A multi-layer structure inspection well and its manufacturing method

A technology for inspecting wells and shafts, applied to underwater structures, infrastructure engineering, buildings, etc., can solve problems such as disconnection, joint gaps, vertical position mismatch, etc., to achieve non-destructive, stable and sealed connections well-behaved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

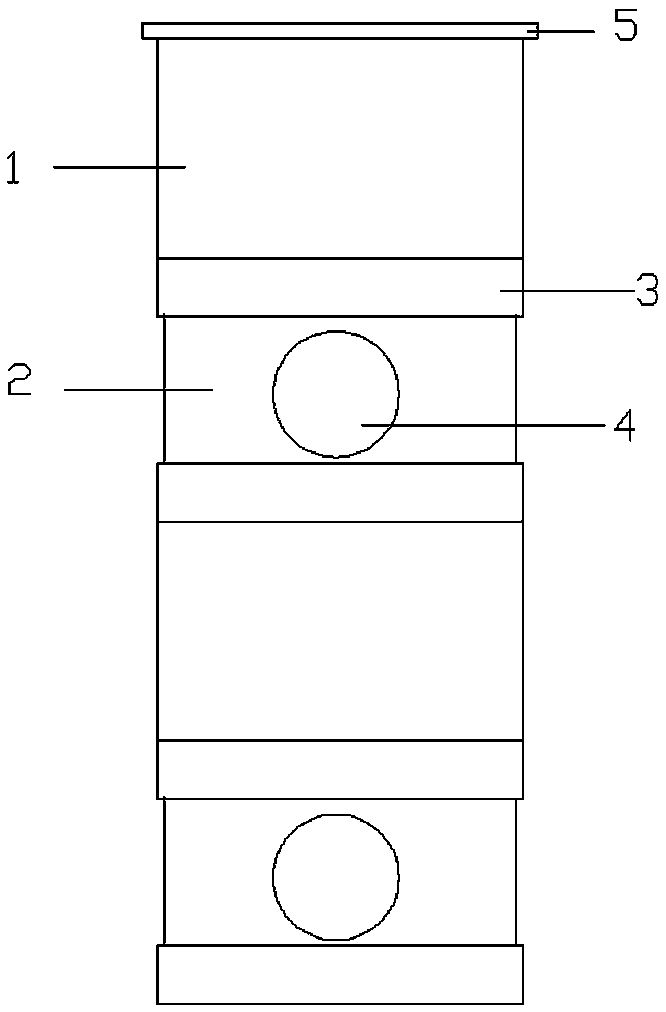

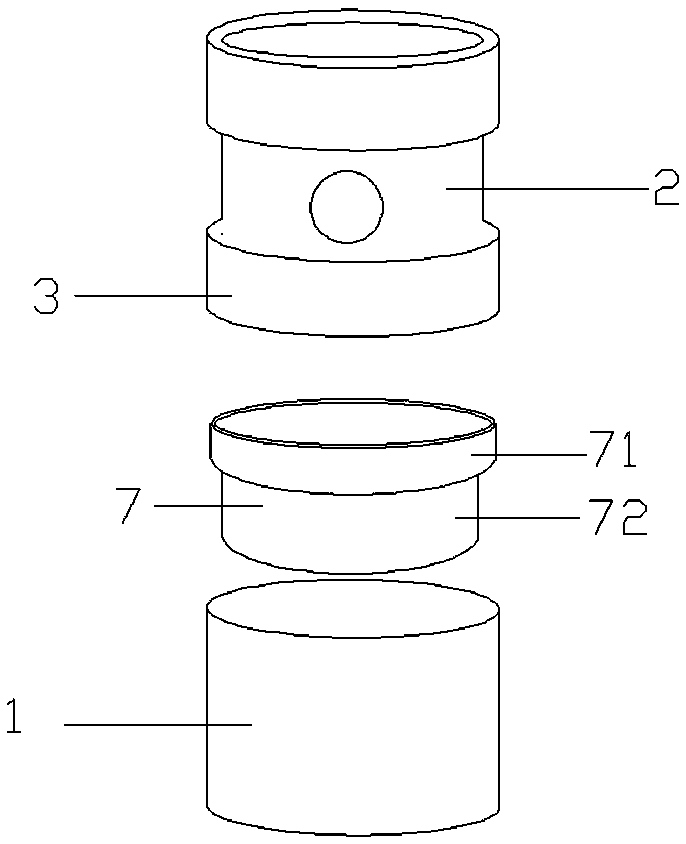

[0018] figure 1 A perspective view of a multilayer inspection well structure according to the present invention is shown. The multi-layer inspection well is composed of a well shaft 1, a well base 2 and a well cover 5; the inspection well includes a multi-layer well shaft 1 and a well base 5, and in this embodiment, two layers of well shafts and well bases are included. Each well block 2 includes a cylindrical base, a wellbore connection port 3 and at least one pipeline interface 4 extending from the base; the wellbore connection port 3 is a double-layer circular tubular structure, including an inner wall and an outer wall; the multi-layer wellbore is The elastic structure is connected with the thermoplastic sealing of the wellbore connection. The uppermost wellbore is connected with the well cover.

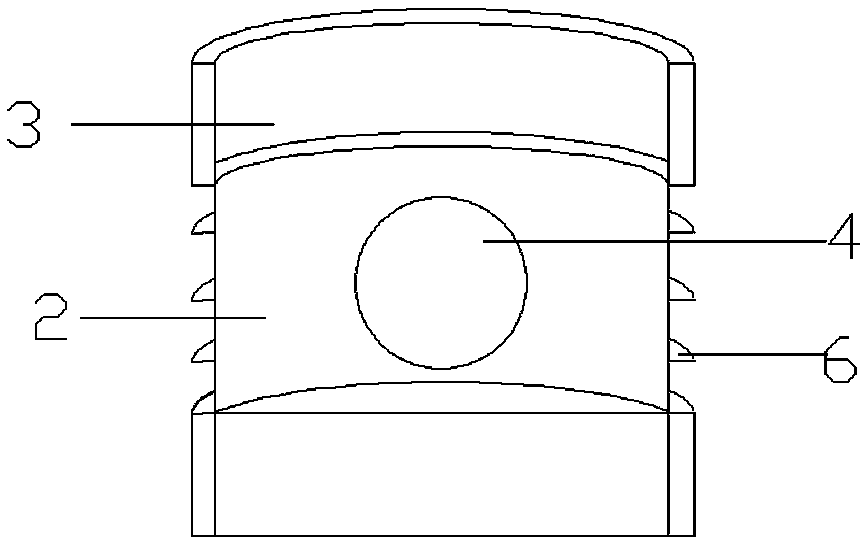

[0019] figure 2 A cross-sectional view of the structure of a one-layer well block according to the present invention is shown. The outer circumference of the base is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com