Sealed connection structure of aluminum alloy window frame

A technology for aluminum alloy windows and connection structures, which is applied to sealing devices, windows/doors, building components, etc. It can solve the problems of unrealistic filling of rainwater and leakage, so as to achieve full gap filling, prevent rainwater leakage, and reliable sealing connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

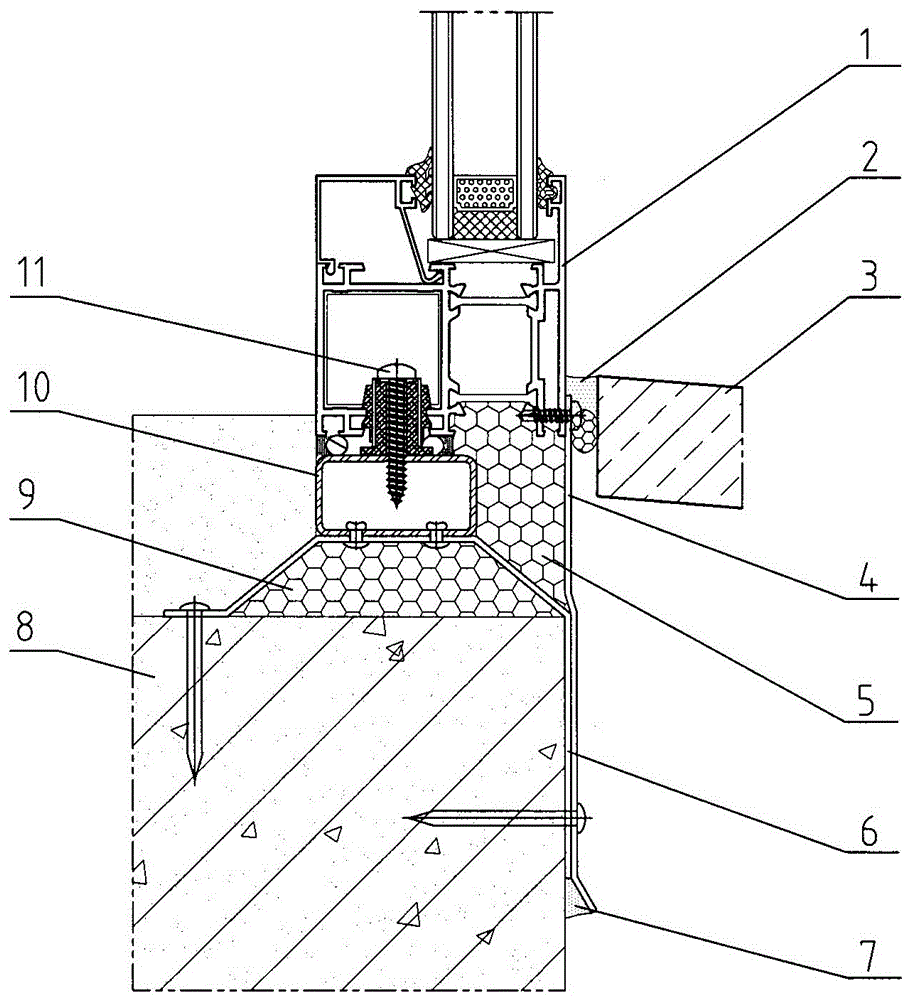

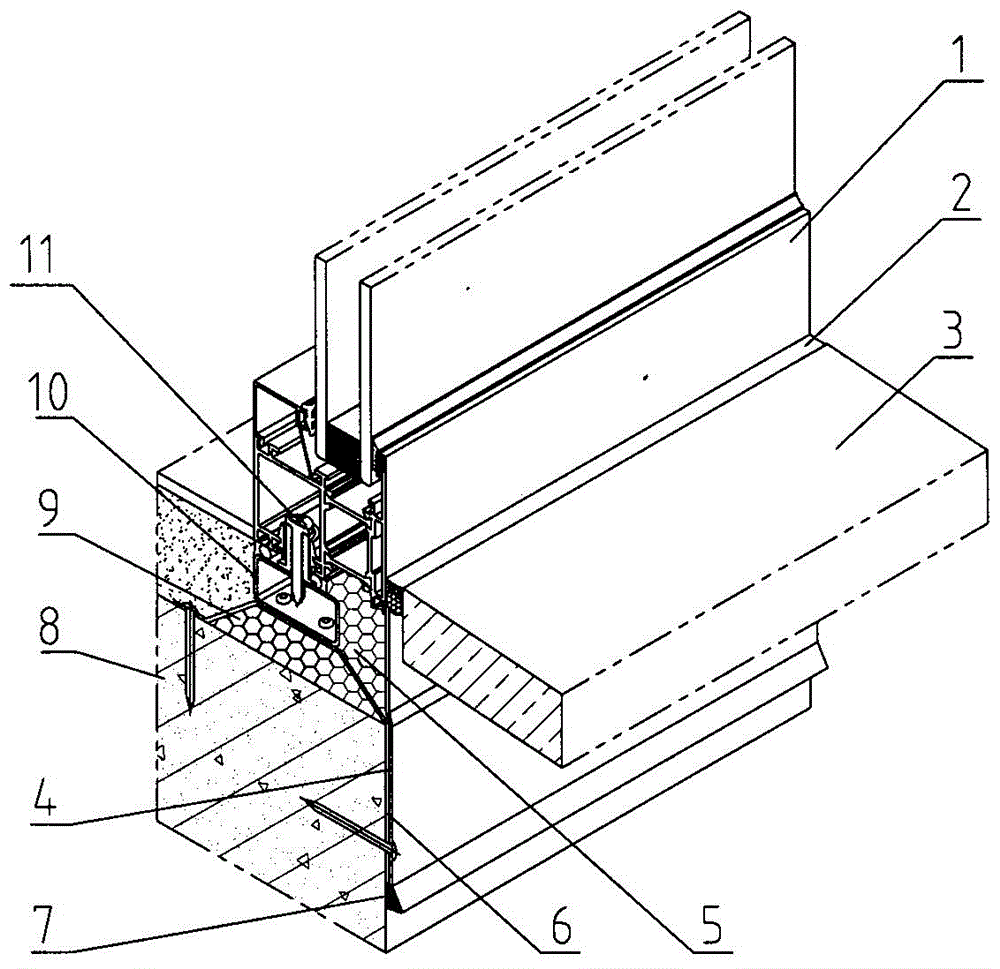

[0016] according to Figure 1~2 The specific structure of the present invention will be described in detail. The aluminum alloy window frame sealing connection structure includes an aluminum alloy window with a steel sub-frame 10 and a stone panel 3 fixed on the wall body 8 of the opening. Wherein the aluminum alloy window and the steel sub-frame 10 adopt a common structure, and are connected and fixed together by set screws 11 . The steel sub-frame 10 of the aluminum alloy window is fixed on the hole wall 8 through the fixing piece 6 and the thermal insulation foam material 9, the steel sub-frame 10 and the fixing piece 6 are connected by rivets, and the fixing piece 6 is fixed on the hole wall 8 with nails superior. The aluminum alloy window frame 1 and the hole wall 8 are sealed and connected with a waterproof rubber sheet 4 (the waterproof rubber sheet is used in this embodiment). After one end of the waterproof rubber plate 4 is connected and fixed with the aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com