Moisture-proof plastic packaging box for hardware tool, and preparation method thereof

A technology for hardware tools and packaging boxes, applied in the field of packaging products, can solve the problems of easy rust and corrosion, easy to be affected by moisture, poor sealing, etc., and achieve the effect of improving moisture-proof performance, reducing cost and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

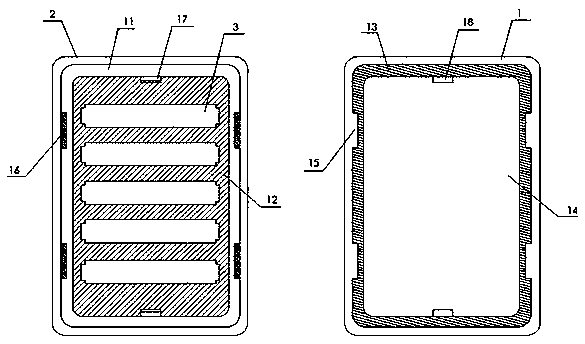

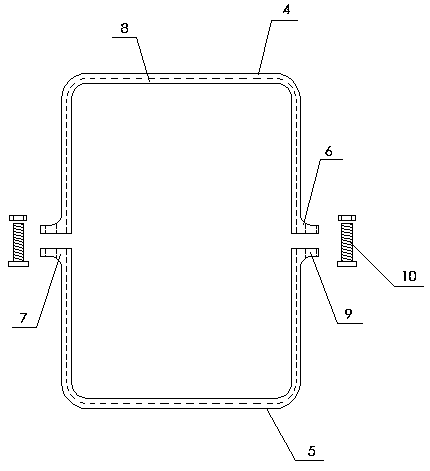

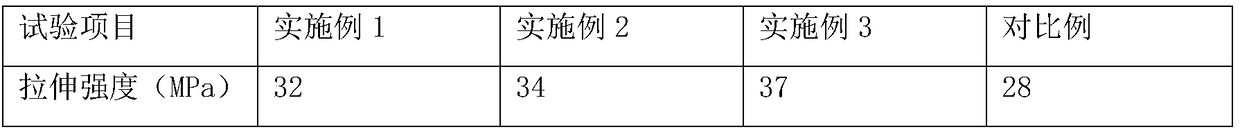

[0033] This embodiment provides a moisture-proof blister packaging box for hardware tools, including an upper casing 1 and a lower casing 2 . A first protrusion 11 is provided in the middle of the upper end surface of the lower casing 2, the middle of the first protrusion 11 is recessed inward to form a recessed groove 12, and the middle of the recessed groove 12 is recessed inward to form a number of storage units 3, Several storage units 3 are evenly arranged from top to bottom, and hardware tools can be placed in the storage units 3 . A first groove 13 that matches the first bump 11 is provided in the middle of the upper casing 1 , a bump 1 protrudes outward from the middle of the first groove 13 , and the bump 1 matches the inner wire groove 1 . After the upper shell 1 is docked with the lower shell 2, the lower end face of the bump 1 is in contact with the upper end face of the inner wire slot 1, so that when the hardware tool is in the storage unit 3, the lower end face...

Embodiment 2

[0044] This embodiment provides a moisture-proof blister packaging box for hardware tools, including an upper casing 1 and a lower casing 2 . A first bump 11 is arranged in the middle of the upper end face of the lower shell 2, the middle of the first bump 11 is recessed inward to form a recessed groove 12, and the middle of the recessed groove 12 is recessed inward to form five storage units 3, The five storage units 3 are evenly arranged from top to bottom, and hardware tools can be placed in the storage units 3 . A first groove 13 that matches the first bump 11 is provided in the middle of the upper casing 1 , and a bump 1 is formed in the middle of the first groove 13 to protrude downward, and the bump 1 matches the inner wire groove 1 . After the upper shell 1 is docked with the lower shell 2, the lower end face of the bump 1 is in contact with the upper end face of the inner wire slot 1, so that when the hardware tool is in the storage unit 3, the lower end face of the ...

Embodiment 3

[0055] This embodiment provides a moisture-proof blister packaging box for hardware tools, including an upper casing 1 and a lower casing 2 . A first bump 11 is arranged in the middle of the upper end face of the lower shell 2, the middle of the first bump 11 is recessed inward to form a recessed groove 12, and the middle of the recessed groove 12 is recessed inward to form five storage units 3, The five storage units 3 are evenly arranged from top to bottom, and hardware tools can be placed in the storage units 3 . A first groove 13 that matches the first bump 11 is provided in the middle of the upper casing 1 , and a bump 1 is formed in the middle of the first groove 13 to protrude downward, and the bump 1 matches the inner wire groove 1 . After the upper shell 1 is docked with the lower shell 2, the lower end face of the bump 1 is in contact with the upper end face of the inner wire slot 1, so that when the hardware tool is in the storage unit 3, the lower end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com