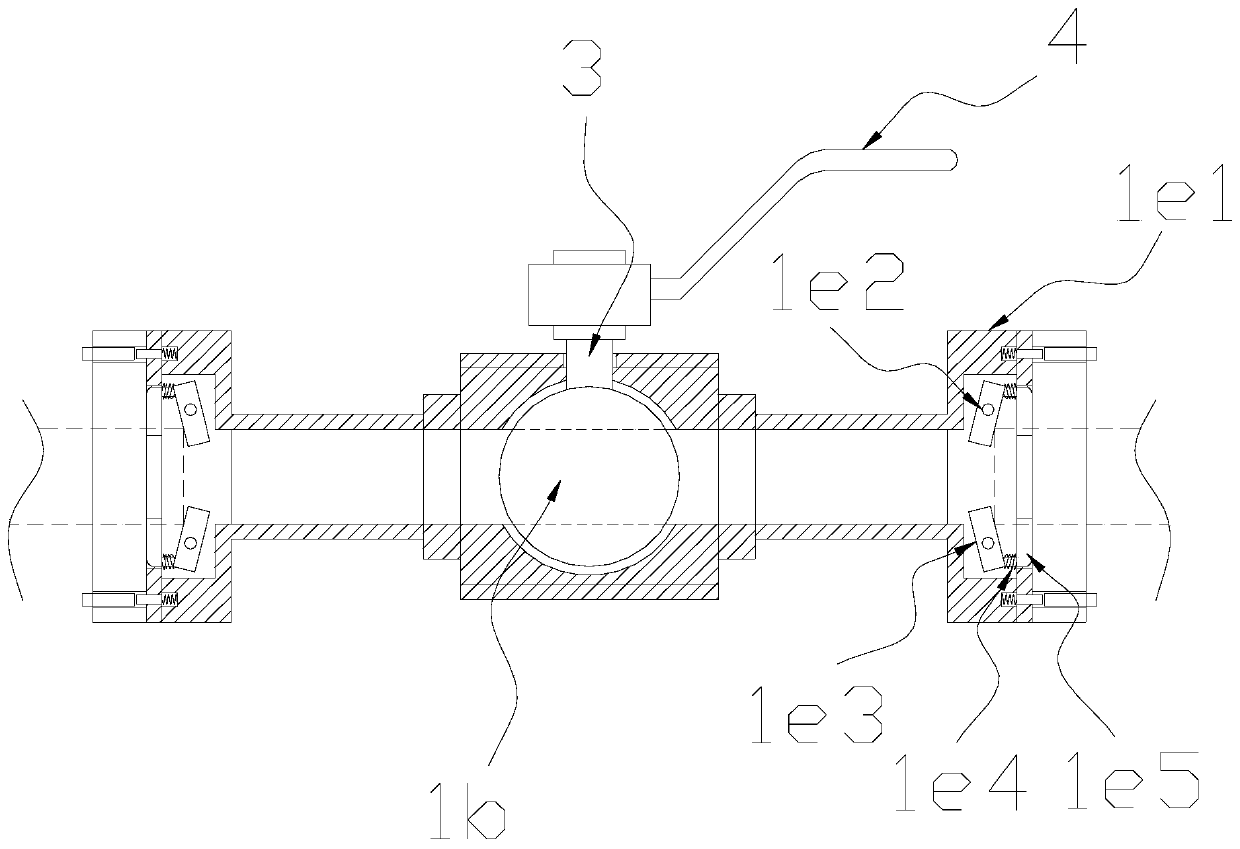

Gas pipe flexible connection valve with multiple seals

InactiveCN111043372APrevent leakageDoes not affect closure workSleeve/socket jointsValve housingsFuel gasVALVE PORT

The invention discloses a gas pipe flexible connection valve with multiple seals. The valve comprises a gas pipe valve, a locking mechanism, a rotating shaft and a valve rod, the gas pipe valve consists of a valve body, a ball valve, a gas circulating cavity, a gas guide pipe, a multi-sealing mechanism and a closing mechanism, the gas pipe valve enables sealing connection between the gas pipe andthe gas guide pipe to be tighter through the multi-sealing mechanism, then the gas pipe and the gas guide pipe are installed and locked through the closing mechanism, and the installation effect on the gas pipe valve is improved. The closing mechanism conducts secondary gas sealing on the gas pipe through a sealing strip, and gas leakage is avoided. The locking mechanism can be used for limiting the valve rod when the valve rod closes fuel gas, and avoids the situation that the ball valve is opened when the valve rod is accidentally impacted, and consequently the fuel gas leaks out of the gascirculating cavity.

Owner:张志坤

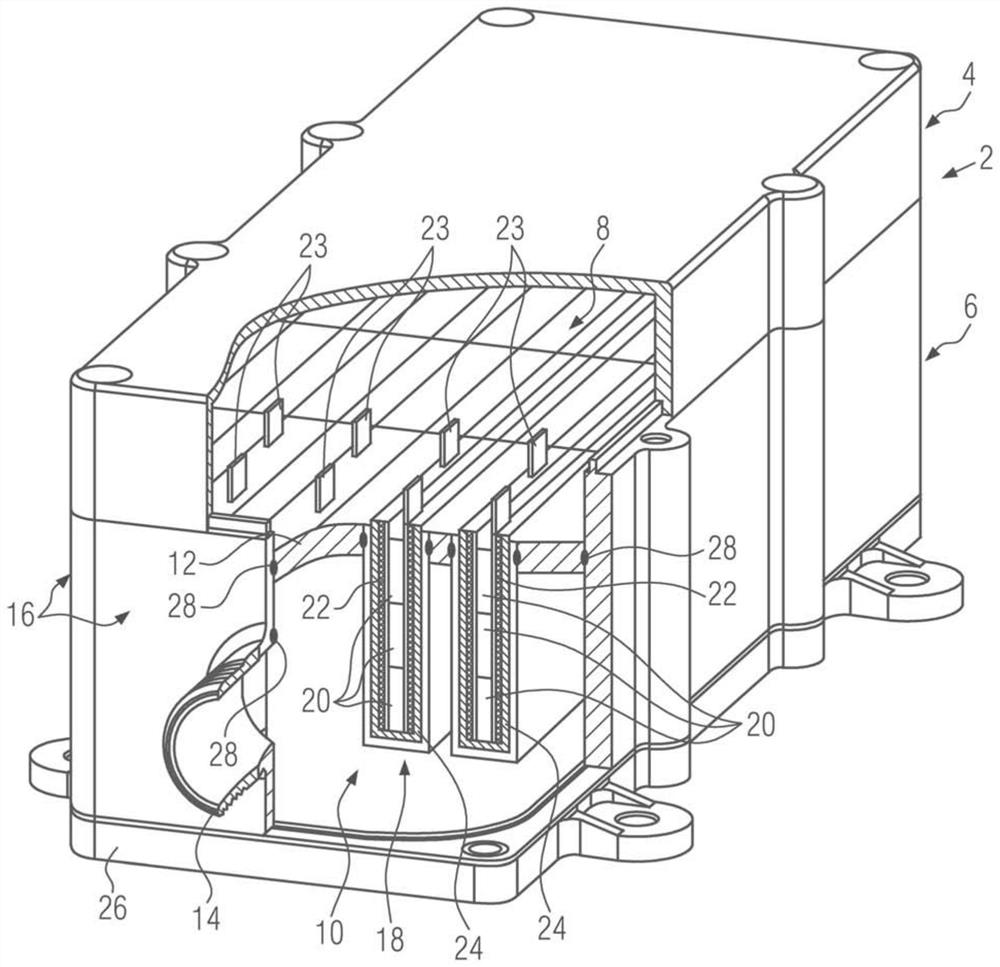

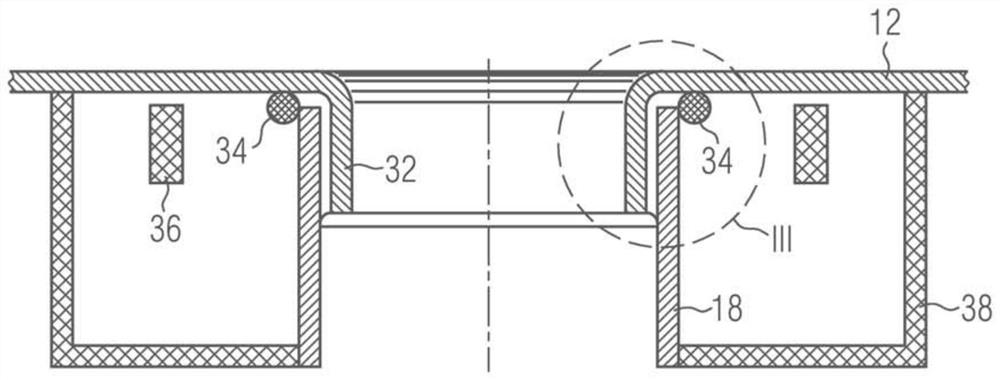

Electric heating device and method for producing same

PendingCN114080070ACompact structureGood dimensional stabilityAir-treating devicesOhmic-resistance electrodesElectrical conductorElectrical polarity

The invention relates to an electric heating device having a housing, comprising a housing (2) having a partition wall (12) which separates a connection chamber (8) from a heating chamber (10) for dissipating heat, and from which partition wall (12) at least one heating element housing (18) protrudes in the direction of the heating chamber (10), wherein at least one PTC element (20) and a bar conductor (22) are supported in an electrically insulating manner in the heating assembly housing (18), the bar conductor (22) is connected to the PTC element (20) in an electrically conductive manner in order to excite the PTC element (20) with different polarities, and the bar conductor (22) is electrically connected in the connection chamber (8). A compact electric heating device is achieved in which a housing wall (16), which protrudes from the partition wall (12) and delimits the connection chamber (8) and / or the heating chamber (10) and / or the heating assembly housing (18), is connected to the partition wall (12) by means of material bonding, in particular by means of induction brazing.

Owner:EBERSPACHER CATEM

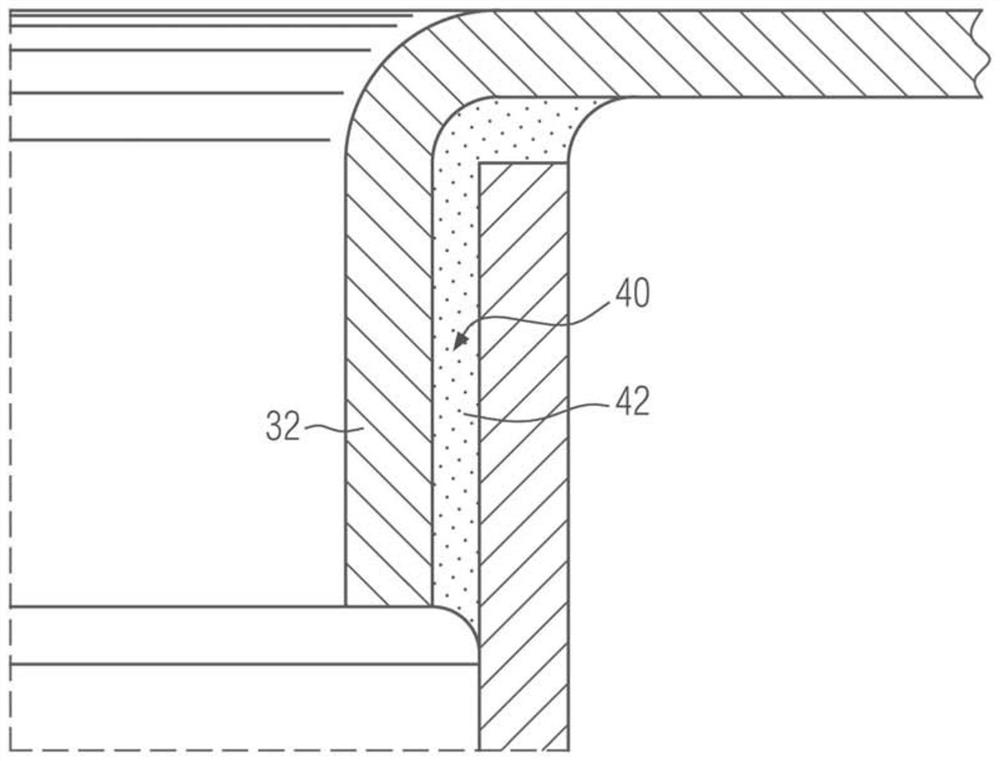

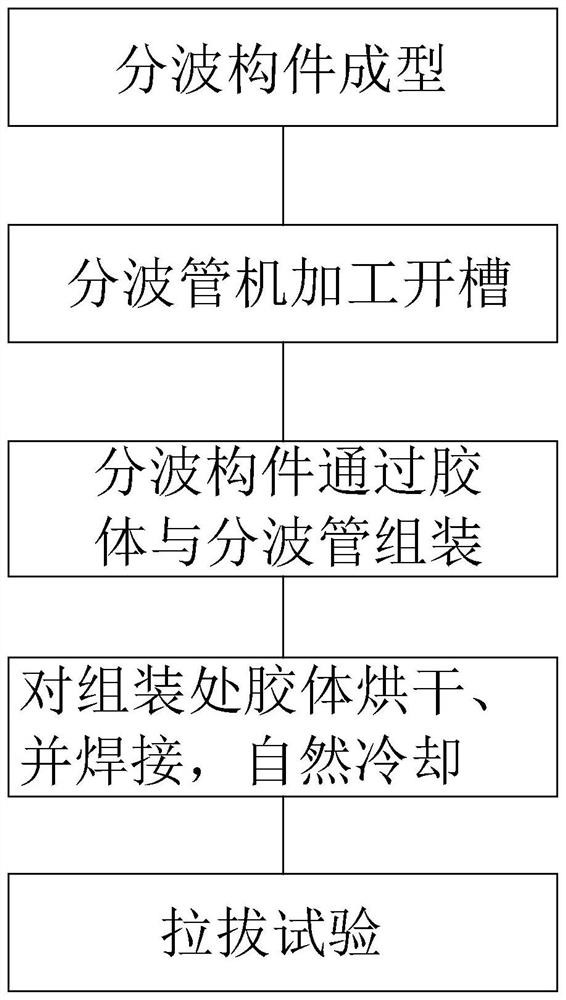

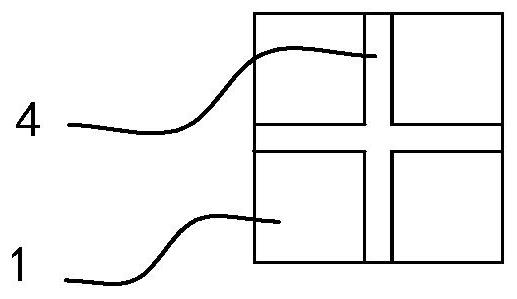

Welding process for wave separating component of wave separator

InactiveCN114346505AImprove performanceTightly sealed connectionWelding/cutting auxillary devicesAuxillary welding devicesSignal waveAdhesive

The invention relates to the field of wave separators, and discloses a welding process for a wave separating component of a wave separator. Comprising the following machining steps that firstly, an aluminum material is machined through a wire cutting machine to obtain a cross-shaped wave division component, secondly, a wave division tube is clamped to a grooving machine, a groove is formed in the open end of the wave division tube, thirdly, the groove is internally coated with adhesive, the wave division component is connected into the groove in a lap joint mode and pre-positioned through the adhesive, and finally the wave division tube is machined through a wire cutting machine to obtain the cross-shaped wave division component. The method comprises the following steps of: (1) preparing a partial wave tube, (2) preparing a partial wave tube, (3) preparing a partial wave component, (4) pressing the partial wave component through a jig for reinforcement to obtain a processed body, (5) drying and curing the adhesive part on the processed body, welding the contact part of the partial wave component and the partial wave tube, and naturally cooling to obtain a molded part, and (6) carrying out a pull-out test on the partial wave component through a preset pull-out force to obtain the partial wave tube. And the connection strength condition of the wave division component and the wave division tube is obtained. The connection between the wave separator and the wave separation component is more sealed and tight, the firmness is high, the signal wave separation precision is high, and the performance of the wave separator is improved.

Owner:SUZHOU JOYO METAL TECH CO LTD

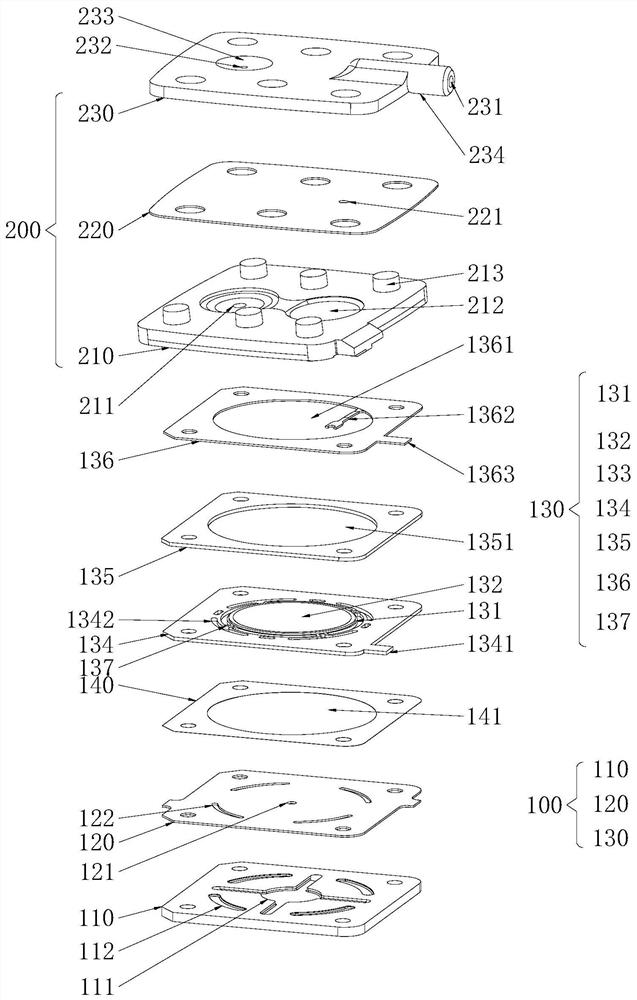

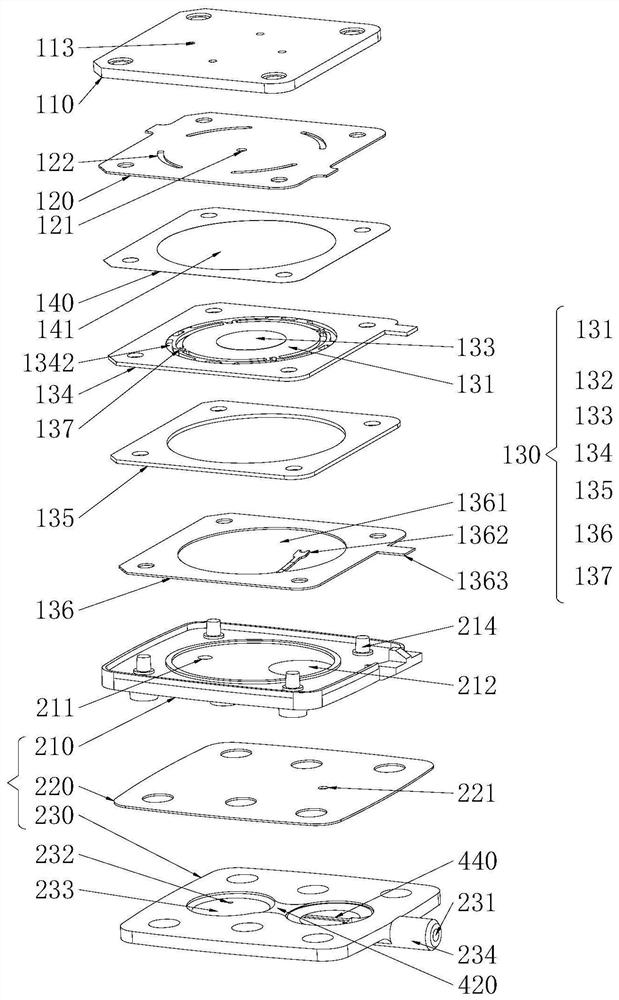

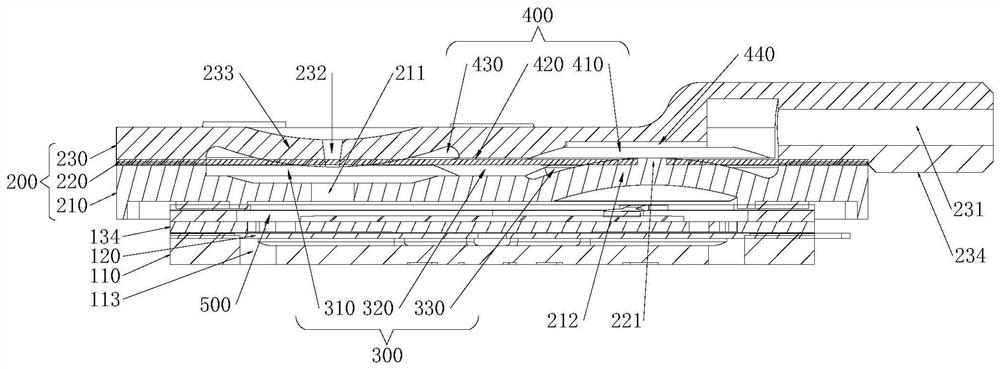

Fluid control device

PendingCN112360729ACompact structureClosely connectedPositive displacement pump componentsFlexible member pumpsFluid controlPiezoelectric actuators

The invention discloses a fluid control device. The fluid control device comprises a piezoelectric pump and a control valve. The piezoelectric pump comprises a base plate with an opening, a flexible plate with a suction hole and a piezoelectric actuator with a vibrating plate and a piezoelectric element. The base plate, the flexible plate and the piezoelectric actuator are sequentially arranged inan overlapped mode. The control valve comprises a valve body lower shell, a diaphragm and a valve body upper shell which are sequentially arranged in an overlapped mode. The valve body lower shell isprovided with an air inlet hole, and the valve body upper shell is provided with an air outlet hole and an exhaust hole. The diaphragm and the valve body lower shell form a first valve chamber, the diaphragm and the valve body upper shell form a second valve chamber, and the diaphragm is provided with a through hole capable of communicating the first valve chamber with the second valve chamber. The valve body lower shell is provided with a first protruding part, and the part, located around the through hole, of the diaphragm abuts against the first protruding part. The valve body upper shellis provided with a second protruding part, the exhaust hole is formed in the second protruding part, and the part, located around the exhaust hole, of the diaphragm abuts against the second protrudingpart. The valve body lower shell covers the piezoelectric actuator in a sealing mode to form a pump chamber. The fluid control device is more compact in structure, and the positions needing to be sealed are reduced.

Owner:广东诗奇制造有限公司

Moisture-proof plastic packaging box for hardware tool, and preparation method thereof

PendingCN109178632AAvoid enteringImprove moisture resistanceSealingRigid containersPlastic packagingButt joint

The invention discloses a moisture-proof plastic packaging box for a hardware tool, and relates to the technical field of packaging products. The moisture-proof plastic packaging box comprises an upper shell and a lower shell, and the middle part of the lower shell is provided with a plurality of storage units; the moisture-proof plastic packaging box further comprises a sealing connector comprising an upper sealing strip and a lower sealing strip, and the lower end of the upper sealing strip is provided with a first connecting part; the upper end of the lower sealing strip is provided with asecond connecting part correspondingly, and the shape formed by butt joint of the upper sealing strip and the lower sealing strip is matched with the packaging box; and the opposite sides of the uppersealing strip and the lower sealing strip are each provided with a slot, and the upper shell and the lower shell are clamped into the slot after butt joint so that the connection of the upper shell with the lower shell is achieved. The invention further discloses a preparation method of the moisture-proof plastic packaging box for the hardware tool. According to the moisture-proof plastic packaging box, the moisture resistance of the packaging box is improved, and the performance of the hardware tool is ensured; and meanwhile the degradation speed of the packaging box is increased greatly, and the moisture-proof plastic packaging box is more environmentally friendly.

Owner:南京德荣包装制品有限公司

A wiring type sealing plug for a pump

ActiveCN113314883BGuaranteed tightnessEnsure connection stabilityLine/current collector detailsRelieving strain on wire connectionEngineeringElectric wire

The invention belongs to the technical field of electrical plugs, and specifically relates to a wiring-type sealing plug for a pump, which includes a plug body and a wire nut; the end of the wire nut far away from the plug body is fixedly connected to a connecting pipe; the inner wall of the connecting pipe is fixedly connected to There is a sealing layer; the inner wall of the wire nut is provided with a No. 1 groove; the No. 1 groove is close to the connecting pipe; the inside of the No. 1 groove is provided with a No. 1 slider, a clamping block and a spring; The end away from the plug body is fixedly connected with a connecting pipe, and then cooperates with the clamping block on the inner wall of the wire nut, so that the wire nut can fix the wires of different diameters and ensure the sealing effect of the wires, and then realize different diameters. All wires can achieve stable and sealed connection at the terminal nut, which improves the application range of the pump wiring type sealing plug, and can ensure the connection stability of the pump wiring type sealing plug when using wires of different diameters.

Owner:LEO GRP ZHEJIANG PUMP CO LTD

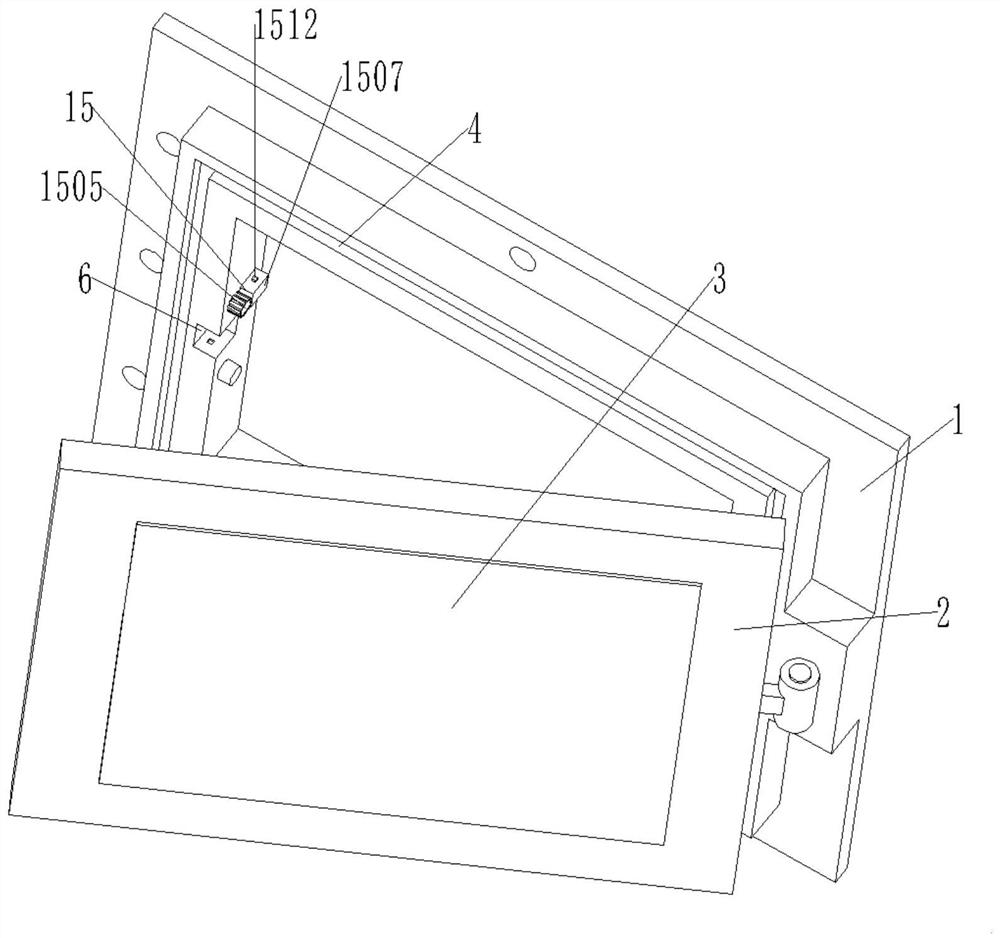

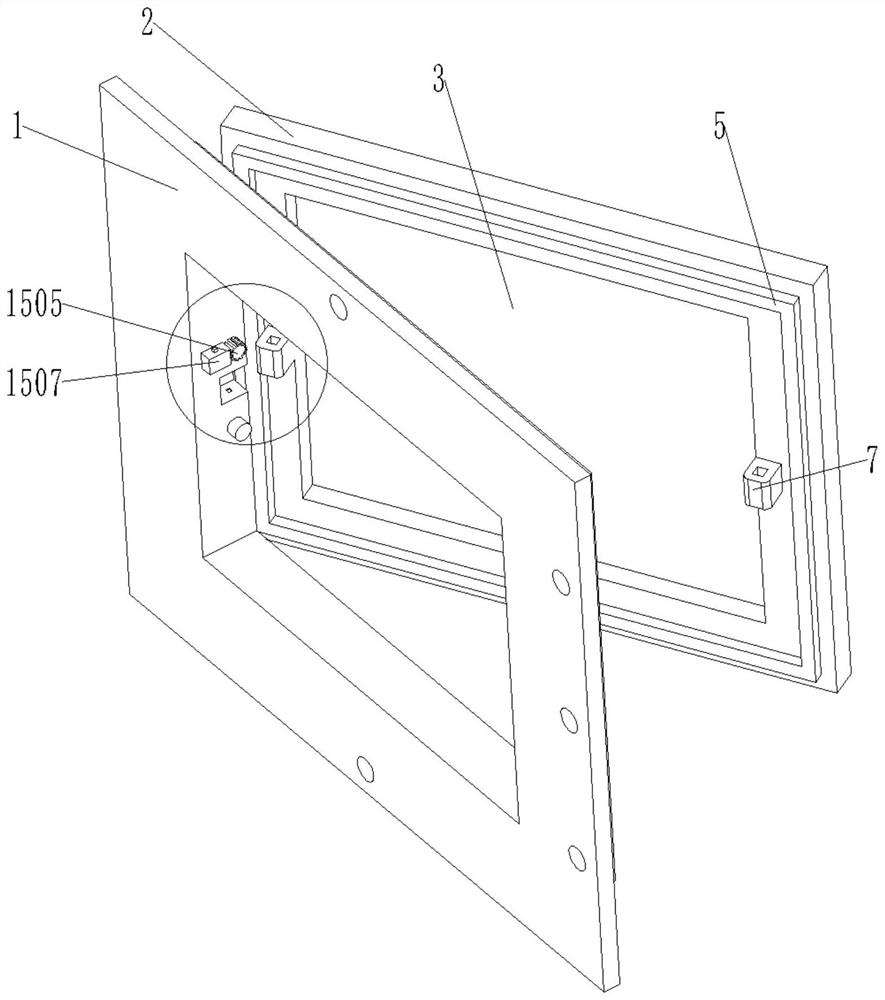

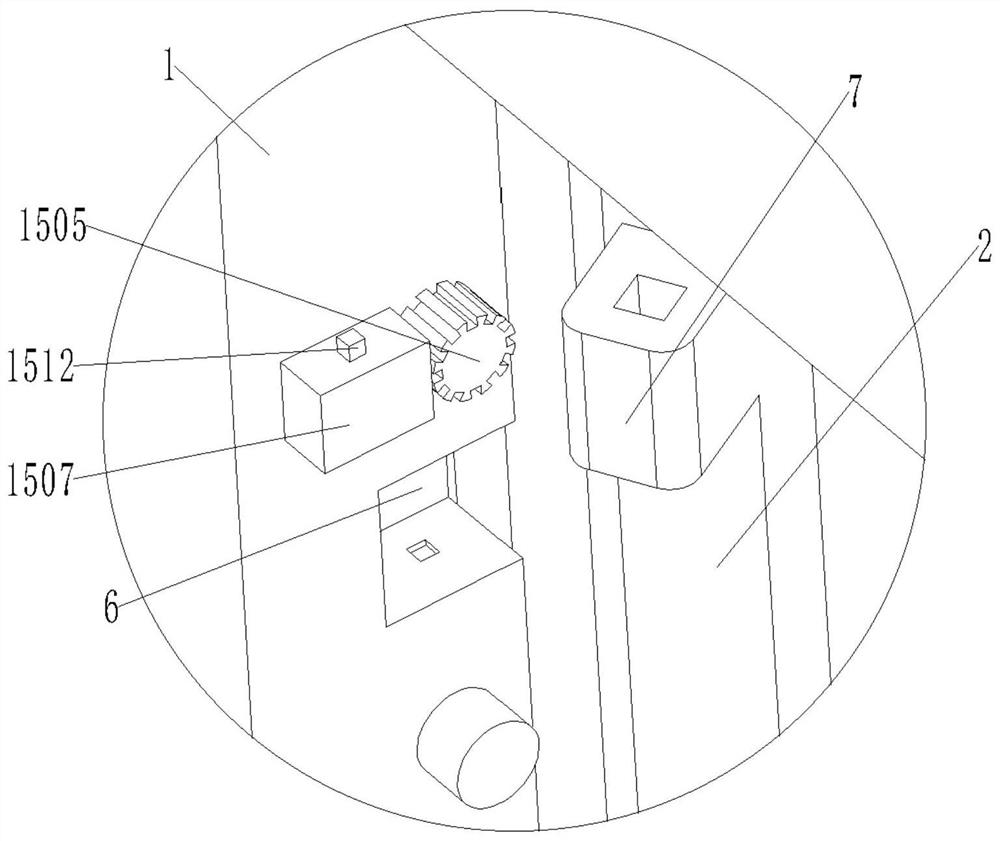

Sealing structure for protective window

InactiveCN113212649AImprove sealingTightly sealed connectionClear-view screensSealing arrangementsFixed frameClassical mechanics

The invention discloses a sealing structure for a protective window, which is characterized in that the sealing structure is provided with a sealing groove and a sealing convex block, the closed sealing of the protective window is primarily sealed, and then a movable rack is clamped with a first clamping groove in a connecting insertion block and a fixed square groove in one side of a movable reinforcing block; so a fixing frame and a mounting base are connected more firmly, then the connecting tightness of the sealing groove and the sealing protruding block is enhanced, the overall sealing performance of the protective window is enhanced, through an arranged sealing locking mechanism, the sealing connection of the sealing groove and the sealing protruding block can be more stable, the sealing stability is guaranteed, therefore, the sealing quality is improved, the overall sealing effect of the protective window is well guaranteed, the working environment of workers in a cabin is ensured, equipment is prevented from being damaged, and economic losses are further avoided.

Owner:翁科达

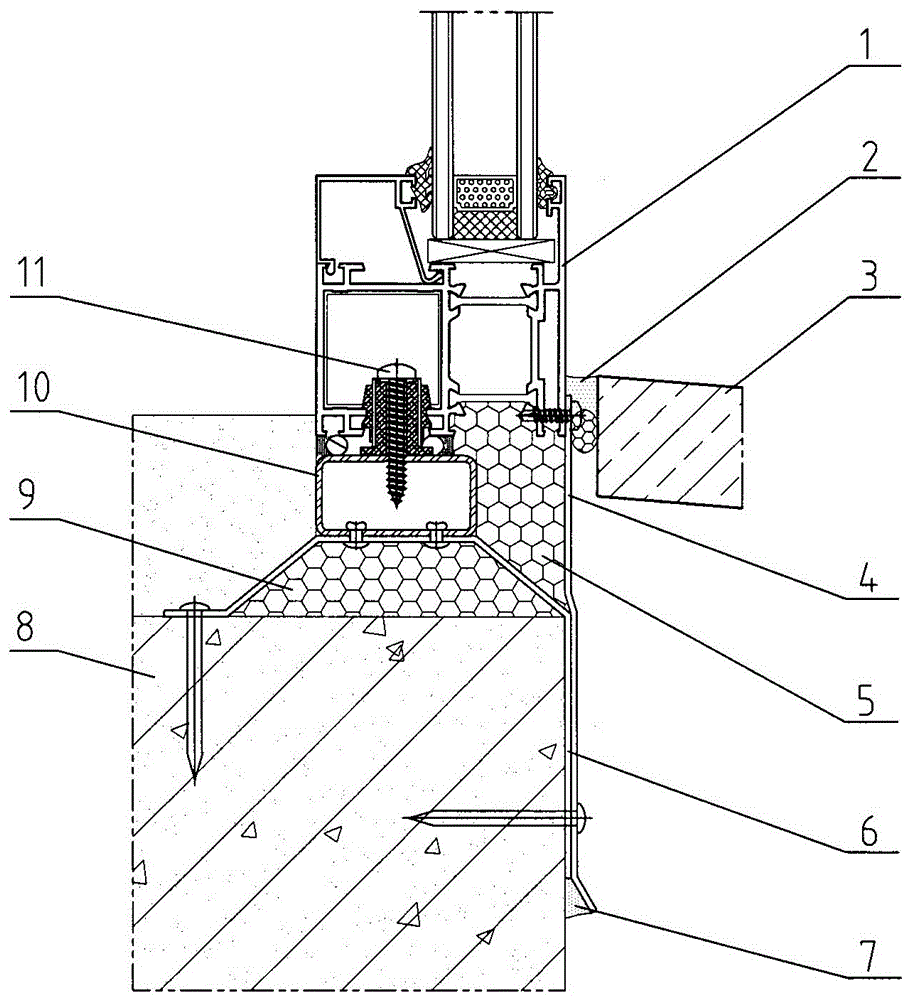

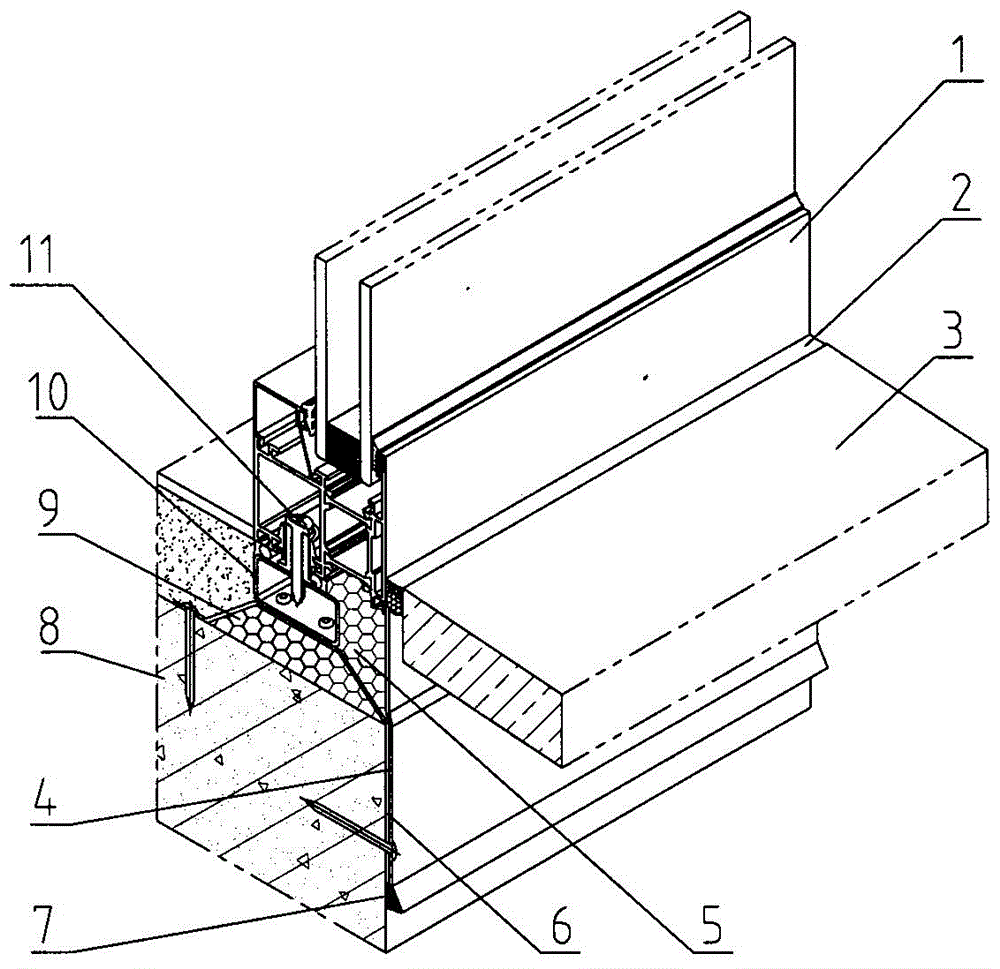

Sealed connection structure of aluminum alloy window frame

ActiveCN105804618BImprove water tightnessImprove air tightnessFrame fasteningCondensed water formation preventionAir tightnessFastener

An aluminum alloy window frame sealing connection structure solves the problem of rainwater leakage caused by insufficient filling of the gap between the aluminum alloy window frame and the opening wall. It includes an aluminum alloy window frame and a stone panel fixed on the wall of the hole. The frame and the hole wall are sealed and connected with a waterproof rubber plate. After one end of the waterproof rubber plate is connected and fixed with the aluminum alloy window frame frame by stainless steel screws, it is sealed with the stone panel by a sealing material. The other end of the waterproof rubber plate is connected to the hole. The wall is connected and fixed by nailing, the gap between the bottom of the waterproof rubber plate and the wall of the hole is sealed with sealant, and the gap between the waterproof rubber plate and the steel sub-frame is filled with thermal insulation material. Its structural design is reasonable to ensure that the gap is filled full and dense without cracks, and the sealing connection is reliable, which can effectively prevent rainwater leakage and improve the airtightness and thermal insulation performance of aluminum alloy windows.

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

A steel-plastic composite pipe joint and method thereof

Owner:CHINA MCC5 GROUP CORP

A multi-layer structure inspection well and its manufacturing method

InactiveCN106567411BNot easy to damageTightly sealed connectionArtificial islandsUnderwater structuresUnderground tunnelEngineering

The invention discloses a multilayer inspection well and a manufacturing method thereof. The inspection well comprises multiple layers of well shafts, multiple layers of well bases, and a well lid, wherein the well base in each layer comprises a cylindrical base part, well shaft connectors which extend from the upper and lower ends of the base part, and at least one transversely formed pipeline connector; at least one ends of the well shafts are in fusion welding with the well shaft connectors in a thermoplastic manner; and the upper end of the well shaft in the topmost layer is connected with the well lid. When the multilayer inspection well is utilized, pipelines which are embedded in different underground vertical positions and have various different functions can be monitored at the same time in one inspection well; the well shafts and the well bases are in sealed connection, so that the inspection well is more stable; and when the well shafts and the well bases are connected and when the ground subsides due to overload or underground tunnels subside due to various reasons, the well shafts of the inspection well can have certain elastic deformation due to the fact that the well shafts have certain elasticity, so that connection of the pipeline connectors of the inspection well and the original pipelines remains stable, sealing performance is good, and the inspection well is not liable to damage.

Owner:HANGZHOU JINCHENG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com