Separate fusible alloy structure security release device

A technology of fusible alloy and safety relief, which is applied to the installation device of container structure, safety valve, valve device, etc., which can solve the problem of large discharge area, failure to fully reflect the protection function of safety devices, and frequent bursting discs. Issues such as detonation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0050] Under the overall framework of the aforementioned technical solutions, the preferred embodiments of the present invention are supplemented as follows:

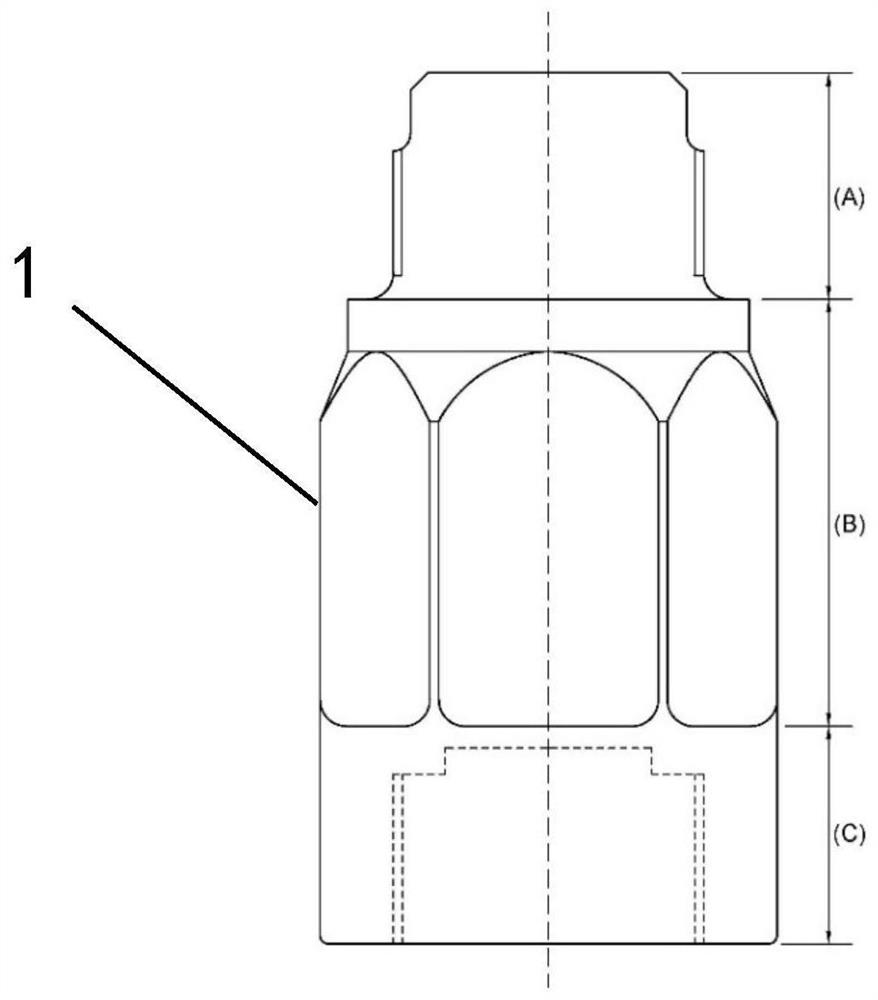

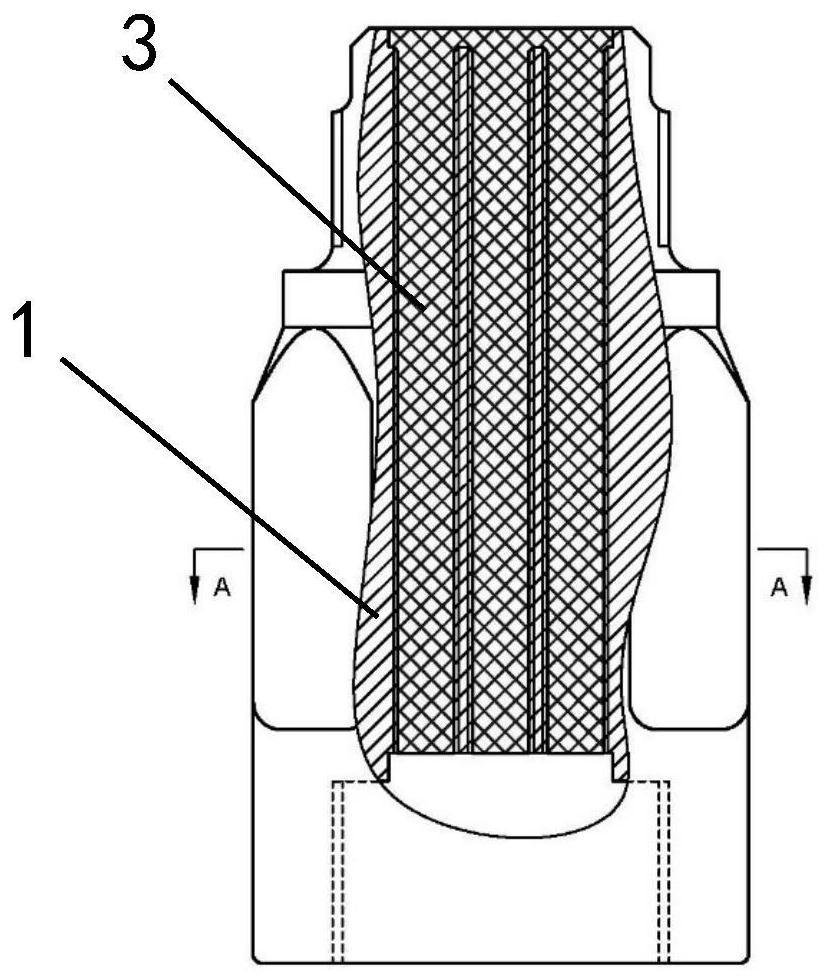

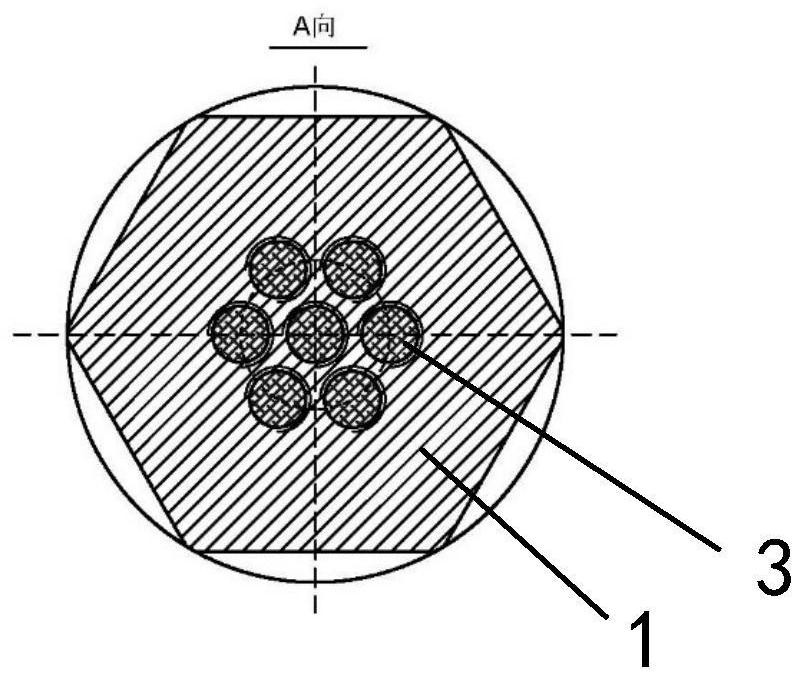

[0051] 1. The base material of the pressure-bearing structure 1 can be made of brass or stainless steel, which can be selected according to the compatibility of the medium in the large-volume high-pressure gas cylinder, and the mechanical properties of the material should meet the requirements of relevant regulations and standards;

[0052] 2. The fusible alloy is recommended to be selected in accordance with the fusible alloy formula in Appendix A of GB8337 "Fusible Alloy Plug Device for Gas Cylinders", the melting zone temperature (action temperature) is 102.5±5°C, that is, the Bi content is 53.9% (weight content, the same below), Sn content 25.9%, Cd content 20.2%, eutectic state; users can also choose fusible alloy materials with other melting temperatures according to working conditions and special needs; design sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com