Combined type suction cup

A combined, suction cup technology, applied in suction cups, connecting components, membrane boxes, etc., can solve problems such as reasonable allocation of unfavorable resources, increase work costs, reduce work efficiency, etc., to achieve reasonable allocation, improve work efficiency, reduce The effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

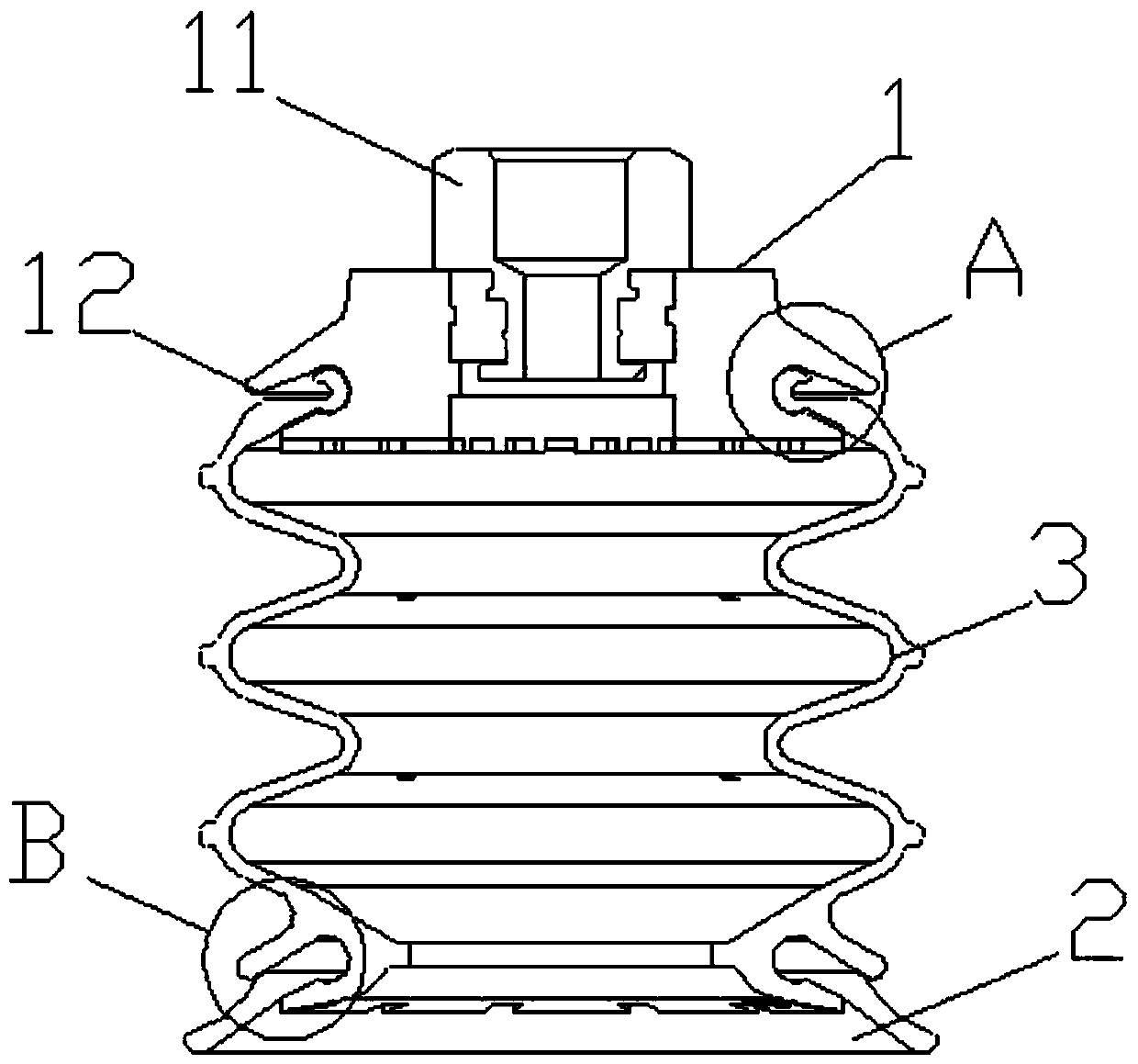

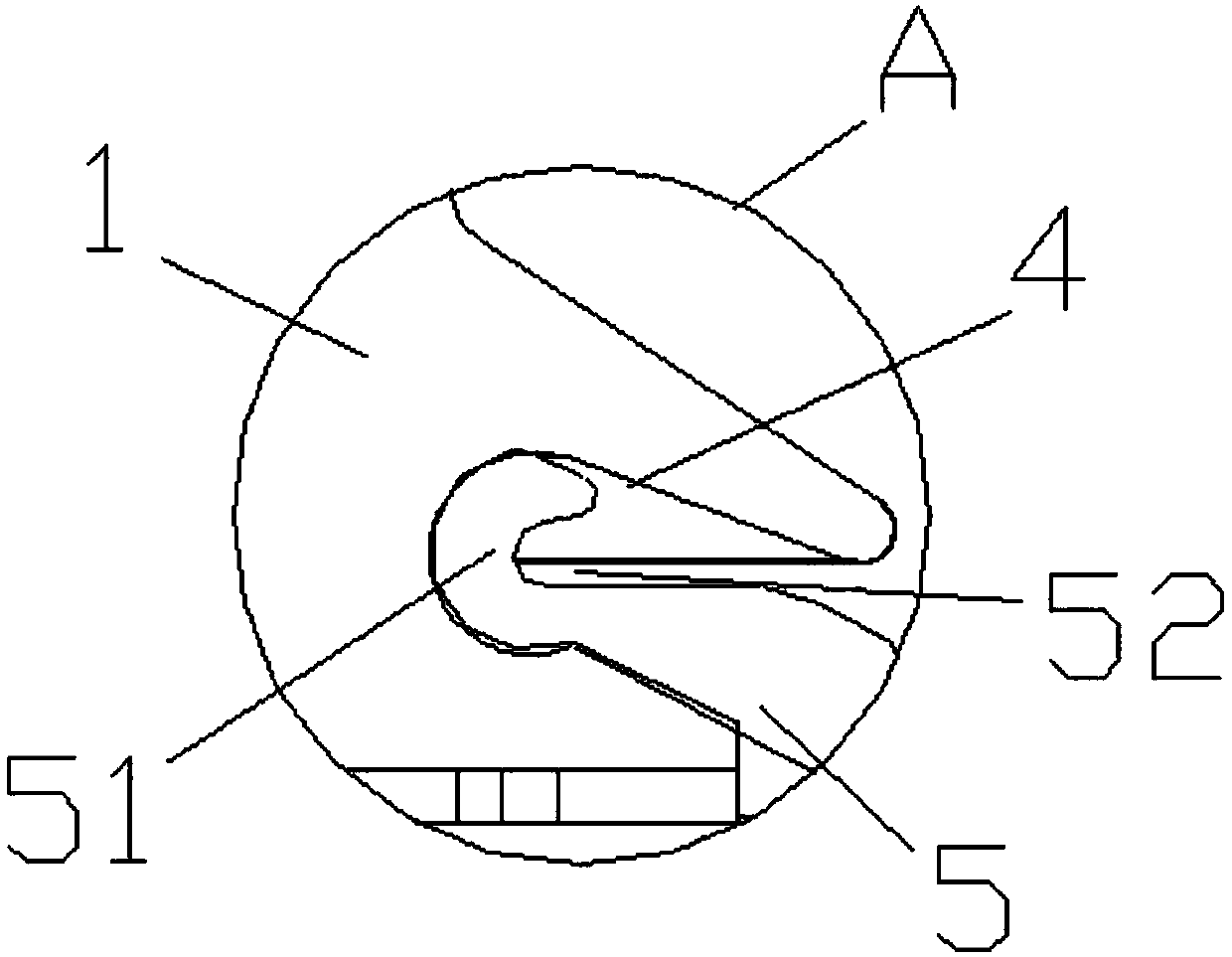

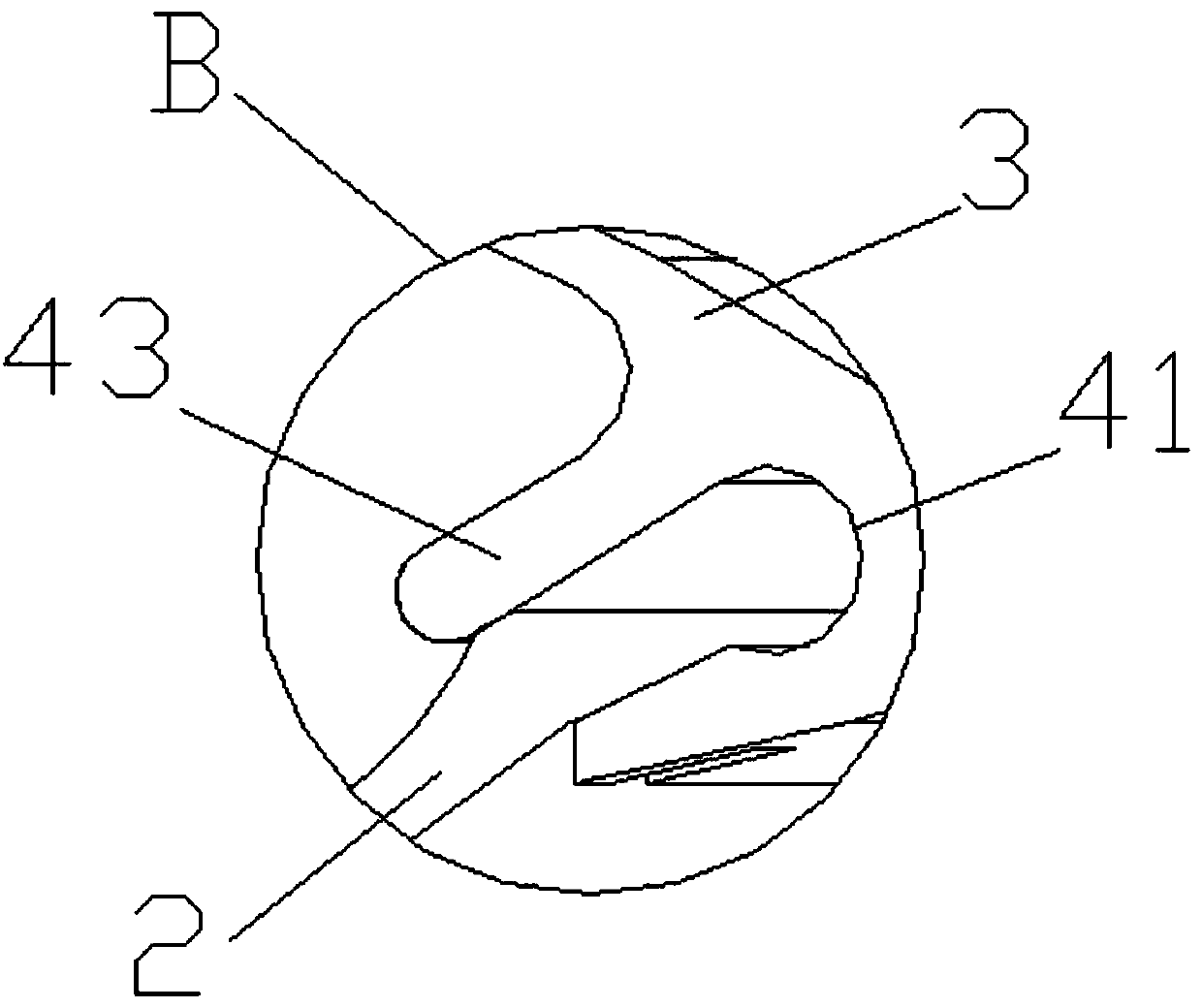

[0025] The finished connection structure of the connecting piece 1, the connecting bellows 3 and the suction cup lip 2 is as follows: Figure 4 shown. The combined suction cup is a schematic diagram of the connection between the connecting piece 1 and a connecting bellows 3 . Its internal structure is figure 1 As shown, the working end 11 of the connecting piece 1 is connected with the vacuum equipment, and the connecting end 12 at the other end of the connecting piece 1 is provided with a circumferential snap groove 4 . The clamping groove 4 located in the connector 1 can directly realize the close clamping connection with the suction cup lip 2 to form a straight vacuum suction cup structure used in daily life. The combined suction cup provided by the present invention realizes the connection operation between the connecting piece 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com